Button with hammer effect and preparation method of button

A button and hammer pattern technology, applied in the field of buttons and their preparation, can solve the problems of inability to produce buttons according to customer needs, difficulty in forming interest relationships for paint factories, and loss of opportunities to obtain orders, etc. General chemical corrosion performance, easy to obtain effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

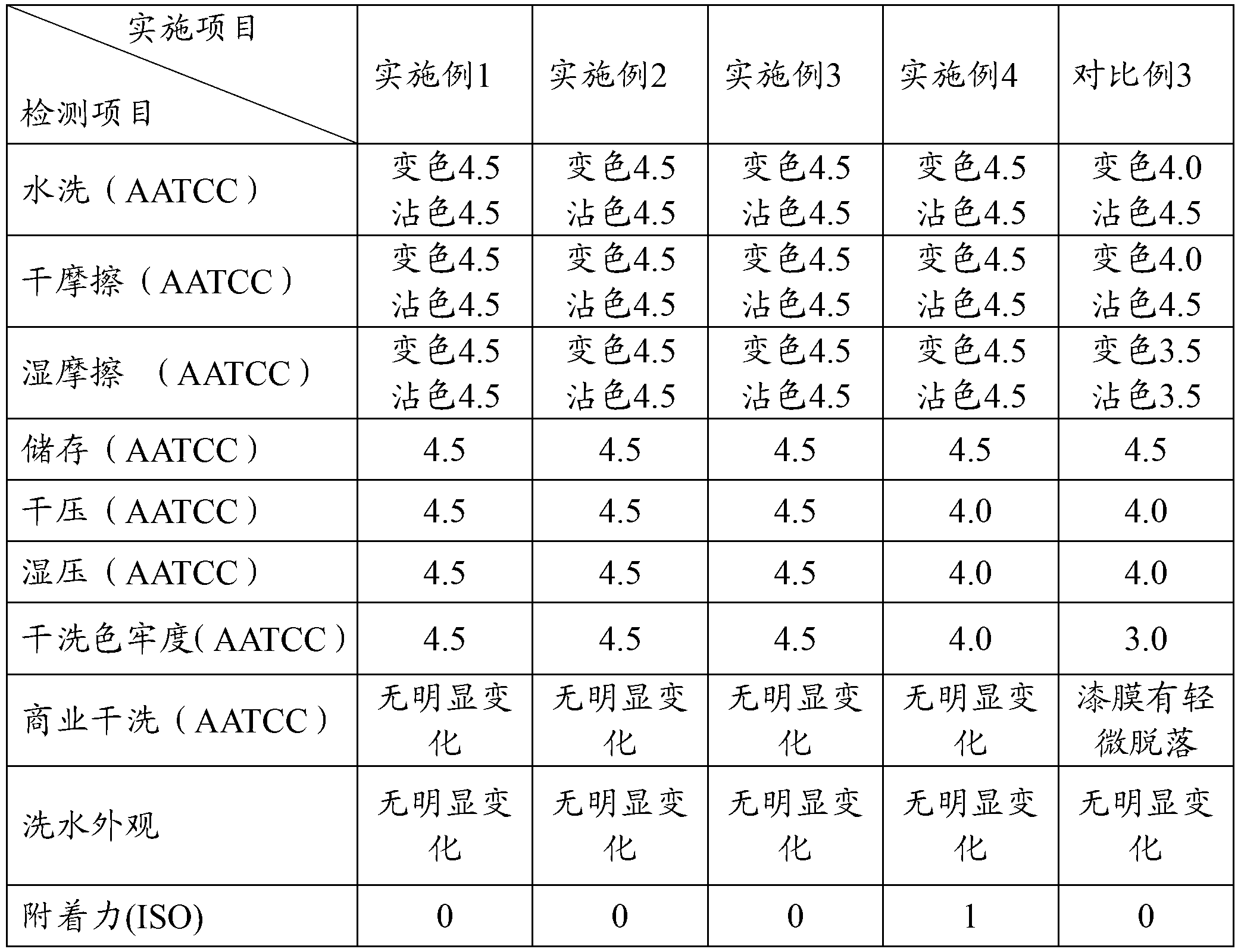

Examples

Embodiment 1

[0049] Example 1 Silver hammer pattern unsaturated polyester buttons

[0050] A silver hammer pattern unsaturated polyester button, the button includes a base material, and a silver hammer grain effect coating is also sprayed on the base material.

[0051] The preparation method of silver hammer grain unsaturated polyester button comprises the steps:

[0052](1) Substrate treatment: The unsaturated polyester substrate to be sprayed is treated with water for 40 minutes to ensure that the surface of the substrate is clean and pollution-free;

[0053] (2) Spraying: Mix hammer paint, curing agent and thinner at a weight ratio of 1:0.25:0.5 to obtain a mixed coating, use an Iwata cup to control the viscosity of the mixed coating to 17 seconds, and then spray the substrate; The method of spraying the substrate is: use a 1.5mm caliber spray gun, control the flow rate at about 300ml / min, adjust the air pressure to about 0.6MPa, set the distance between the gun nozzle and the button s...

Embodiment 2

[0062] Example 2 Tender green hammer pattern unsaturated polyester buttons

[0063] A light green hammer-grain unsaturated polyester button, the button includes a base material, and a coating with a silver hammer-grain effect is also sprayed on the base material.

[0064] A kind of preparation method of tender green hammer pattern unsaturated polyester button, comprises the steps:

[0065] (1) Substrate treatment: The unsaturated polyester substrate to be sprayed is treated with water for 40 minutes to ensure that the surface of the substrate is clean and pollution-free;

[0066] (2) Spraying: Mix hammer paint, curing agent and thinner at a weight ratio of 1:0.25:0.5 to obtain a mixed coating, use an Iwata cup to control the viscosity of the mixed coating to 17 seconds, and then spray the substrate; The method of spraying the substrate is: use a 1.5mm caliber spray gun, control the flow rate at about 300ml / min, adjust the air pressure to about 0.6MPa, set the distance between...

Embodiment 3

[0075] Example 3 Rose red hammered copper buttons

[0076] A rose red hammer pattern copper button, the button includes a base material, and a silver hammer effect coating is also sprayed on the base material.

[0077] A preparation method for a rose red hammer pattern copper button, comprising the steps of:

[0078] (1) Substrate treatment: Slightly grind the copper substrate to be sprayed for 10 minutes to ensure that the surface of the substrate is clean and pollution-free;

[0079] (2) Spraying: Mix hammer paint, curing agent and thinner at a weight ratio of 1:0.25:0.5 to obtain a mixed coating, use an Iwata cup to control the viscosity of the mixed coating to 17 seconds, and then spray the substrate; The method of spraying the substrate is: use a 1.5mm caliber spray gun, control the flow rate at about 300ml / min, adjust the air pressure to about 0.6MPa, set the distance between the gun nozzle and the button surface at 25cm, adjust the spray width to medium, and spray a cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com