Two-end pre-tightening type low-friction-characteristic cylinder with cylinder body in multi-mode vibration caused by piezoelectric stacks

A piezoelectric stack and multi-mode technology, applied in the direction of fluid pressure actuation devices, can solve the problems of difficult manufacturing, oil pollution, and low reliability, and achieve easy processing, strong applicability, and high reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

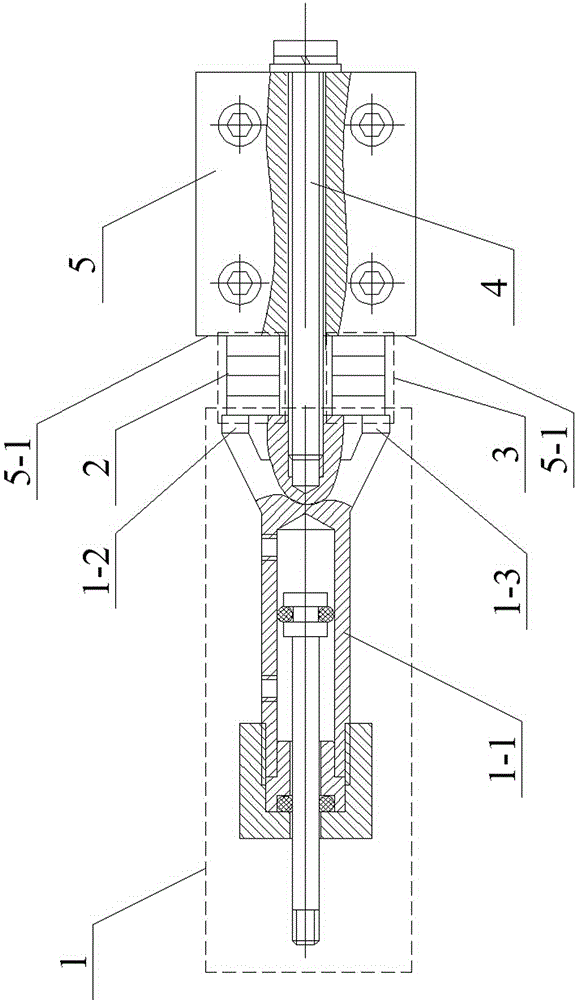

[0012] Specific implementation mode one: combine figure 1 Describe this embodiment. This embodiment is composed of a general-purpose cylinder assembly 1, a first piezoelectric stack 2, a second piezoelectric stack 3, fastening bolts 4, and a mounting seat 5;

[0013] The two sides of the tail end of the cylinder barrel 1-1 of the general-purpose cylinder assembly 1 are respectively provided with a first support foot 1-2 and a second support foot 1-3, and the bottom end surface of the first support foot 1-2 is connected with the first piezoelectric One end face of the stack 2 is top-connected, the bottom end face of the second support leg 1-3 is connected to one end face of the second piezoelectric stack 3, the other end face of the first piezoelectric stack 2, the other end face of the second piezoelectric stack 3 Both are top-connected with the end face 5-1 of the mounting seat 5, and the fastening bolt 4 passes through the mounting seat 5 and is threadedly connected with the...

specific Embodiment approach 2

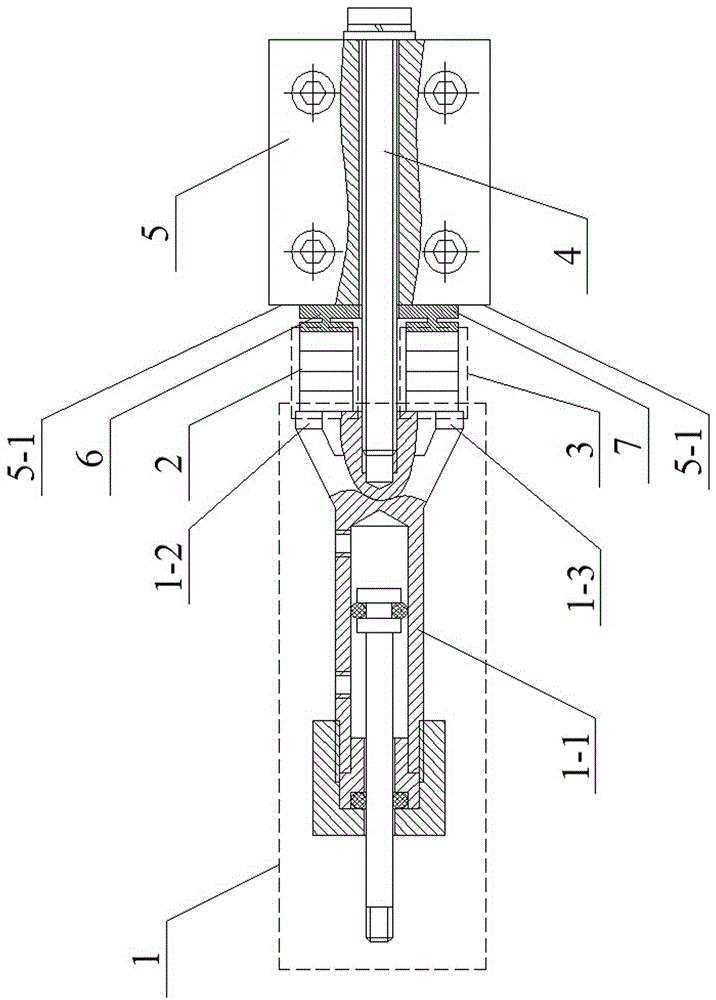

[0017] Specific implementation mode two: combination figure 2 Describe this embodiment, this embodiment adds a first H-shaped flexible hinge 6 and a second H-shaped flexible hinge 7 on the basis of the first specific embodiment; the first H-shaped flexible hinge 6 is arranged between the first piezoelectric stack 2 and the Between the end faces 5-1, the second H-shaped flexible hinge 7 is arranged between the second piezoelectric stack 3 and the end faces 5-1.

[0018] This embodiment has the functions of increasing the rotational freedom of the fastening bolt 4 in the axial direction, optimizing the vibration effect, and prolonging the working life of the first piezoelectric stack 2 and the second piezoelectric stack 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com