Waste plastic tray dismembering machine

A technology for discarding plastics and pallets, applied in metal processing and other directions, can solve the problems of high labor intensity, unseen and low efficiency of operators, and achieve the effect of avoiding up and down jumping, reducing work intensity and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] In the following descriptions, all directional concepts such as up, down, left, right, front, and rear are aimed at the illustrated position status, and thus cannot be interpreted as a specific limitation on the technical solution of the present invention .

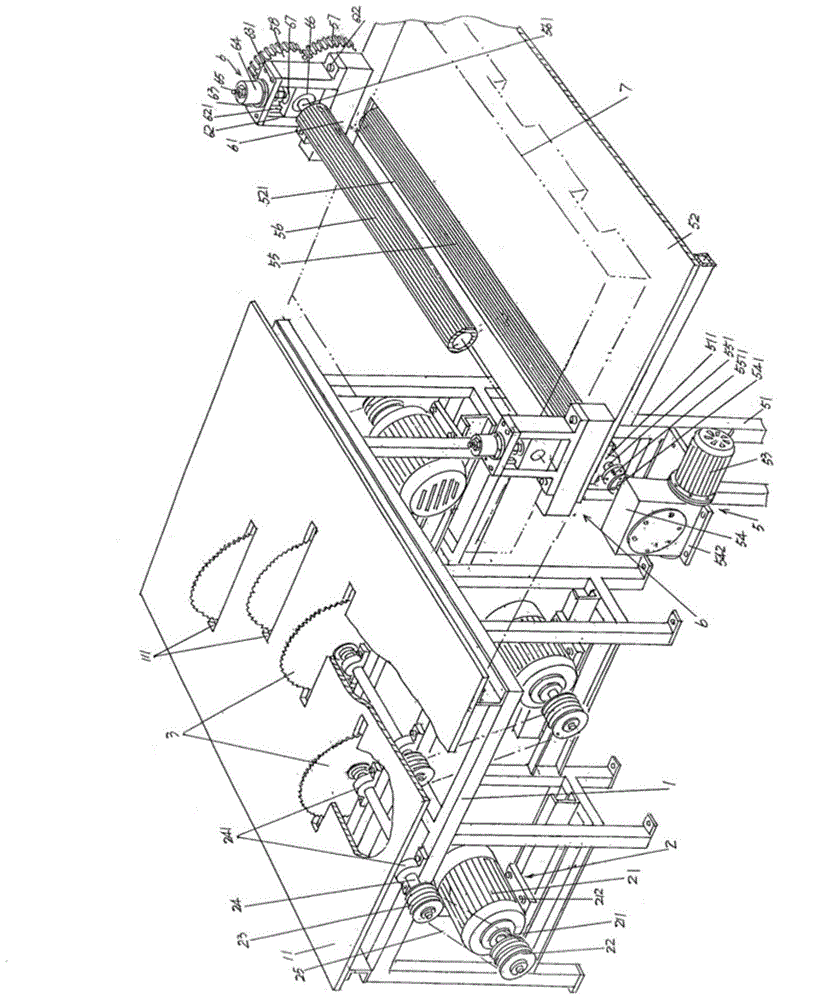

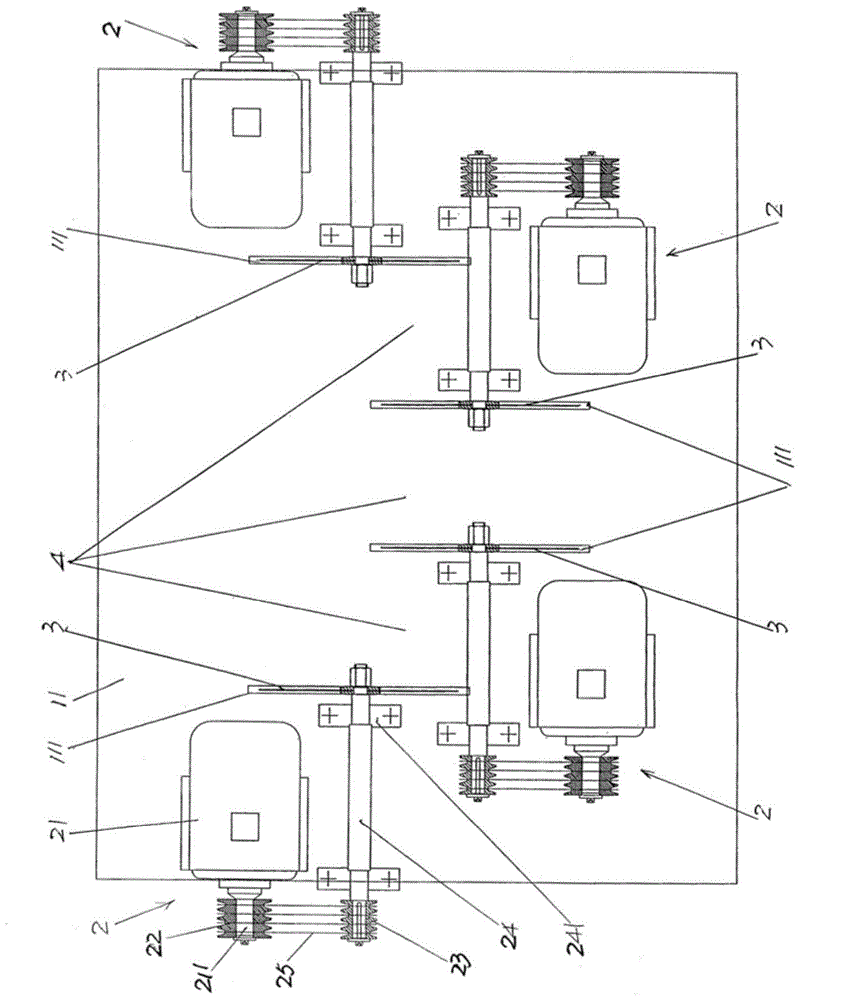

[0021] See figure 1 , a frame 1 with a frame-like structure is given, a circular saw table 11 is fixed on the upper part of the frame 1, and a group of circular saws are provided in a dislocation manner on the circular saw table 11. Position slots 111, in the present embodiment, there are four sets of circular saw relief slots 111, and they are distributed in dislocation states. The dislocation states mentioned here are distributed as two of them in a group of circular saw relief slots 111. The two circular saw give way slots are the two circular saw give way slots in the middle and the positions of the circular saw give way slots on each side are arranged in front and back to form the positional relationship of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com