Hydraulic-transmission-braking three-use lubricating oil composition

A lubricating oil composition and hydraulic technology, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems that cannot be applied to large and medium-sized tractors, achieve the effects of eliminating brake noise, reducing equipment maintenance and repair costs, and reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

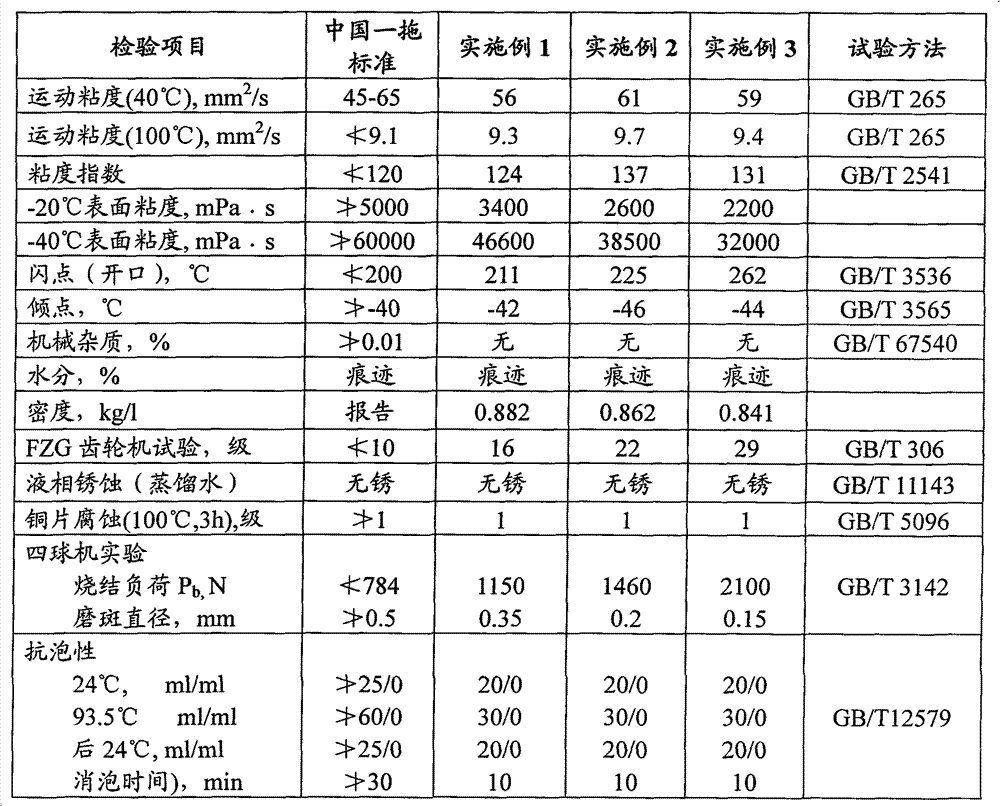

Examples

Embodiment 1

[0023] Weigh the following raw materials: Type III mineral base oil 150N90.4kg, tricresyl phosphate 2.0kg, 2,6-dimethyl-p-cresol 0.6kg, N-phenyl-α-naphthylamine 0.6kg, thiophene Oxadiazole derivatives 0.4kg, dodecenylsuccinic acid 0.4kg, ethylene glycol oleate 0.6kg, boronated succinimide 1.5kg, polymethacrylate (PMA) 3kg, amine and epoxy 0.01kg of ethane condensate, 0.3kg of polyα-olefin pour point depressant, 0.2kg of styrene fumarate copolymer, and 0.005kg of methyl silicone oil composite antifoaming agent.

[0024] Add type III mineral base oil into the reaction kettle, raise the temperature to 55-65 degrees Celsius, then add the remaining additives mentioned above, stir for 90-120 minutes, take samples for testing, and filter the qualified products, and the viscosity at 40 degrees Celsius is about 68mm 2 / s mineral oil type hydraulic-transmission-brake three-purpose lubricating oil composition finished product.

Embodiment 2

[0026] Weigh the raw materials of the following weights: 53.3Nkg of Group III mineral base oil, 40kg of polyalphaolefin synthetic oil (PAO-10) with a viscosity of 10 centtorr at 100°C, 1.6kg of tricresyl phosphate, 2,6-dimethyl 0.5 kg of p-cresol, 0.5 kg of N-phenyl-α-naphthylamine, 0.3 kg of thiadiazole derivatives, 0.3 kg of dodecenyl succinic acid, 0.3 kg of ethylene glycol oleate, and borated dibutyl Imide 1.2kg, polymethacrylate (PMA) 2kg, amine and ethylene oxide condensate 0.01kg, styrene fumarate copolymer pour point depressant 0.3kg, methyl silicone oil composite antifoaming agent (T902 )0.005kg.

[0027] Add type III mineral base oil and poly-α-olefin synthetic oil into the reaction kettle, raise the temperature to 55-65 degrees Celsius, then put in the rest of the above-mentioned additives, stir for 90-120 minutes, take samples for testing, and filter the qualified products , it is obtained that the viscosity at 40 degrees Celsius is about 68mm 2 / s semi-synthetic...

Embodiment 3

[0029] Weigh the following raw materials: 90kg polyalphaolefin synthetic oil (PAO-10) with a viscosity of 10 centtorr at 100°C, 6kg diester synthetic oil, 1.6kg tricresyl phosphate, 2,6-dimethyl p-methyl 0.3kg of phenol, 0.3kg of N-phenyl-α-naphthylamine, 0.3kg of thiadiazole derivatives, 0.3kg of dodecenylsuccinic acid, 0.2kg of ethylene glycol oleate, boronated succinimide 1.0kg, 0.01kg of condensate of amine and ethylene oxide, 0.005kg of methyl silicone oil composite antifoaming agent (T902).

[0030] Add poly-α-olefin synthetic oil with a viscosity of 10 centistorr at 100°C into the reaction kettle, raise the temperature to 55-65°C, then put in the rest of the above-mentioned additives, stir for 90-120 minutes, take samples for testing, and test the qualified products Filtration, the obtained 40 degrees Celsius viscosity is about 68mm 2 / s The finished product of fully synthetic hydraulic-transmission-brake three-purpose lubricating oil composition.

[0031] Regarding t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com