Cr-doped DLC (diamond-like carbon) coating with anticorrosion and antifriction properties and preparation method

An anti-corrosion and coating technology, applied in coating, metal material coating process, ion implantation plating, etc., can solve the problems of poor surface roughness and cannot be completely eliminated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] This embodiment provides a method for preparing a Cr-doped DLC coating on the surface of high-speed steel with anti-corrosion and anti-friction properties. It should be noted that the Cr-doped DLC coating prepared by the method of the present invention can be used on any cutting tool , molds and mechanical wear-resistant parts selected materials, not limited to this embodiment.

[0023] The concrete preparation process of this embodiment is:

[0024] (1) A high-speed steel substrate (material: W18Cr4V) with a hardness of HRC=60 (material: W18Cr4V) quenched at 1170°C and tempered at 550°C was used as a sample. After surface degreasing and polishing, it was immersed in acetone for ultrasonic cleaning and alcohol dehydration.

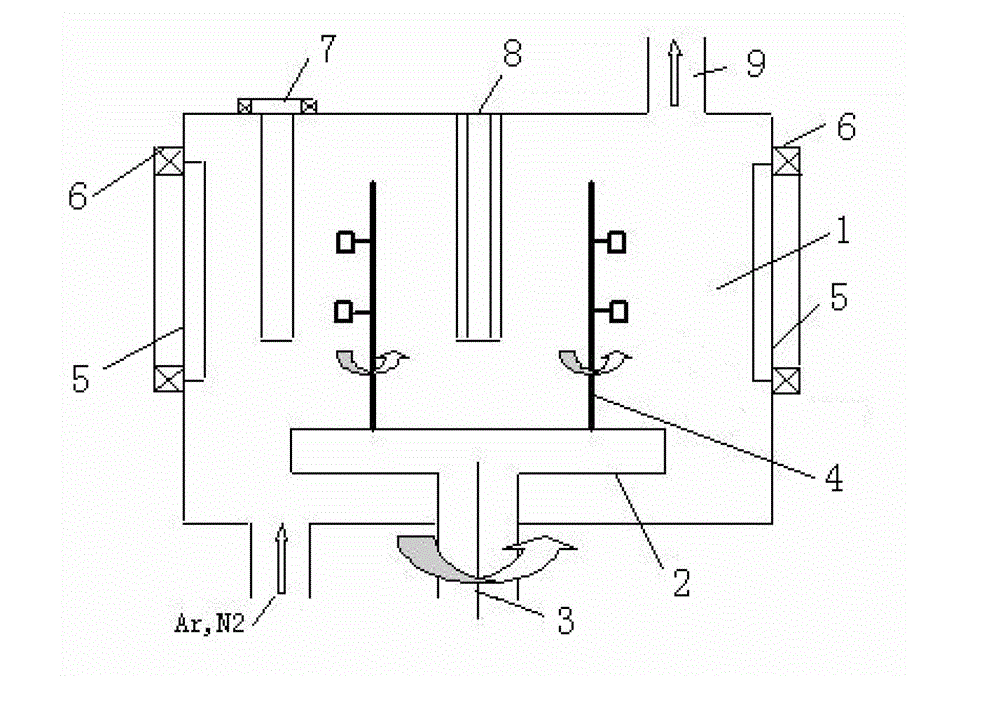

[0025] (2) Put the pretreated sample into the arc and magnetron sputtering composite coating equipment. Such as figure 1 As shown, the arc and magnetron sputtering composite coating equipment at least includes a vacuum chamber 1, a turret 2, a bia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com