Nano lubricating oil additive

A lubricating oil additive and lubricating oil technology, applied in the direction of additives, lubricating compositions, petroleum industry, etc., can solve the problems of increased user cost, large usage, affecting use function and industrial application, etc., and can repair wear and scratches Surface, extended service life, excellent anti-friction and anti-wear effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

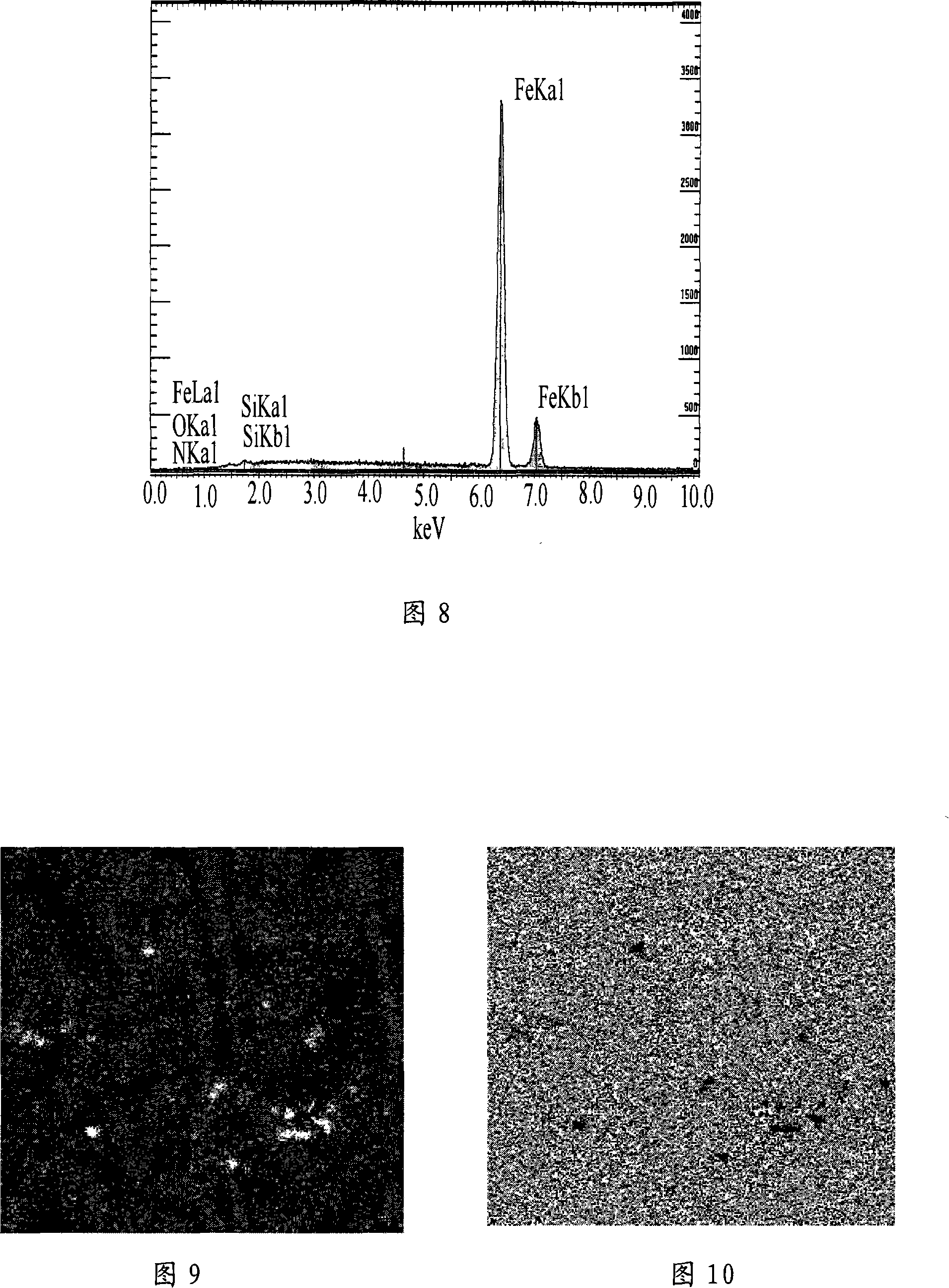

[0044] The mechanism of action of the nano lubricating oil additive of the present invention:

[0045] Firstly, the oil-soluble nano-copper (or nano-copper alloy) and reactive nano-silicon The action mechanism of the nano lubricating oil additive composed of silicon of the present invention is analyzed.

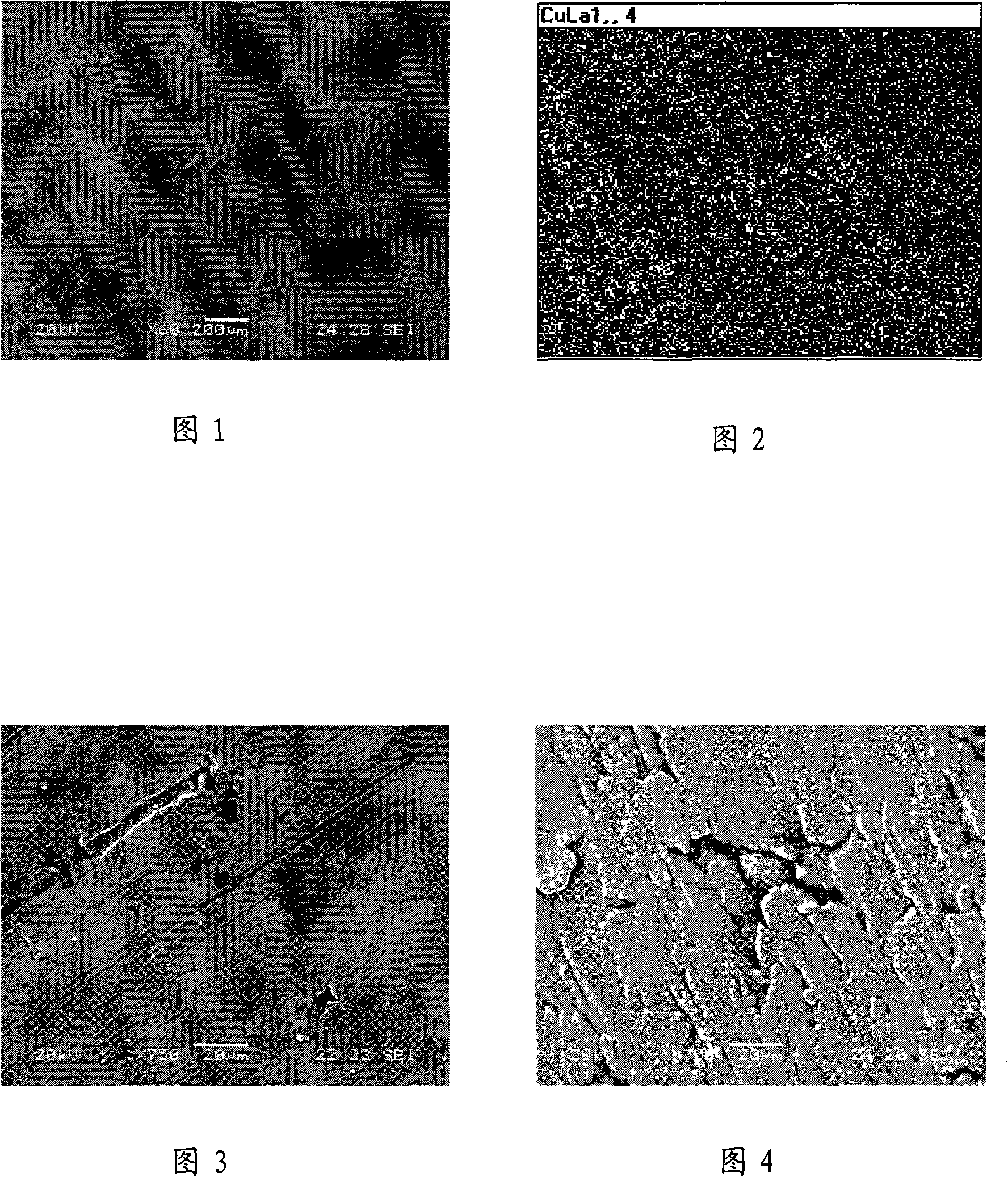

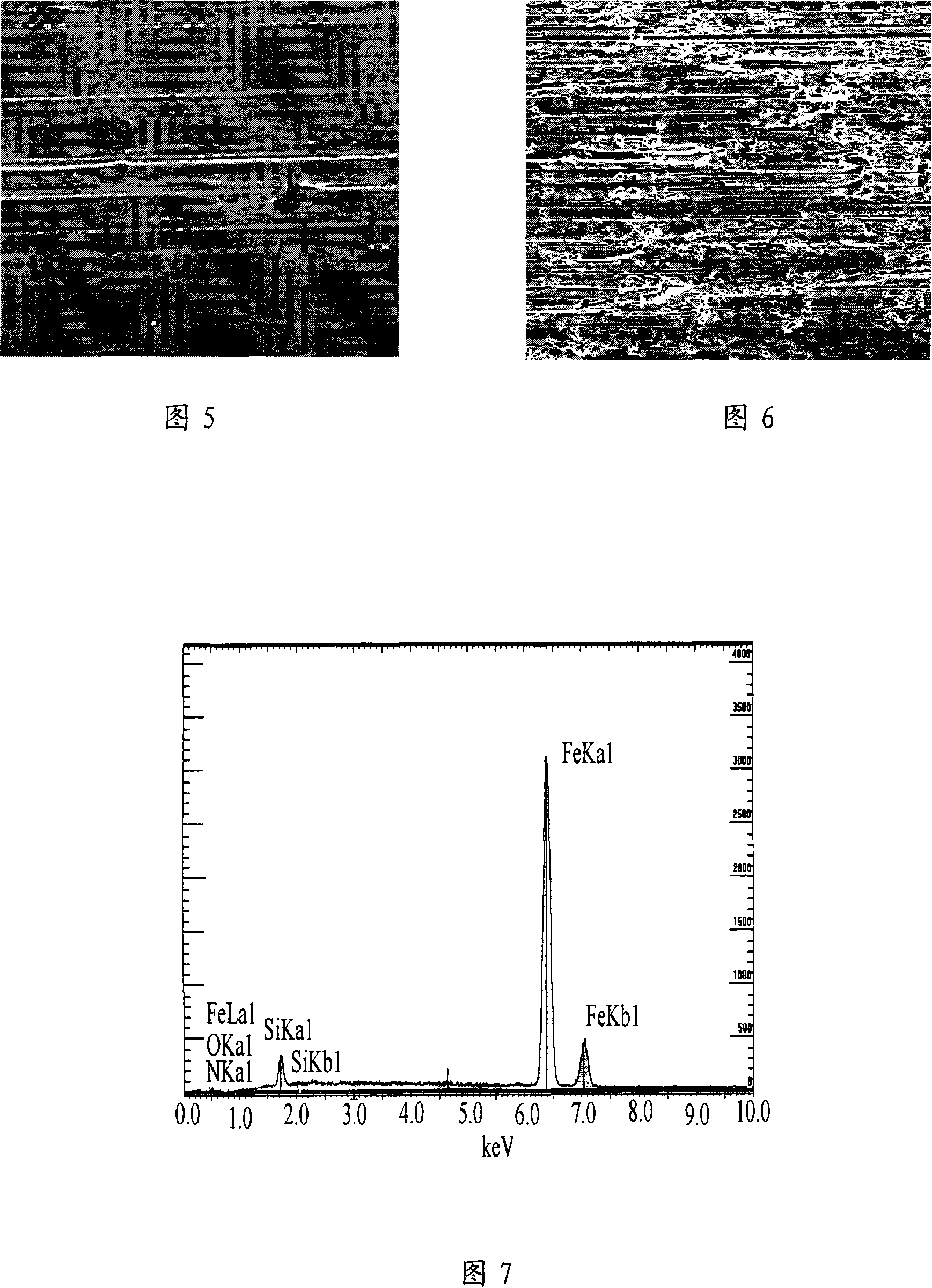

[0046] (1) Repair and anti-wear performance and mechanism analysis of oil-soluble nano-copper (sports car experiment):

[0047] Add 30ml of oil-soluble nano-copper to 3L of SP series gasoline engine lubricating oil produced by Beijing Sunshine Lubricating Oil Co., Ltd., a Sino-US joint venture, and mix evenly. After the gasoline engine has been working normally for about half a month, take out the connecting rod bush for analysis , and compared with the connecting rod bearing of the SP series lubricating oil without oil-soluble nano-copper. The worn surface morphology was measured by a JSM5600LV scanning electron microscope, and the corresponding copper element surface dist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com