Production method of food grade liquid carbon dioxide product for recycling resurgent gases

A liquid carbon dioxide, carbon dioxide technology, applied in chemical instruments and methods, liquefaction, refrigeration and liquefaction, etc., can solve problems such as increasing cost input, increasing safety hazards, reducing service life, etc., to increase output, reduce production costs, and utilize rate increase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

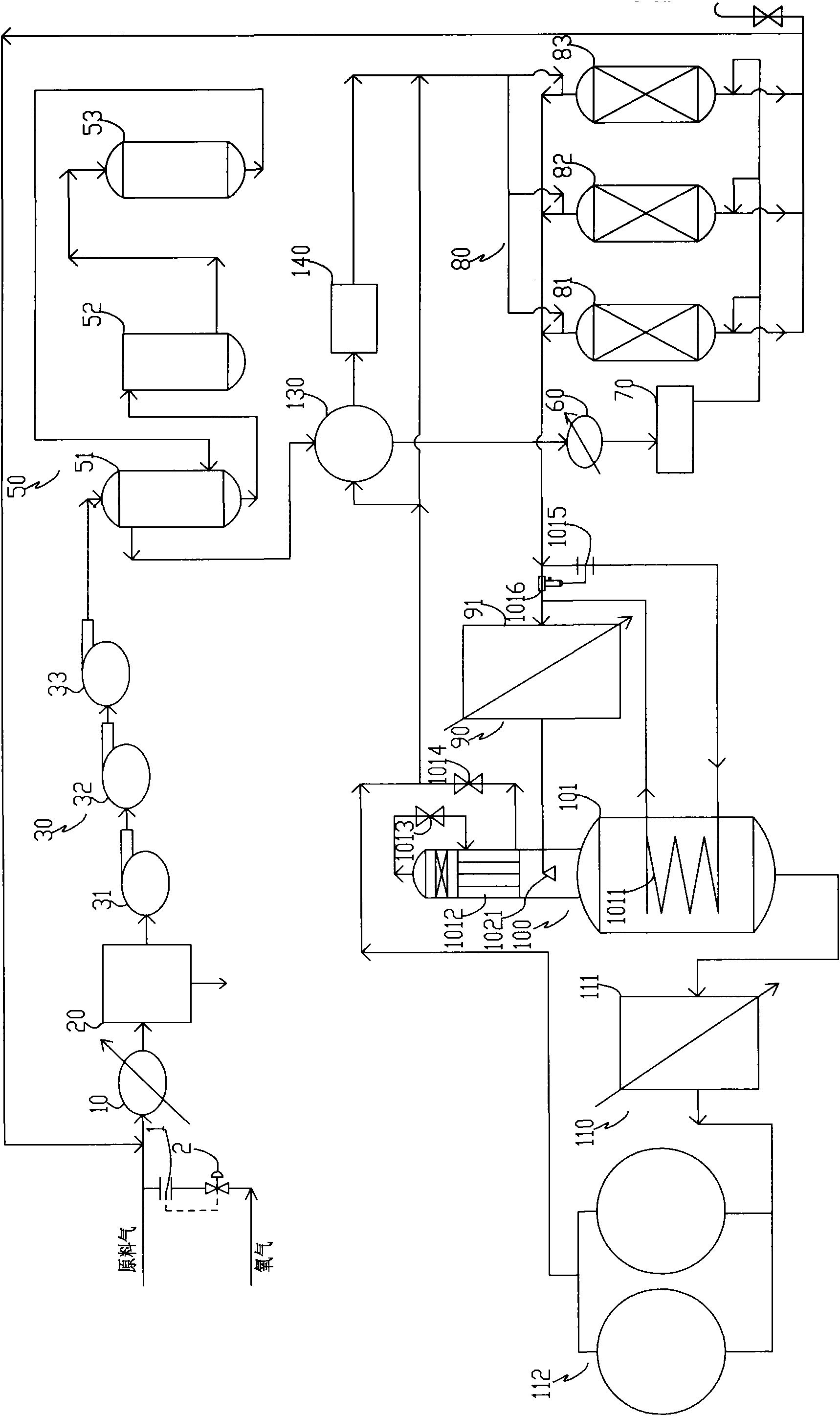

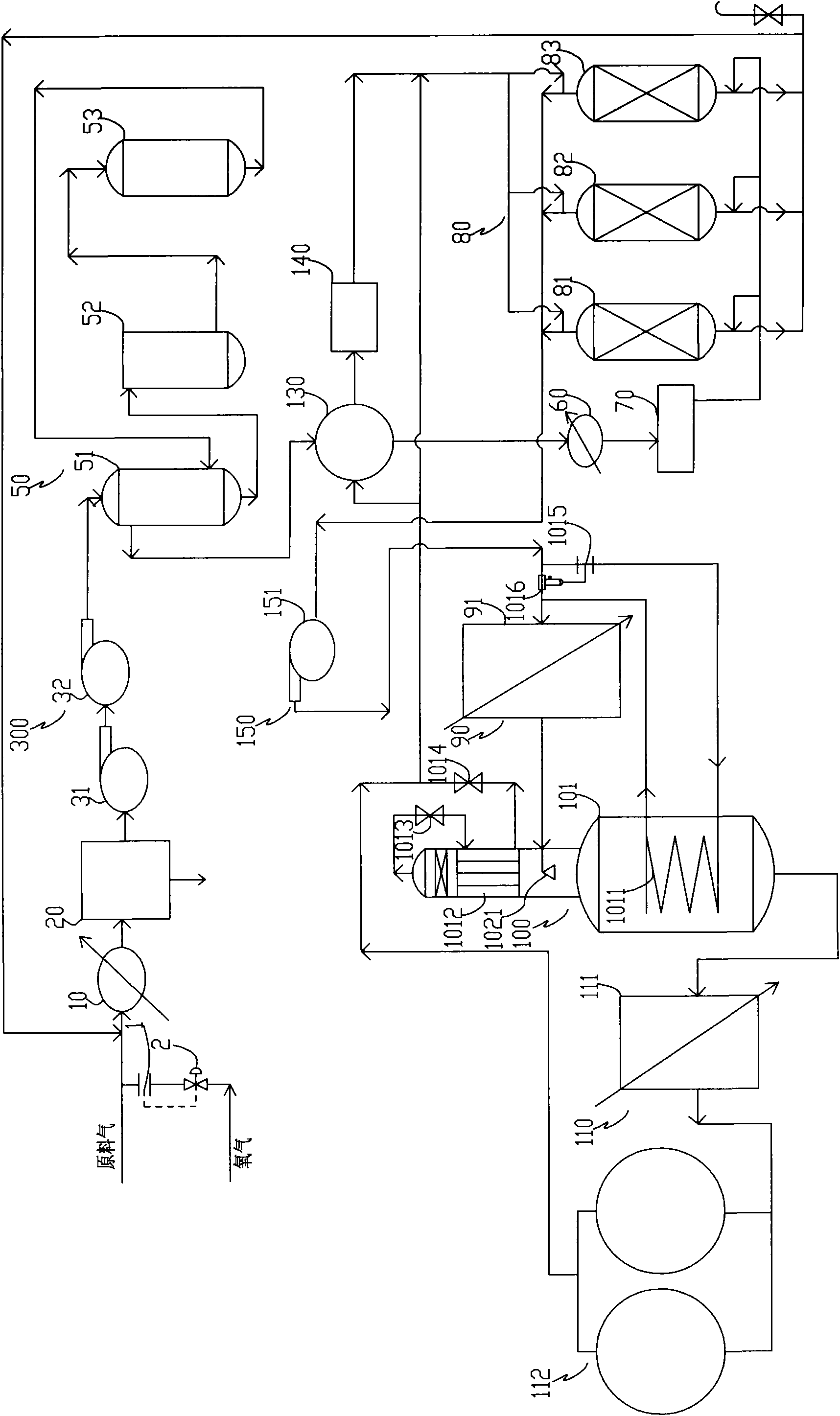

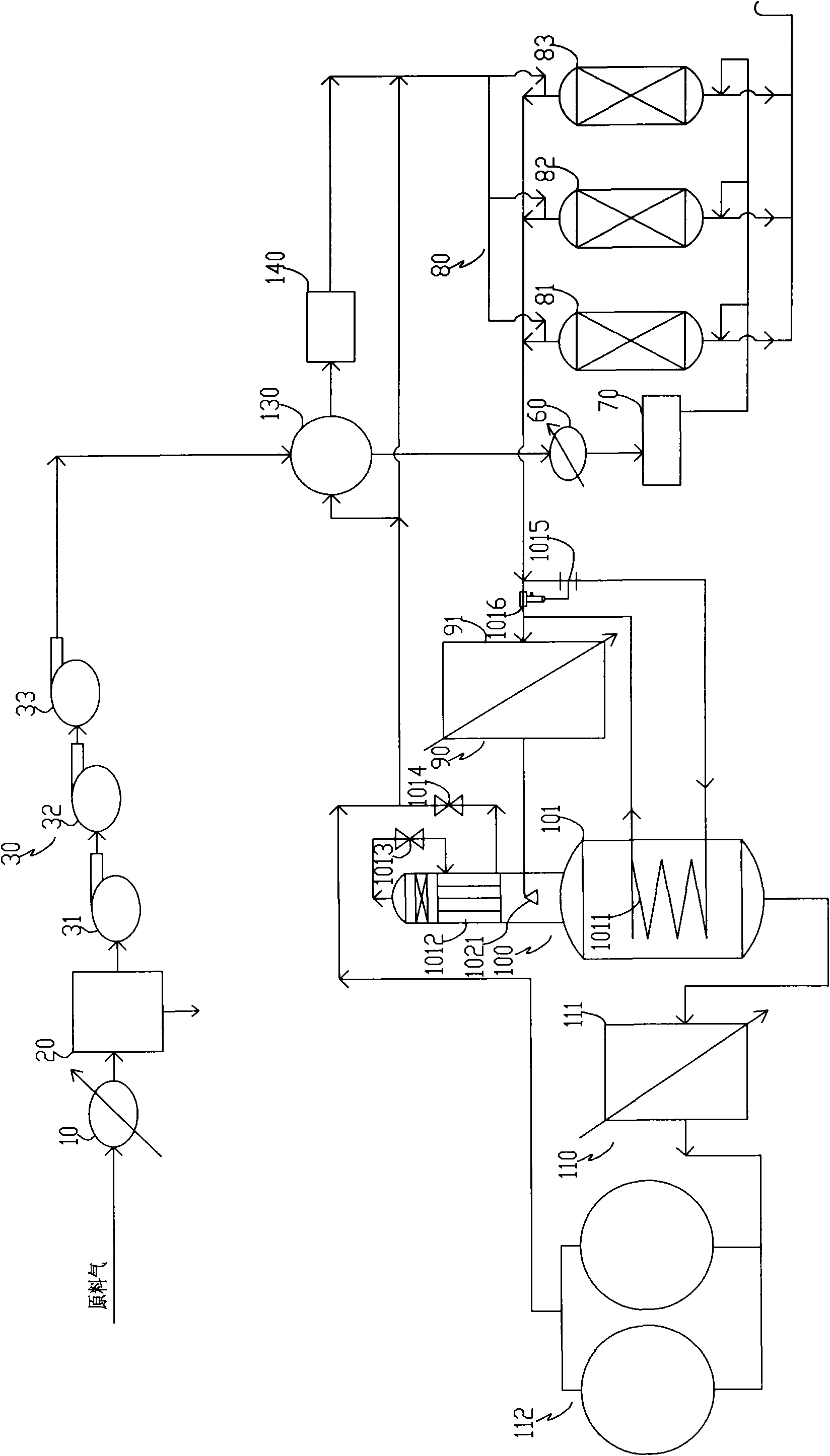

[0065] The specific embodiment of the production method of the food-grade liquid carbon dioxide product of the recovery gas of the present invention will be described in detail below with reference to the accompanying drawings, and the characteristics and advantages of the production method of the food-grade liquid carbon dioxide product of the recovery gas of the present invention will become more obvious.

[0066] see figure 1 , the first embodiment of the production method of the food-grade liquid carbon dioxide product that reclaims regenerated gas of the present invention, comprises the following steps:

[0067] (1) Compression process 30

[0068] The carbon dioxide raw material gas containing mechanical water, methane, ethylene, benzene and other impurities with a carbon dioxide content of about 99.2% from outside the boundary area is washed with water, and the chemical reaction that is mediated by the regulating valve 2 controlled by the orifice flowmeter 1 is slightl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com