Rail sensor mounting structure and application

A technology of installation structure and sensor, applied in transportation and packaging, railway signal and safety, vehicle route interaction equipment, etc. The effect of shifting and increasing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

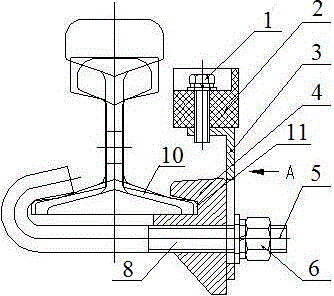

[0023] This embodiment provides a track sensor installation structure, including a gauge bar iron clip 4 fixed on the gauge bar 10 on the outside of one side of the track, a bracket 3 arranged on the outside of the gauge bar iron clip 4, and a fixed gauge The iron clamp 4 for the rod and the locking bolt 5 of the bracket 3, the first through hole 8 is provided at the lower part of the iron clamp 4 for the gauge rod, the second through hole 9 is provided at the lower part of the support 3, and the locking bolt One end of 5 is fixed on the lower edge of the track on the other side, and the other end is fixed by nut 6 after passing through the first through hole 8 and the second through hole 9;

[0024] The top of the bracket 3 is provided with a fixed block 2 on which a sensor 7 is installed.

[0025] Installation process:

[0026] Dig an installation hole under the track of the required detection site, fix one end of the locking bolt 5 with the lower edge of one side of the tr...

Embodiment 2

[0029] On the basis of embodiment 1, this embodiment provides a kind of figure 1 , 2 In the track sensor installation structure shown, the locking bolt 5 is a bent bolt with one end bent, and the bent end of the bent bolt faces upwards and clamps the lower edge of the track on the other side.

[0030] Installation process:

[0031] Dig an installation pit under the track of the required detection site, fix the gauge bar on the gauge bar 10 on the outside of one side of the track with iron clamp 4, and use a bent bolt to bend one end to clamp the lower edge of the other side of the track to fix, and then the gauge The first through hole 8 of the iron clip 4 for the rod and the second through hole 9 of the bracket 3 pass through the bent bolts sequentially and then locked and fixed with the nut 6; then the fixing block 2 is fixed on the bracket 3 with the bolt 1, and the sensor 7 Fix it on the fixed block 2, lock it after reaching a suitable detection position, and finally con...

Embodiment 3

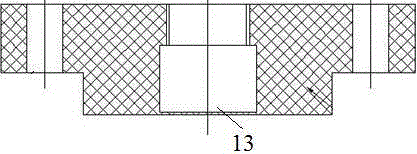

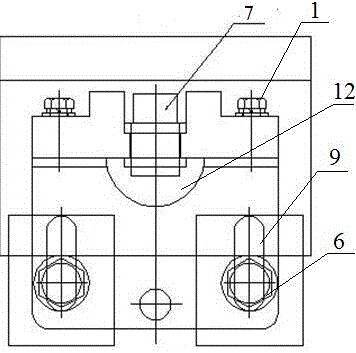

[0034] On the basis of Embodiment 2, this embodiment provides a rail sensor installation structure, such as figure 1 As shown, a U-shaped groove 11 is arranged in the middle of the iron clip 4 for the gauge rod, and a first through hole 8 is symmetrically arranged about the U-shaped groove 11, as Figure 4 As shown, the lower end of the bracket 3 is symmetrically provided with a second through hole 9 corresponding to the two first through holes 8 of the iron clip 4 for the gauge rod.

[0035] Installation process:

[0036] Dig an installation pit under the track of the required detection site, and the gauge bar is stuck on the gauge bar 10 on the outside of one side of the track with the U-shaped groove 11 of the iron clip 4, and two symmetrically placed on both sides of the gauge bar 10 One end of the bent bolt is bent and fixed to the lower edge of the track on the other side, and then the two first through holes 8 of the iron clip 4 for the gauge rod and the two second thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com