Medicinal effervescent tablet and preparation method thereof

A technology for effervescent tablets and medicines, applied in the field of medicine effervescent tablets and their preparation, can solve the problems of low environmental humidity, unfavorable storage, easy occurrence of sticking and punching, etc., and achieve the effects of reducing production costs and reducing environmental humidity requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

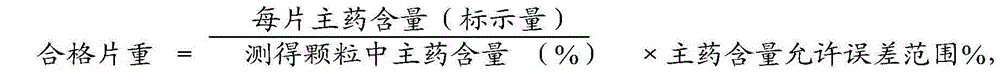

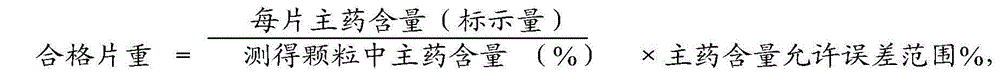

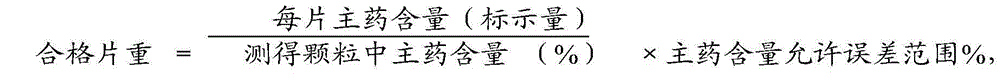

Image

Examples

Embodiment 1

[0049] The preparation method of fudosteine effervescent tablet is as follows:

[0050] (A) In terms of parts by mass, 1 part of carbon dioxide source and 2 parts of filler are pulverized for later use, and 0.2 part of adhesive is mixed with 1 part of wetting agent to prepare a solute with a mass percentage concentration of 1-20%. Adhesive solution ready for use;

[0051] (B) After mixing 1 part of fudosteine, 1 part of organic acid, 0.1 part of disintegrant and 0.1 part of sweetener, it is crushed, passed through a 80-100 mesh sieve, mixed with a binder solution, and sieved Granulating, drying, and sieving to obtain the first granular mixture;

[0052] (C) After melting 0.5 part of the release agent, add 1 part of the pulverized carbon dioxide source, after stirring, cooling, pulverizing and passing through a 80-100 mesh sieve, add the filler for mixing and stirring, and then mix with the remaining binder solution Finally, sieve and granulate, dry, and then sieve to obtai...

Embodiment 2

[0056] The preparation method of acetylcysteine effervescent tablet is as follows:

[0057] (A) In terms of parts by mass, 15 parts of sodium bicarbonate and 10 parts of mannitol are first pulverized for later use, and 0.6 parts of povidone K30 is mixed with 5 parts of water to prepare a solute with a mass percentage concentration of 1-20%. Adhesive solution ready for use;

[0058] (B) After mixing 12 parts of acetylcysteine, 12 parts of citric acid, 0.5 parts of low-substituted hydroxypropyl cellulose and 0.3 parts of sucralose, they are crushed, passed through an 80-mesh sieve, and mixed with a binder solution 1. Sieve and granulate, dry at 50-60°C, and then sieve to obtain the first granule mixture with a mesh size above 18 mesh;

[0059] (C) After melting 10 parts of polyethylene glycol 4000 at 60-80°C, add 15 parts of pulverized sodium bicarbonate, after stirring, cooling, pulverizing and passing through an 80-mesh sieve, add mannitol for mixing and stirring, and then ...

Embodiment 3

[0066] The preparation method of vitamin C effervescent tablet is as follows:

[0067] (A) In terms of parts by mass, 10 parts of a mixture of potassium bicarbonate and sodium carbonate, 8 parts of a mixture of mannitol and lactose are pulverized for later use, and 0.4 parts of povidone K30 is mixed with 3 parts of a mixture of ethanol and water to prepare The mass percent concentration of solute is 1-20% binder solution for subsequent use;

[0068] (B) After mixing 10 parts of vitamin C, 10 parts of a mixture of malic acid and tartaric acid, 0.3 parts of cross-linked polyvinylpyrrolidone, and 0.2 parts of aspartame, they are crushed, passed through an 80-mesh sieve, and mixed with a binder solution 1. Sieve and granulate, dry at 50-60°C, and then sieve to obtain the first granule mixture with a mesh size above 18 mesh;

[0069] (C) Melt 8 parts of polyethylene glycol 6000 at 60-80°C, add 15 parts of the mixture of crushed potassium bicarbonate and sodium carbonate, and add m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com