Patents

Literature

40results about How to "Lower ethylene content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

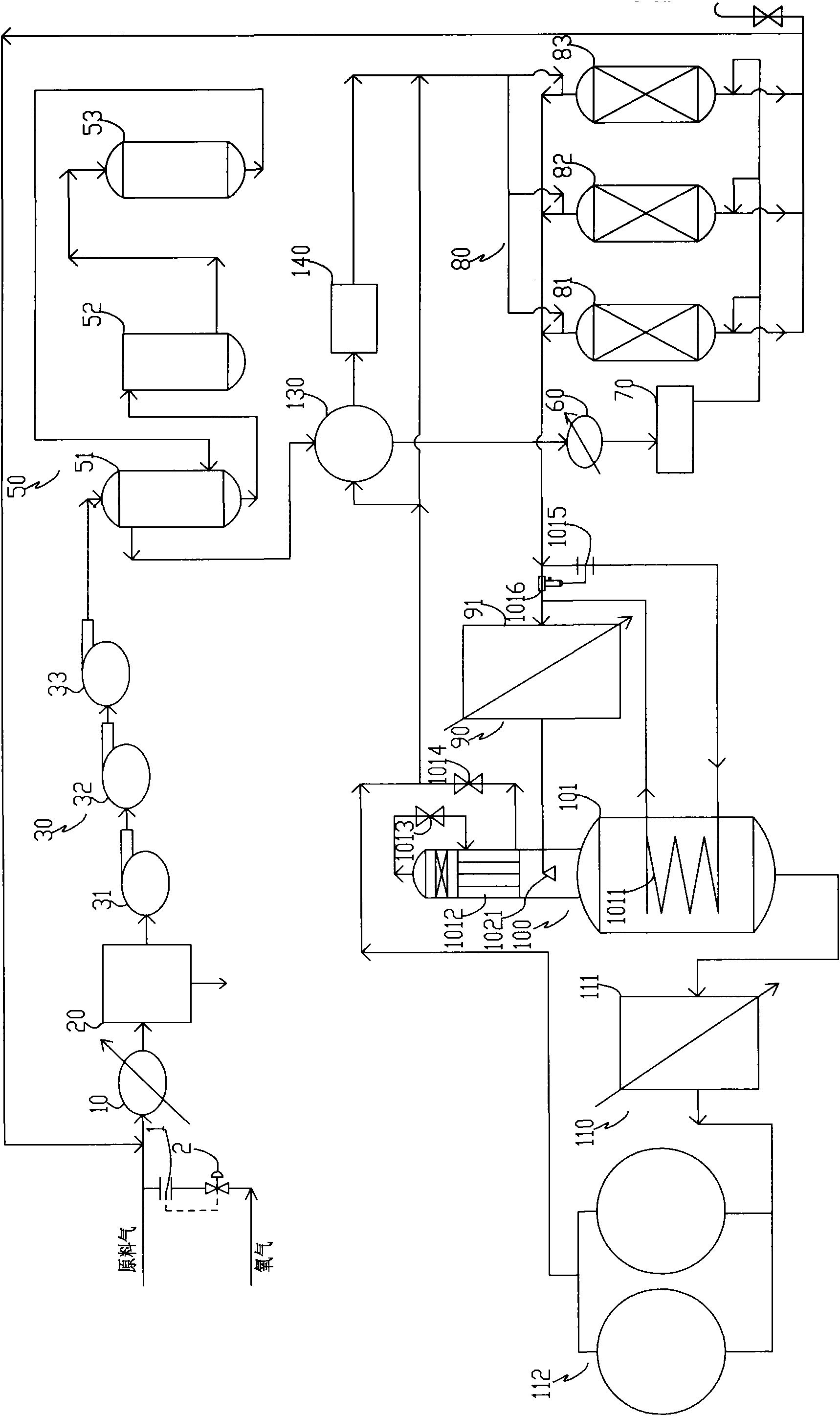

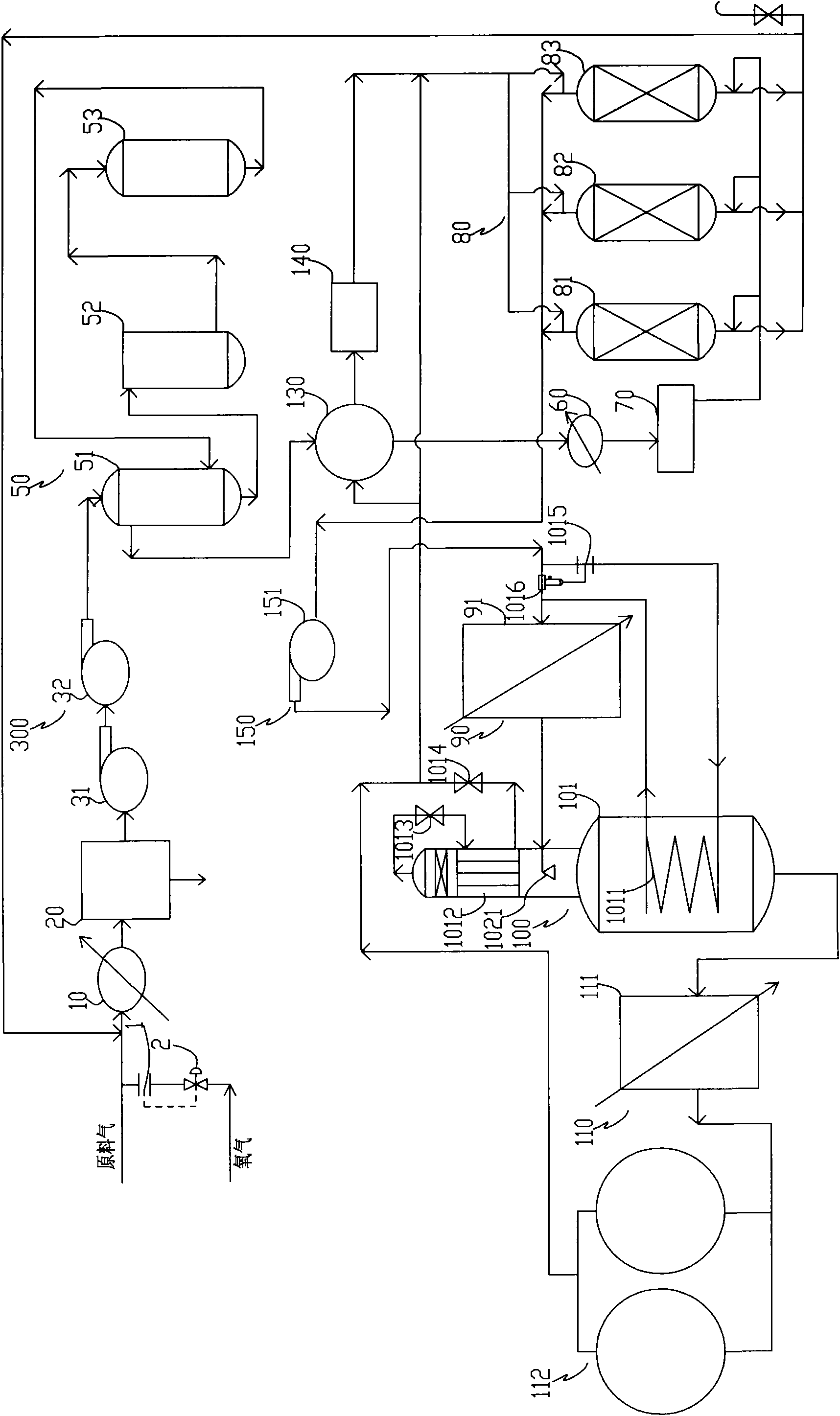

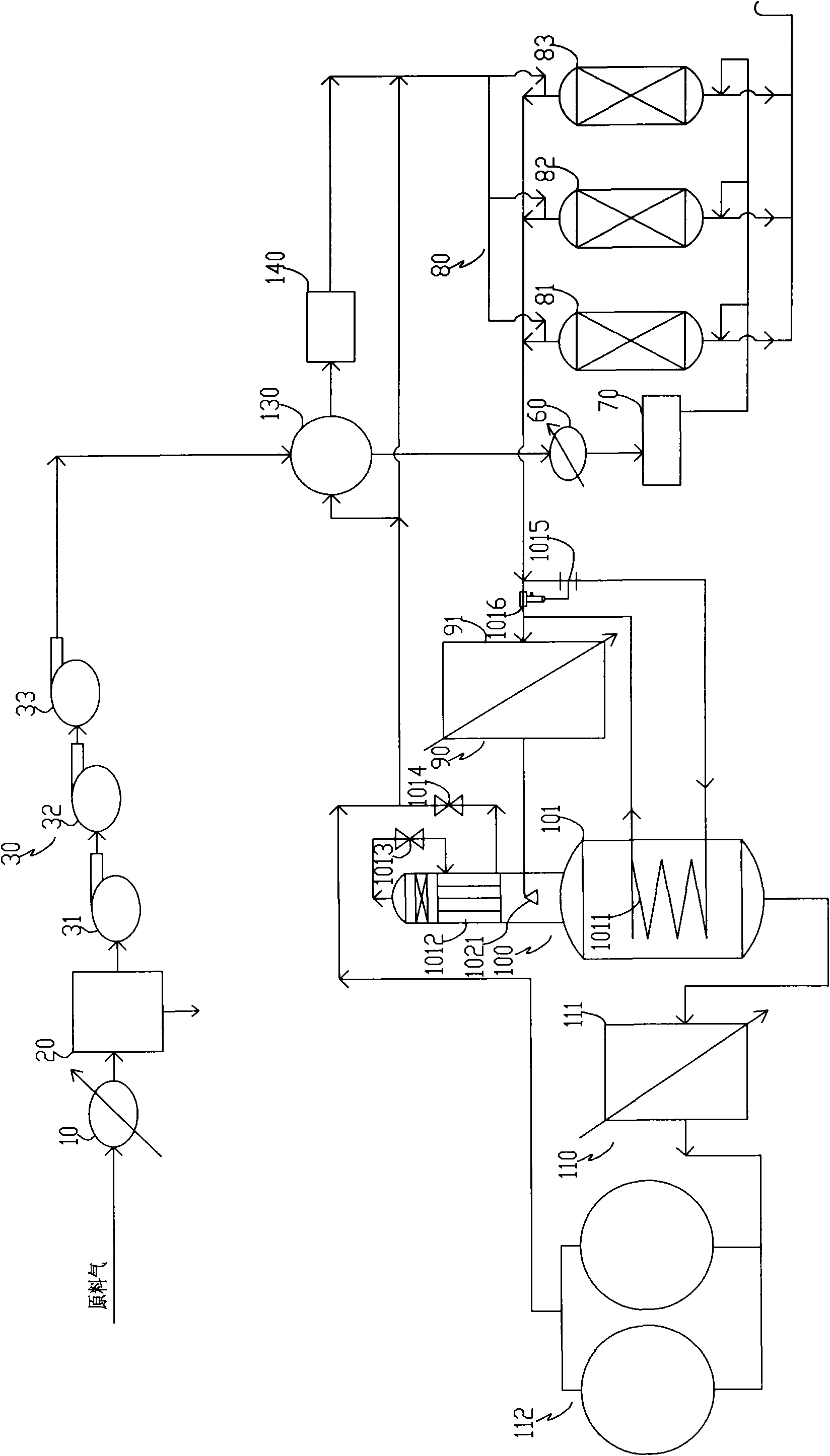

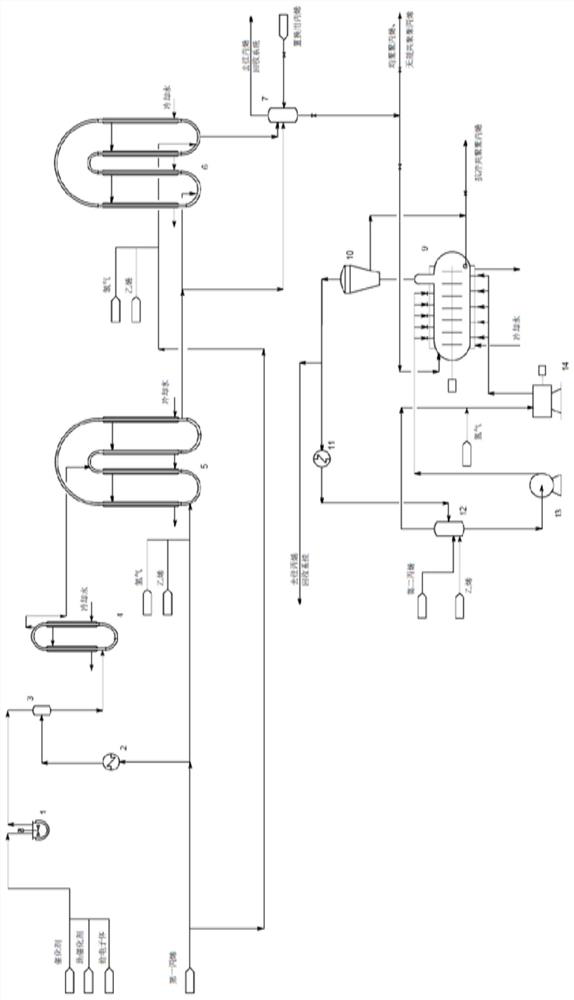

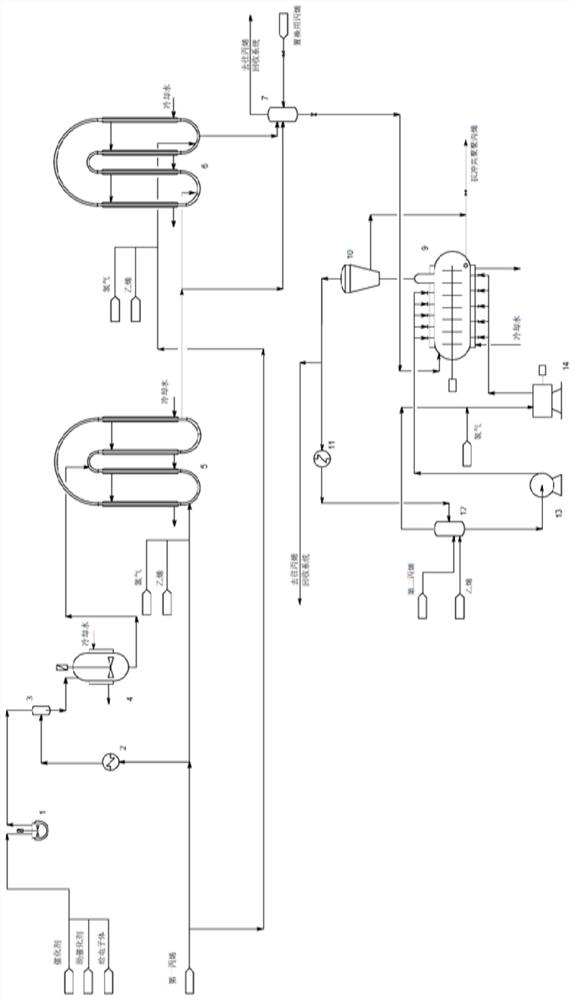

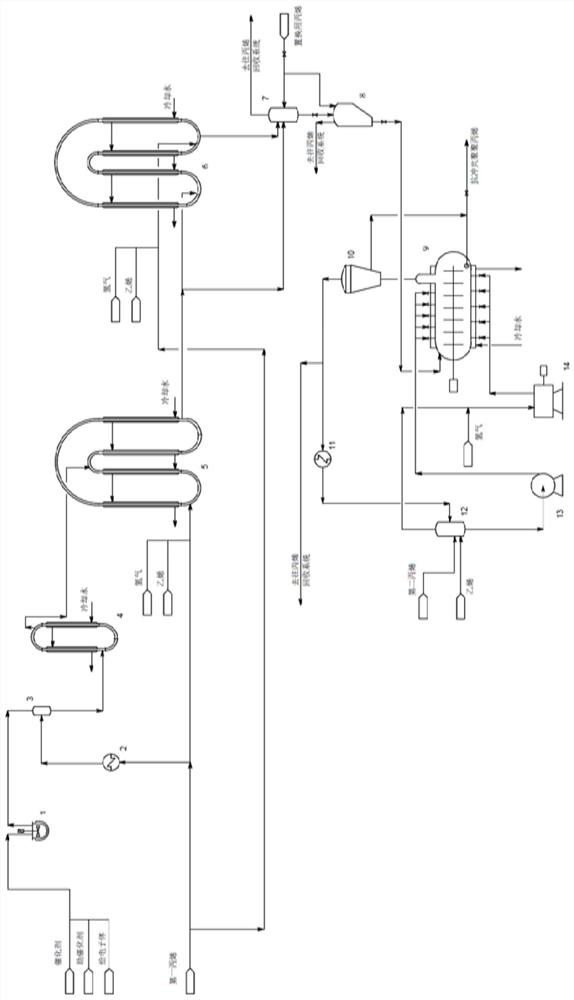

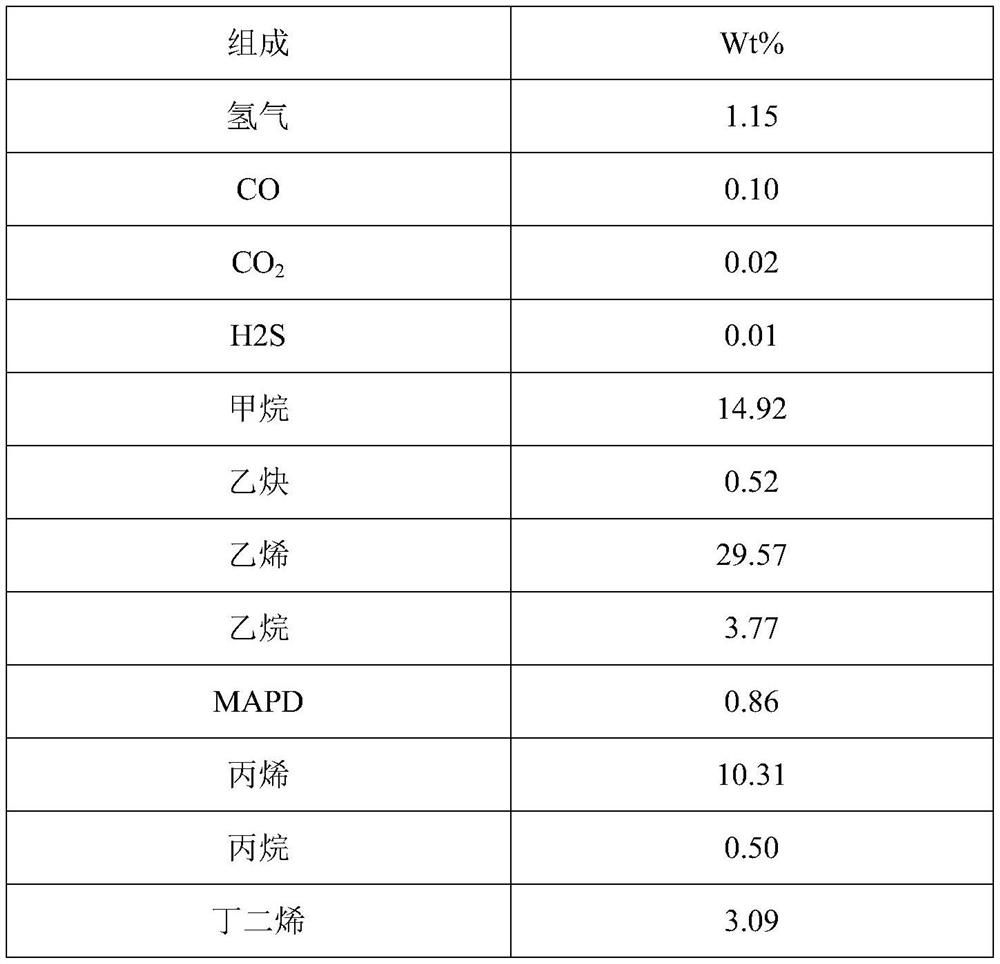

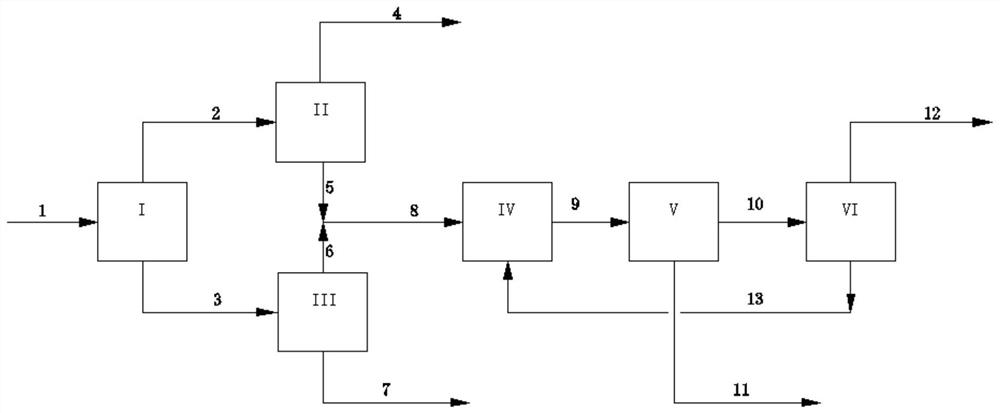

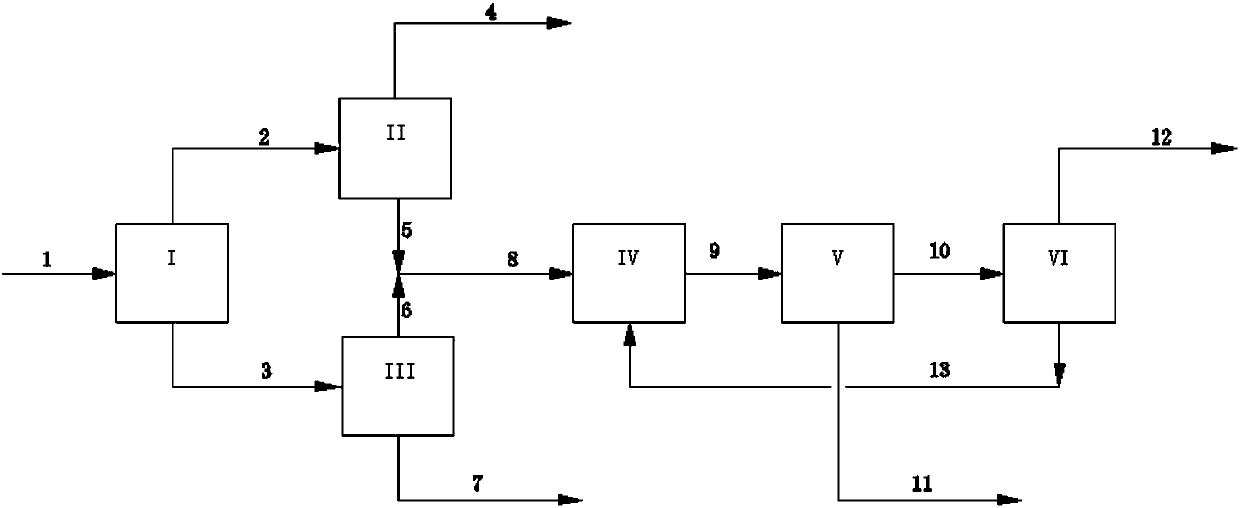

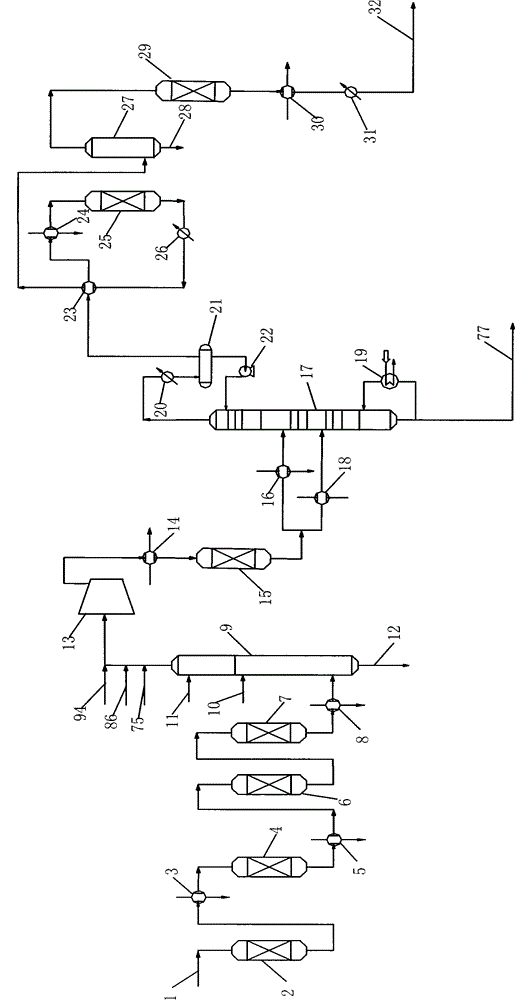

Technology for separating low carbon olefin gases

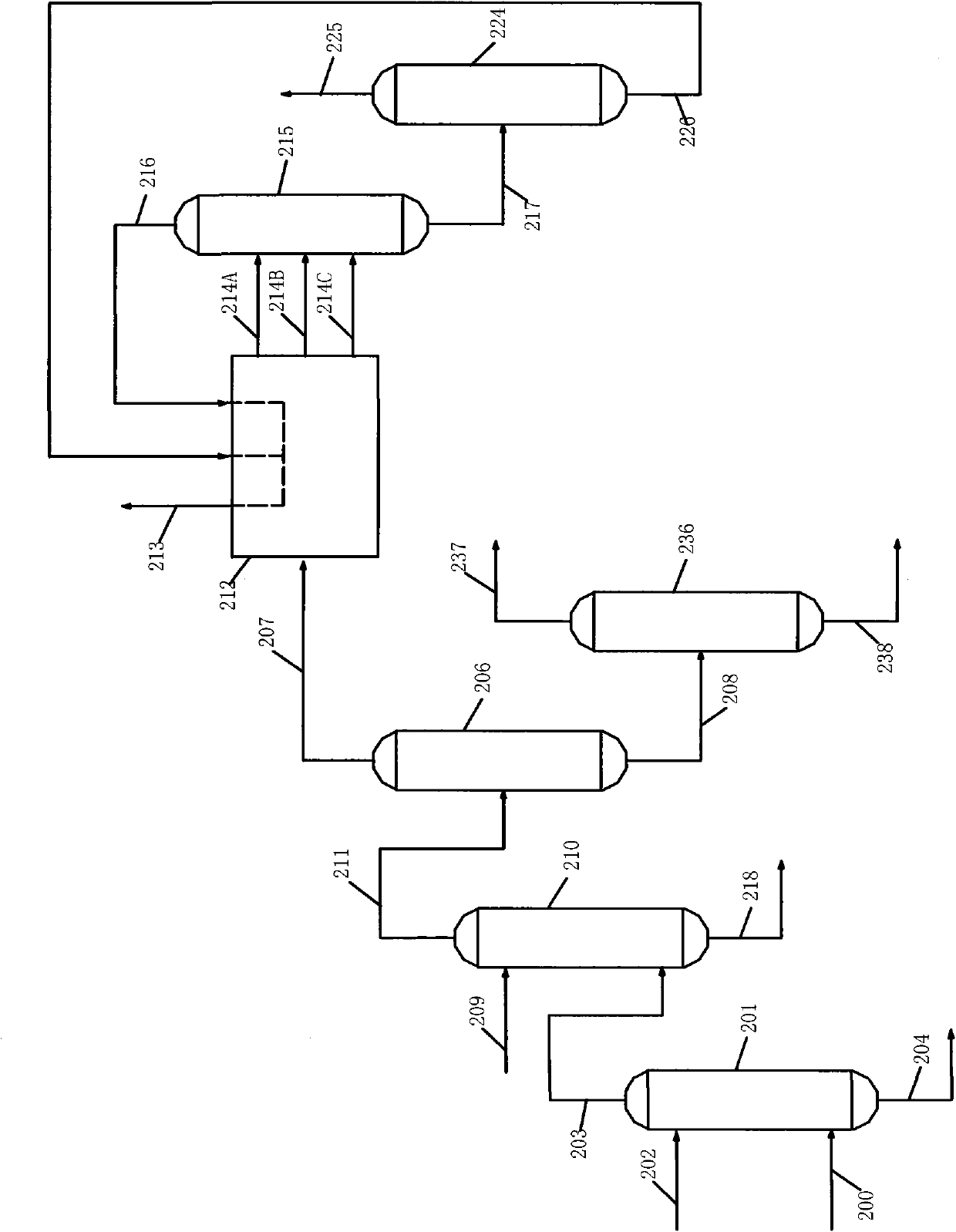

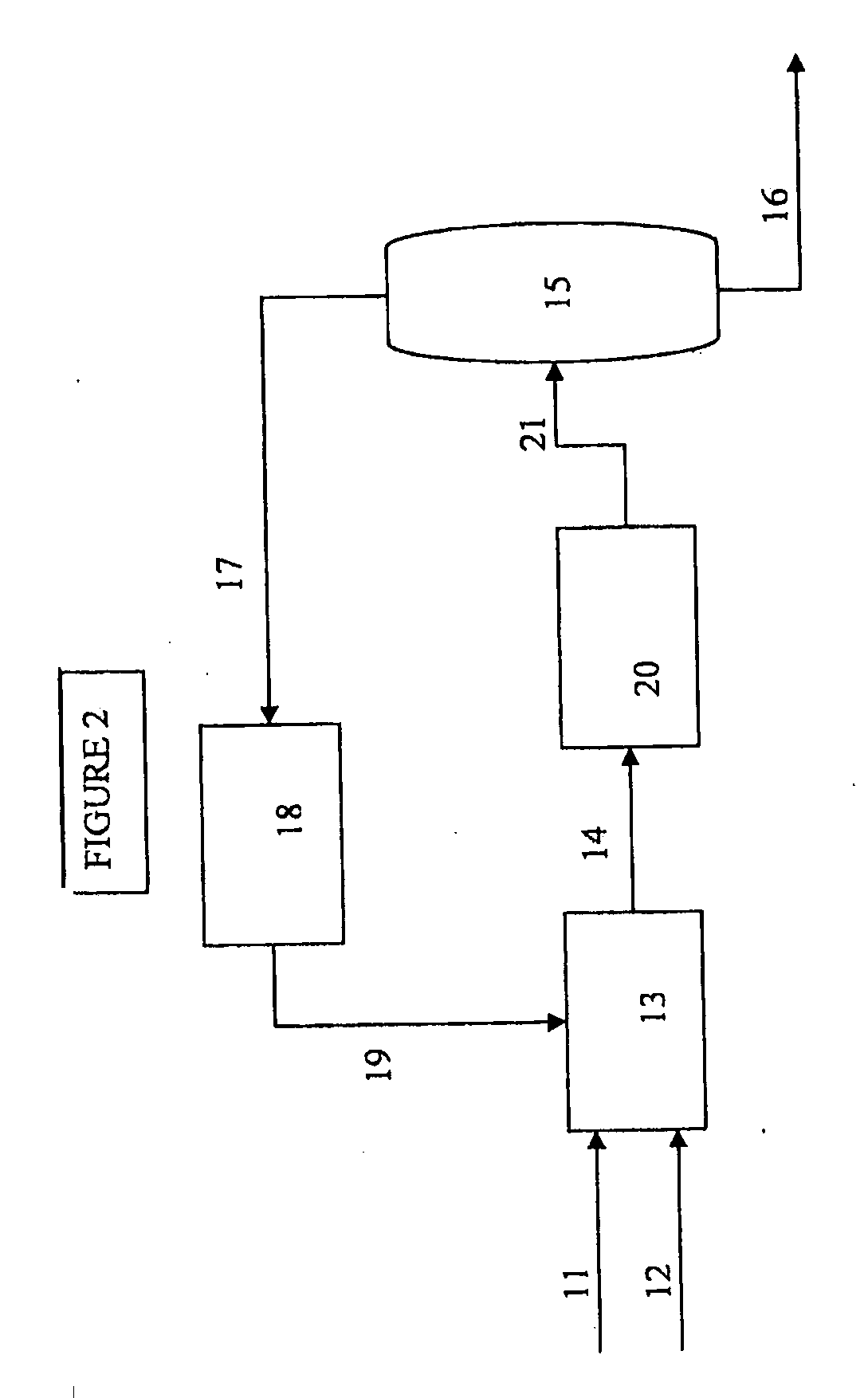

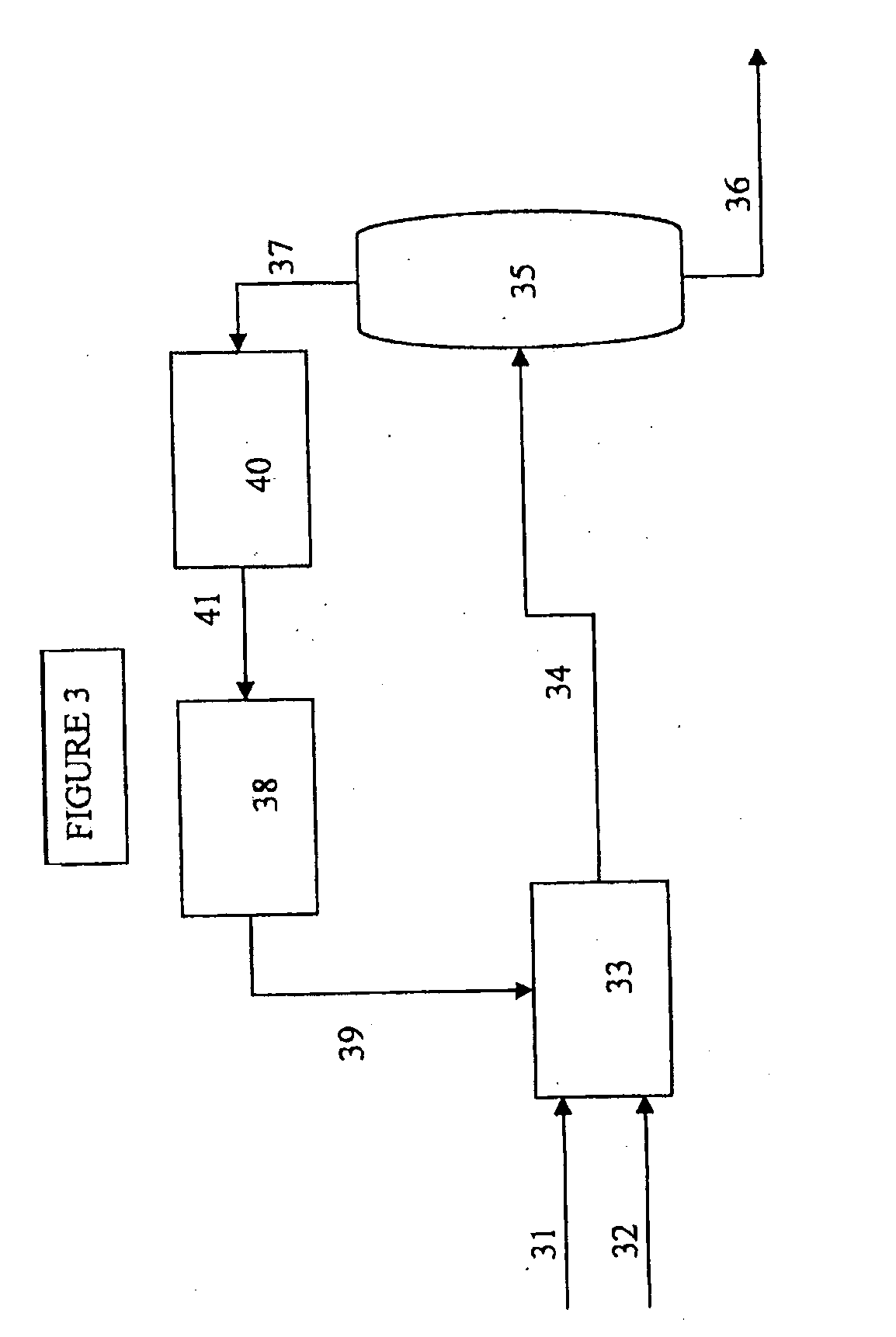

The invention discloses a technology for separating low carbon olefin gases, for solving the problems that hydrogen, methane, ethane and propane and other products with high purity can not be acquired and dimethyl ether and oxygen and carbon monoxide in impurities are not removed efficiently, etc. in the prior art. The technology is characterized in that a step of removing carbon monoxide and oxygen is added, methanol-to-olefin gas streams processed by removing carbon monoxide and oxygen enter into a deethanizing column, deethanizing column overhead streams successively pass through an ethene hydrogenation reactor, six separation pots, a low pressure demethanizing column and an ethene rectification column, etc. to separate to obtain ethene and ethane products, and deethanizing column bottom streams successively pass through a propyne hydrogenation reactor, a methane stripper and a propylene rectification column, etc. to separate to obtain propylene and propane products. According to the invention, polymer grade ethene and propylene products can be obtained, and hydrogen, methane, ethane and propane products, etc. with high purity can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

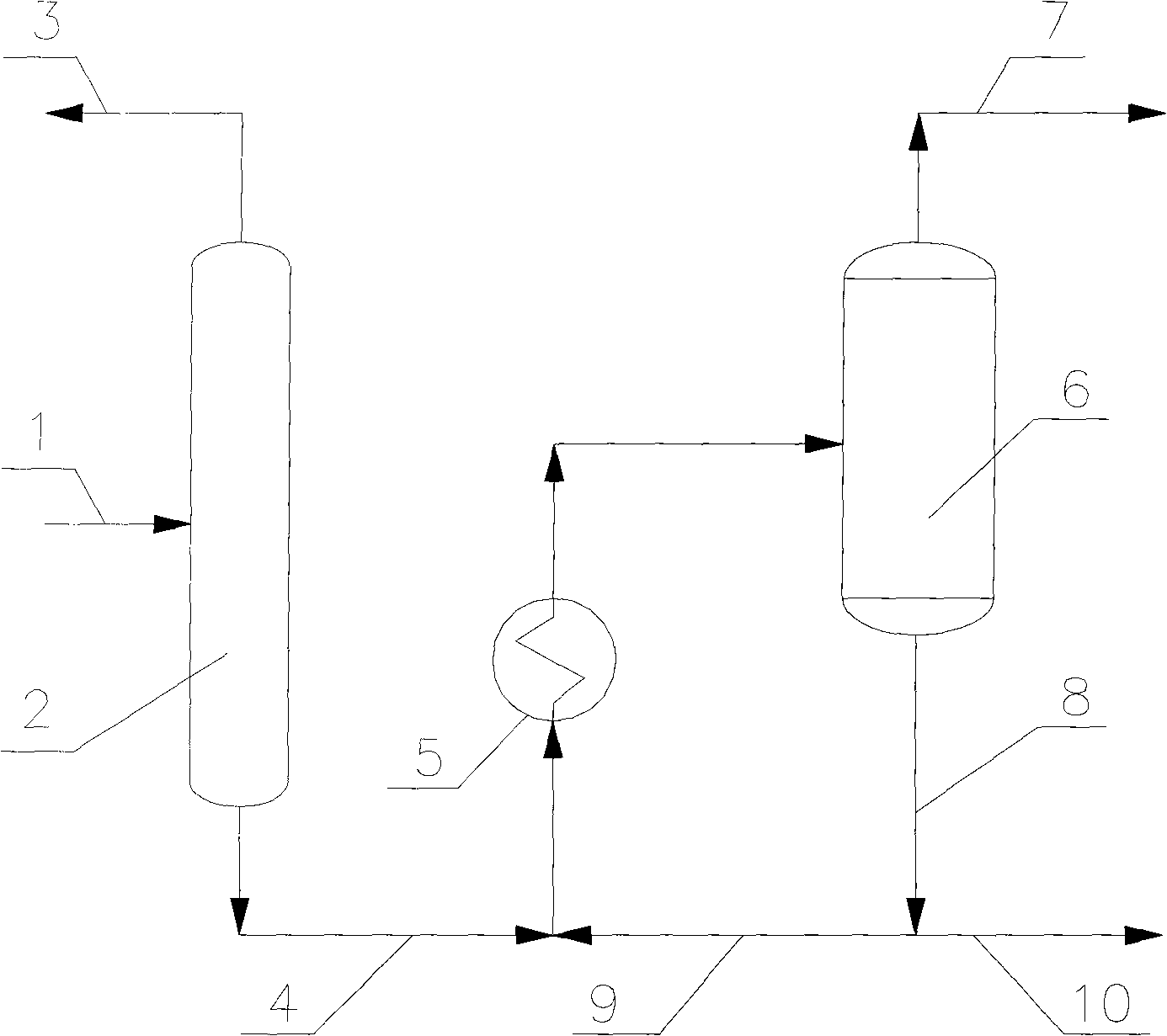

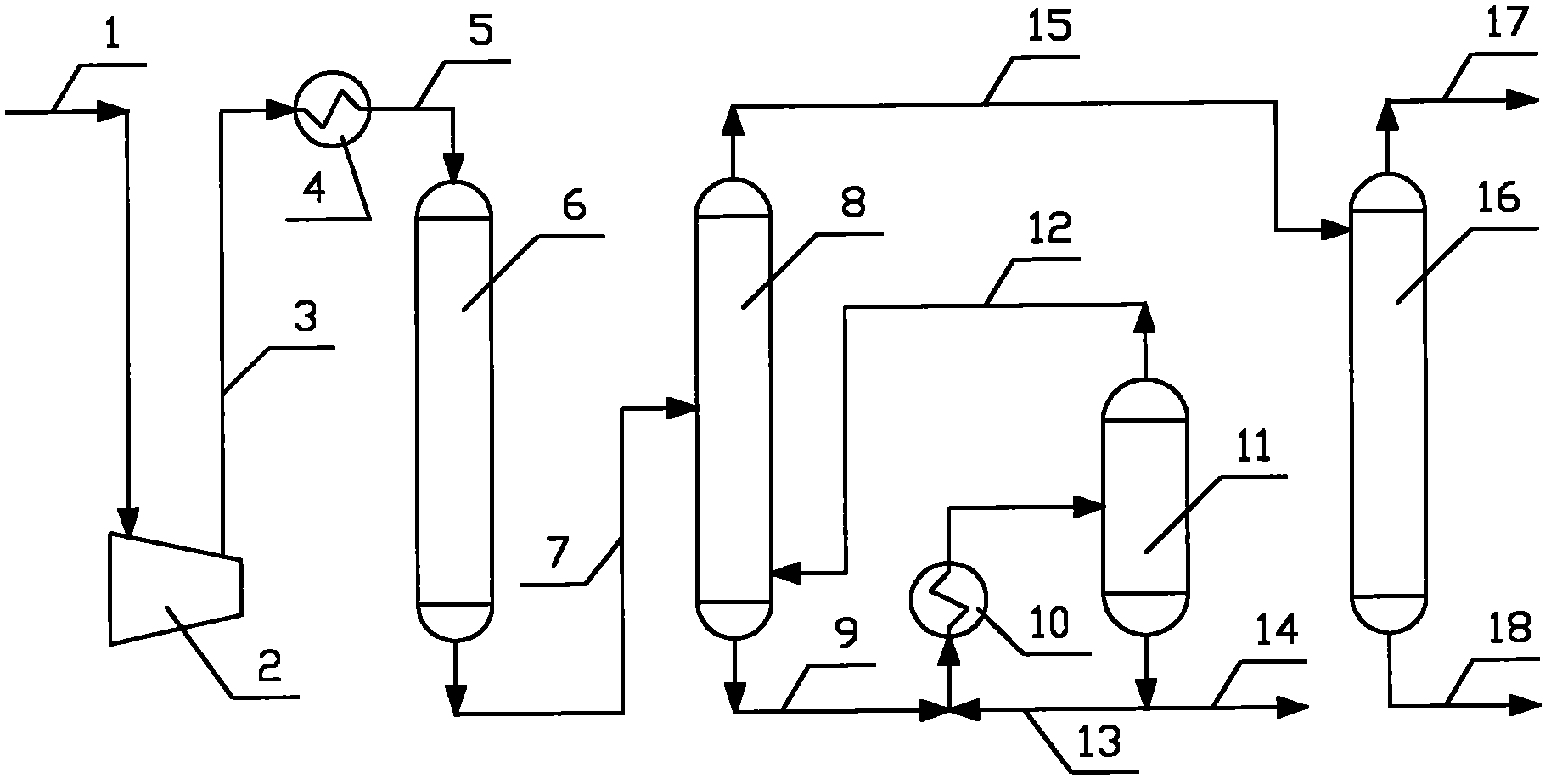

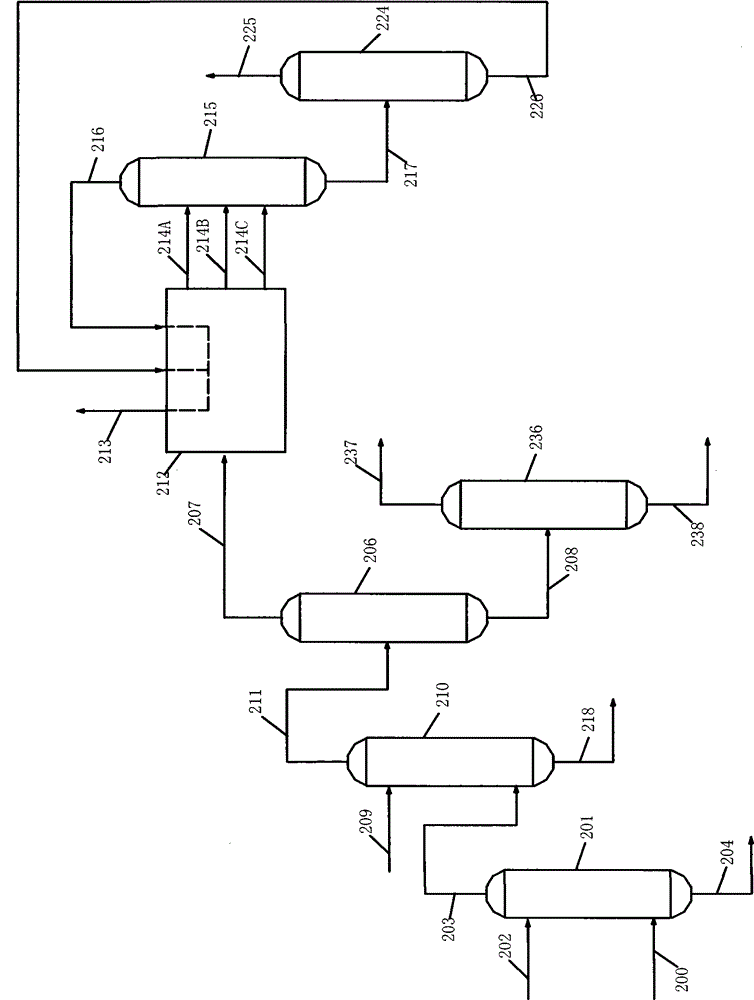

Process for recovering ethylene in process of ethylene preparation by ethanol dehydration

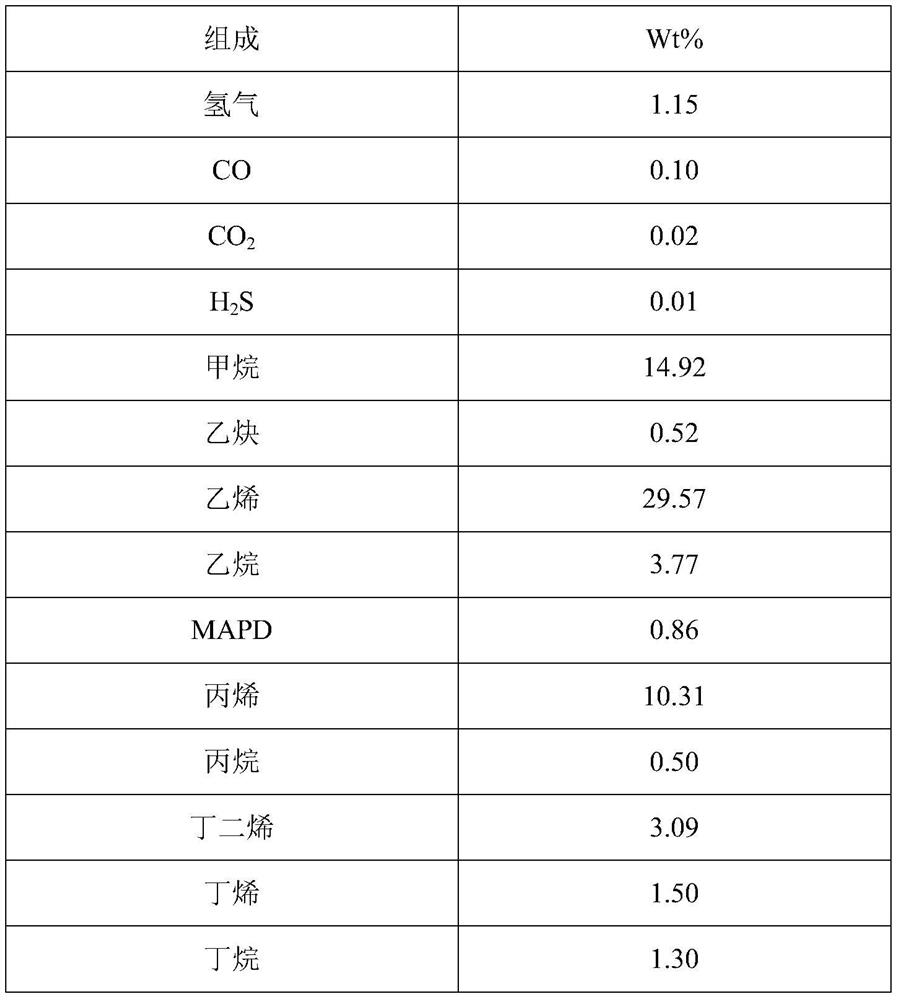

ActiveCN101306973AFlash fullyHigh ethylene contentDistillation purification/separationPolymer scienceTower

The invention relates to a method for reclaiming ethylene in the process for making ethylene through ethanol dehydration, mainly solving the problems not mentioned in the prior literature including ethylene rectification tower bottoms treatment or greater ethylene loss. The method solves the problems better through adopting the following technical proposal that: ethylene rectification tower bottoms are fed in an adiabatic flash drum; the adiabatic temperature of the flash drum is between 15 DEG C below zero and 80 DEG C and the pressure inside the flash drum is between 1.0 and 4.0 MPaG; finally, after adiabatic flash evaporation, the materials at the top of the flash drum is returned to the middle part of an ethylene rectification tower, and the heavy component at the bottom of the flash drum is discharged. The method can be used in the industrial production of ethylene through adopting ethanol dehydration.

Owner:CHINA PETROLEUM & CHEM CORP +1

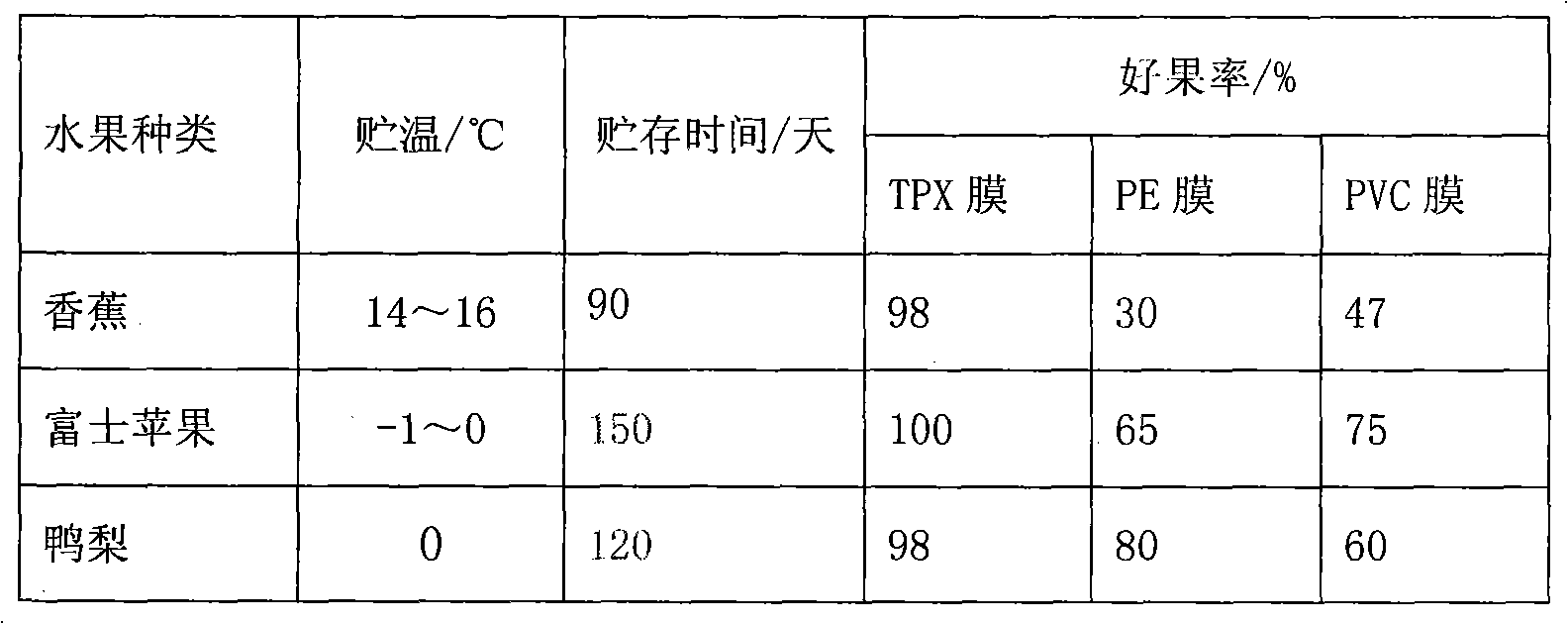

Method for preparing modified atmosphere fresh-keeping film for fruits and vegetables

InactiveCN102079834ASmooth outIncrease humidityFruit and vegetables preservationLow-density polyethyleneDecomposition

The invention relates to a method for preparing a modified atmosphere fresh-keeping film for fruits and vegetables. The fresh-keeping film is prepared by compounding an ethylene absorption and decomposition agent with gas absorbency and resin. The modified atmosphere fresh-keeping film comprises the following components in percentage by weight: 60 to 80 percent of poly(4-methyl-1-pentene) resin, 10 to 20 percent of low-density polyethylene, 2 to 5 percent of inorganic moisture-penetrating agent and 0.1 to 5 percent of ethylene absorption and decomposition agent. The modified atmosphere fresh-keeping film has the advantages of retarding the metabolic ageing of the fruits and the vegetables and prolonging the quality guarantee periods of the fruits and the vegetables, along with high carbon dioxide and oxygen permeability, high moisture-penetrability, ethylene absorption and decomposition functions, and relatively better fresh-keeping effects on the fruits such as bananas, apples and the like.

Owner:NAT ENG AN TECH RES CENT FOR PRESERVATION OF AGRI PROD TIANJIN

Ethylene separation method

ActiveCN102372559AFlexible control of quality requirementsReduce energy consumptionDistillation purification/separationHydrocarbonsMaterial flowSeparation method

The invention relates to an ethylene separation method, which mainly solves the problems of large loss amount of ethylene in an ethylene rectifying tower and low recovery rate of ethylene in prior art. The separation method of the invention is characterized in that the crude ethylene is compressed and dried to enter in the ethylene rectifying tower, a material flow at the top of the ethylene rectifying tower enters into a light component eliminating tower for separating, a light component is eliminated at the top of the light component eliminating tower to obtain a ethylene product; a material in a tower kettle of the ethylene rectifying tower is flash evaporated through a flash evaporation pot, the material at the top enters in the bottom part of the ethylene rectifying tower, a part of the material at the bottom circularly enters in a central part of the flash evaporation pot, the other part of the material is discharged outside. The technical scheme better solves the problems and can be used in industrial production of ethylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

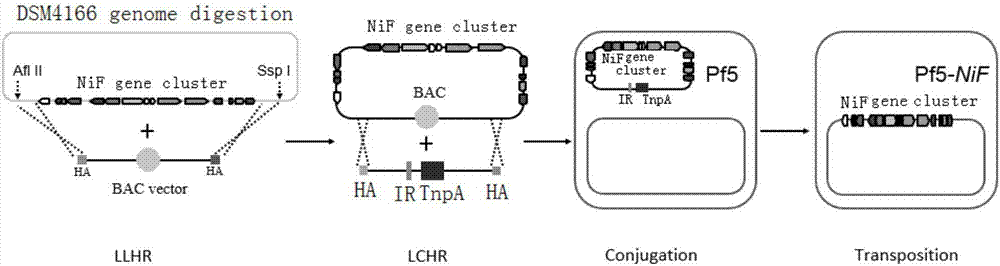

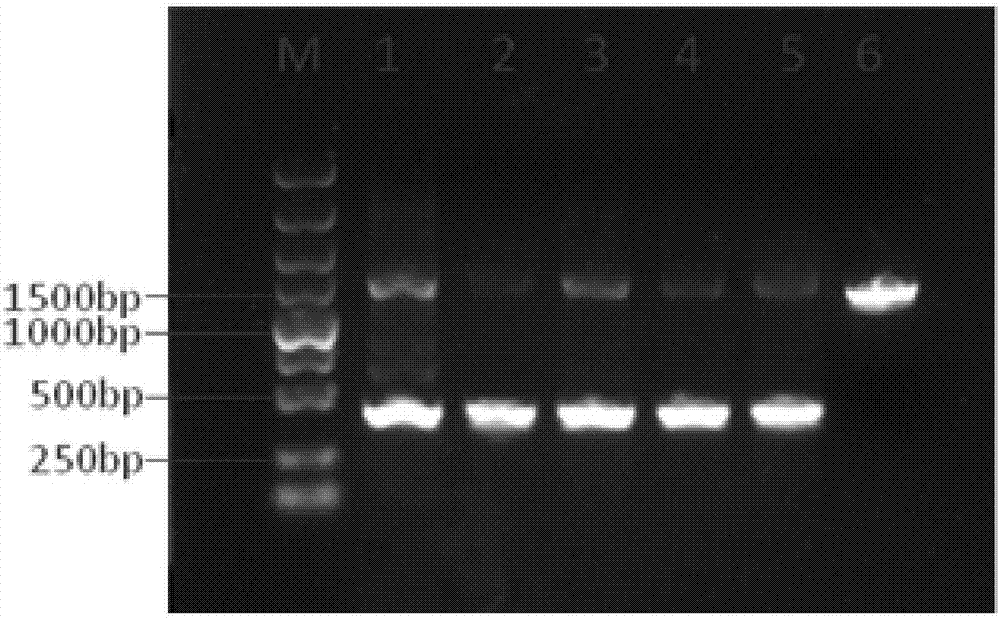

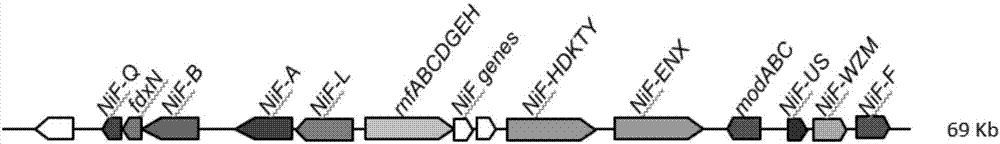

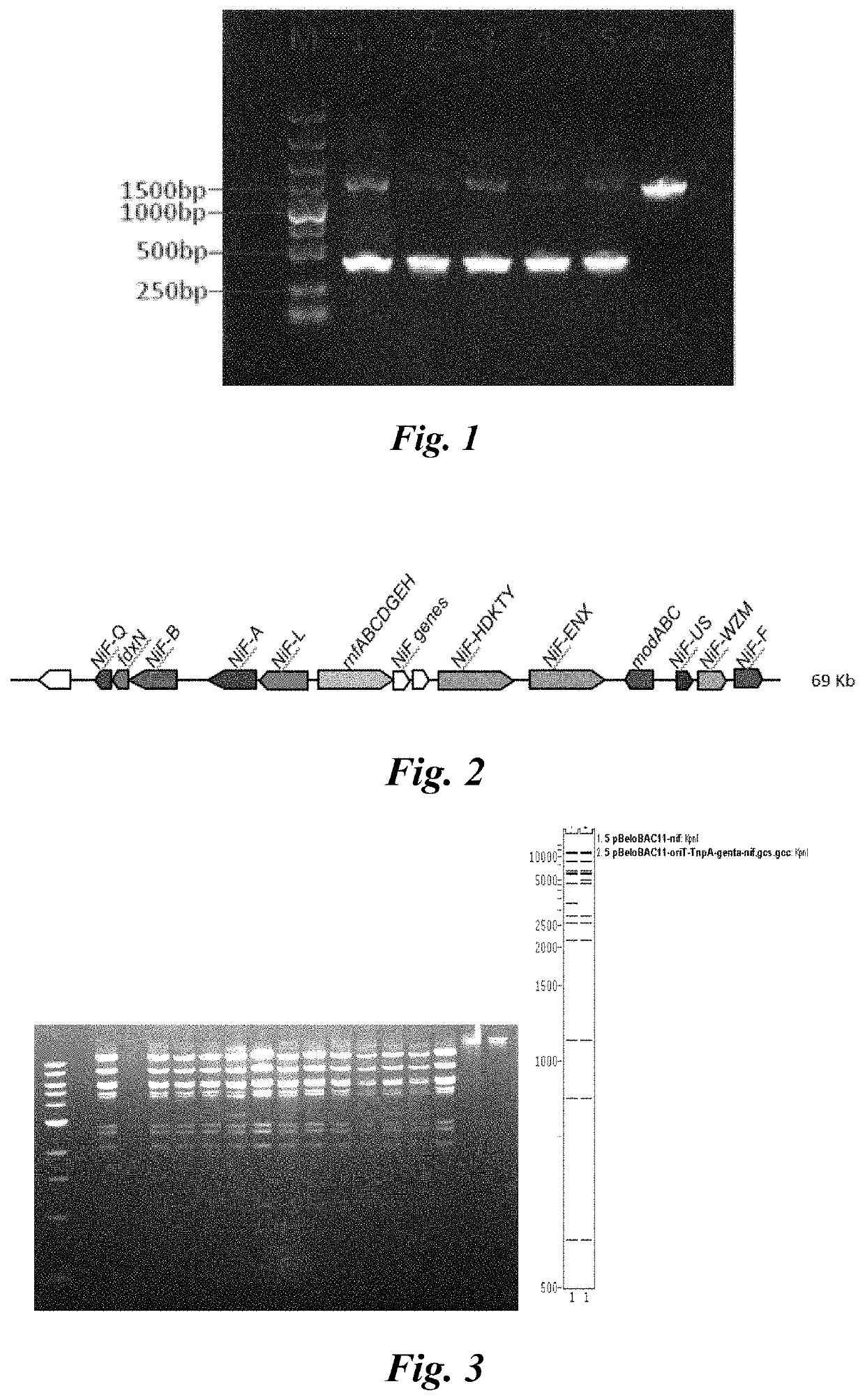

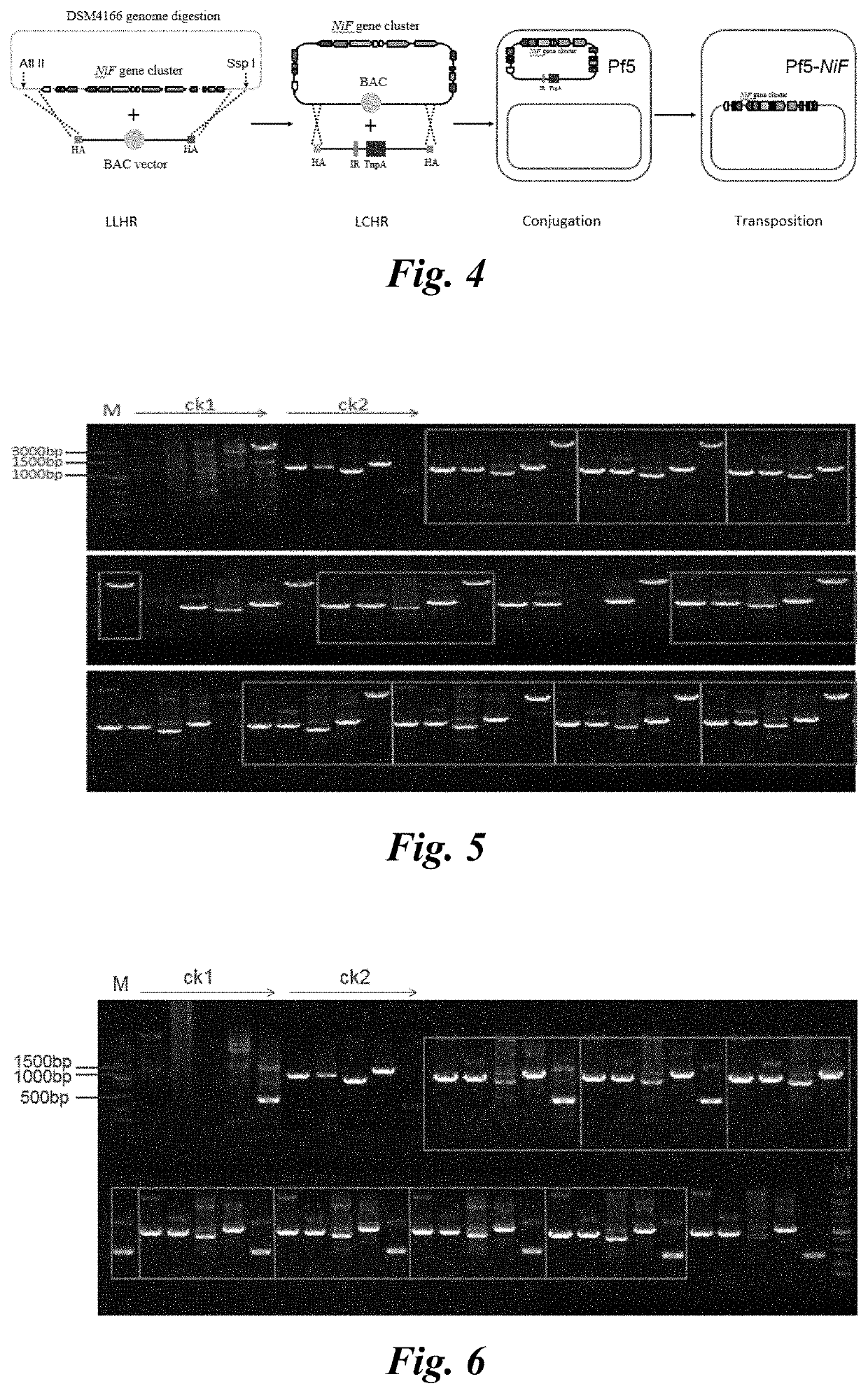

Screening method of pseudomonas protegens mutant strain and application thereof to biological control

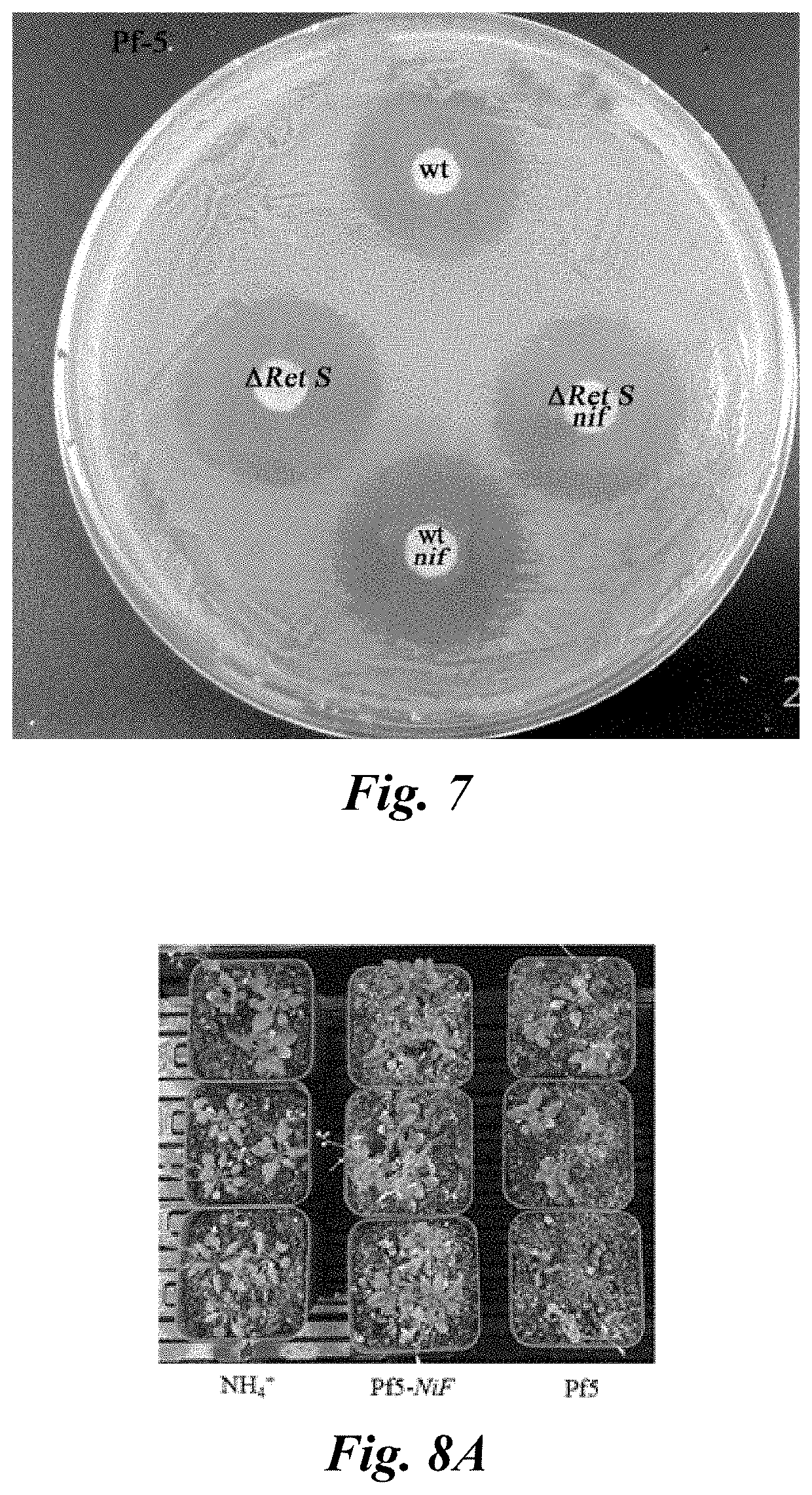

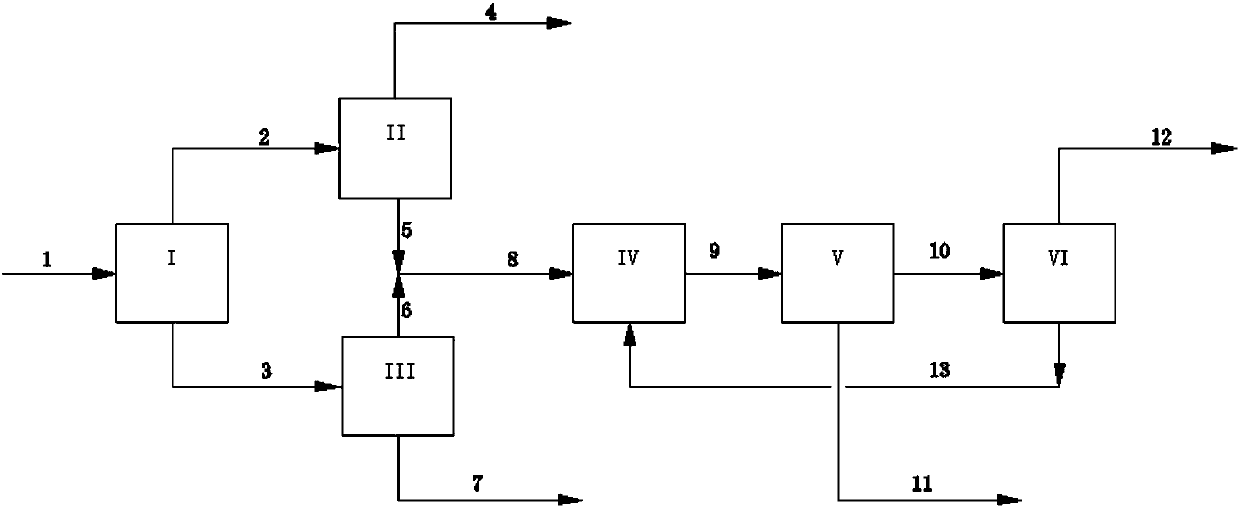

ActiveCN107119000AHigh bactericidal activityHigh expressionPlant growth regulatorsBiocideHeterologousGenetic engineering

The invention discloses a pseudomonas protegens mutant strain Pf5-NiF, Pf5-delatretS or Pf5-delatretS-NiF, a screening method and application thereof. By a Red / ET recombining and direct cloning technology, an NiF nitrogen fix gene island in a genome of pseudomonas stutzeri DSM4166 is integrally cloned into a genome of the pseudomonas protegens Pf5 to obtain a genetic engineering strain Pf5-NiF through smooth heterogeneous expression, so that the pseudomonas protegens Pf5 without a biological nitrogen fixing function itself generates the biological nitrogen fixing function; in addition, a retS gene in the genome of the pseudomonas protegens Pf5 is knocked out through directional unmarked gene knockout to obtain a genetic engineering strain Pf5-delatretS, so that the expression amount of antibiotic 2, 4-diacetyl phloroglucinol and haematochrome is increased, and thus the pseudomonas protegens Pf5 mutant strain with stronger bactericidal activity is obtained.

Owner:SHANDONG UNIV +1

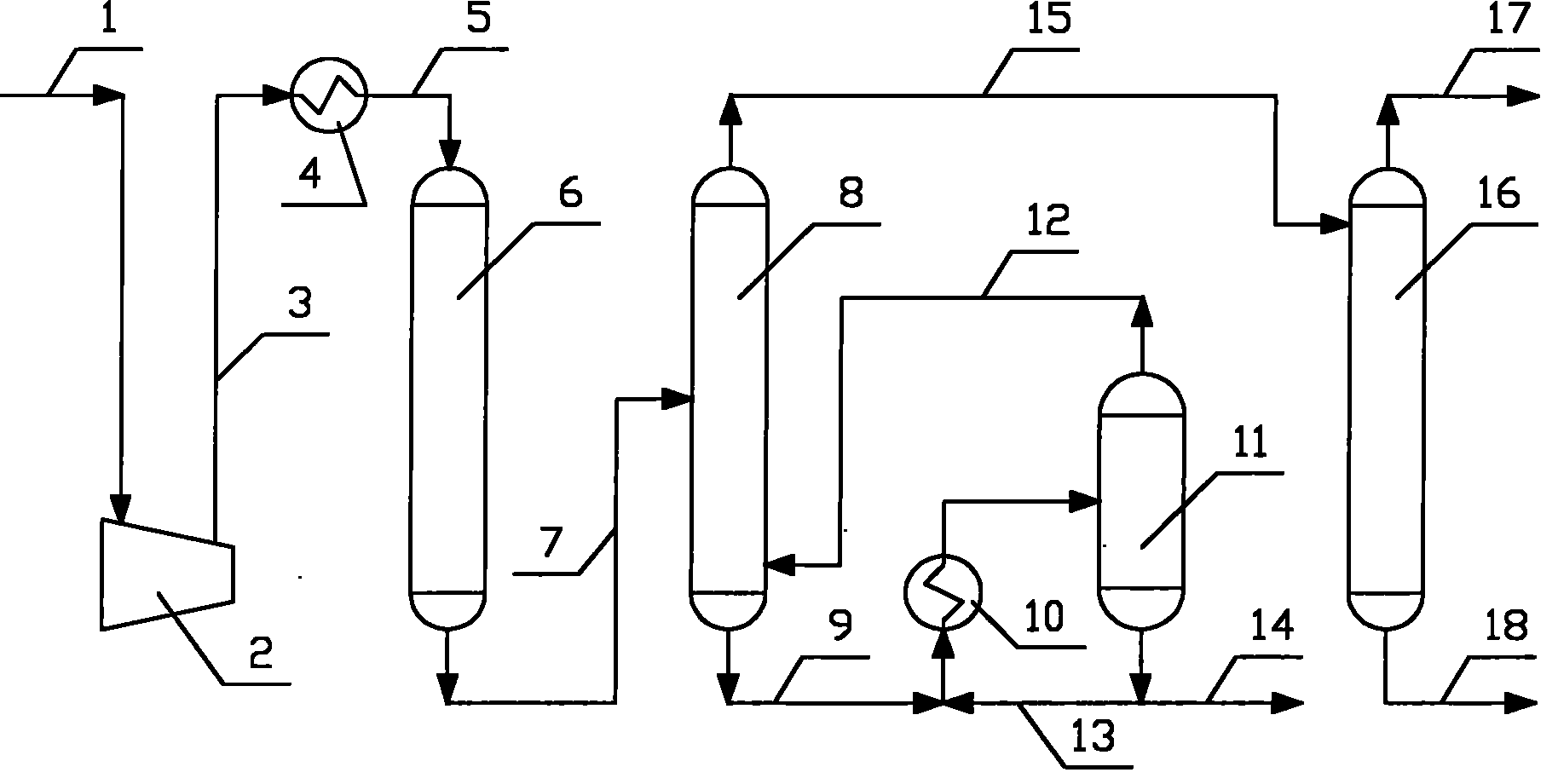

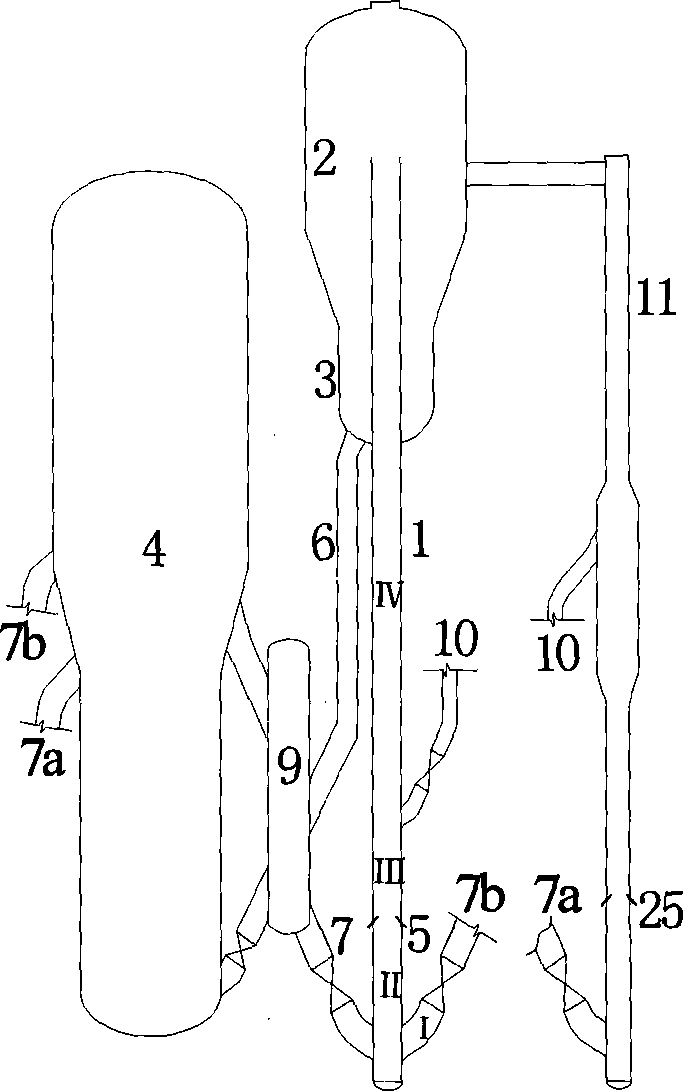

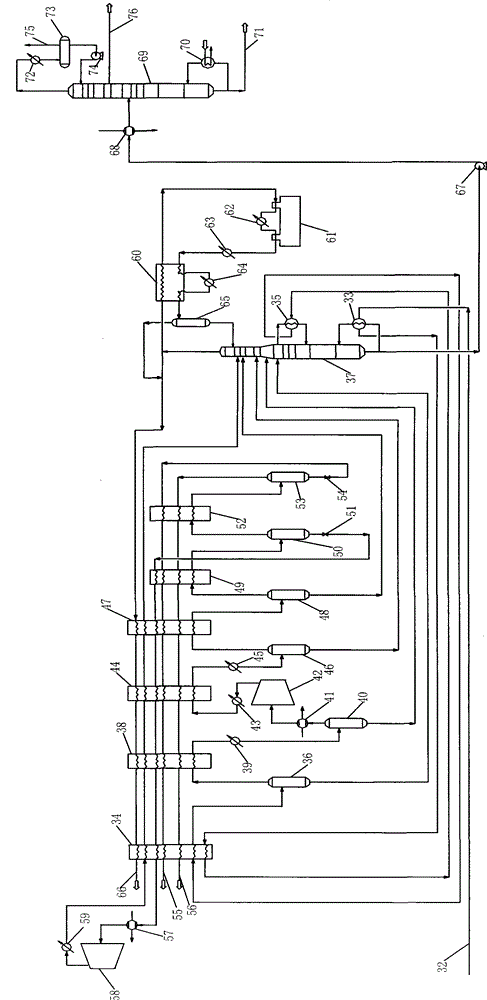

Production method of food grade liquid carbon dioxide product for recycling resurgent gases

ActiveCN102410704ALower ethylene contentIncrease productionSolidificationLiquefactionCarbon dioxide productionDistillation

The invention relates to a carbon dioxide production method, and particularly discloses a production method of a food grade liquid carbon dioxide product for recycling resurgent gases, which comprises the following steps of: (1) compression process, (2) dealkylation process, (3) purification process, (4) liquefaction process, and (5) distillation and purification process, wherein in the purification process, an impurity heating desorbing step is used for heating the adsorbent, so impurities which are adsorbed by the adsorbent are heated to be desorbed, the adsorbent obtains adequate resurgent gas flow, and a cooling adsorbent step is used for cooling the adsorbent, and the gas flows return to the carbon dioxide raw gas which contains the impurities. Because of the production method of the food grade liquid carbon dioxide product, the contents of methane and ethylene in a food grade liquid carbon dioxide product are greatly reduced, and are lower than the international standard, meanwhile, the resurgent gases of a purification tower are recycled, so the utilization ratio of the carbon dioxide raw gases which contain the impurities is greatly improved and is improved to 88% from 76%, the yield of the food grade liquid carbon dioxide is increased, the production cost is reduced, and the emission of the greenhouse gases is greatly reduced.

Owner:HUNAN KAIMEITE GASES

Method for reinforcing salt endurance of vegetable crop

InactiveCN101492647AReduced 1-aminocyclopropane 1-carboxylic acid contentLower ethylene contentBacteriaMicroorganism based processesBiotechnologyCarboxylic acid

The invention relates to a method for enhancing the salt endurance of vegetable crops and belongs to the technical field of edaphon. In the invention, a pseudomonad strain DW1 CGTCC No.2729 with high 1-amino-cyclopropane 1-carboxylic acid deaminase activity is first screened and obtained from coastal soils; further more, a method for enhancing the salt endurance of vegetable crops is proposed; the method comprises the steps as follows: the preparation of a DF culture medium; the activating culture of the strains; the fermentation culture of the strains; the screening of salt-resistant vegetable variety, and the construction of vegetable variety-microbic system. The method can remarkably improve the fresh weight of the vegetable crops under a salt concentration of 0.1 percent and 0.2 percent as well as the content of Caand k ions, reduce the content of proline and Na ion, simultaneously increase the antioxidase activity of seedlings, conduce to the plant growth under a salt stress condition and improve the productivity. The invention can be popularized and applied in improving and using seashore saline soil.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

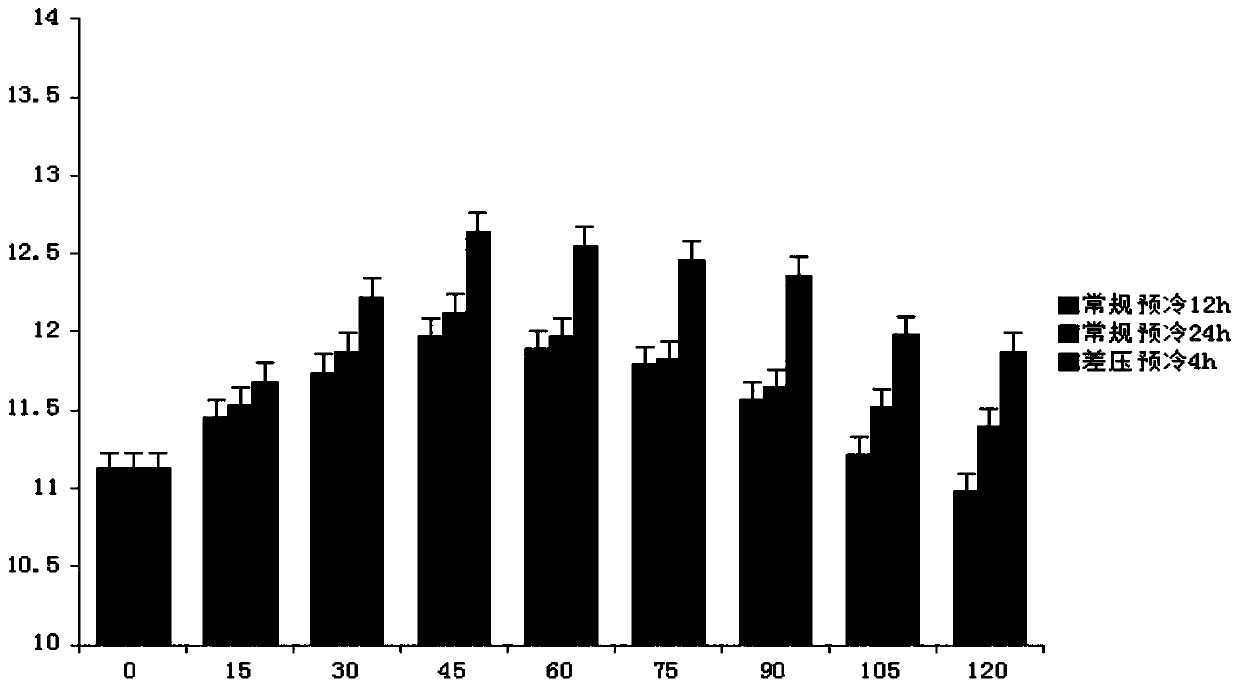

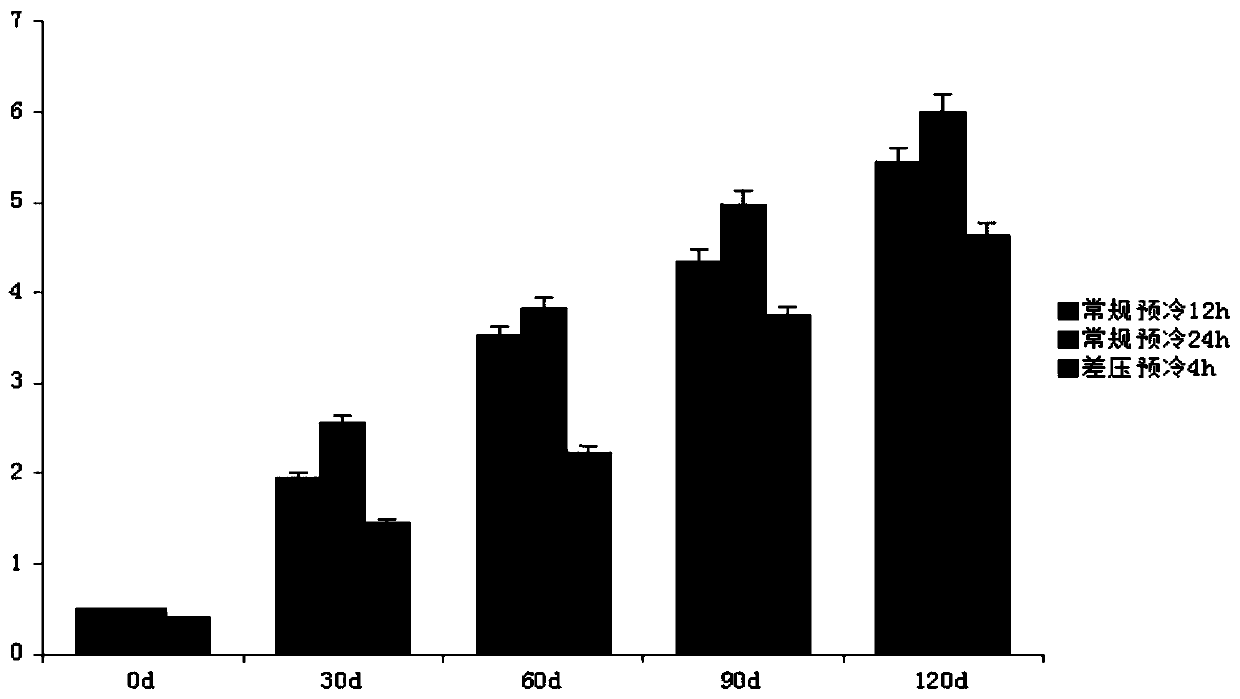

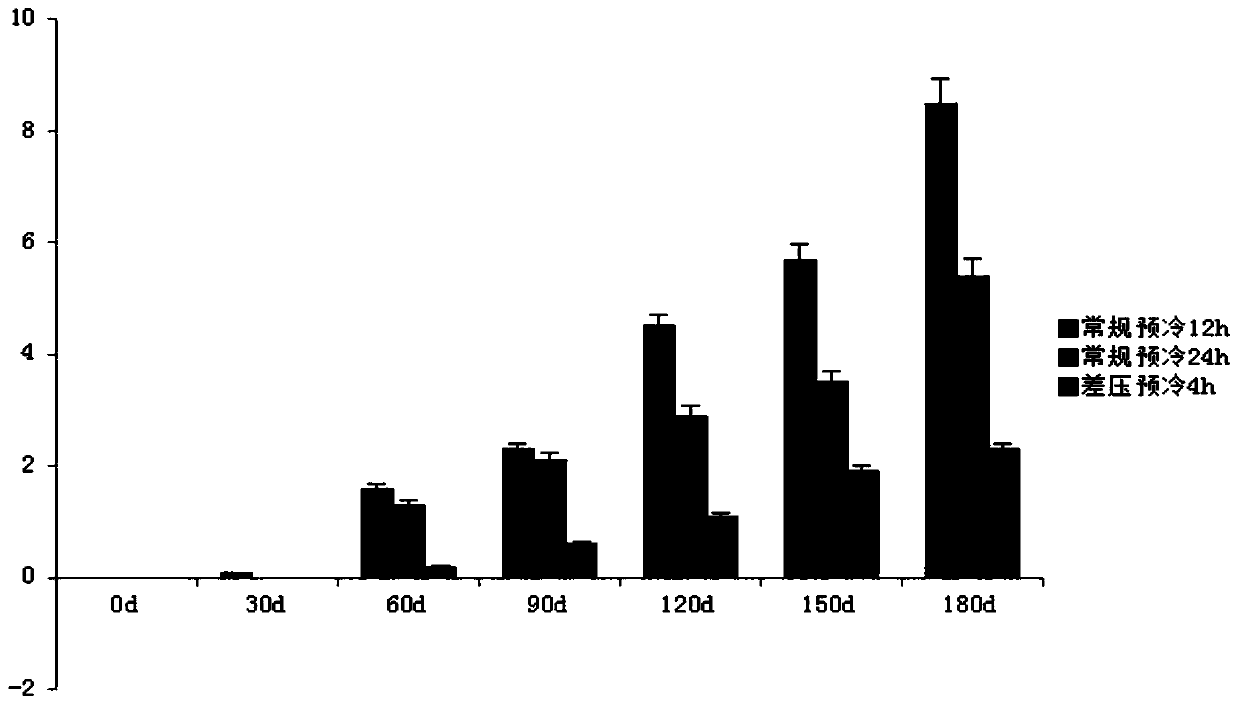

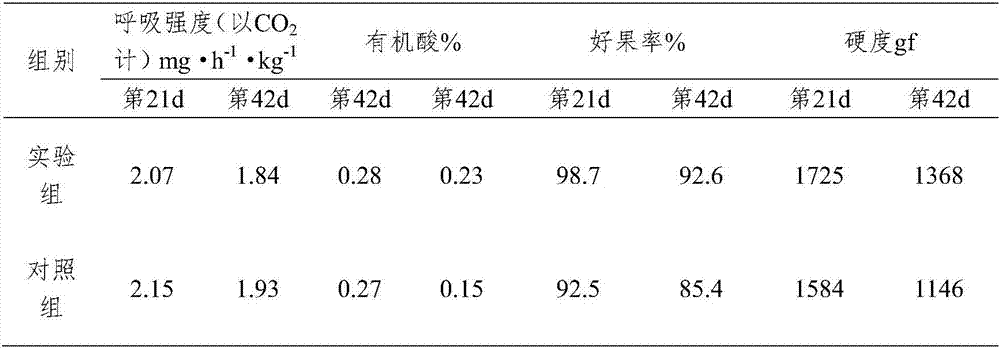

Near-freezing point spontaneous modified atmosphere preservation method for Zaojin crisp pears

The present invention provides a near-freezing point spontaneous modified atmosphere preservation method for Zaojin crisp pears and belongs to the technical field of fruit preservation and storage. The method comprises Zaojin crisp pear fruit harvesting, MAP packaging, pre-cooling, preservative treating, boxing and stacking, near-freezing point storing, etc. and is a complete set of a near-freezing point spontaneous modified atmosphere packaging method for the Zaojin crisp pears. Compared with a conventional cold storage method, the Zaojin crisp pear fruits meet technical requirements in storage and preservation temperature control indexes and at the same time, an O<2> and CO<2> ratio in packaging bags is kept within a suitable range, thereby maximizing inhibition of growth of microorganisms causing spoilage of the Zaojin crisp pears and reducing rot and browning. The method is used to store the Zaojin crisp pear fruits, storage time can be as long as 10 months, a fruit loss rate is less than 5%, and a good fruit rate is higher than 95%.

Owner:辽宁省果树科学研究所 +2

Fruit and vegetable preservative and preparation method and application thereof

InactiveCN108719456ALower ethylene contentDelayed respiratory transitionFruit and vegetables preservationChemistryHydrogen sulfide

The invention discloses a fruit and vegetable preservative. The fruit and vegetable preservative is an attapulgite@metal-organic frame composite material (ATP@MOF for short); and the metal-organic frame is hydroxylated Al2(OH)2(C8O6H4). The invention also discloses a preparation method and application of the fruit and vegetable preservative. The preservative disclosed by the invention can remove ethylene gas capable of inducing aging of fruits and vegetables and hydrogen sulfide gas released by mechanical injury wounds from storing and transporting environments, and also has bacteriostatic andinactivating effects.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation method of polypropylene

The invention relates to a preparation method of polypropylene. The method comprises the following steps: cooling first liquid-phase propylene, mixing the cooled first liquid-phase propylene with a polypropylene catalyst, and carrying out low-temperature prepolymerization reaction, feeding an obtained slurry containing the low-molecular-weight polypropylene prepolymer into a double-loop reactor, carrying out liquid-phase bulk slurry polymerization on the slurry and supplemented second liquid-phase propylene, hydrogen and ethylene monomers, and feeding part or all of polypropylene slurry flowing out of the first loop reactor into a second loop reactor, carrying out directflash evaporation on the polypropylene slurry flowing out of the second loop reactor to remove non-condensable gas and most of propylene monomers, and carrying out purification and granulationan obtained polypropylene intermediate to obtain the product; or carrying out copolymerization reaction on the polypropylene intermediate, and then carrying out powder purification and granulation to obtain the product. According to the preparation method disclosed by the invention, high-melt-index / high-rigidity and high-rubber-content impact-resistant co-polypropylene can be produced through flexible switching of devices, and meanwhile, high-isotacticity homo-polypropylene and random co-polypropylene can also be produced.

Owner:PETROCHINA CO LTD

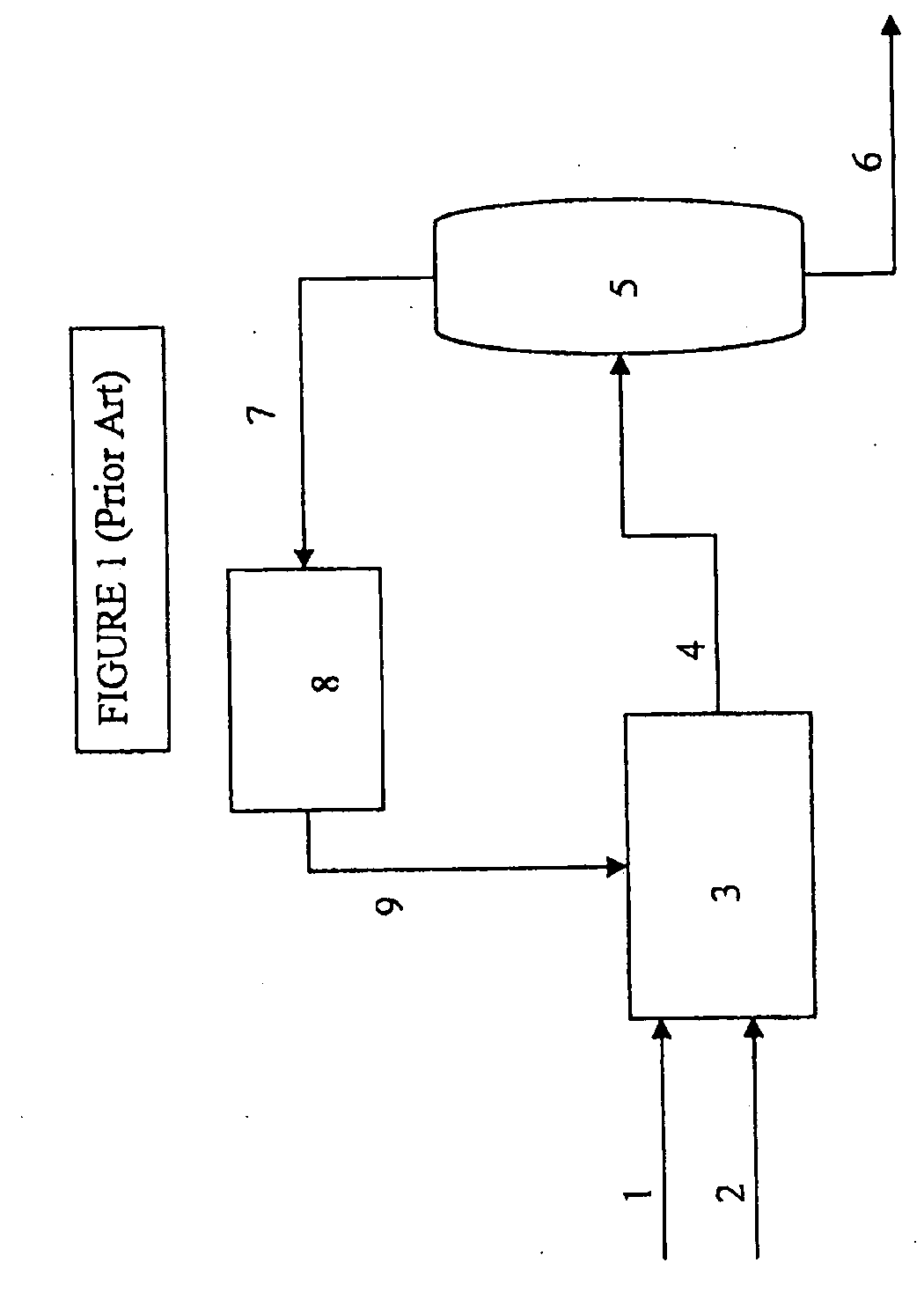

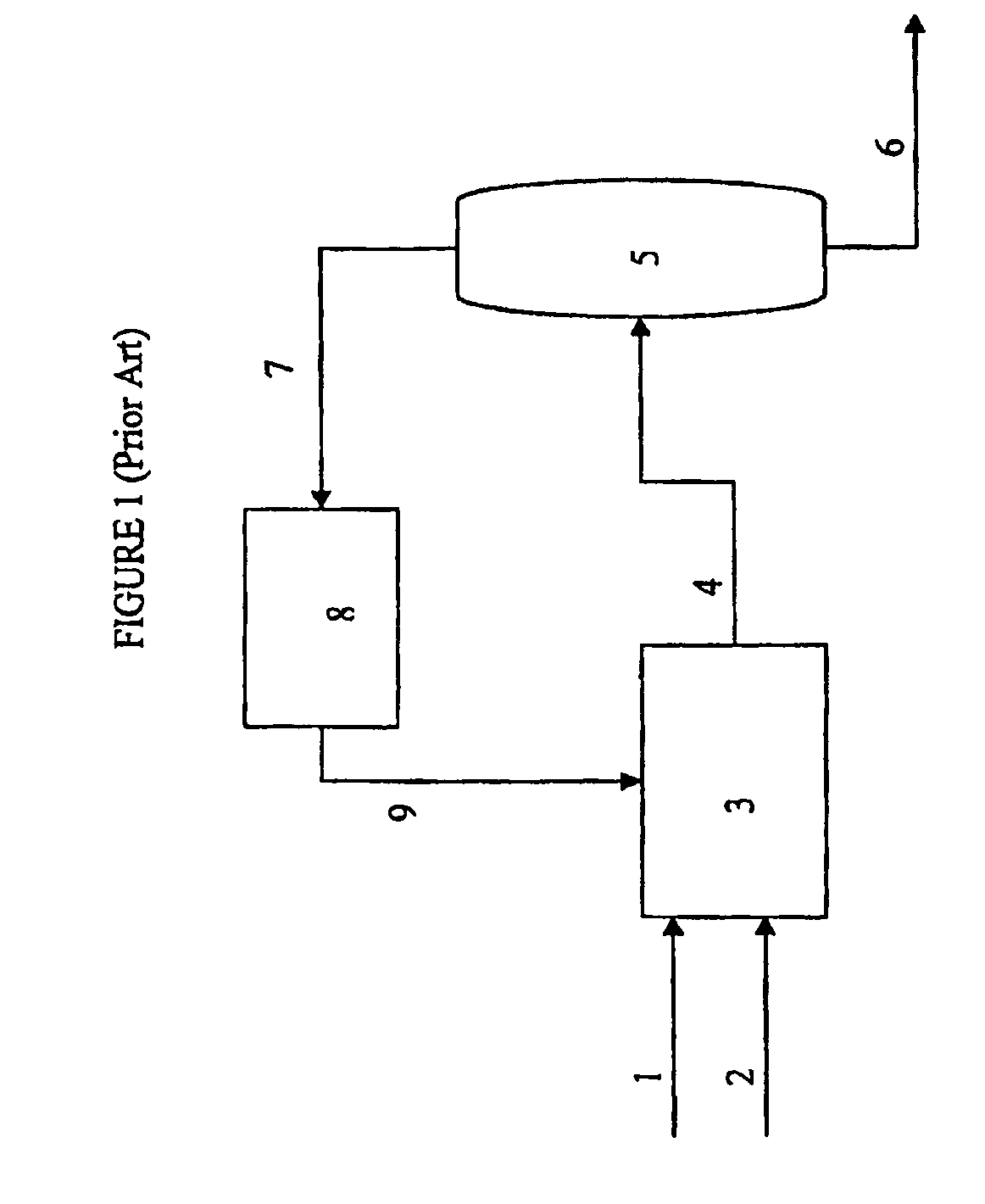

Use of Chemical Reaction to Separate Ethylene FromEthane in Ethane-Base Processes to Produce Acetic Acid

InactiveUS20110009667A1Lower ethylene contentOrganic compound preparationHeterogenous catalyst chemical elementsAcetic acidChemical reaction

Described herein is a process in which acetic acid is produced by ethane oxidation. One byproduct of the ethane oxidation is ethylene. High ethylene content in the recycle gas stream will lead to poor efficiencies and higher losses to the COx byproduct in the acetic acid reactor. In fact, ethylene in the recycle feed competes with the ethane for the limited amount of oxygen feed, resulting in higher inefficiencies to carbon oxides than straight ethane oxidation. Ethylene is removed in this process by a further oxidation reaction at a temperature low enough such that ethane is not reactive, but the ethylene is converted to acetic acid. Either the ethane oxidation reactor effluent or a portion or all of the recycle stream to the ethane oxidation reactor, or any combination of the same, can be processed in this manner to reduce the ethylene content of those streams.

Owner:CELANESE INT CORP

Method For Screening Pseudomonas Protegens Mutant Strain, And Application Thereof In Biological Control

InactiveUS20200120939A1High bactericidal activitySignificant biological nitrogen fixationBiocideMicroorganismsBiotechnologyHeterologous

Provided are Pseudomonas protegens mutant strain Pf5-NiF, Pf5-ΔretS, or Pf5-ΔretS-NiF, and a screening method therefor and an application thereof. By means of Red / ET recombination and direct cloning technologies, the NiF nitrogen fixation gene island in the genome of Pseudomonas stutzeri DSM4166, taken as a whole, is cloned into the genome of Pseudomonas protegens Pf5, so as to heterologously express the same successfully to obtain a genetically engineered strain Pf5-NiF, thereby bringing a biological nitrogen fixation function to Pseudomonas protegens Pf5 which does not own a biological nitrogen fixation function. In addition, gene-directed markerless knockout of retS gene in the genome of Pseudomonas protegens Pf5 is performed to obtain a genetically engineered strain Pf5-ΔretS. Thus, the expression levels of an antibiotic 2,4-diacetylphloroglucinol and red pigment are increased, and a mutant strain of Pseudomonas protegens Pf5 having a stronger bactericidal activity is obtained.

Owner:SHANDONG UNIV +1

Method for preparing aromatic hydrocarbon from mixed light hydrocarbon

ActiveCN108017493AReduce hydrogen contentGuaranteed selectivityHydrocarbon by hydrocarbon condensationHydrogenGas phase

The invention relates to a method for preparing an aromatic hydrocarbon from a mixed light hydrocarbon. In the prior art, the energy consumption for recycling ethylene in the mixed light hydrocarbon raw material is high. A purpose of the present invention is mainly to solve the problem in the prior art. The technical scheme of the present invention comprises that 1) a light hydrocarbon raw material is subjected to cooling separation to obtain hydrogen-rich gas and a hydrogen-depleted liquid; 2) the hydrogen-rich gas is separated by a dehydrogenation unit to obtain hydrogen and a dehydrogenation stream; 3) the hydrogen-depleted liquid is subjected to rectification separation to obtain a heavy removing stream and a first aromatic hydrocarbon stream; 4) the methane removing stream and the heavy removing stream are converged, and the converged stream is fed into a light hydrocarbon aromatization reactor, and is converted into an aromatization product; 5) the aromatization product is subjected to cooing separation to obtain a gas phase product and a second aromatic hydrocarbon stream; 6) the gas phase product is compressed, and the compressed product is fed into an ethane removing towerto obtain fuel gas and a circulation stream; and 7) the circulation stream returns the light hydrocarbon aromatization reactor. With the technical scheme, the problem in the prior art is well solved.The method of the present invention can be used in the industrial production of light hydrocarbon aromatization.

Owner:CHINA PETROLEUM & CHEM CORP +1

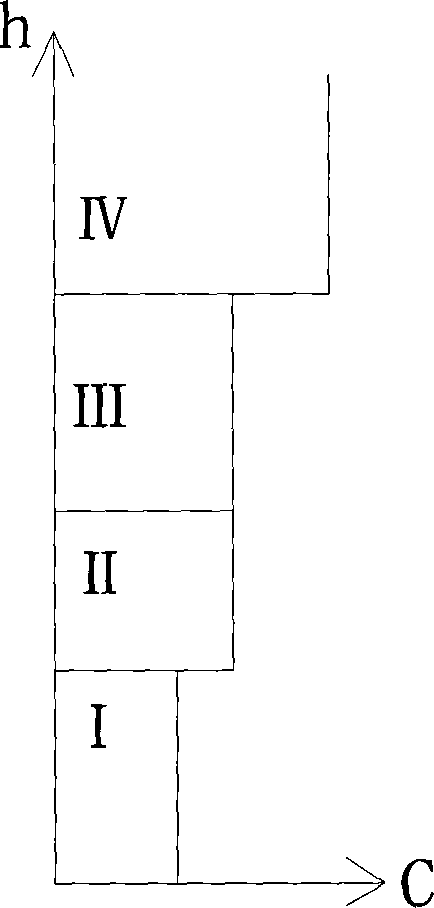

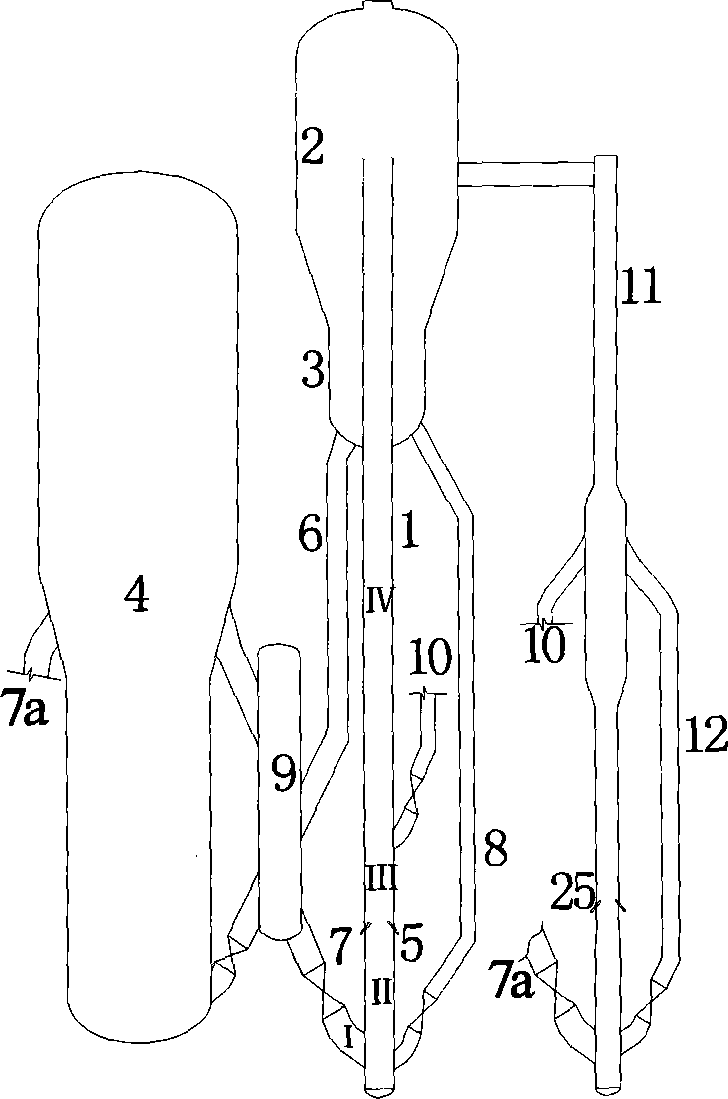

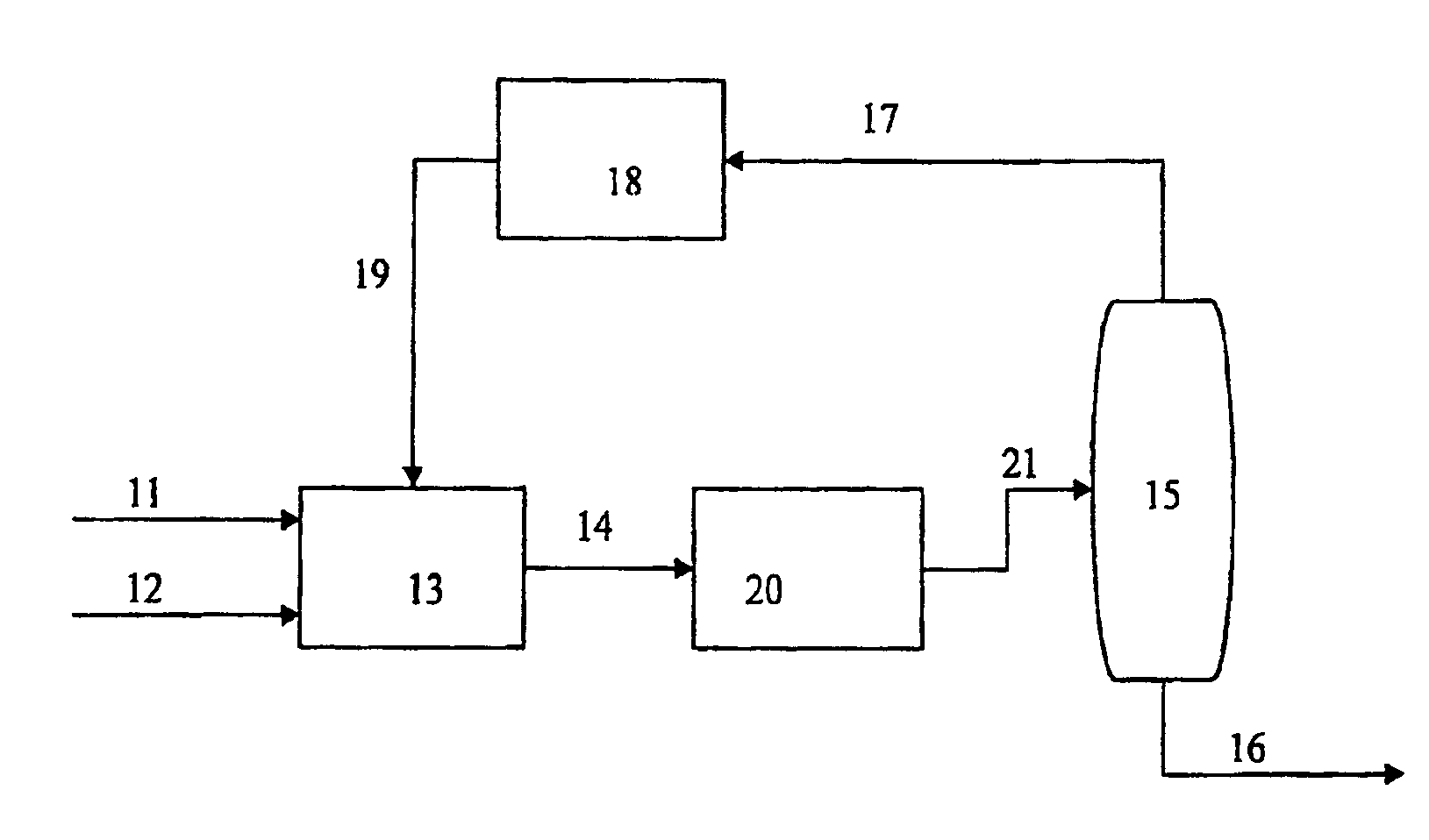

Dual-riser petroleum hydrocarbon feed stock catalytic conversion method and device

InactiveCN102051210BControl responseControlling the overall conversion reactionCatalytic crackingTreatment with plural parallel cracking stages onlyCracking reactionPetroleum

A catalytic conversion process of petroleum hydrocarbons in double reactor, and apparatus thereof are disclosed. The catalytic conversion process takes place in both the main reactor and the secondary reactor where reaction feedstock is lighter than the former. The first low temperature catalyst is introduced into the pre-lift section of the main reactor, and the said catalyst is conveyed to the oil / catalyst contact reaction section by the pre-lift gas and contacts with the feedstock from the feeding nozzle for the catalytic conversion reaction. The reaction mixture goes up and contacts with the second low temperature catalyst fed to the main reactor above the feeding nozzle, and the catalytic conversion reaction continues in the post-reaction section so as to complete the catalytic conversion reaction of the feedstock from the main reactor. Through flexible control over the reaction condition of the contact reaction section and post-reaction section of the reactor,thermal cracking reaction is effectively reduced, the reacting efficiency of the post-reaction section is improved. Accordingly, the reaction byproduct is effectively reduced and the product distribution is flexibly modified.

Owner:QINGDAO JINGRUN PETROCHEM DESIGN INST CO LTD

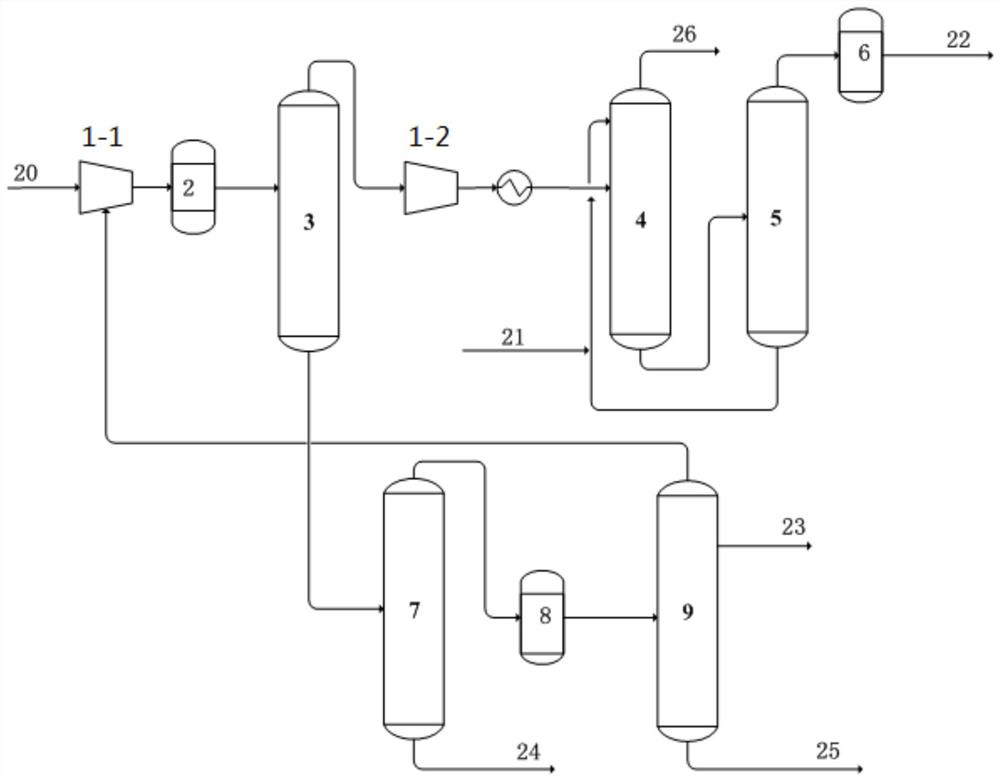

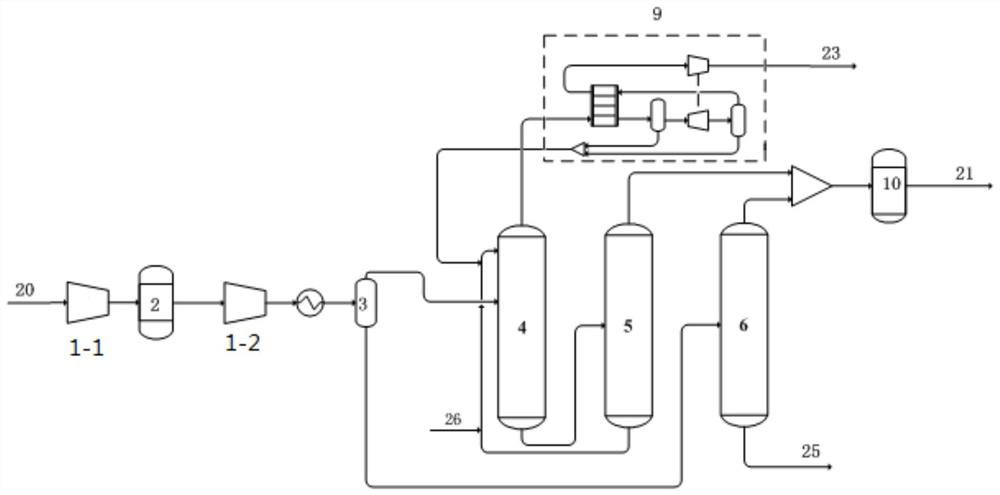

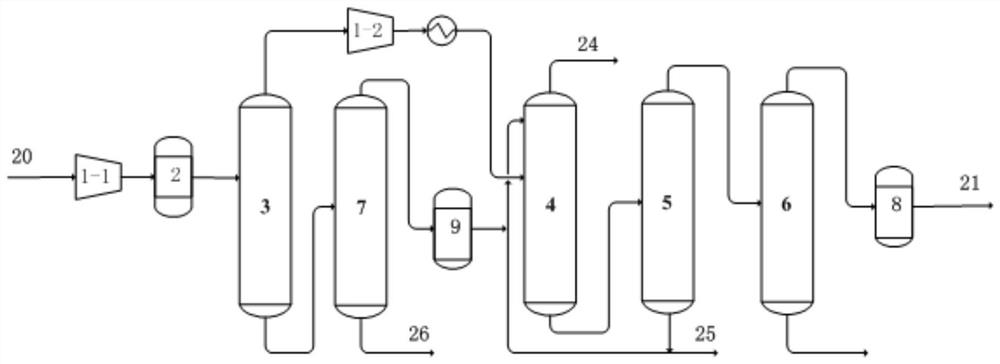

Pyrolysis gas separation system with purification function and utilization method

ActiveCN112707787AReduce energy consumptionLess investmentHydrocarbonsGaseous mixture working upTowerMechanical engineering

The invention discloses a pyrolysis gas separation system with a purification function and a separation method. The system comprises a compressor, a purification system, a heavy component removal tower, an absorption tower, a desorption tower and a C2 hydrogenation reactor, the purification system and the de-heavy tower are sequentially connected between the compressor sections, the top of the de-heavy tower is connected with the compressor rear section and then connected with the absorption tower, and the tower kettle of the absorption tower is connected with the desorption tower; the top of the desorption tower is connected with the C2 hydrogenation reactor and then connected with the outside, and the bottom of the desorption tower is connected with the upper part of the absorption tower. The system and the method have the characteristics of low investment, low energy consumption and remarkable benefit.

Owner:CHINA PETROLEUM & CHEM CORP +1

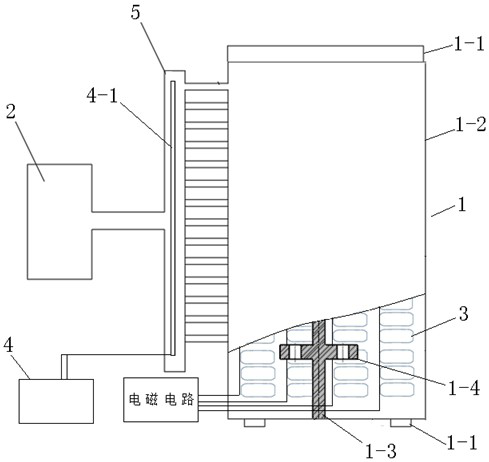

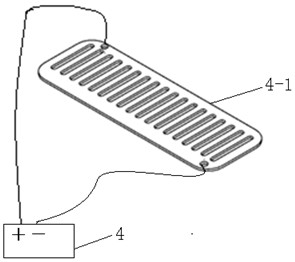

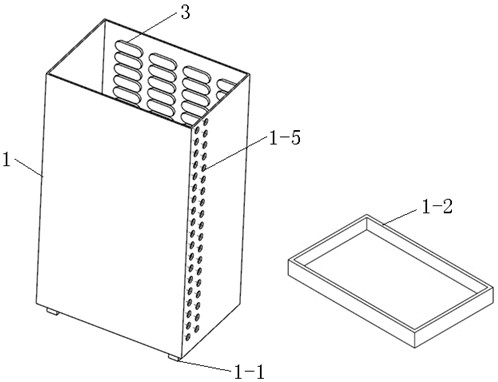

Rare flower fresh-keeping transport device and using method

PendingCN112520192AReduce plant water lossReduce material consumptionContainers preventing decayContainers to prevent mechanical damageChemistryEcology

The invention relates to a using method of a rare fresh flower fresh-keeping transport device. The using method comprises the following steps of opening an upper cover of a box body, and inserting fresh flowers on a plurality of discs of an upright post of a box body bracket; turning on a fan and a non-equilibrium plasma generator, generating a large number of positive and negative ions through the non-equilibrium plasma generator, sending plasma clusters into the space in the box body by the fan through a plurality of air pipes, so that the sterilization purpose is achieved, and the flowers are kept fresh; turning on an electromagnetic circuit to release an electrostatic field, while water molecules in plants form polar molecules; when an electrostatic field is applied to the plants, thedipole moment of the water molecules is increased until the associated molecular structure of the water is cracked to form single polar molecular structures, and the polar molecules are directionallyarranged in the electric field according to the sequence of positive and negative electrodes. The permeability of cell membranes in plants to the ions is changed, and a resting membrane potential disappears or decreases, or polarity reversion occurs; plant respiration is inhibited through an alternating electromagnetic field, and plant moisture loss is effectively reduced; and the biochemical reaction of the plants is blocked, and the metabolism is inhibited, so that the flowering phase is delayed.

Owner:天津市星拓科技发展有限公司

Fruit and vegetable modified atmosphere packaging film

InactiveCN103819790AImprove mechanical propertiesImprove breathabilityFlexible coversFruit and vegetables preservationModified atmosphereMethyl group

The invention discloses a fruit and vegetable modified atmosphere packaging film. The film consists of the following components in parts by weight: 100 parts of polyethylene resin, 20-24 parts of poly-4-methyl-1-amylene, 30-34 parts of polyvinyl acetate, 4-6 parts of zinc stearate, 3-5 parts of calcium stearate, 5-7 parts of heavy calcium carbonate, 4-6 parts of diatomite powder, 3-5 parts of activated carbon powder, 6-8 parts of isopropyl dimethacrylate, 1.5-2.5 parts of 3,5-di-tert-butyl-4-hydroxy phenylpropionic octadecyl ester and 2-4 parts of liquid paraffin.

Owner:WUXI HUANGSHENG PACKING PROD

Method for producing aromatics by mixing light hydrocarbons

ActiveCN108017493BReduce hydrogen contentGuaranteed selectivityHydrocarbon by hydrocarbon condensationDehydrogenationPhysical chemistry

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing aromatic hydrocarbon from mixed light hydrocarbon

ActiveCN108017494AReduce contentReduce methane contentLiquid hydrocarbon mixtures productionHydrocarbon by hydrocarbon condensationHydrogenGas phase

The invention relates to a method for preparing an aromatic hydrocarbon from a mixed light hydrocarbon. In the prior art, the energy consumption for recycling ethylene in the mixed light hydrocarbon raw material is high. A purpose of the present invention is mainly to solve the problem in the prior art. The technical scheme of the present invention comprises that 1) a light hydrocarbon raw material is subjected to cooling separation to obtain hydrogen-rich gas and a hydrogen-depleted liquid; 2) the hydrogen-rich gas is separated by a methane removing unit to obtain methane-hydrogen mixing gasand a methane removing stream; 3) the hydrogen-depleted liquid is subjected to rectification separation to obtain a heavy removing stream and a first aromatic hydrocarbon stream; 4) the methane removing stream and the heavy removing stream are converged, and the converged stream is fed into a light hydrocarbon aromatization reactor, and is converted into an aromatization product; 5) the aromatization product is subjected to cooing separation to obtain a gas phase product and a second aromatic hydrocarbon stream; 6) the gas phase product is compressed, and the compressed product is fed into anethane removing tower to obtain ethane gas and a circulation stream; and 7) the circulation stream returns the light hydrocarbon aromatization reactor. With the technical scheme, the problem in the prior art is well solved. The method of the present invention can be used in the industrial production of light hydrocarbon aromatization.

Owner:CHINA PETROLEUM & CHEM CORP +1

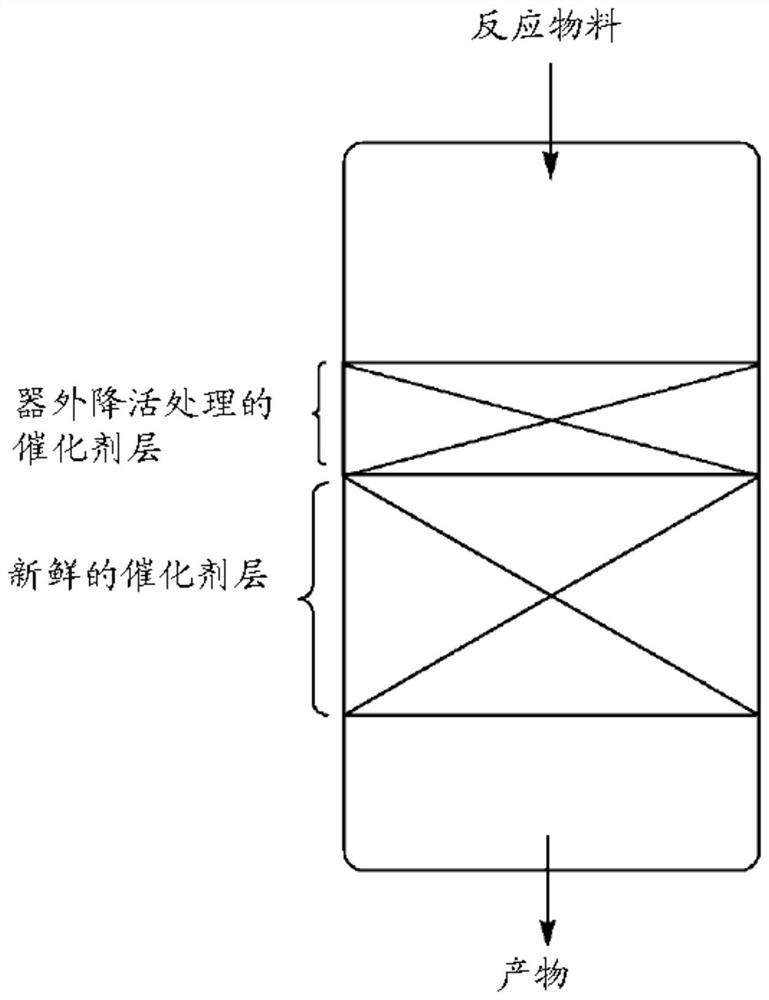

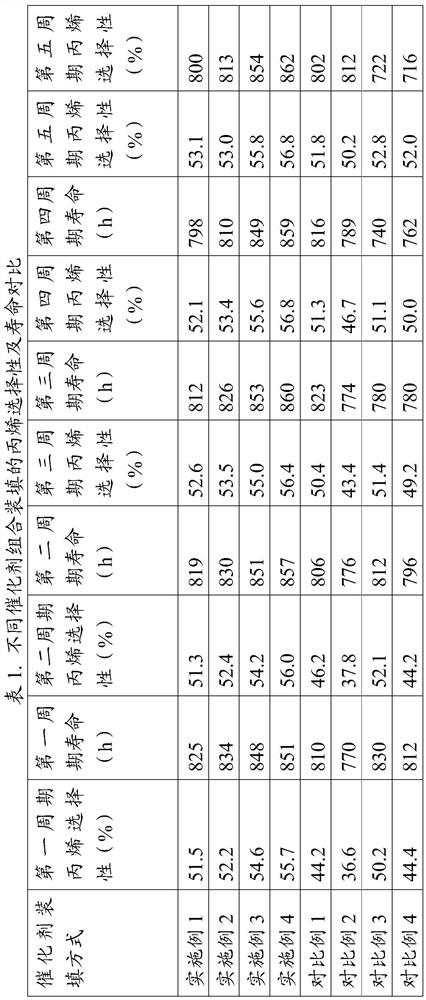

Catalytic reactor for preparing propylene from methanol and method for preparing propylene from methanol

ActiveCN112090375AReduced activityReduce alkanesHydrocarbon from oxygen organic compoundsChemical/physical processesPtru catalystMaterials science

The invention provides a catalytic reactor for preparing propylene from methanol, which comprises a catalyst bed layer, and the catalyst bed layer comprises an out-of-vessel deactivated catalyst layerand a fresh catalyst layer, the out-of-vessel deactivated catalyst layer and fresh catalyst layer are provided such that the reaction feedstock first contacts the out-of-vessel deactivated catalyst and then contacts the fresh catalyst. The invention also provides a method for preparing propylene from methanol. The method comprises a step of using the catalytic reactor for preparing propylene frommethanol. Through the catalytic reactor and the method for preparing propylene from methanol, the unit consumption of per ton of propylene and methanol in the whole life cycle of the catalyst can beeffectively reduced.

Owner:DATANG INT CHEM TECH RESINST

Plum fresh-keeping agent, and preparation method and applications thereof

InactiveCN107094871ALower ethylene contentInhibition of cellular respirationFruit and vegetables preservationChemistryPentaerythritol

The invention belongs to the technical field of fresh-keeping, and especially discloses a plum fresh-keeping agent, and a preparation method and applications thereof. The fresh-keeping agent is prepared from radix salviae miltiorrhizae extract, cinnamaldehyde, sodium dichloro isoyanurate, vitamin E9, honey, tetra pentaerythritol ester, microcrystalline cellulose, stearic acid, and purified water via reasonable combination. The plum fresh-keeping agent is prepared via the preparation method, fresh keeping is realized via reasonable immersion. The plum fresh-keeping agent is capable of reducing the content of ethene effectively, inhibiting cell respiration intensity, delaying reducing of acid content, prolonging self life, and realizing fresh keeping.

Owner:普定县亿源芳种养殖专业合作社

Technology for separating low carbon olefin gases

The invention discloses a technology for separating low carbon olefin gases, for solving the problems that hydrogen, methane, ethane and propane and other products with high purity can not be acquired and dimethyl ether and oxygen and carbon monoxide in impurities are not removed efficiently, etc. in the prior art. The technology is characterized in that a step of removing carbon monoxide and oxygen is added, methanol-to-olefin gas streams processed by removing carbon monoxide and oxygen enter into a deethanizing column, deethanizing column overhead streams successively pass through an ethene hydrogenation reactor, six separation pots, a low pressure demethanizing column and an ethene rectification column, etc. to separate to obtain ethene and ethane products, and deethanizing column bottom streams successively pass through a propyne hydrogenation reactor, a methane stripper and a propylene rectification column, etc. to separate to obtain propylene and propane products. According to the invention, polymer grade ethene and propylene products can be obtained, and hydrogen, methane, ethane and propane products, etc. with high purity can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

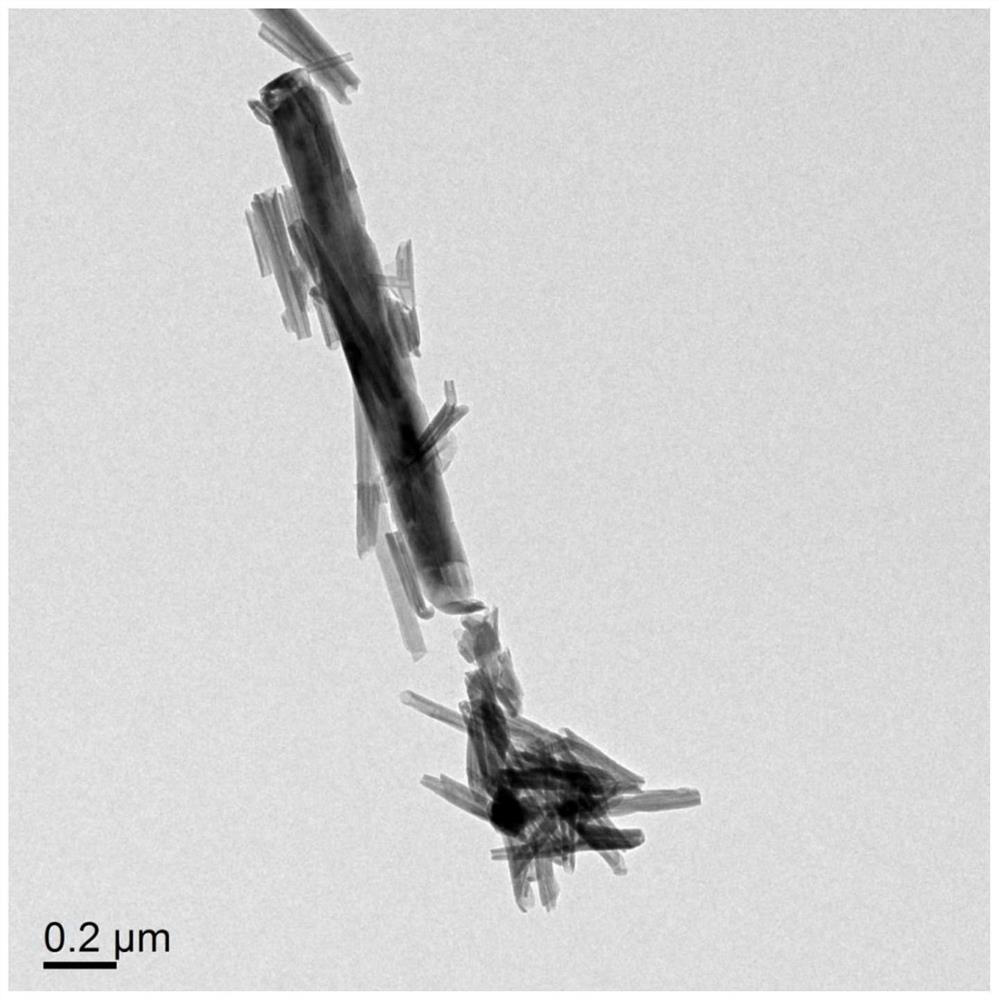

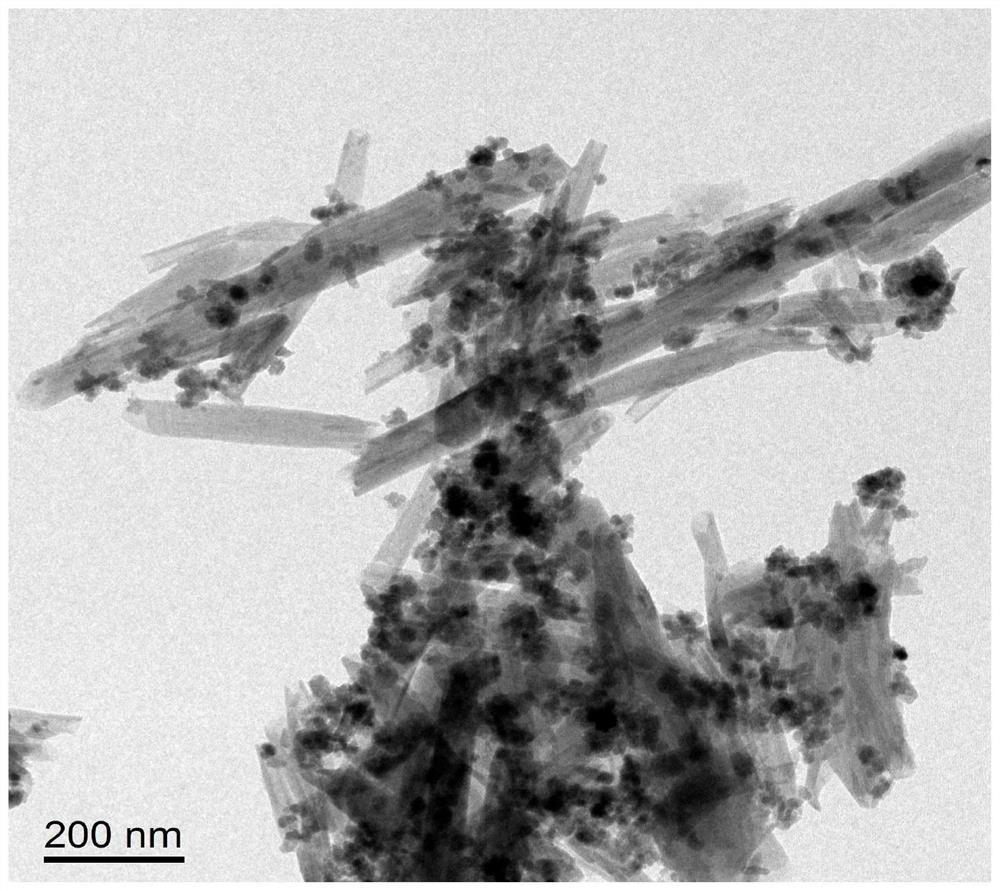

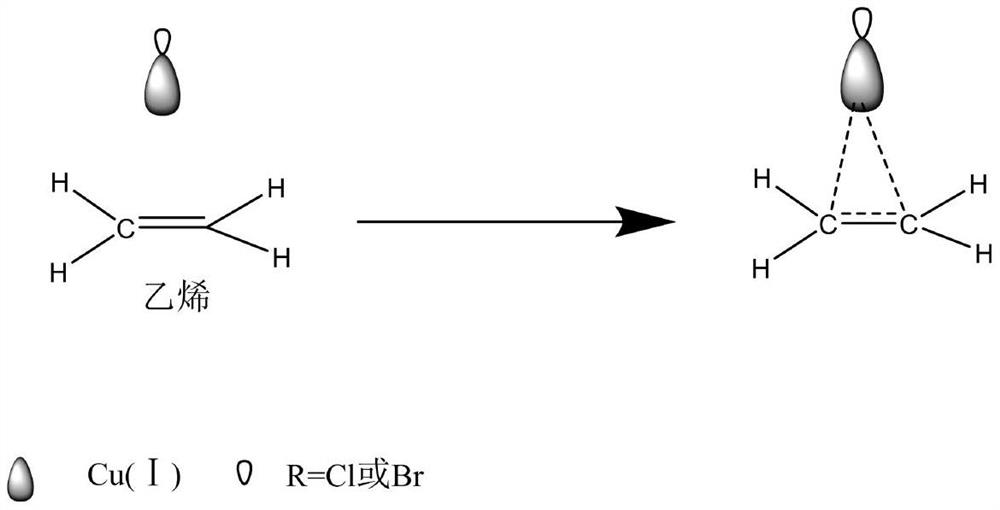

Fresh-keeping material capable of efficiently removing ethylene and preparation method of fresh-keeping material

PendingCN114190430AHigh adsorption capacityEvenly dispersedDead plant preservationFruit and vegetables preservationMolecular sieveActivated carbon

The invention discloses a fresh-keeping material capable of efficiently removing ethylene, and belongs to the technical field of fresh keeping of fruits and vegetables. A transition metal Cu (I) compound is used as an ethylene fixing agent, and the ethylene fixing agent is loaded on an acidized porous carrier material to form the fresh-keeping material capable of efficiently removing ethylene. The porous carrier material is one of a halloysite nanotube, a carbon nanotube, activated carbon, montmorillonite, attapulgite, diatomite and a molecular sieve. According to the invention, the fixing agent is adsorbed on the porous carrier material, so that the fixing agent adsorbed on the porous carrier material reacts with ethylene through a sigma-pi bond to form a complex, and the porous carrier material with a relatively large specific surface area not only can improve the adsorption capacity to ethylene, but also can load the fixing agent to a great extent; the preparation method of the fresh-keeping material provided by the invention is simple, easy to operate and outstanding in effect, ethylene released by the fruits and vegetables can be effectively removed, and the freshness and shelf life of the fruits and vegetables are prolonged.

Owner:SOUTH SUBTROPICAL CROPS RES INST CHINESE ACAD OF TROPICAL AGRI SCI

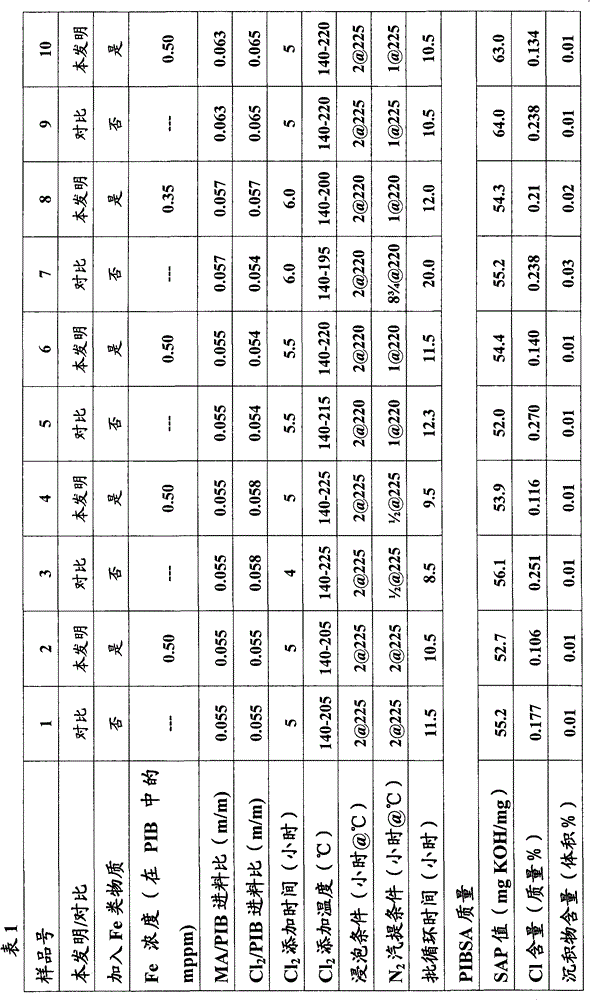

Method of forming polyalkene substituted carboxylic acid compositions

This invention relates to methods of forming polyalkene-substituted carboxylic acid compositions. When the reaction is carried out in the presence of a controlled amount of a metal compound, the formation of polyolefin-substituted carboxylic acids by the halogen-assisted reaction of polyolefins with at least one ethylenically monounsaturated monocarboxylic or dicarboxylic acid, anhydride or ester is reduced. Residual chlorine content of acid acylating agents.

Owner:INFINEUM INT LTD

Use of chemical reaction to separate ethylene from ethane in ethane-based processes to produce acetic acid

InactiveUS8383854B2Lower ethylene contentOrganic compound preparationHeterogenous catalyst chemical elementsAcetic acidChemical reaction

Owner:CELANESE INT CORP

Solid antistaling agent for storing winter Chinese jujube

InactiveCN1237886CInhibition of physical activityLower ethylene contentFruit and vegetables preservationCalcium silicateActivated carbon

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

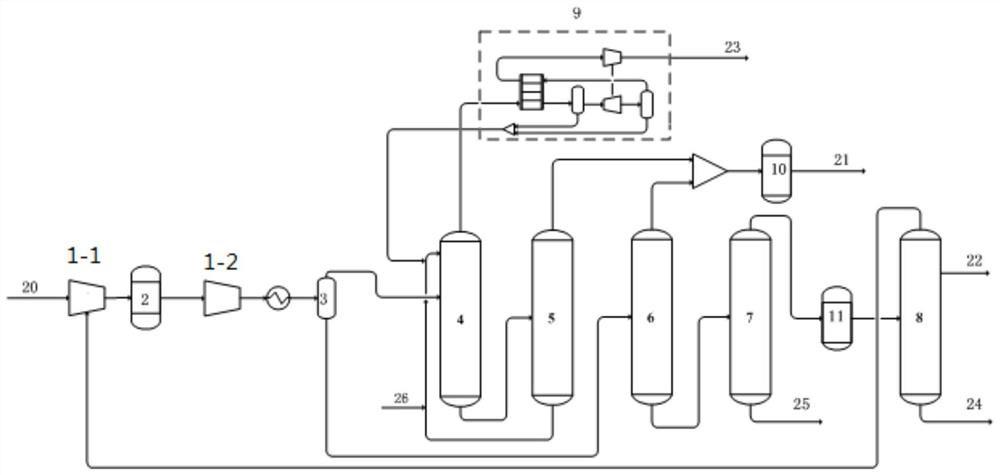

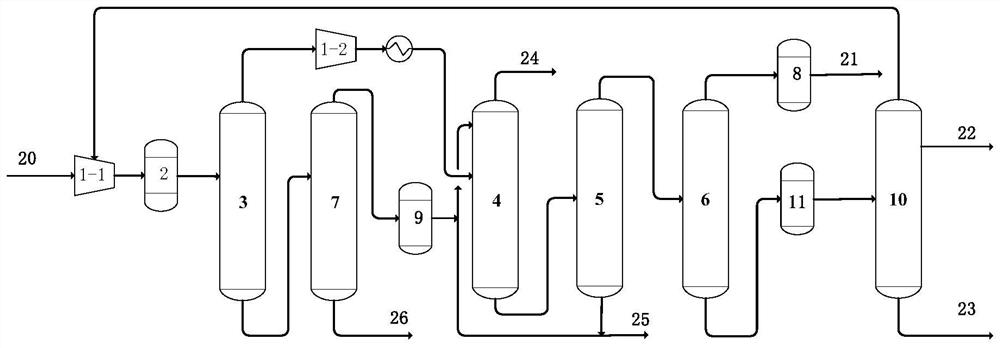

Pyrolysis gas separation system with cooling capacity recovery function and separation method thereof

ActiveCN112707785AReduce energy consumptionLess investmentHydrocarbon by hydrogenationChemical industryFluid phaseEngineering

The invention discloses a pyrolysis gas separation system with a cooling capacity recovery function and a separation method thereof. The separation system comprises a compressor, a purification system, a cooler, a gas-liquid separation tank, an absorption tower, a desorption tower, a heavy component removal tower, a cold energy recovery system and a C2 hydrogenation reactor, the compressor sections are connected with the purification system and then connected with a compressor rear section; a rear-section outlet of the compressor is connected with the cooler and then connected with the gas-liquid separation tank, a gas-phase outlet of the separation tank is connected with the absorption tower, and a liquid-phase outlet of the separation tank is connected with the de-heavy tower; the top of the absorption tower is connected with a cooling capacity recovery system; the bottom of the absorption tower is connected with the desorption tower; crude ethylene gas is extracted from the top of the desorption tower; the desorption tower kettle is connected with the upper part of the absorption tower; and a heavy component removal tower top pipeline is combined with a desorption tower top pipeline and then is connected with the C2 hydrogenation reactor. The system and the method have the characteristics of low investment, low energy consumption and remarkable benefit.

Owner:CHINA PETROLEUM & CHEM CORP +1

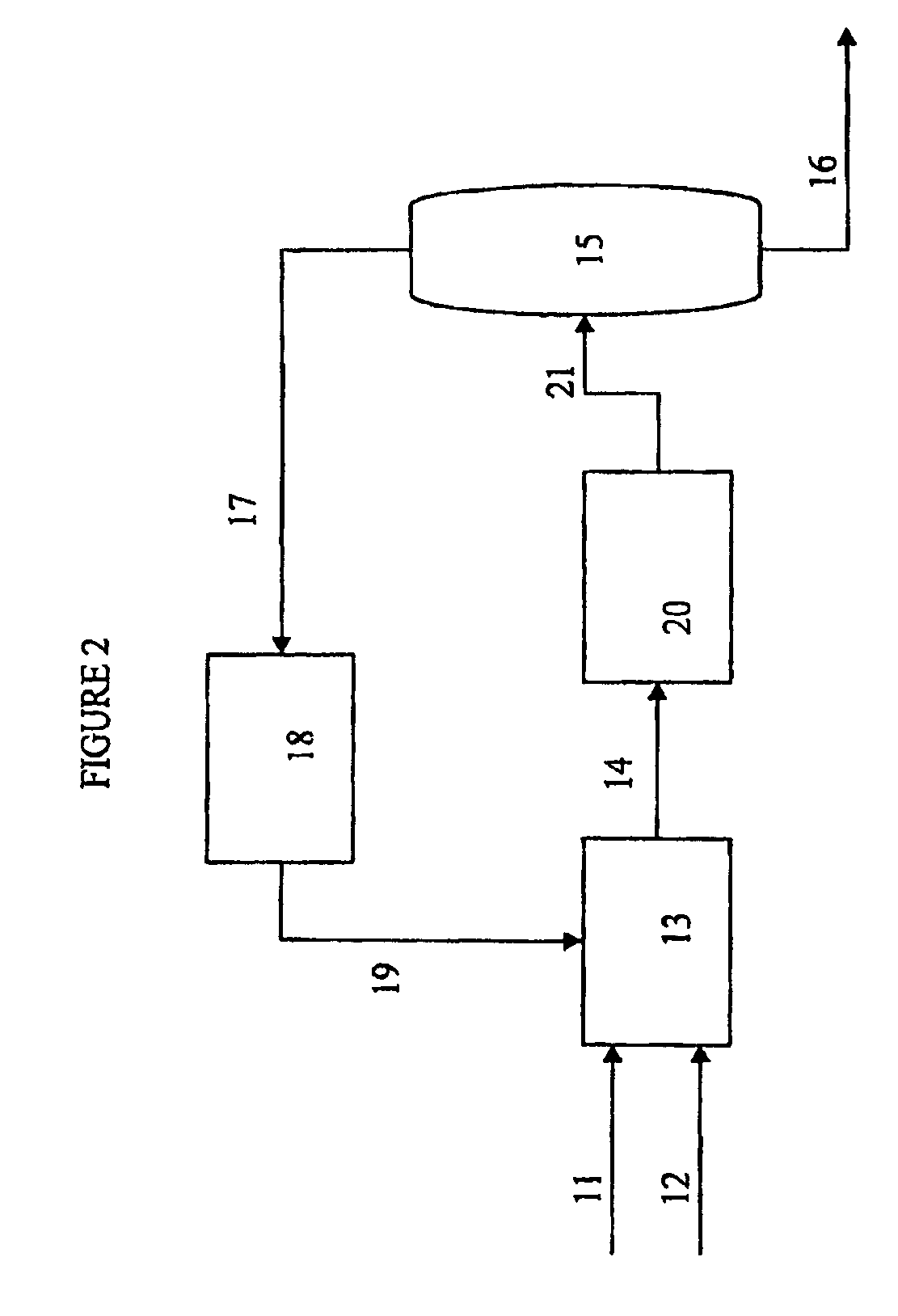

Method for improving ethylene yield in ethanol dehydration to ethylene process

ActiveCN103739426BHigh ethylene contentLower ethylene contentDistillation purification/separationDistillationTower

The invention relates to a method for increasing the ethylene yield in a process of preparing ethylene through ethanol dehydration, and mainly solves a problem, which is not involved in documents in the past, of increasing the ethylene yield in the process of preparing ethylene through ethanol dehydration, especially a problem of ethylene rectification tower bottoms treatment or great ethylene loss. According to the technical scheme of the method, the tower bottom of an ethylene rectification tower is fed to the top of a heavy-component stripping distillation tower, the tower top vapour phase of the heavy-component stripping distillation tower is fed back to the middle and lower part of the ethylene rectification tower, and the heavy components are discharged from the bottom of the heavy-component stripping distillation tower. By the technical scheme, the problem is solved well and the method can be used in industrial production of the ethylene through ethanol dehydration.

Owner:CHINA PETROLEUM & CHEM CORP +1

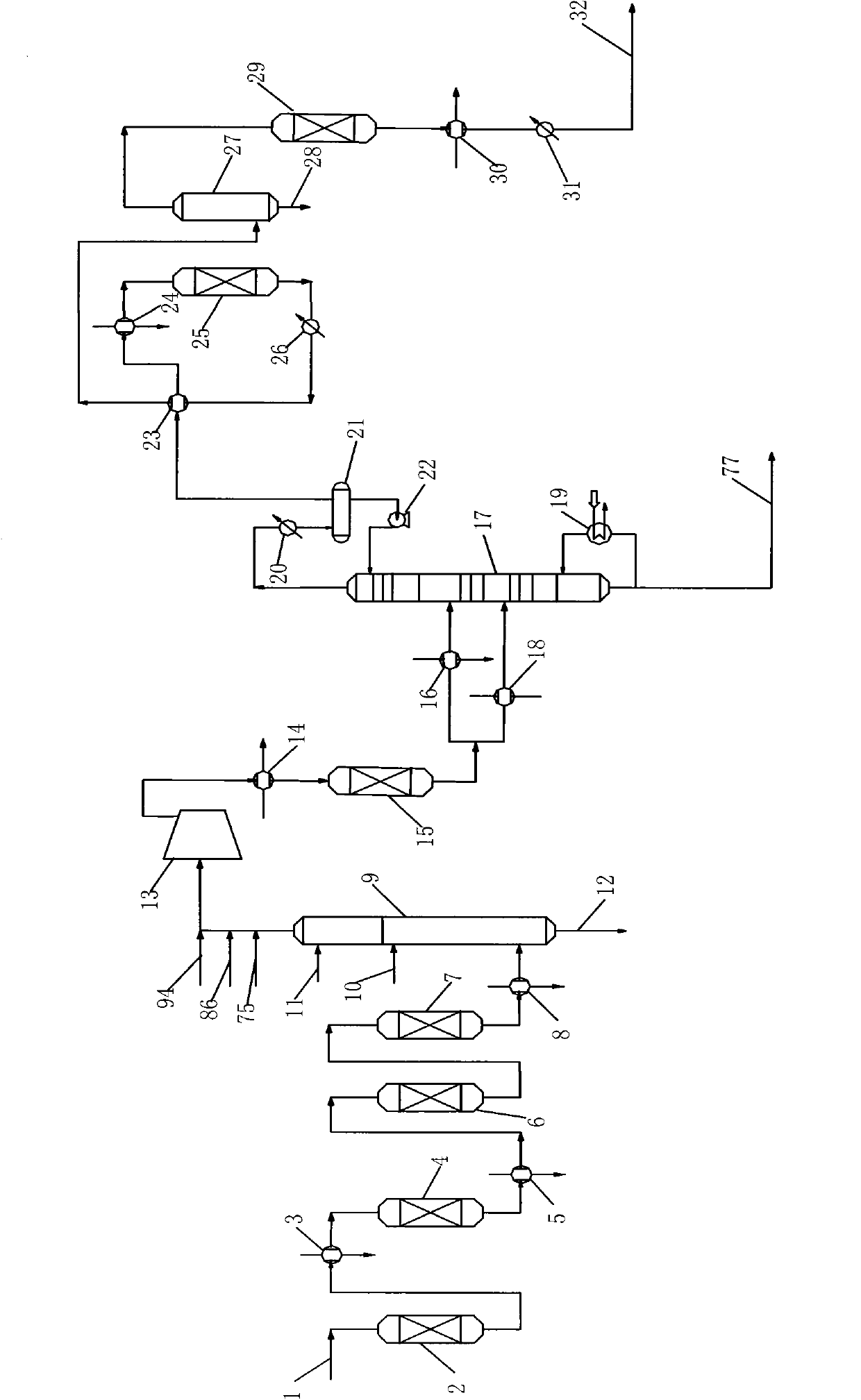

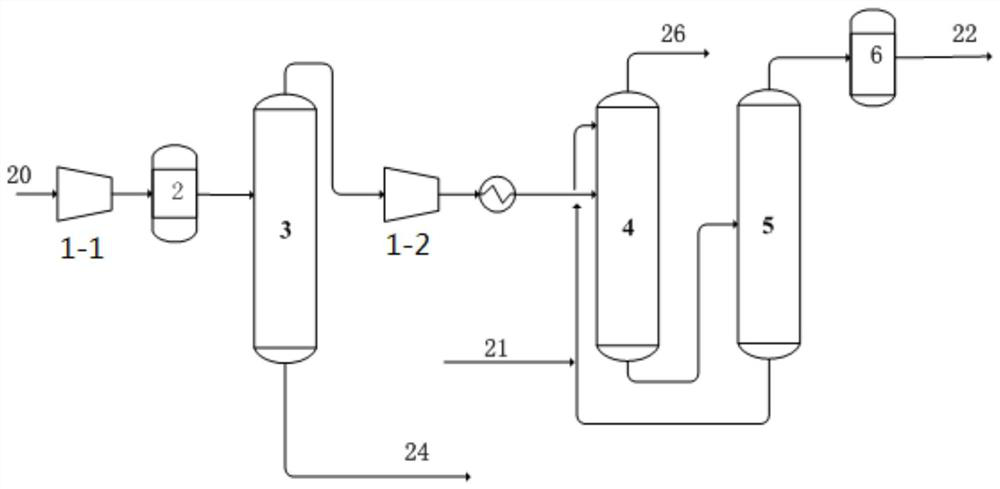

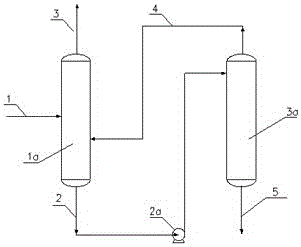

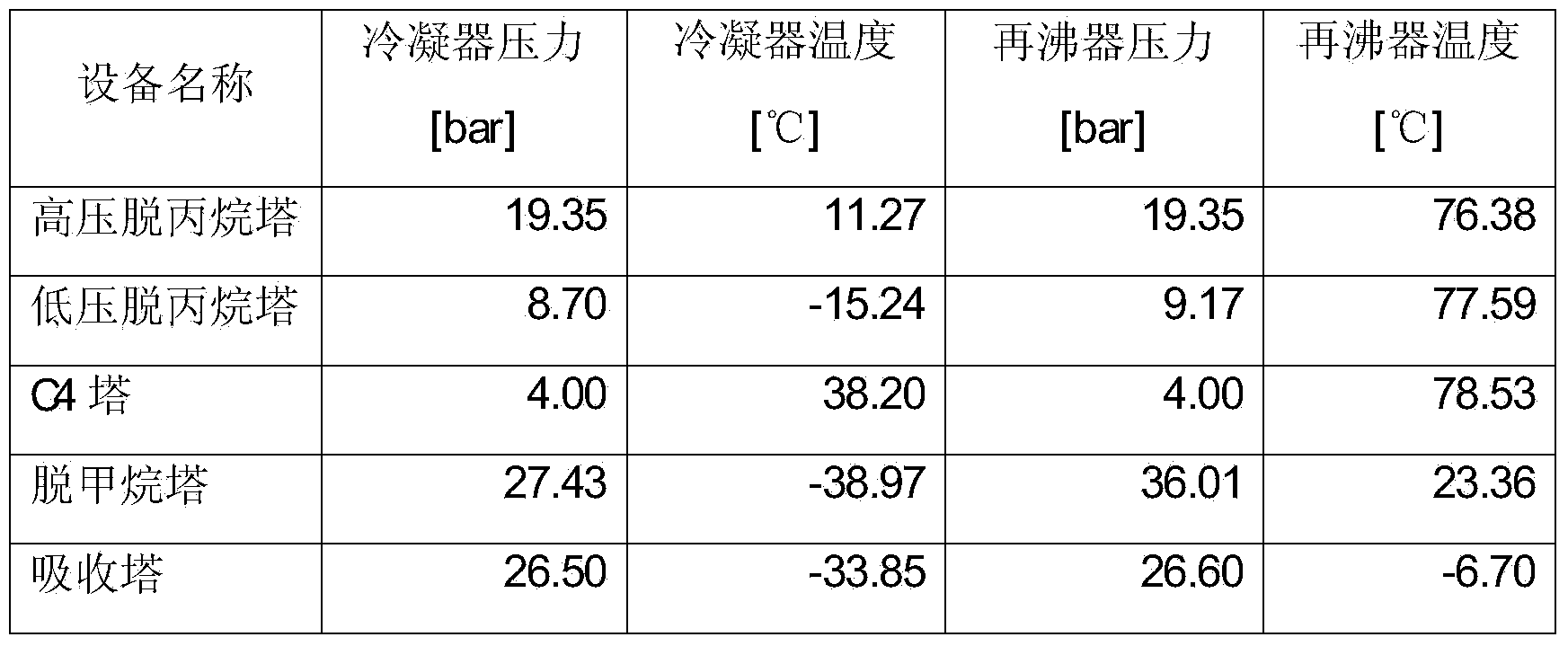

Method for separating low carbon olefin mixed gas by rectifying and absorbing

ActiveCN102304010BAchieve separationEasy to separateChemical industryLiquid hydrocarbon mixture recoveryOxygenSolvent

The invention relates to a method for separating low carbon olefin mixed gas by rectifying and absorbing. The method utilizes a hydrocarbon or oxygen-containing organic compound absorbent to separate methane from C2; a rectifying method is used for separating C2-C4 so that polymeric layer ethylene and propylene are obtained. By utilizing the method, the ethylene is separated from the methane by using the absorbent and without setting any deep freeze refrigeration plant (such as a refrigerator, an expander and the like); the lowest operation temperature of the process is more than minus 40 DEG C and the material cost of the device is reduced. By utilizing the absorbent, the ethylene is absorbed in an absorption tower so that the separation between the ethylene and the methane is realized; as boiling points of the absorbent and the ethylene are greatly different, the absorbent is easily separated from the ethylene, the solvent loss is less, and the absorbent does not pass through other towers and does not cause incomplete separation formed by generating azeotropy with C5 and the like.

Owner:CHINA TIANCHEN ENG +1

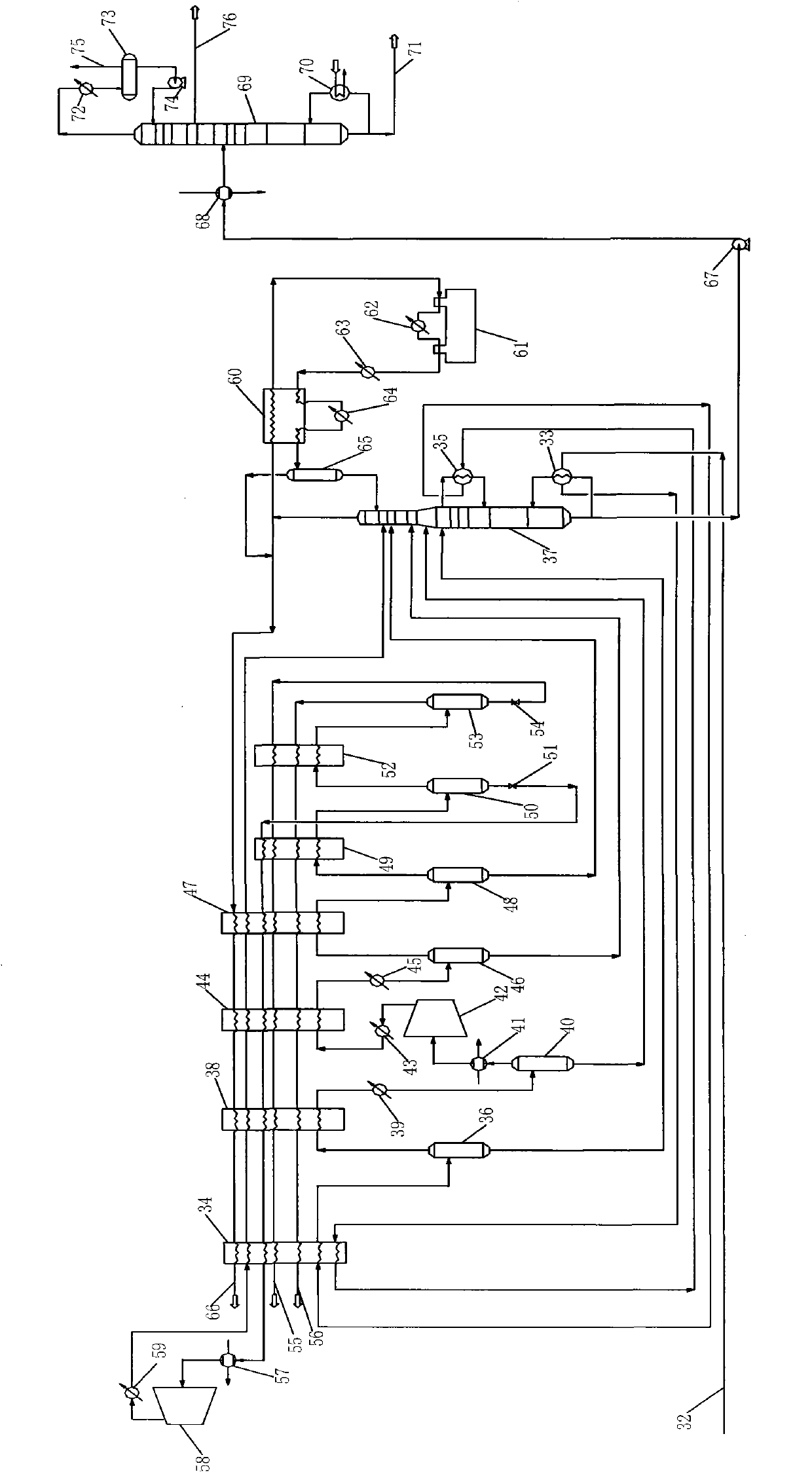

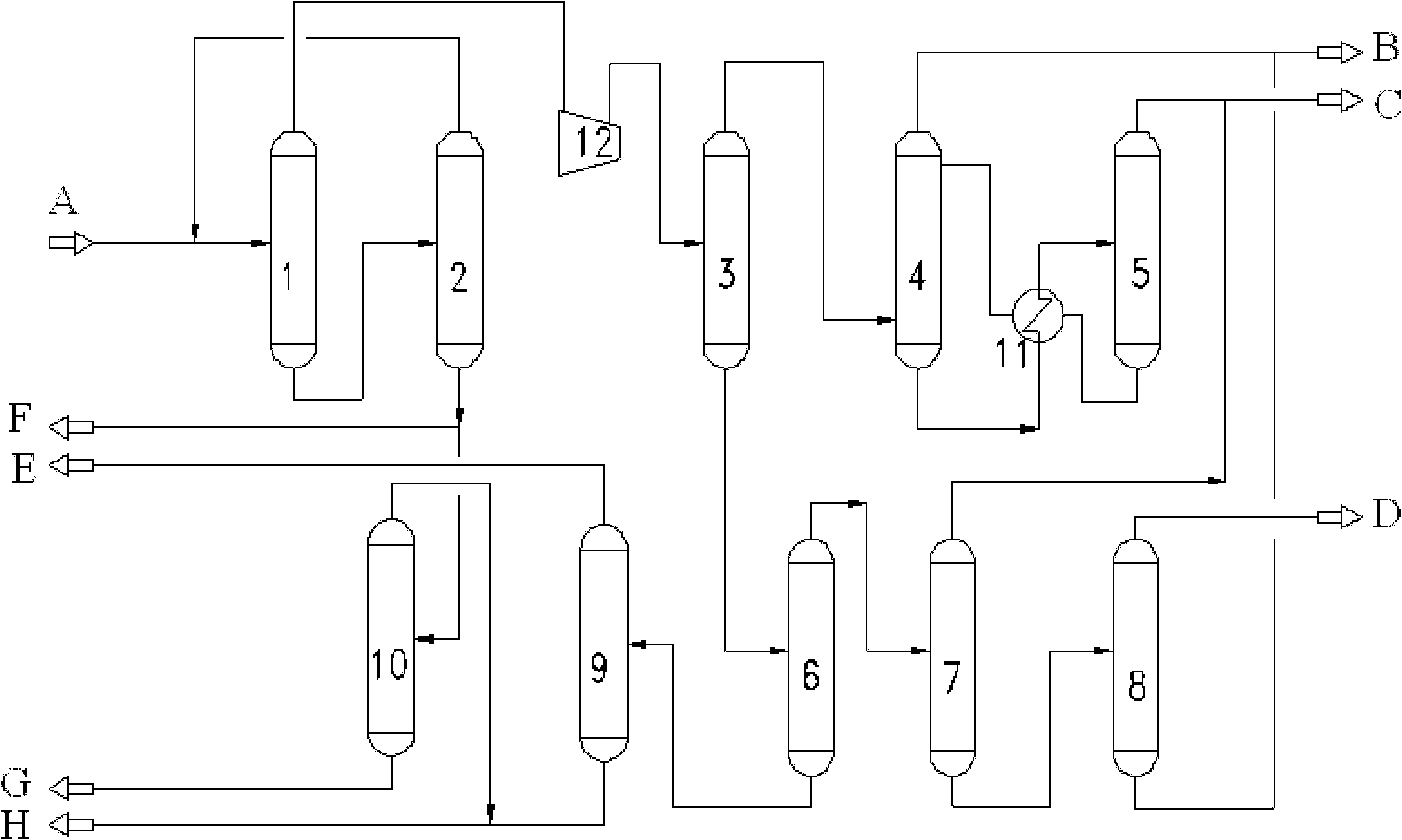

Cracking gas separation system and method adopting absorption-desorption

PendingCN112794784AReduce energy consumptionLess investmentHydrocarbon by hydrogenationLiquid hydrocarbon mixture recoveryProcess engineeringGas separation

The invention discloses a cracking gas separation system and method adopting absorption-desorption. The system comprises a compressor, a purification system, a C4 removal tower, an absorption tower, a desorption tower, a depropanization tower, a heavy component removal tower, a C2 hydrogenation reactor and a C4 hydrogenation reactor, wherein the purification system and the C4 removal tower are sequentially connected between the compressor sections, the C4 removal tower top is connected with the rear section of the compressor and then connected with the absorption tower, and the C4 removal tower kettle is connected with the heavy component removal tower; the tower top of the heavy component removal tower is connected with the C4 hydrogenation reactor; an outlet pipeline of the C4 hydrogenation reactor and a tower kettle outlet pipeline of the desorption tower are combined and then connected with the upper part of the absorption tower; the absorption tower kettle is connected with a desorption tower; the top of thedesorption tower is connected with thedepropanization tower, a tower kettle of the desorption tower is combined with an outlet pipeline of the C4 hydrogenation reactor and then is connected with the upper part of the absorption tower; and the top of the depropanization tower is connected with a C2 hydrogenation reactor. The system has the characteristics of low investment, low energy consumption and remarkable benefit.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com