Medium-free micro pulverizer

A micro-powder mill, medium-free technology, applied in the field of pulverizing machinery, can solve the problems of low one-time grinding ratio, unsatisfactory grinding effect, and inconvenient maintenance, etc., to reduce production cost, prolong service life, High crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

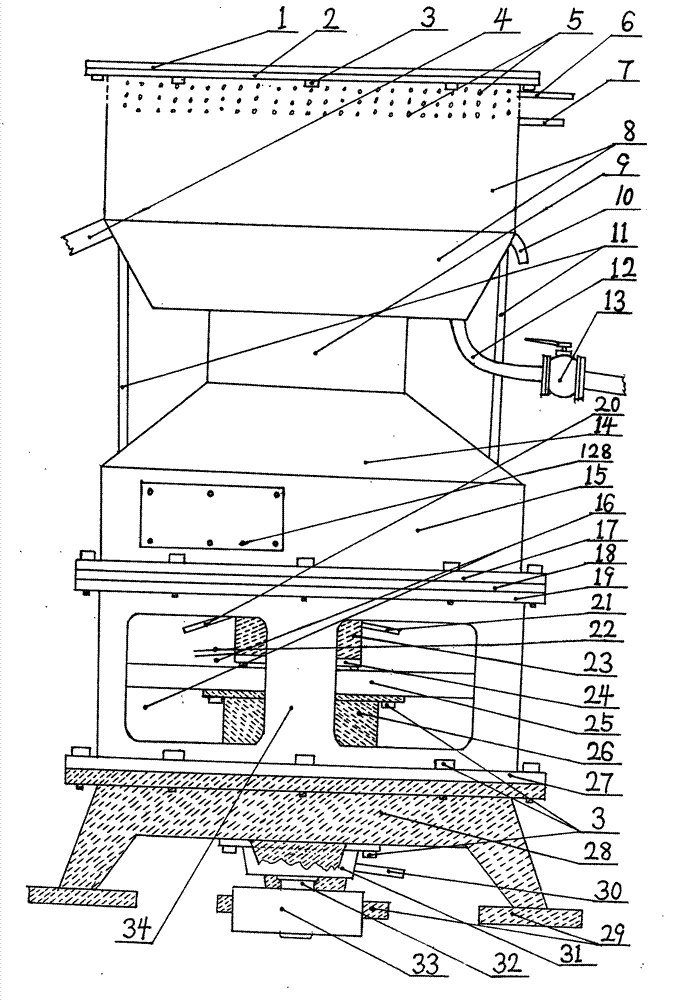

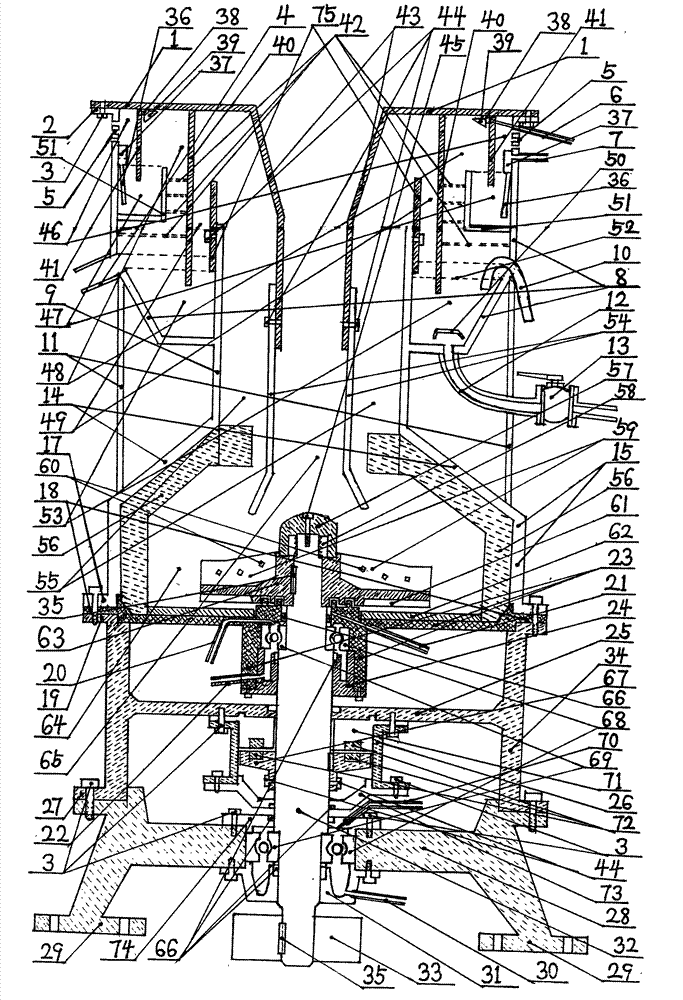

[0074] Embodiment 1, taking the single impeller assembly as an example, refer to the attached figure 1 , attached figure 2 , attached Figure 6 , attached Figure 7 , attached Figure 8 As shown, the mediumless micropowder mill is a kind of machine driven by the motor to provide power and work. It is mainly composed of two parts: the rotating part and the fixed part. The rotating part is the most important part of the machine. Its operation The quality directly determines the performance and service life of the machine, so there are strict requirements on the selection of materials and machining accuracy of its components; the rotating part is mainly composed of the driving wheel or coupling, the lower rotating bearing Assemblies, permanent magnetic thrust bearing assembly (or mechanical static pressure thrust bearing assembly), upper rotating bearing assembly, main shaft and impeller assembly, etc.; lower rotating bearing assembly consists of lower bearing housing 28, bea...

Embodiment 2

[0079] Embodiment two, referring to the attached image 3 , 6 , 7, 8, 9, 10, 11, 12, and 13 show that it is basically the same as the structure of Embodiment 1, and its improvements are:

[0080] 1. The crushing chamber 64 in Embodiment 2 adopts a flat cylindrical cylinder structure completely, and the main liner in the crushing chamber is also changed to be composed of an upper liner 81 and an arc-shaped main liner 82. The upper and lower parts are combined, and a And fixed in the crushing chamber cylinder shell 15 and keep close fit with its inner wall; the upper liner 81 is a disc-shaped thick wear-resistant plate whose outer diameter is as large as the inner diameter of the crushing chamber cylindrical shell 15, and its center The aperture is slightly smaller than the inner diameter of the powder guide barrel 9 located at its upper end, and its thickness is the same as or slightly thinner than that of the arc-shaped main liner 82, and its lower surface is set to a certain...

Embodiment 3

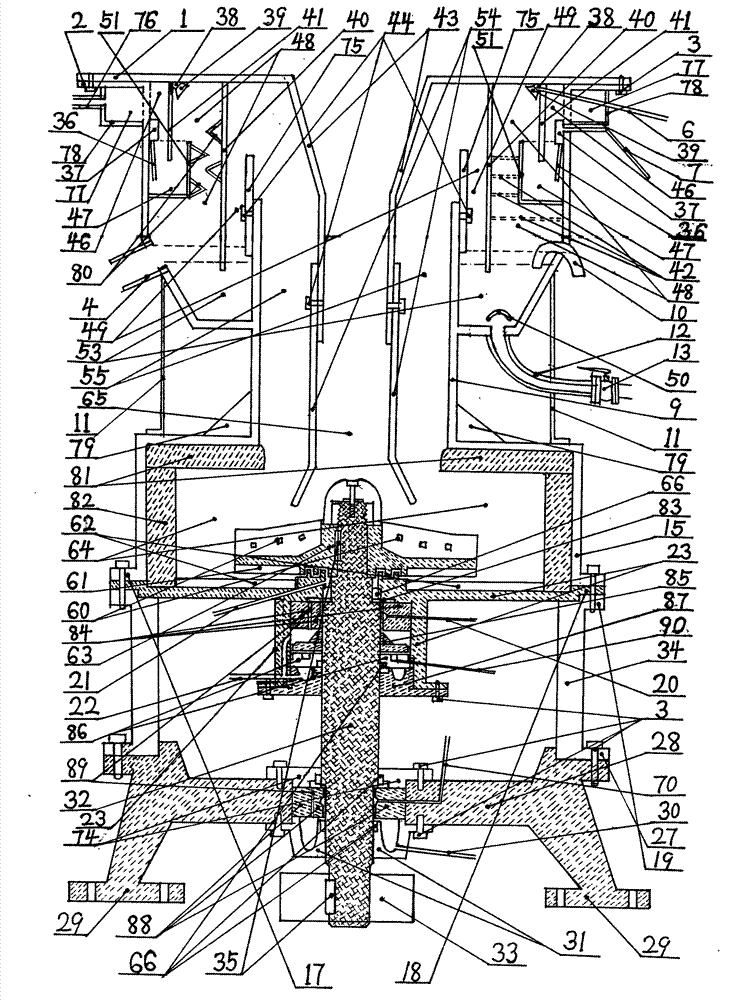

[0085] Embodiment three, with reference to the attached Figure 4 , 6 , 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, and 17, embodiment three has many similarities with the foregoing embodiment one and embodiment two, and its improvements are as follows:

[0086] 1. In Embodiment 3, the primary crushing form in Embodiment 1 and Embodiment 2 is improved to a multi-stage crushing form. Embodiment 3 here is illustrated by taking the secondary crushing form as an example: the crushing chamber in Embodiment 3 The shell is divided into upper, middle and lower parts. The upper part is the upper crushing chamber shell (also known as the primary crushing chamber shell) 120, the middle part is the cyclone separation chamber 96, and the lower part is the crushing chamber cylinder shell (also known as the secondary crushing chamber body). shell) 15; upper liner 94, arc-shaped main liner 82, wear-resistant ring 144 and material guide liner 93 are arranged from top to bottom in upper crushing cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com