Double cam mechanism

A cam mechanism and cam technology, applied in the direction of cams, mechanical equipment, belts/chains/gears, etc., can solve the problems that the maximum pressure angle of the cam exceeds the allowable limit, the cam cannot be arranged, self-locking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

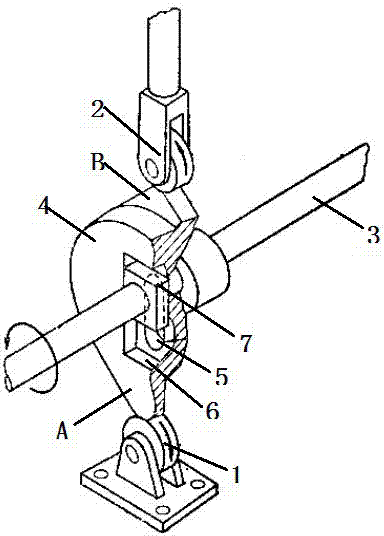

[0009] Such as figure 1 Shown: double cam mechanism, including fixed roller 1, driven roller 2, camshaft 3 and double cam 4, the center of double cam 4 is provided with a square groove 6 along the long diameter direction of double cam 4, The square groove 6 runs through a slotted hole 5, and the double cam 4 is assembled on the camshaft 3 through the slotted hole 5, and the camshaft 3 is fixed with a limit block 7 at the direction groove 6; the upper end of the double cam 4 It consists of two cams with different base circle radii, cam A and cam B in the figure, cam B with larger base circle radius is in contact with driven roller 2, and cam A is in contact with fixed roller. One side of the center of the double cam 4 is provided with a square groove 6 , and the cam shaft 3 is fixed with a limit block 7 at the position corresponding to the square groove 6 .

[0010] The above description is only a detailed description of the preferred embodiments of the present invention, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com