Icebreaker and icebreaking method thereof

A technology for icebreakers and hulls, which is applied to icebreakers, special-purpose ships, ships, etc., and can solve the problems of high energy consumption, low icebreaking efficiency, and the hull is easily stuck by ice.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

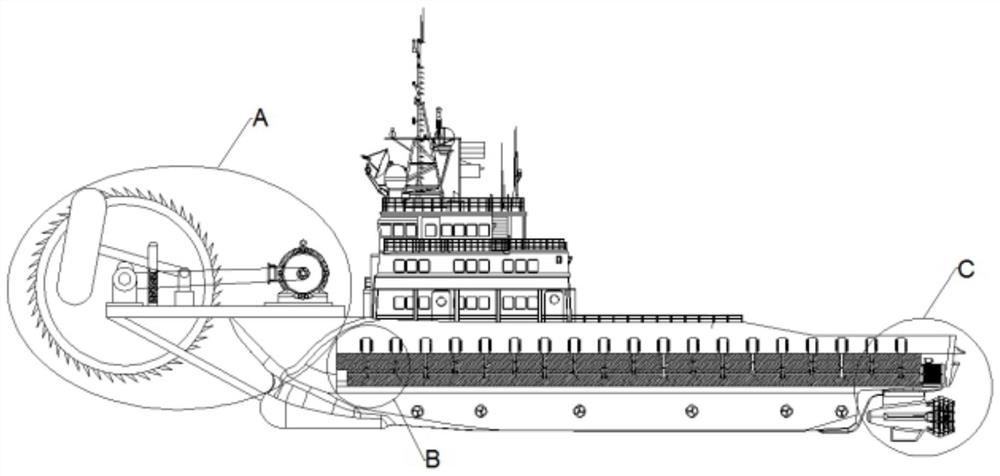

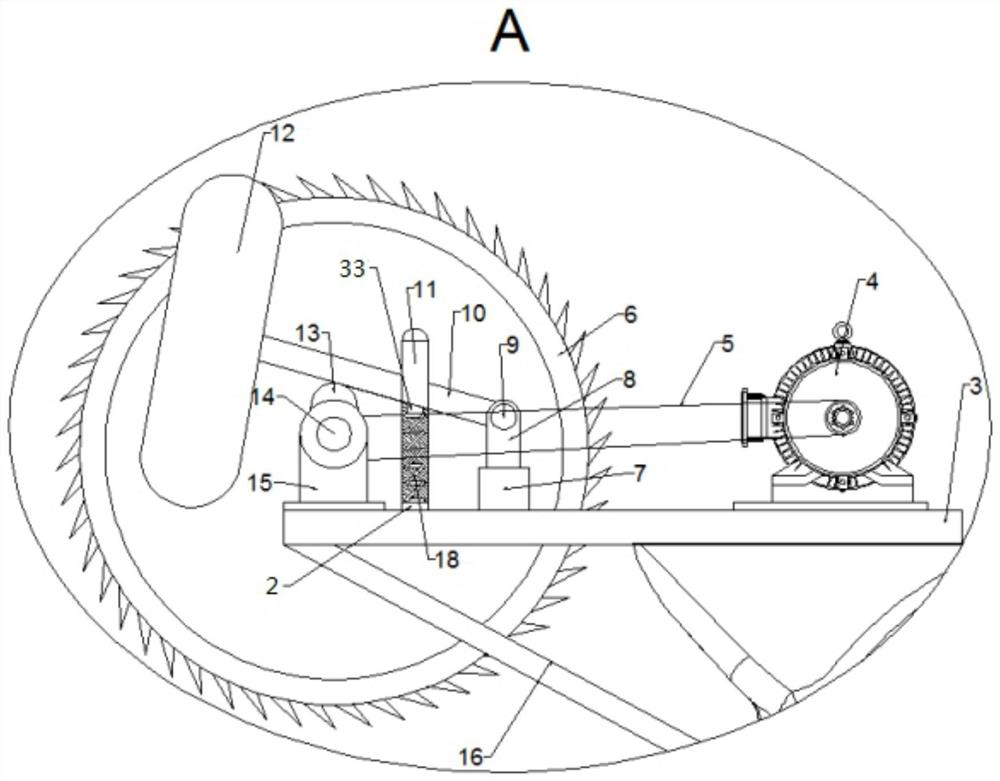

[0031] This embodiment proposes an icebreaker, the stern of the hull is provided with a propeller traveler 1, the bow of the hull is provided with a fixed support plate 3, the bottom surface of the fixed support plate 3 is fixedly connected with a support rib 16, and the middle part of the front end of the fixed support plate 3 is provided with a Groove; fixed support plate 3 is provided with motor base 17, two raised bases 7 and four bearing support bases 15; motor base 17 is provided with two main motors 4, and the motor is connected with pulley I19, pulley I19 Connect the pulley II14 by the belt 5, the pulley II14 is fixedly connected on the rotating shaft 20, the rotating shaft 20 is provided with a saw blade 6, and the saw blade 6 is positioned in the groove at the middle part of the front end of the fixed support plate 3; Bearing 23 is arranged, and bearing 23 is fixedly connected with rotating shaft 20; Rotating shaft 20 is also provided with two cams 13, is provided wit...

Embodiment 2

[0038] This embodiment proposes an icebreaker, including the entire structure of the icebreaker described in Embodiment 1. The difference from Embodiment 1 is that two spring supports 2 are also provided on the fixed support plate 3, and the spring supports 2 are located on the lifting lugs. The front end of I8 is fixedly connected with spring 18 on the spring support 2, and the other end of spring 18 is fixedly connected with spacer 33, and spacer 33 contacts with hammer handle 10 and is connected, and the both sides of spring 18 are provided with limit baffle 11, position-limiting The baffle 11 is fixedly connected with the spring support 2 , and the height of the limit baffle 11 is higher than that of the spring 18 .

Embodiment 3

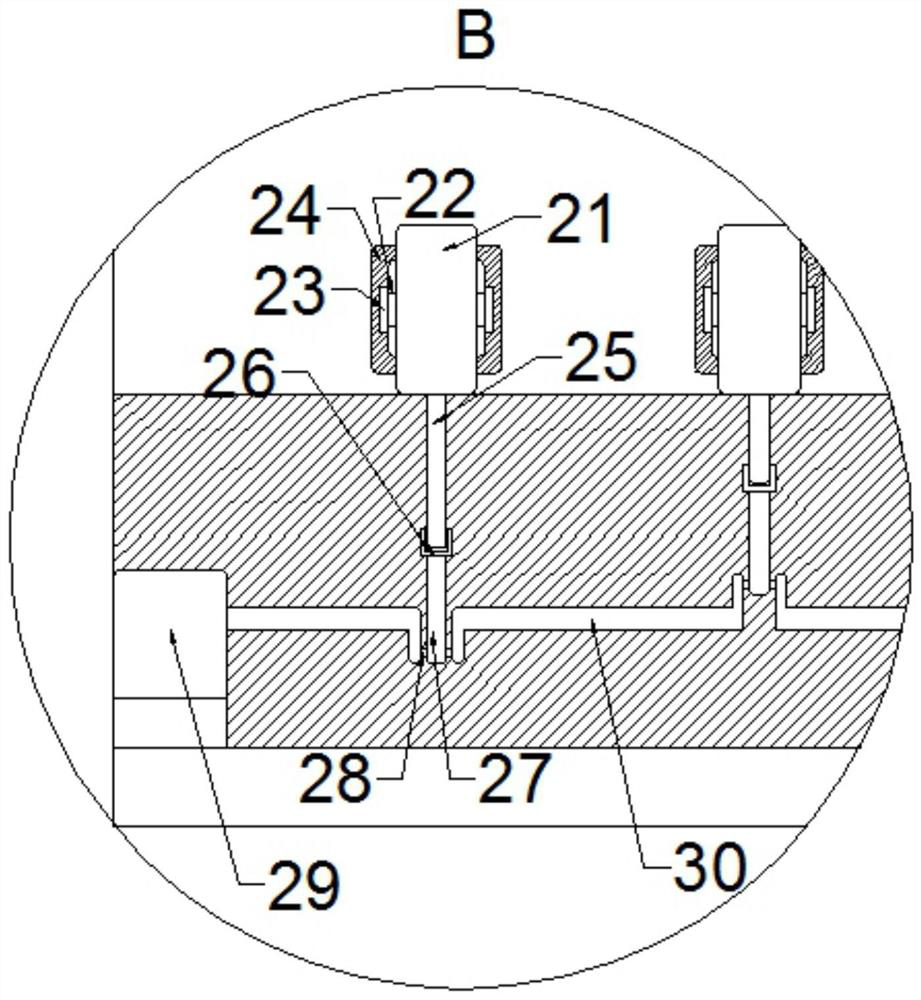

[0040] Such as Figure 1~5 As shown, this embodiment proposes an icebreaker, including all the structures of Embodiment 1 and Embodiment 2. The difference from Embodiment 1 and Embodiment 2 is that in an optional implementation of this embodiment, the hull also includes a transmission area 32 , the transmission area 32 is provided with an auxiliary motor 31; the auxiliary motor 31 is connected to the crankshaft 30, the other end of the crankshaft 30 is connected to the bearing housing 29, and the crankshaft 30 is also connected to nineteen connecting rods; the other end of each connecting rod is connected to a small icebreaker 21. The small ice-breaking hammer 21 is set in the slot 24 on the side of the hull; the slot 24 is also provided with a bearing 23 and a pin shaft II22, and the other end of the small ice-breaking hammer 21 is fixed on the slot 24 through the bearing 23 and the pin shaft II22 Inside; connecting rod comprises rod I27 and rod II25, and rod I27 and rod II25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com