Mixed nanometer lubricating grease additive and application thereof

A grease additive and grease technology, which is applied in the direction of additives, lubricating compositions, petroleum industry, etc., to achieve the effects of improving bearing capacity, reducing friction bearing capacity, and reducing friction coefficient

Inactive Publication Date: 2012-06-13

DALIAN JIAOTONG UNIVERSITY

View PDF5 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

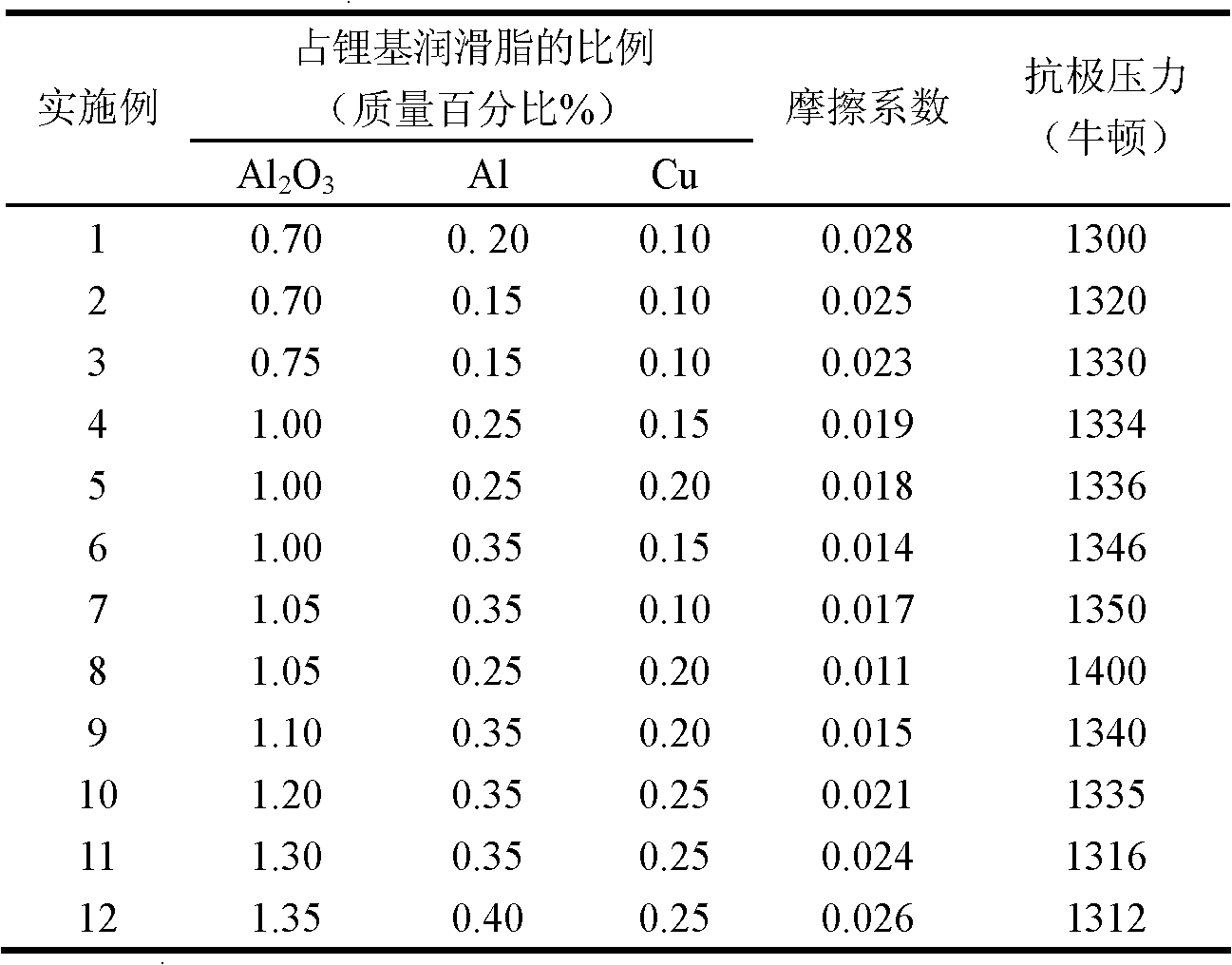

Embodiment 1~12

[0023] 1. Test material

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a mixed nanometer lubricating grease additive and application thereof, and belongs to the technical field of lubrication. The mixed nanometer lubricating grease additive consists of the following components in percentage by mass: 50 to 80 percent of Al2O3 powder, 5 to 15 percent of Cu powder and 15 to 35 percent of Al powder, wherein the particle sizes of the Al2O3 powder, the Cu powder and the Al powder are 20 to 60 nanometers. The prepared additive is added into base lubricating grease, so that the anti-extreme pressure, wear-resistant and antifriction performance of the base lubricating grease can be improved; and the additive can act on the surface of a friction pair to improve the roughness of the surface of the friction pair and repair the grinding cracks on the surface, so that the abrasion loss of the friction pair is reduced, the accuracy of the friction pair is ensured effectively and the service life of the friction pair is prolonged. Experimental data display that compared with the lubricating grease into which the additive is not added, the lubricating grease into which the additive is added has the advantages that the friction coefficients are reduced by 42 to 79 percent, and the anti-extreme pressure performance is improved by 36.8 to 47.4 percent.

Description

technical field [0001] The invention relates to a mixed nano grease additive and its application, belonging to the technical field of lubrication. Background technique [0002] Lubricating grease is a petrochemical product that is widely used in machinery industry and power industry and consumes a lot. The composition of grease is mainly base oil (accounting for 70% to 90%), thickener (accounting for 10% to 20%) and additives (less than 10%). Grease is made by adding a thickener to the base oil to make it into a solid or semi-solid state, and adding some additives to improve performance. Among them, additives play a very important role. According to the environment and conditions used, the performance of the required additives is also different. [0003] With the continuous development of nanomaterials and nanotribology, in recent years, in the process of developing additives with excellent properties, domestic and foreign scholars have noticed that nanomaterials have trib...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10M125/10C10M125/04C10N30/06

Inventor 李宝良

Owner DALIAN JIAOTONG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com