Production method for grinding-free and polishing-free black transparent microcrystalline glass plate

A production method and technology for glass plates, applied in glass production, glass forming, glass rolling, etc., can solve the problems of poor labor environment for workers, high product breakage rate, large energy loss, etc., and achieve stable and reliable product quality, dust and dust. The effect of reducing and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] A method for producing a non-grinding and non-polishing black transparent glass-ceramic plate, the technological process comprising: 1) ingredients: the weight percentage of each component is: Li 2 O: 3.1%; CaO: 1.0%; BaO: 1.2%; 2 o 3 : 20.2%; SiO 2 : 69.0%; NiO: 0.07%; V 2 o 5 : 0.14%; Fe 2 o 3 : 0.09%; TiO 2 : 2.0%; ZrO 2 : 1.8%; P 2 o 5 : 1.2%; Nb 2 o 5 : 0.2%. 2) Mixing; 3) Melting, the melting temperature is 1600°C; 4) Cooling; 5) Calendering through the calendering device, the temperature is 1400°C; 6) Annealing, the color of the glass plate is light brown at this time; 7) Crystal Chemical treatment, the temperature is 850°C, the time is 2 hours, at this time the color of the glass is black and transparent; 8) Cutting the board, cutting it into plates according to the required size; 9) Trimming; 10) Inspection; 11) Printing ;12) Drying; 13) Finished product inspection; 14) Packaging; 15) Storage.

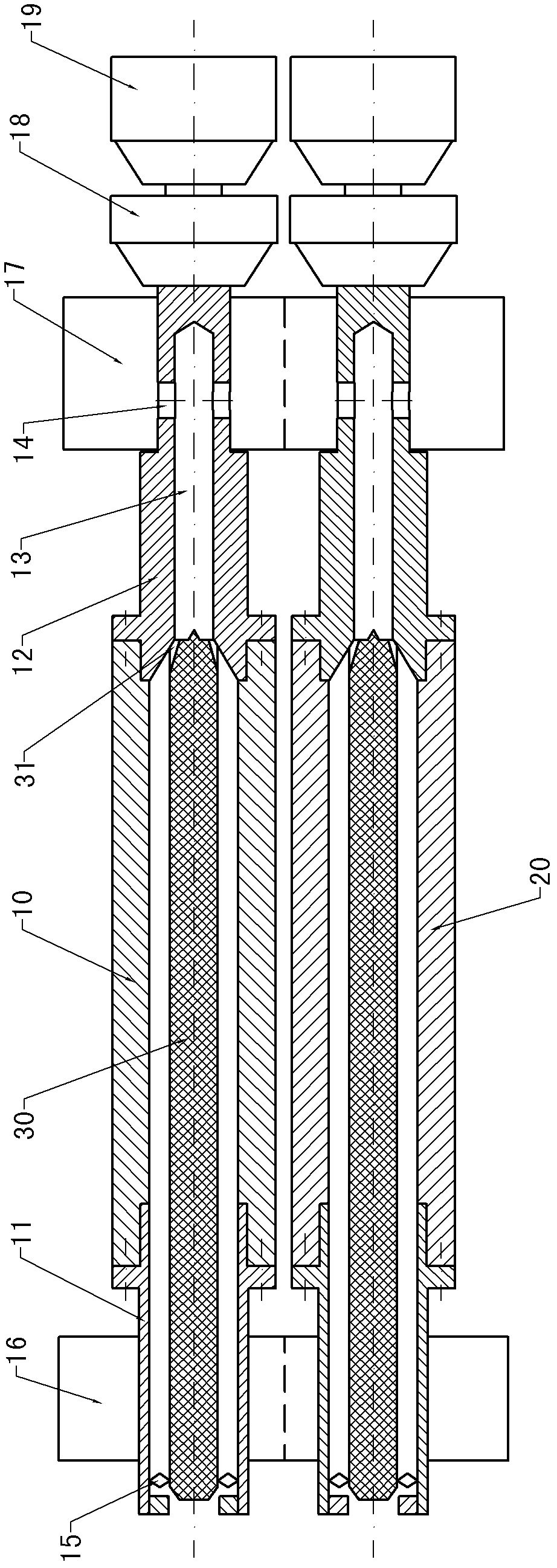

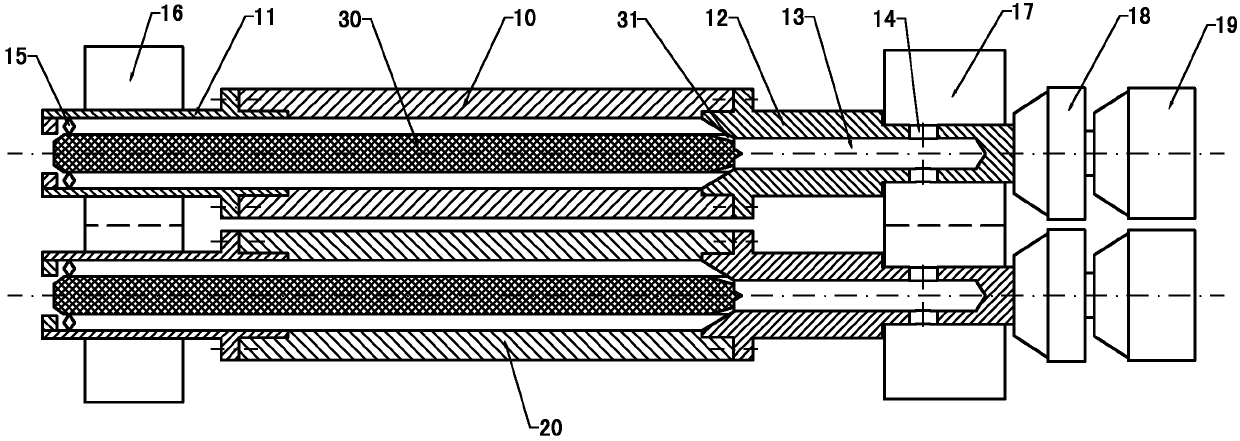

[0014] In this embodiment, the calendering device in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com