Nanometer hybrid material-modified epoxy resin self-lubricating composite coating layer and preparation method thereof

A technology of nano-hybrid materials and epoxy resin, which is applied in the direction of epoxy resin coating, coating, etc., can solve the problem of affecting the quality and service life of solid lubricating coating, it is difficult to ensure the uniform distribution of lubricant, and the amount of solid lubricant added is large And other problems, to achieve outstanding anti-friction and anti-wear performance, excellent anti-friction performance, easy to peel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) First prepare 30 mL of an aqueous solution of graphene oxide with a concentration of 0.5 mg / mL, then add 0.03 g of carbon nanotubes, and ultrasonically mix until uniform. Hours, after natural cooling, freeze-dry overnight to obtain a carbon nanotube / graphene oxide hybrid material.

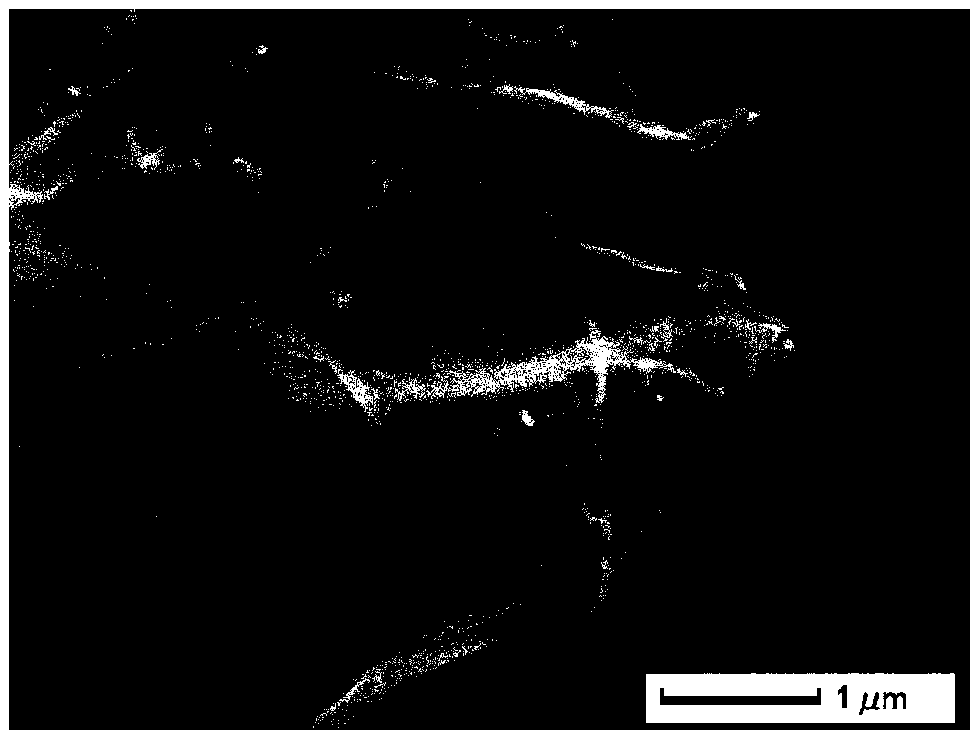

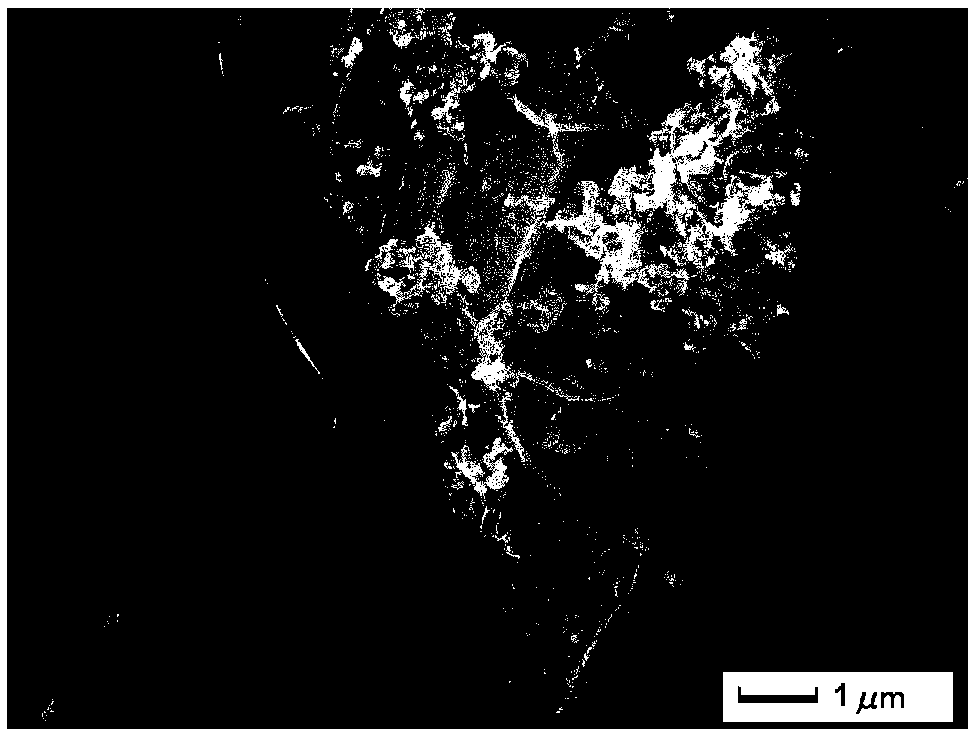

[0028] figure 1 Field emission scanning electron microscope topography of the prepared carbon nanotube / graphene oxide hybrid material. It can be seen that there is no agglomeration phenomenon of carbon nanotubes, and they are uniformly composited with graphene oxide.

[0029] (2) According to the mass ratio of carbon nanotube / graphene oxide hybrid material and tetrathiomolybdate ammonium is 1:3, 0.012g carbon nanotube / graphene oxide hybrid material and 0.036g tetrathiomolybdate Ammonium is dispersed in N,N-dimethylformamide solvent, ultrasonically dispersed and mixed evenly. Continue to add 0.2 mL of hydrazine hydrate dropwise, place the obtained mixed solution in a 50 mL reaction ket...

Embodiment 2

[0032] Weigh 1 g of epoxy resin and curing agent respectively according to the mass ratio of 1:1. First, the epoxy resin was dissolved in 20 mL of a mixed solution of absolute ethanol and acetone with a volume ratio of 1:1, and the mixture was evenly mixed by magnetic stirring. Next, add 1g of curing agent into the above mixed solvent, continue to stir, and mix evenly. Finally, the known mixed solution was coated on the surface of the substrate by a spray gun, placed in a vacuum drying oven, and cured for molding. The curing temperature was 110° C. and the curing time was 2 hours to obtain coating A.

Embodiment 3

[0034] (1) First prepare 30 mL of graphene oxide aqueous solution with a concentration of 0.5 mg / mL, then add 0.06 g of carbon nanotubes, ultrasonically mix until uniform, put the obtained solution in a 50 mL reactor, and conduct a hydrothermal reaction at 200 ° C for 24 hour, after natural cooling, freeze-dry overnight to obtain carbon nanotube / graphene oxide hybrid material;

[0035] (2) Disperse 0.012g of carbon nanotubes / graphene oxide and 0.012g of ammonium tetrathiomolybdate in N,N-dimethylformamide solvent according to the mass ratio of 1:1, ultrasonically disperse and mix evenly, and continue to drop Add 0.1mL of hydrazine hydrate, put the obtained mixed solution in a 50mL reaction kettle, and conduct a hydrothermal reaction at 220°C for 24 hours. After natural cooling, centrifuge, wash repeatedly with deionized water and absolute ethanol several times, and dry. A carbon nanotube / graphene oxide / molybdenum disulfide nano-hybrid material is obtained.

[0036] (3) Weigh ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com