Pyrolysis gas separation system with purification function and utilization method

A separation system and cracking gas technology, applied in the field of cracking and separation, can solve the problems of high energy consumption, low cooling capacity, large investment in cracking gas separation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

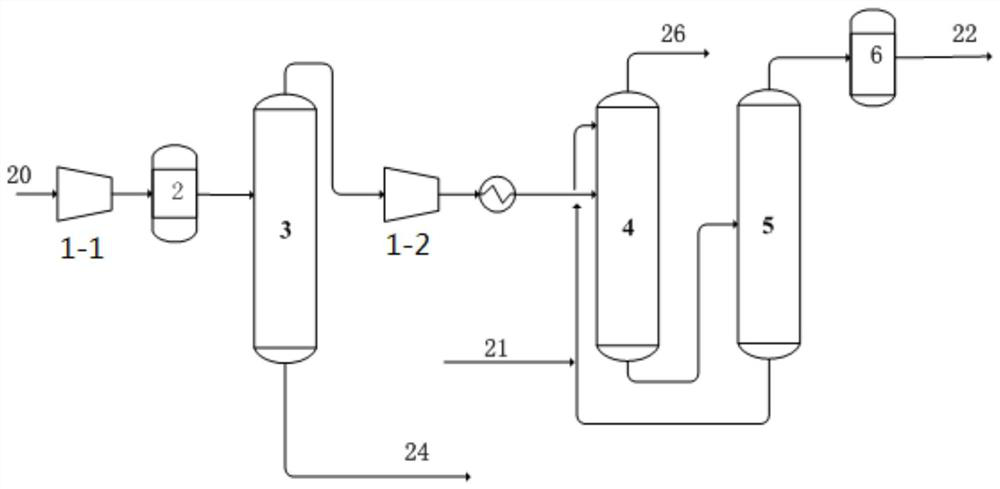

[0077] use as figure 1 A kind of pyrolysis gas separation system shown comprises: compressor (compressor front section 1-1, compressor rear section 1-2); 2 purification system; 3 weight-removing tower; 4 absorption tower; 5 desorption tower; 6 carbon Two hydrogenation reactors;

[0078] The weight removal tower is operated with two towers, namely a high pressure weight removal tower and a low pressure weight removal tower.

[0079] The compressor sections are connected to the purification system 2 and the high-pressure weight removal tower in sequence, and then to the absorption tower 4. The tank of the high-pressure de-weighting tower is connected to the low-pressure de-weighting tower, and after the top of the low-pressure de-weighting tower is connected to the rear section 1-2 of the compressor, it is connected to the cooler and the gas-liquid separation tank, and the gas phase outlet of the gas-liquid separation tank is connected to the absorption tower 4. The liquid pha...

Embodiment 2

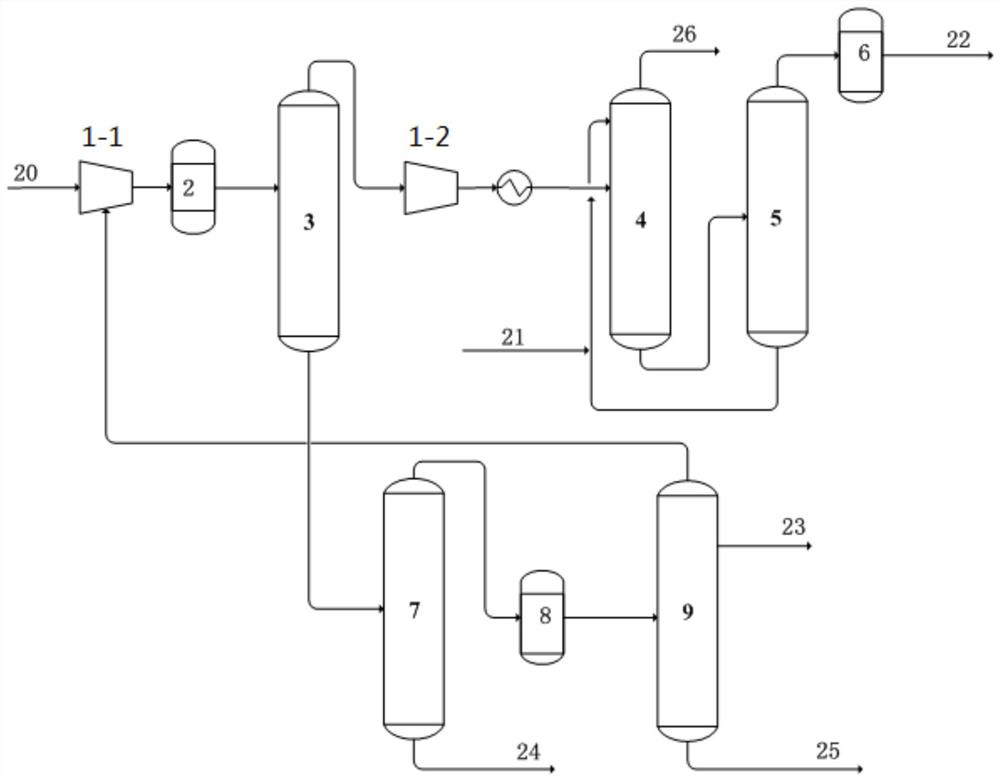

[0101] A cracking gas separation system, comprising: compressor (compressor front section 1-1, compressor rear section 1-2); purification system 2; weight removal tower 3; absorption tower 4; desorption tower 5; Device 6; Depropanizer 7; C3 hydrogenation reactor 8; Propylene rectification tower 9.

[0102] The compressor sections are connected to the purification system 2 and the high-pressure weight removal tower in sequence, and then to the absorption tower 4. The tank of the high-pressure de-weighting tower is connected to the low-pressure de-weighting tower, and after the top of the low-pressure de-weighting tower is connected to the rear section 1-2 of the compressor, it is connected to the cooler and the gas-liquid separation tank, and the gas phase outlet of the gas-liquid separation tank is connected to the absorption tower 4. The liquid phase outlet of the gas-liquid separation tank is connected to the upper part of the high-pressure de-weighting tower, the top of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com