A kind of low-temperature curing hammer grain powder coating and preparation method thereof

A powder coating and low-temperature technology, which is applied in powder coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems of high curing temperature and cannot be popularized, and achieves simple preparation methods, suitable for large-scale production and application, and good artistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions in the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0023] A low temperature curing hammer grain powder coating

[0024] In terms of parts by mass, it includes the following components: 25-40 parts of polyester resin, 25-40 parts of epoxy resin, 10-25 parts of titanium dioxide, 10-20 parts of filler, 0.1-0.3 parts of hammering agent, 0.00 parts of pigment ~5 parts, low-temperature curing accelerator 0.5~2.0 parts.

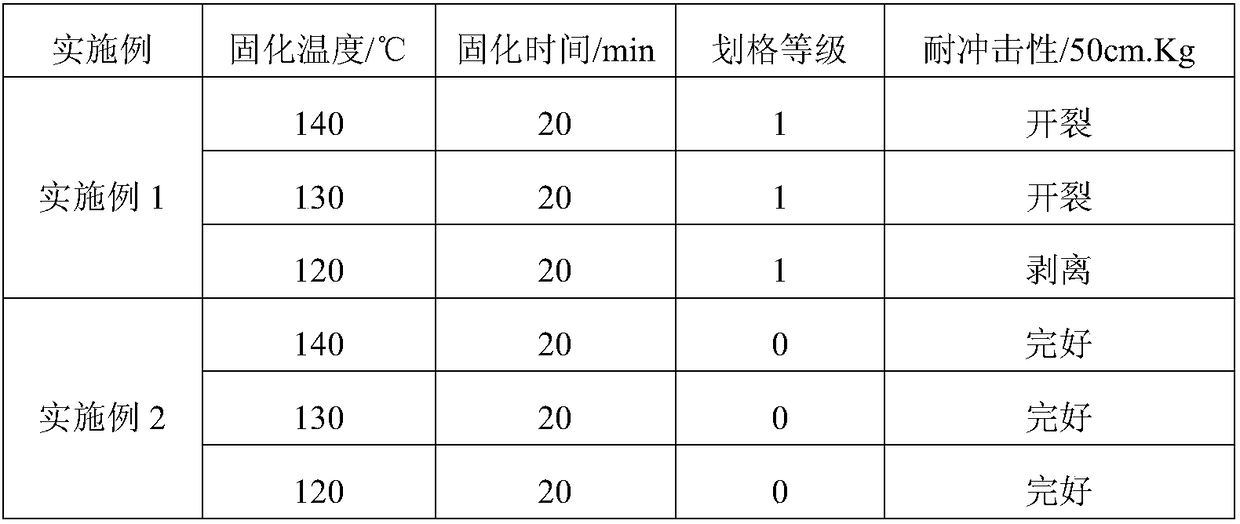

[0025] As shown in the table below, each component in the preferred embodiments is expressed in parts by mass.

[0026] components

Example 1

Example 2

Example 3

Example 4

Example 5

30

30

30

30

30

epoxy r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com