Gather and delivery pump set for thick oil containing sand

A technology for gathering and transportation of heavy oil, applied in the direction of pumps, pump components, rotary piston pumps, etc., can solve the problems of high oil production cost, low sand-containing heavy oil efficiency, poor wear resistance, etc. Optimized rotor profile and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

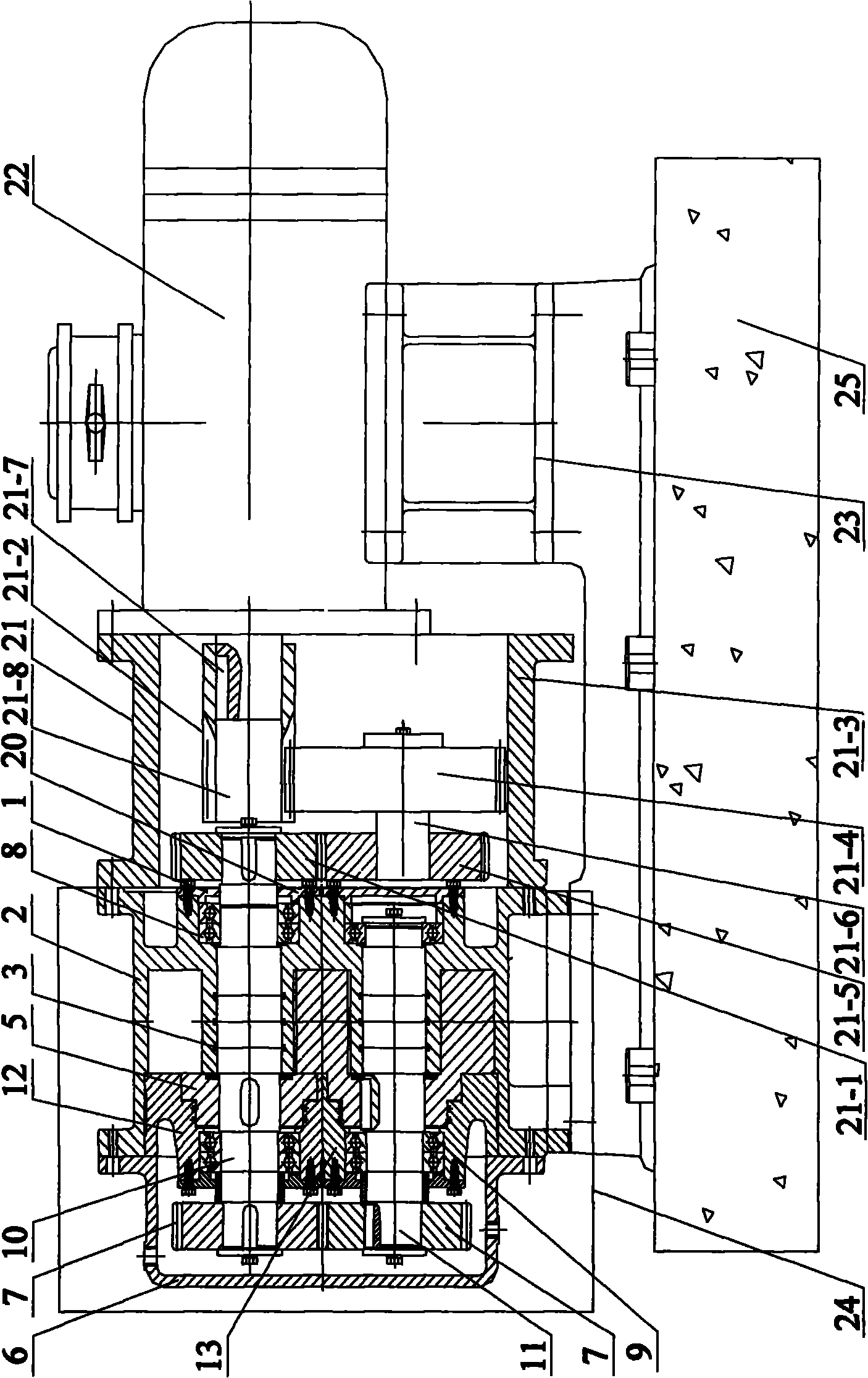

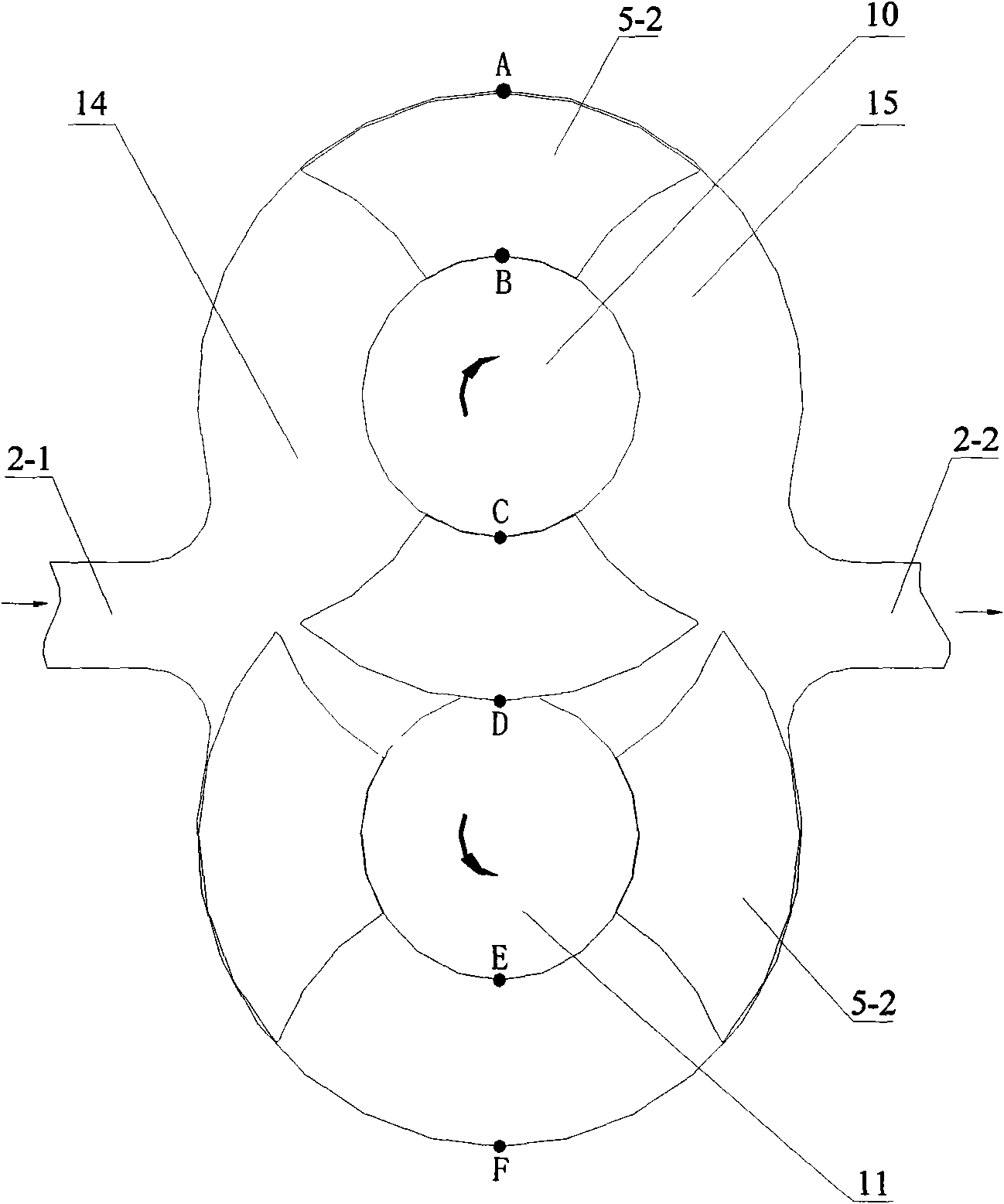

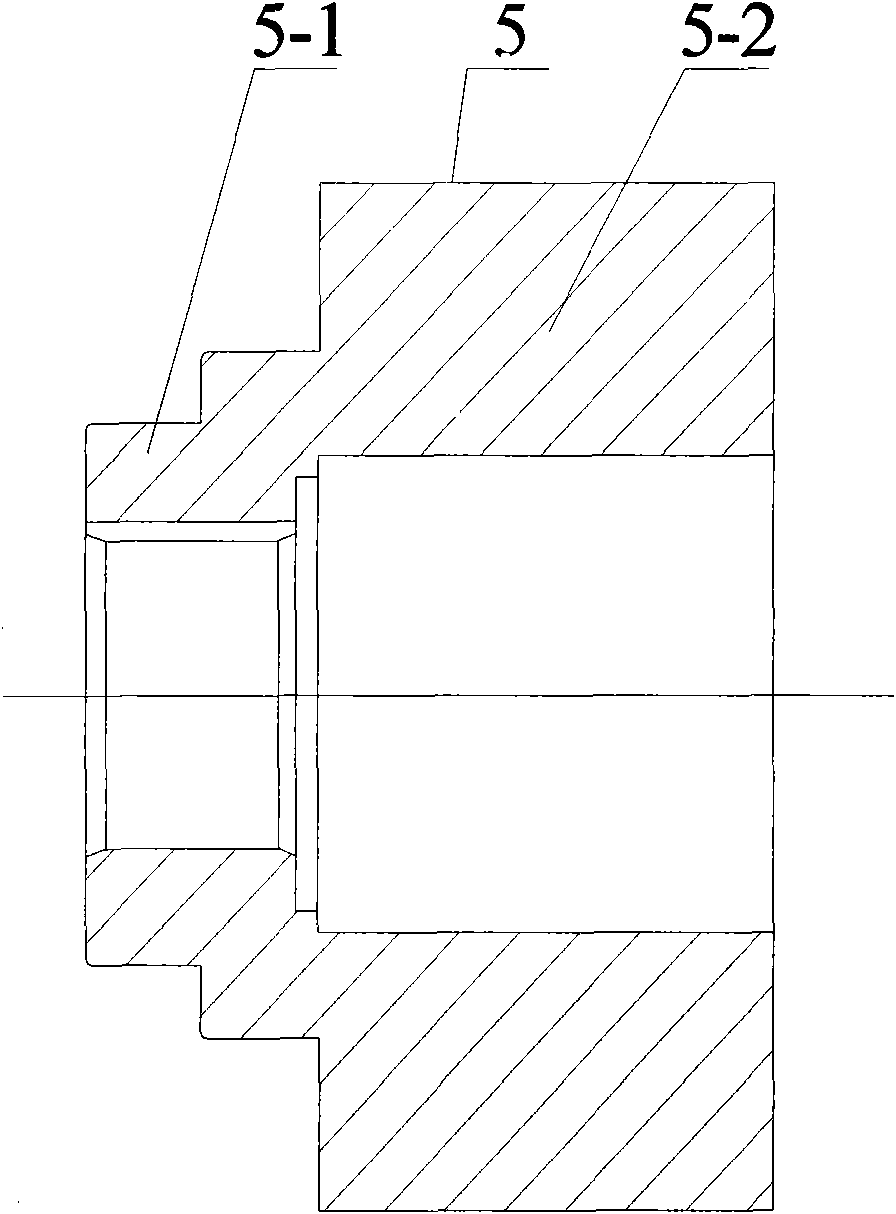

[0007] Specific implementation mode one: combine Figure 1 ~ Figure 4 To illustrate this embodiment, the gathering pump set of this embodiment is composed of a sandy heavy oil gathering pump 24, a speed reducer 21 (a suspended two-stage speed reducer is used), a motor 22, and a machine base 23. The sandy heavy oil The gathering pump 24 consists of a transparent cover 1, a pump casing 2, a plurality of sealing rings 3, a bearing seat, two rotors 5, a gear end cover 6, two synchronous gears 7, four first bearings 8, and three second bearings. The bearing 9, the driving shaft 10, the driven shaft 11 and the flange end cover 20; the bearing seats are respectively the first bearing seat 12 and the second bearing seat 13, and one side of the pump casing 2 is provided with an oil inlet 2 -1, the other side of the pump housing 2 is provided with an oil outlet 2-2, and each rotor 5 is composed of a stepped flange 5-1 and a pair of fan-shaped blades 5-2, and the pair of fan-shaped blade...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 Describe this embodiment, the speed reducer 21 of this embodiment is made up of speed reducer housing 21-3, input gear 21-2, output gear 21-1, first transition gear 21-4, second transition gear 21-5, transition shaft 21-6 and key 21-7; the input gear 21-2, output gear 21-1, first transition gear 21-4, second transition gear 21-5 and transition shaft 21-6 are all mounted on the reduction gear In the machine housing 21-3, the input gear 21-2 meshes with the first transition gear 21-4, and the first transition gear 21-4 and the second transition gear 21-5 are fixed on the transition shaft 21-6. The two transition gears 21-5 mesh with the output gear 21-1, and the input gear 21-2 is provided with a keyhole 21-8 axially, and the output shaft of the motor 22 is installed in the keyhole 21-2 of the input gear 21-2. 8, and the two are affixed by key 21-7. Speed reducer 21 is connected with motor 22 by key 21-7, simple i...

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 1 Describe this embodiment, between the first bearing seat 12 of this embodiment and the rotor 5 fixed on the driving shaft 10 and between the second bearing seat 13 and the rotor 5 fixed on the driven shaft 11 are equipped with Two sealing rings 3. With such setting, the sealing effect is good. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com