Box nailing machine control method

A box and nail head technology, used in container manufacturing machinery, box manufacturing operations, rigid/semi-rigid container manufacturing, etc., can solve problems such as low precision and poor flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

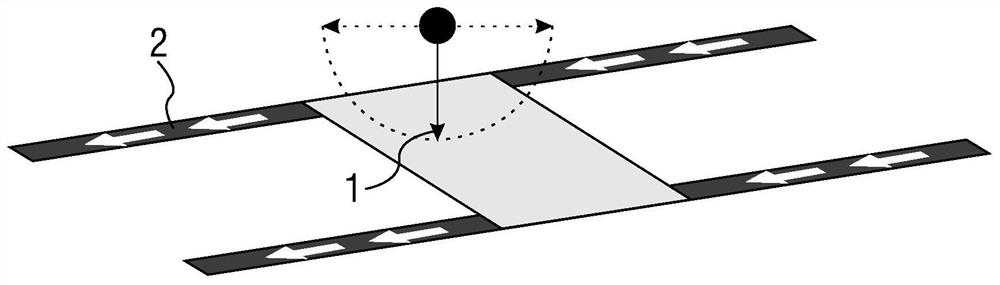

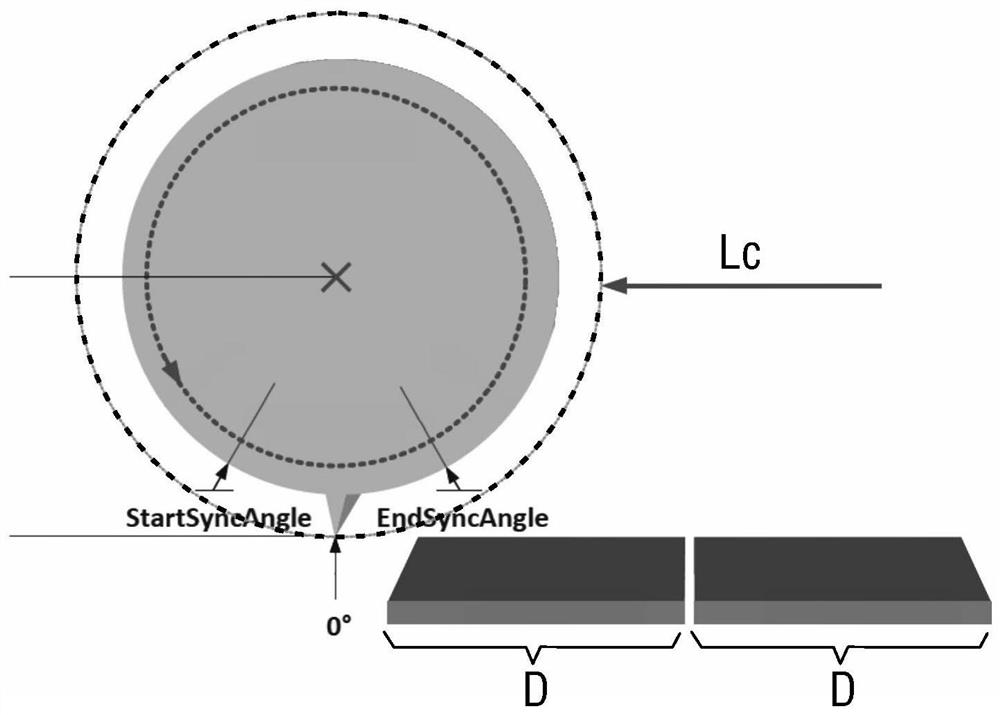

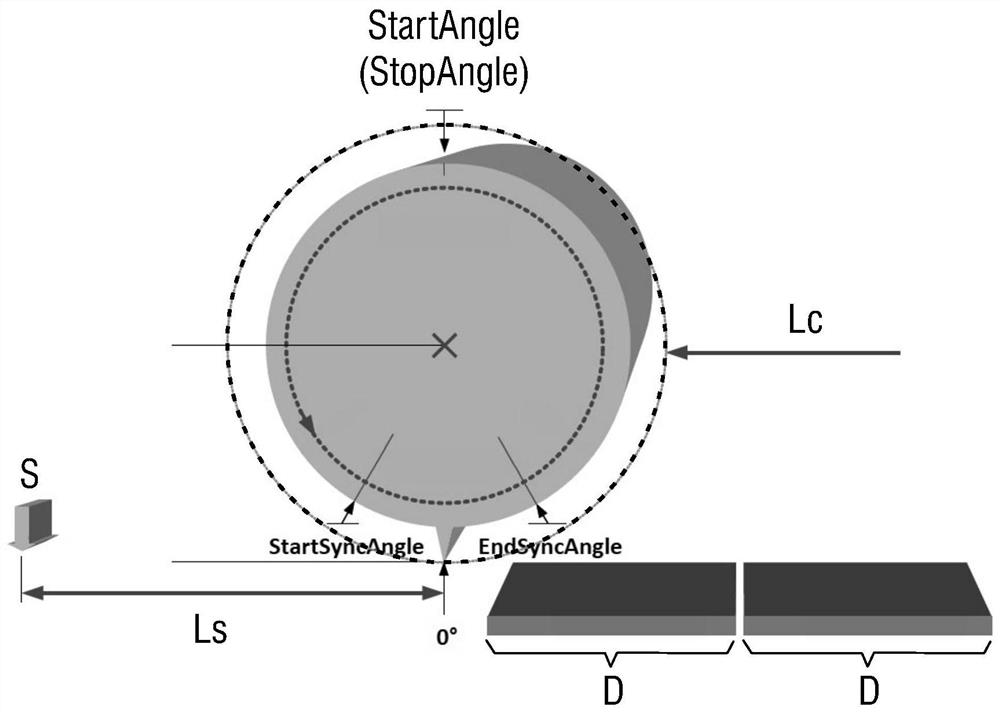

[0012] For the traditional nail box machine, in the process of nail box operation through the reciprocating swing of the nail head, since the swing amplitude has been designed in advance according to the traveling speed of the conveyor belt to match the specific nail distance requirements, the nail head swings at a fixed angular speed during the whole process . To this end, one cycle of the nail head's oscillation can be modeled as a circular motion, such as figure 2 As shown, the actual completion of a nail box operation by the nail head can be simulated as a round cutting operation of the cutting knife on the strip moving forward on the conveyor belt. As shown in the figure, the length of each section of strip cut by the round corresponds to the nail distance D , that is, the circumference of the rotation of the cutter for one revolution (hereinafter also referred to as the die length) Lc. On the circle model shown in the figure, StartSyncAngle represents the synchronous s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com