Patents

Literature

58results about How to "High ethylene content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermoplastic olefin compositions, processes and articles

A thermoplastic olefin (TPO) composition comprises (1) a major amount by weight of (a) a substantially linear homopolymer or copolymer of a C2-C10 α-olefin in major proportion to (b) a long chain branched a linear homopolymer or copolymer of a C2-C10 α-olefin, (2) a minor amount by weight of a cross linkable elastomer, and (3) at least one thermally decomposing free radical generating agent present in an amount sufficient to promote an increase in melt strength of the composition over that of the melt strength of the linear homopolymer or copolymer of a C2-C10 α-olefin alone and insufficient to substantially degrade the α-olefinic polymers. The TPO composition is prepared by melt blending the components at a temperature sufficient to melt said homopolymers or copolymers of a C2-C10 α-olefin and thermally decompose said agent. Articles are thermoformed from the thermoplastic olefin.

Owner:EXOUSIA IP LLC

Supported catalyst for olefin polymerization

ActiveUS20070021573A1High ethylene contentLow costOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolyolefinAlcohol

Disclosed are catalyst systems and methods of making the catalyst systems for the polymerization of an olefin containing a solid titanium catalyst component containing an inorganic titanium compound, a magnesium alcohol adduct made from an inorganic magnesium compound and an alcohol, and a porous support having at least one of a certain specific surface area, a certain pore volume, and a certain median particle size. The catalyst system may further contain an organoaluminum compound and optionally an organosilicon compound. Also disclosed are methods of making polyolefins.

Owner:ENGELHARD CORP +1

Propylene polymer compositions

The invention relates to propylene polymer compositions comprising 45-79 parts per weight of a propylene homo- or copolymer, 10-27 parts per weight of a first elastomeric ethylenepropylene copolymer, 5-22 parts per weight of a second elastomeric ethylene-propylene copolymer, 1-15 parts per weight of an elastomeric ethylene-1-octene copolymer and 5-15 parts per weight of inorganic filler. The propylene polymer compositions are suitable for injection molding of large articles, which do not show flow marks and which have a good impact strength / stiffness ratio.

Owner:BOREALIS TECH OY

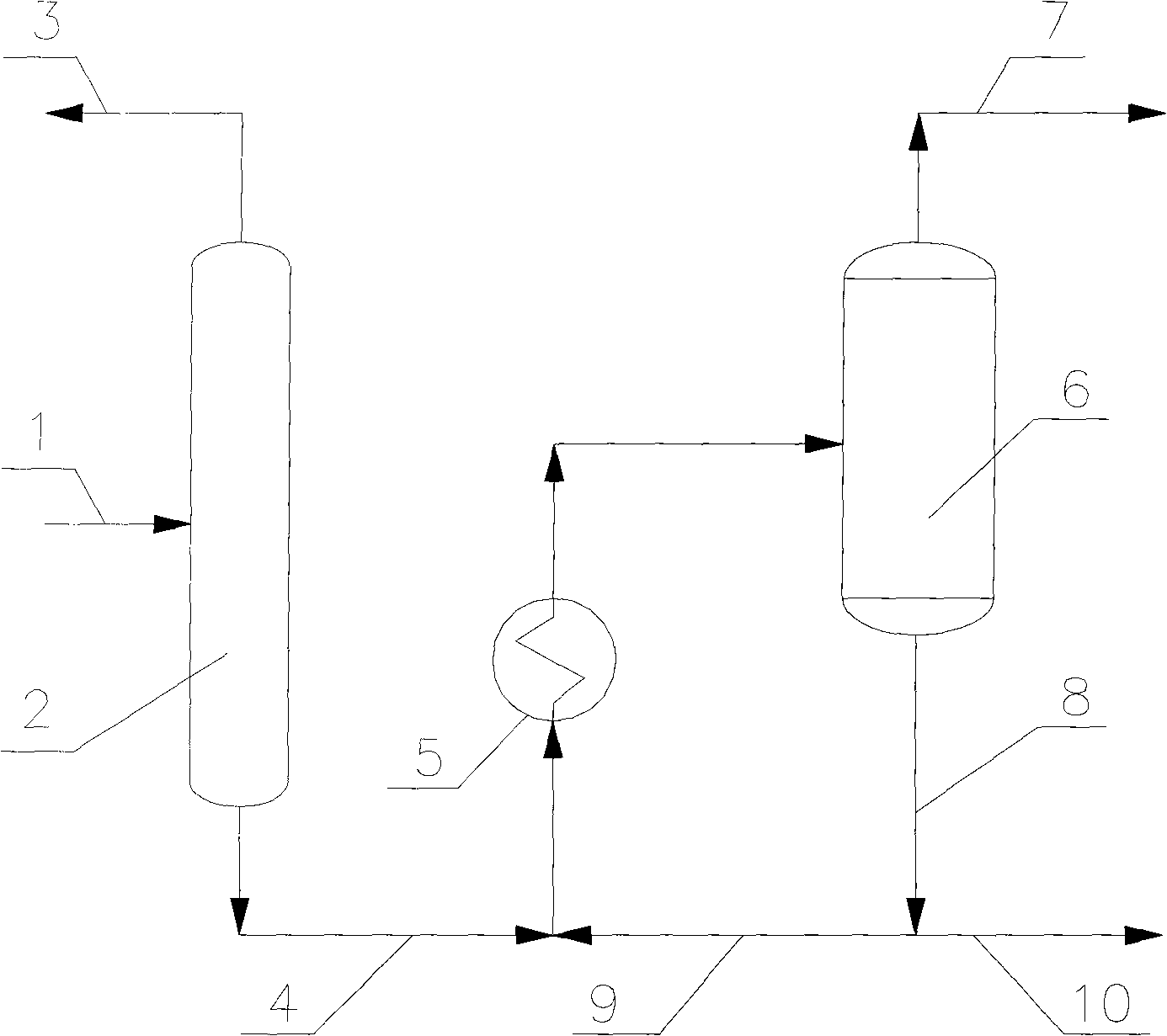

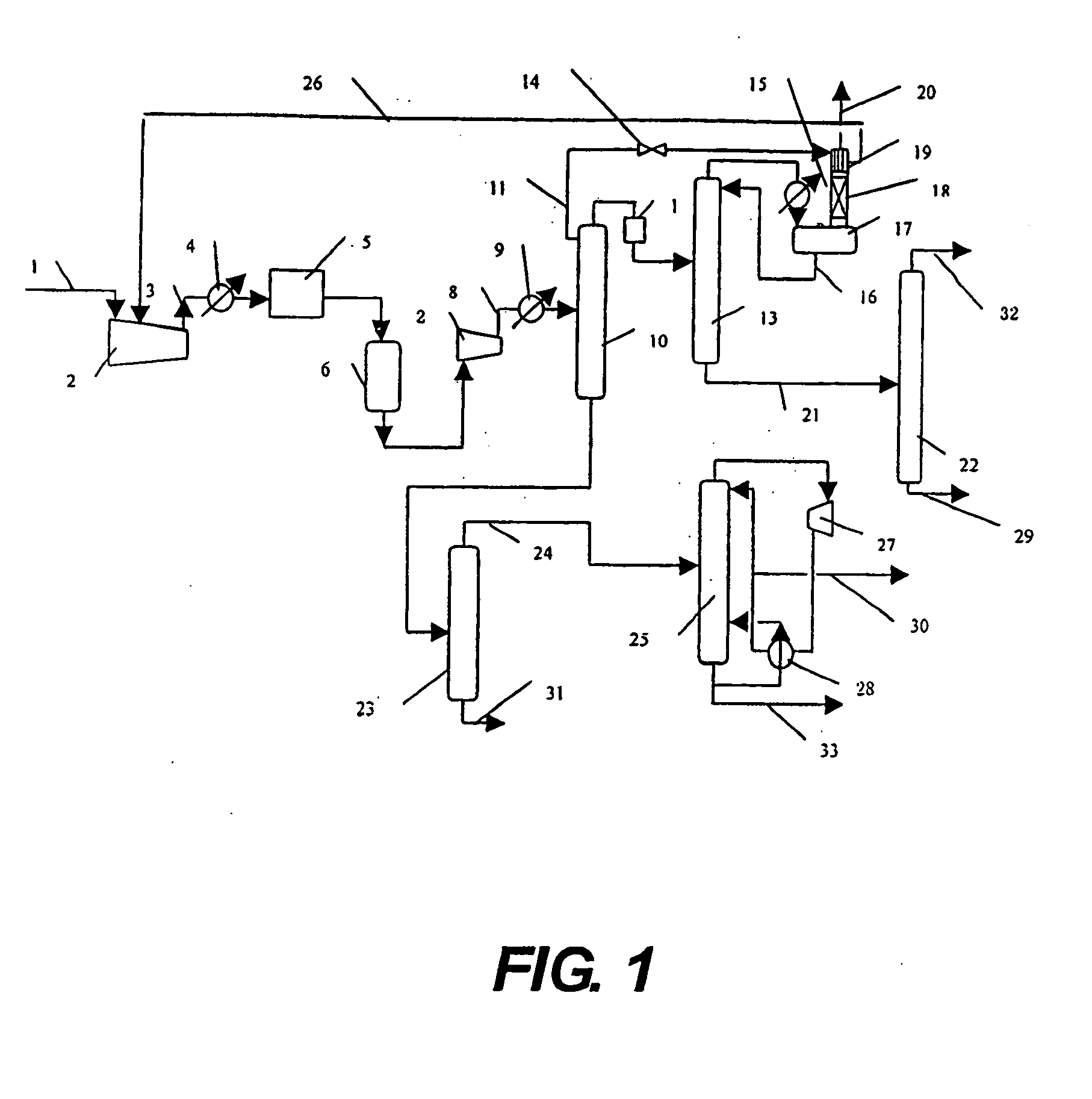

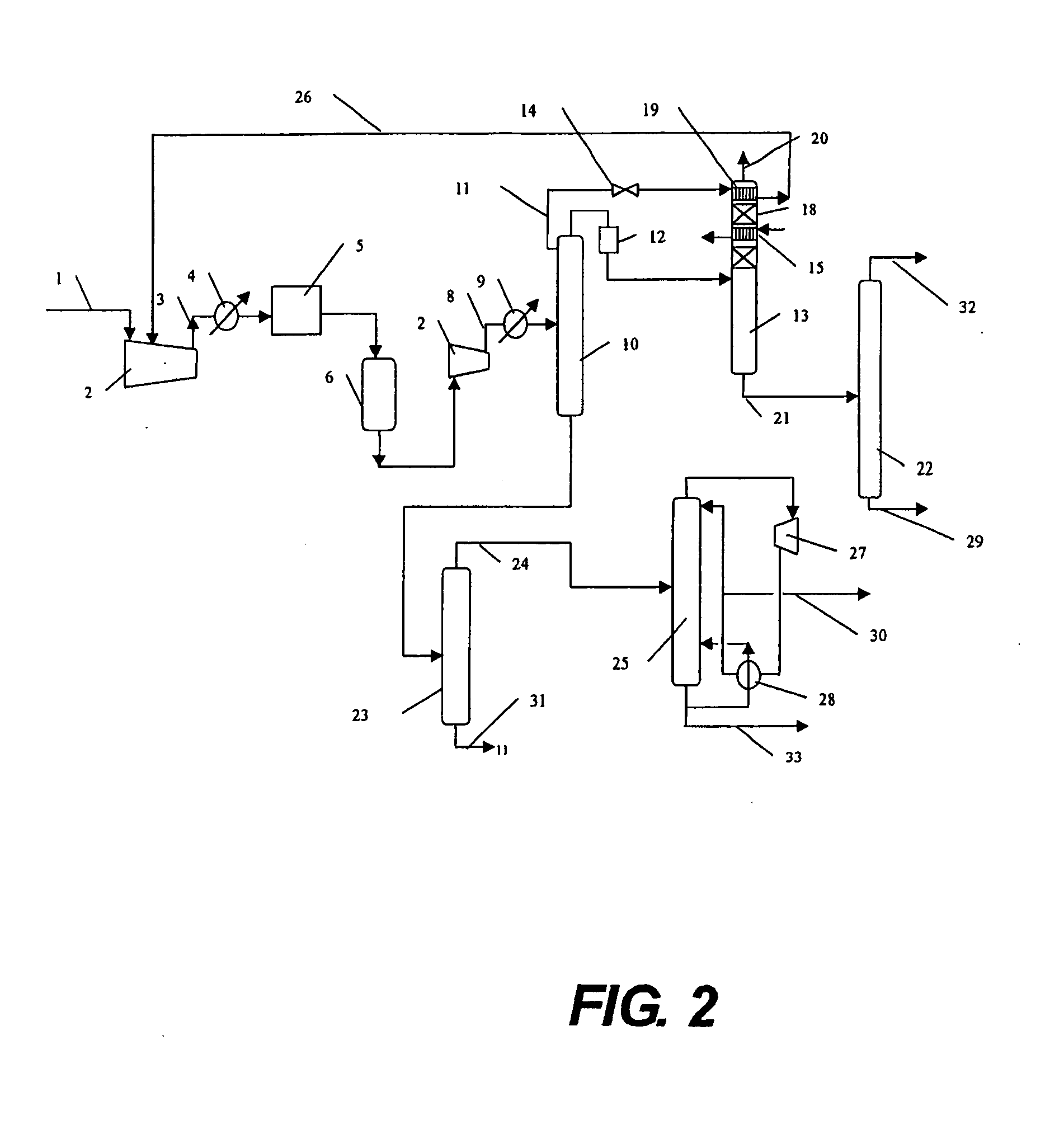

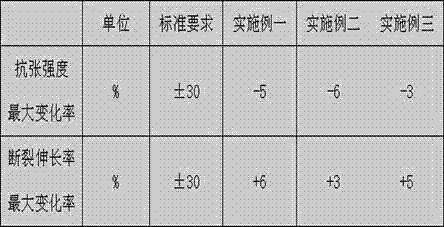

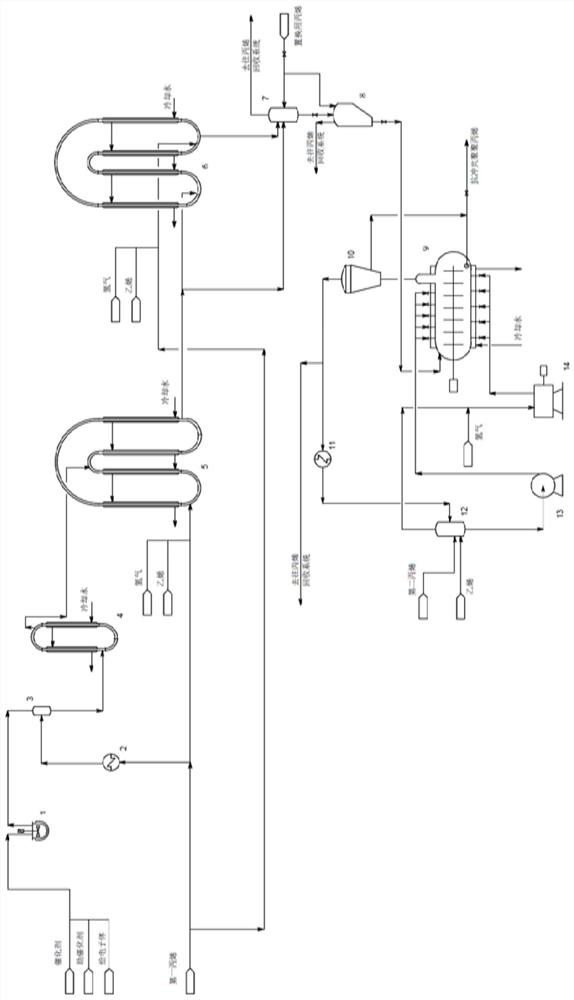

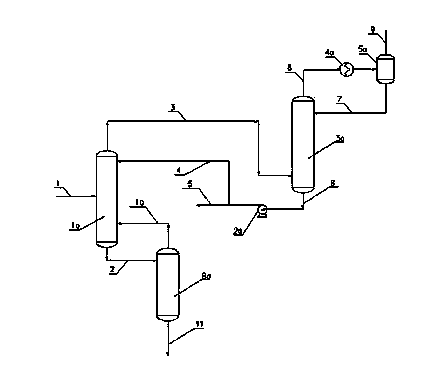

Process for recovering ethylene in process of ethylene preparation by ethanol dehydration

ActiveCN101306973AFlash fullyHigh ethylene contentDistillation purification/separationPolymer scienceTower

The invention relates to a method for reclaiming ethylene in the process for making ethylene through ethanol dehydration, mainly solving the problems not mentioned in the prior literature including ethylene rectification tower bottoms treatment or greater ethylene loss. The method solves the problems better through adopting the following technical proposal that: ethylene rectification tower bottoms are fed in an adiabatic flash drum; the adiabatic temperature of the flash drum is between 15 DEG C below zero and 80 DEG C and the pressure inside the flash drum is between 1.0 and 4.0 MPaG; finally, after adiabatic flash evaporation, the materials at the top of the flash drum is returned to the middle part of an ethylene rectification tower, and the heavy component at the bottom of the flash drum is discharged. The method can be used in the industrial production of ethylene through adopting ethanol dehydration.

Owner:CHINA PETROLEUM & CHEM CORP +1

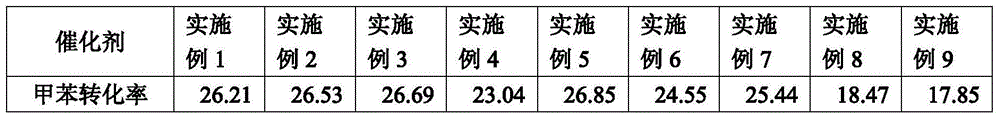

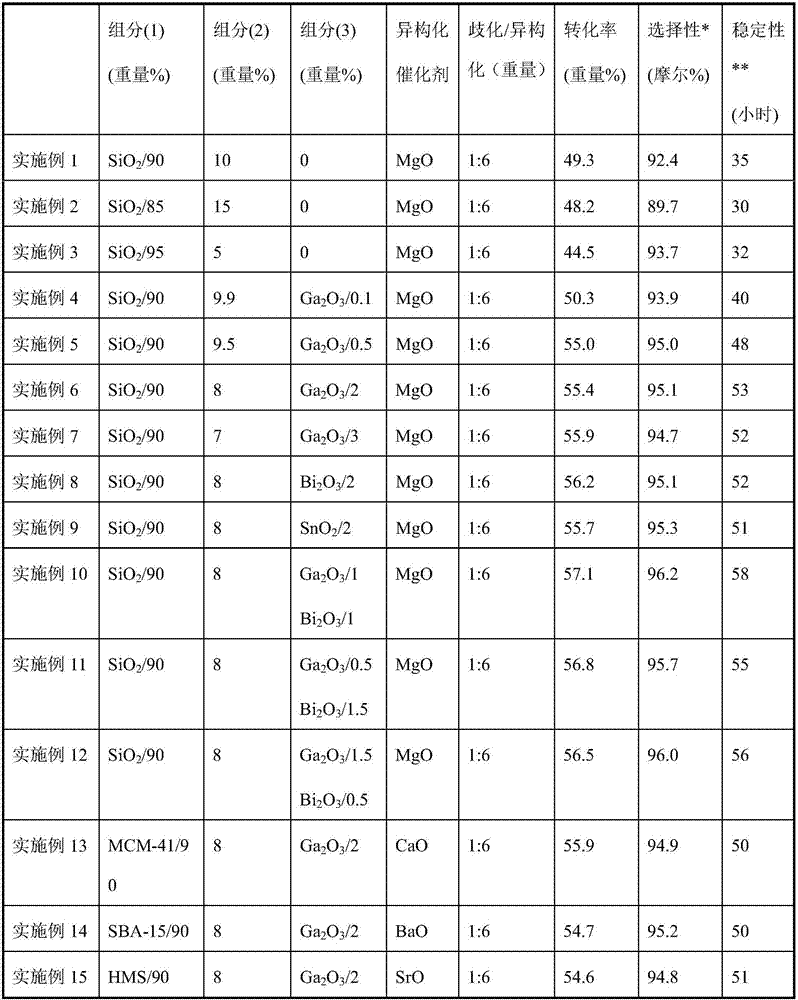

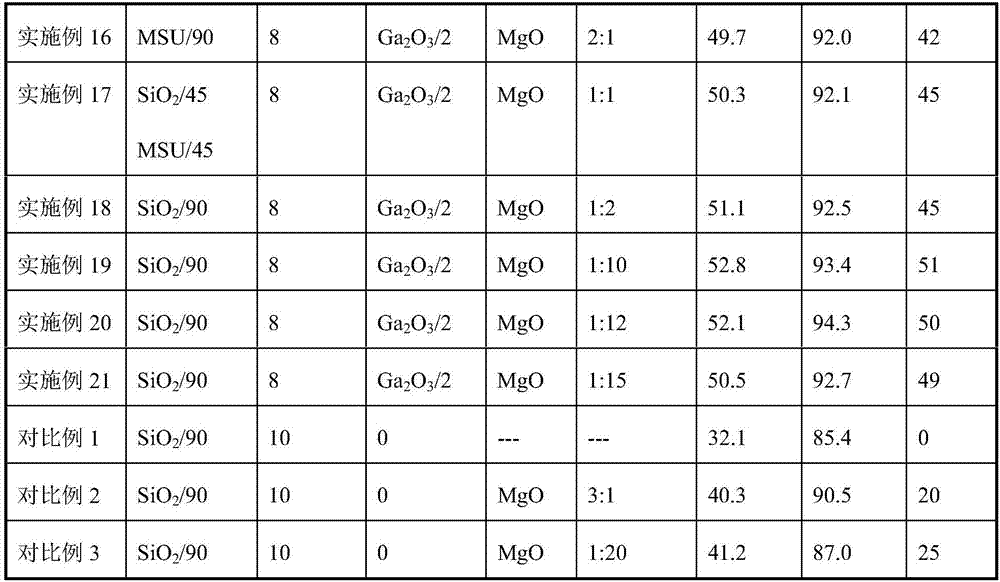

Catalyst for alkylation of toluene with methanol to produce paraxylene with coproduction of ethylene and application thereof

InactiveCN104128198AHigh selectivityEfficient use ofMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveMetal

The invention discloses a catalyst for alkylation of toluene with methanol to produce paraxylene with coproduction of ethylene and application thereof. The catalyst is prepared by modifying zeolite molecular sieve with alkaline earth metal, non-metallic or / and rare earth metal and modifying surface acidity and pore structure by a siloxane compound. The invention aims at the characteristics of the two raw materials paraxylene and ethylene for polyester production, and uses one catalyst for high selectivity production of paraxylene and ethylene at the same time; and the catalyst can be used for industrial shape selective alkylation of toluene with methanol to produce paraxylene, and further can be used in industrial production of polyester.

Owner:陕西煤化工技术工程中心有限公司

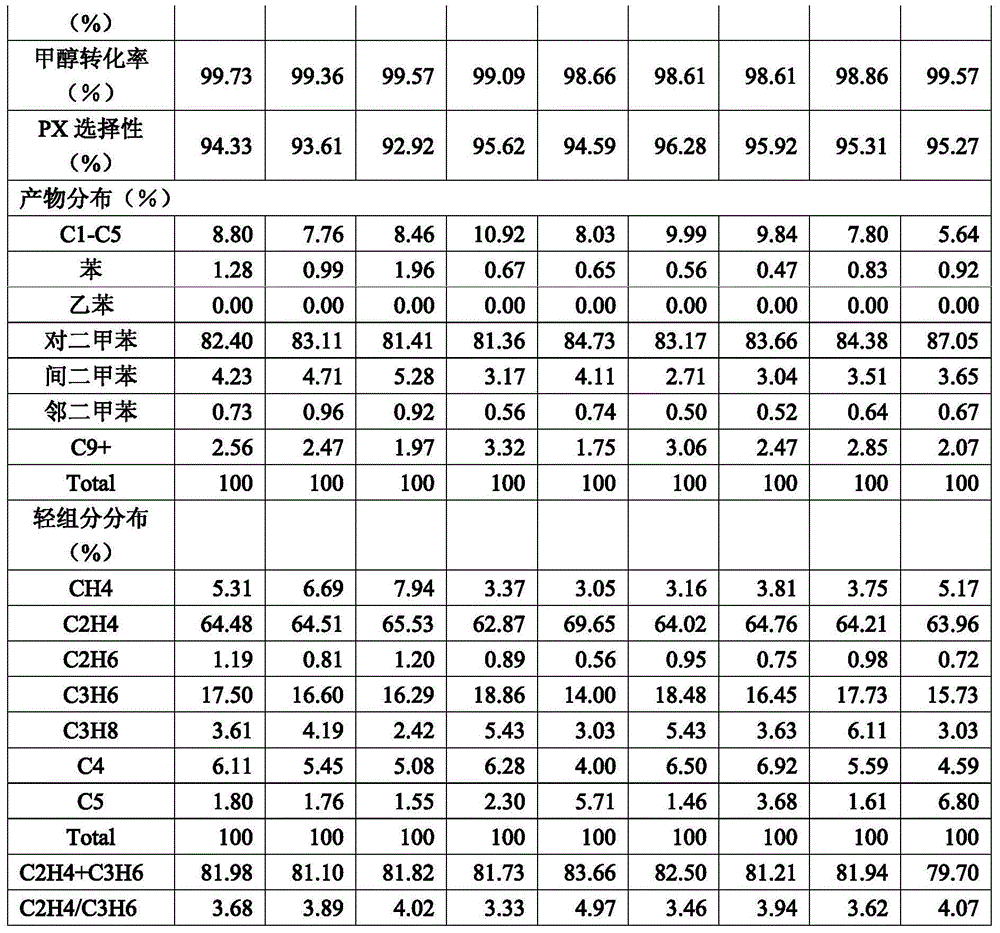

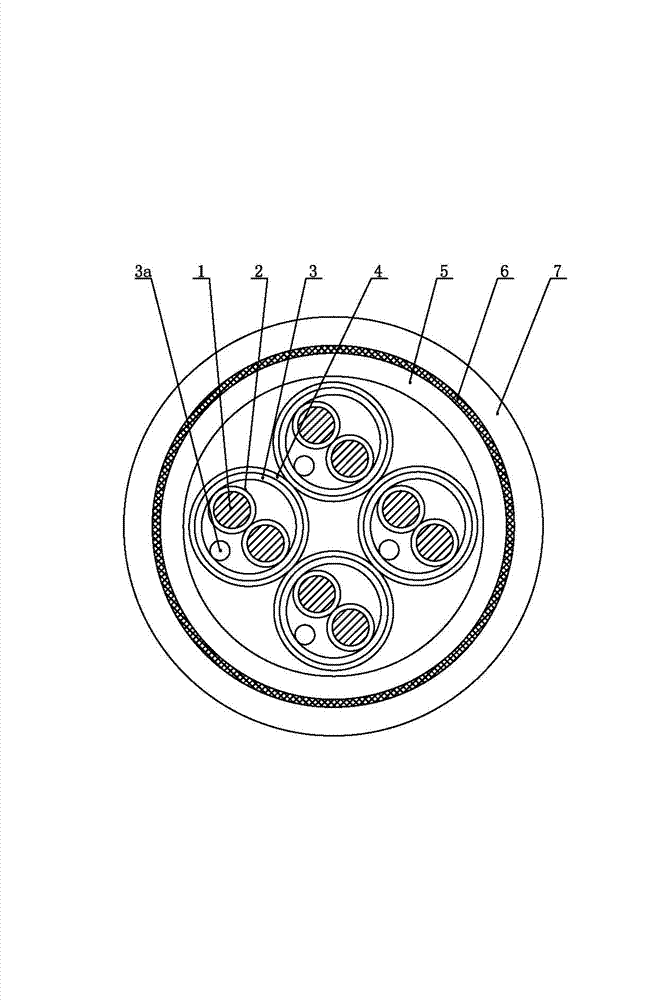

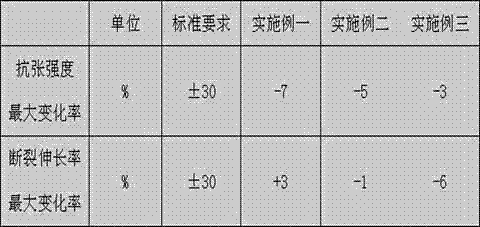

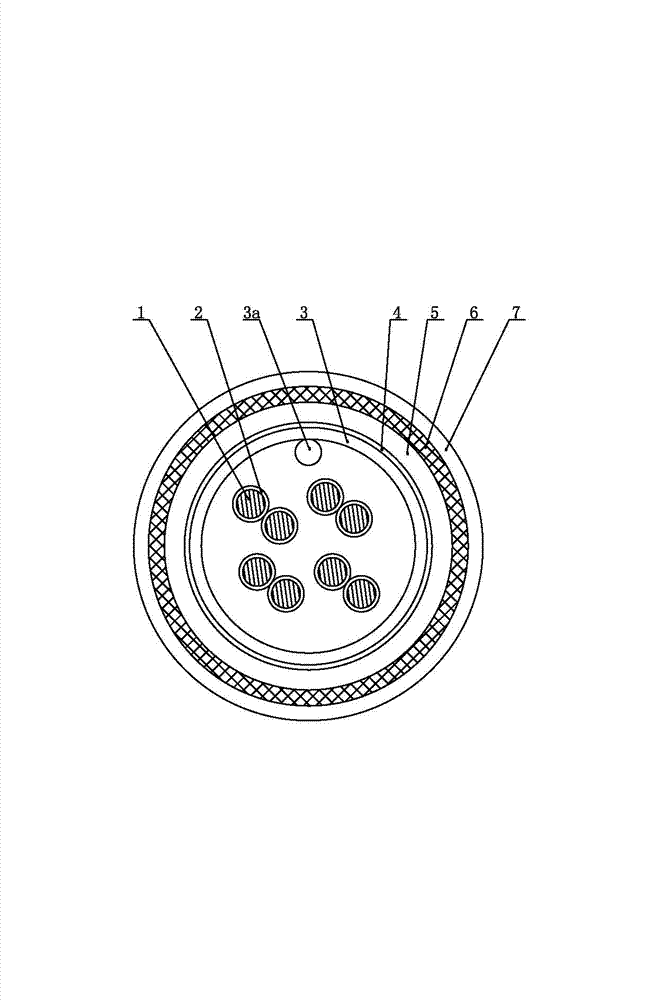

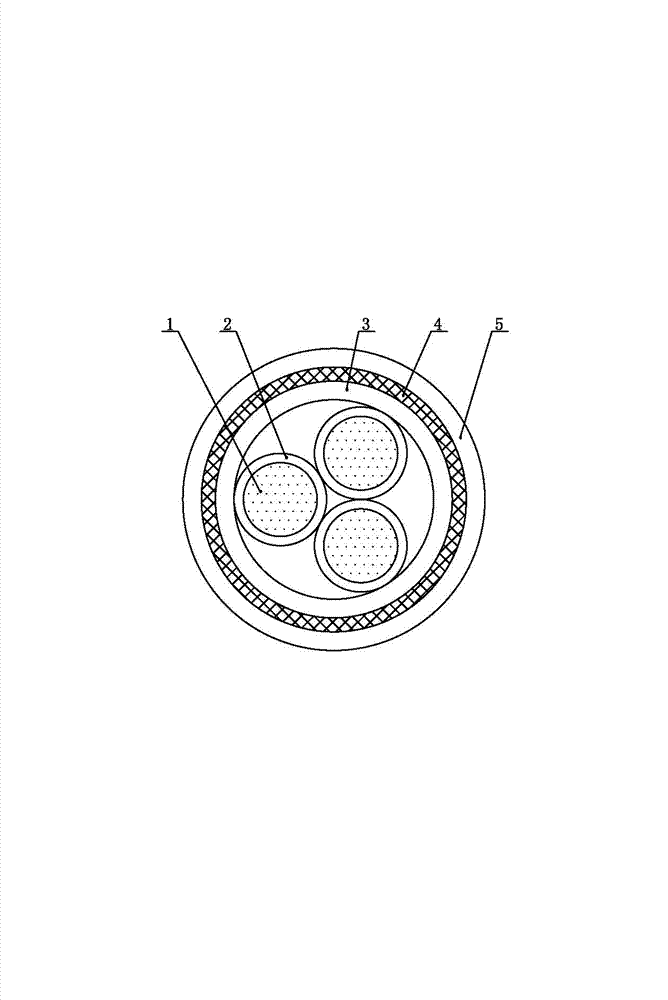

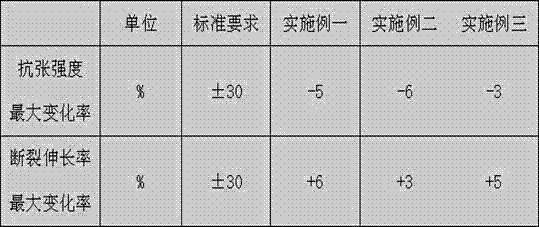

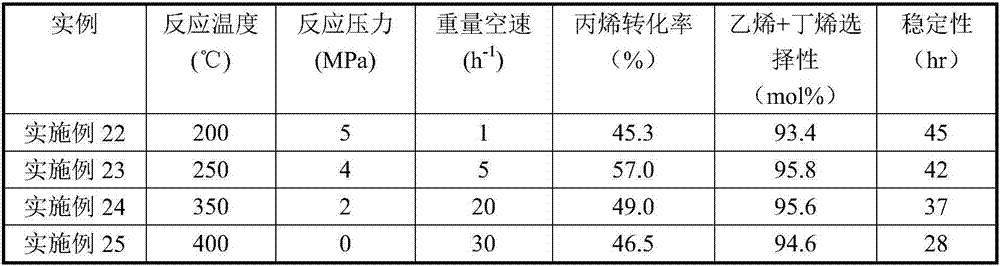

Whitening ultraviolet-proof double-shield instrument cable for ships and manufacturing method thereof

InactiveCN102969046AColor whiteGood physical and mechanical propertiesClimate change adaptationInsulated cablesCopper foilInsulation layer

The invention relates to a whitening ultraviolet-proof double-shield instrument cable for ships and a manufacturing method thereof. The cable is characterized in that a whitening ultraviolet-proof ethylene-propylene rubber insulation layer is extruded at the periphery of a tin-plated annealed stranded copper conductor to form an insulation wire core; every two insulation wire cores are twisted to form twisted wire pairs; each twisted wire pair is wrapped with a wire core copper foil polyester composite tape shielding layer at the periphery; the wire core copper foil polyester composite tape shielding layers are each wrapped with a wire core polyester tape at the periphery to form a pair-twist group; all the pair-twist groups are stranded to the right at 16-24 times of stranding lay ratio to form a cable core; the cable core is wrapped with a cable core copper foil polyester composite tape shielding layer at the periphery; the cable core copper foil polyester composite tape shielding layer is wrapped with a cable core polyester tape at the periphery; an inner sheath is extruded at the periphery of the cable core polyester tape; the inner sheath is coated with a copper alloy wire weaving armor layer at the periphery; and an outer sheath is extruded at the periphery of the copper alloy wire weaving armor layer. The insulation layer of the double-shield cable is white in color, good in mechanical property, excellent in anti-ultraviolet irradiation and anti-aging performance, and long in service life.

Owner:JIANGSU YUANYANG DONGZE CABLE

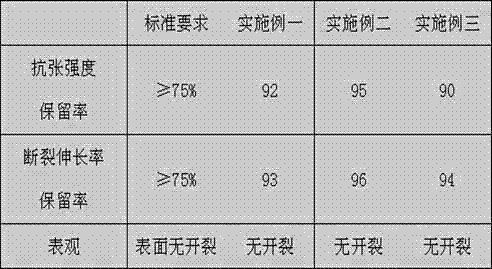

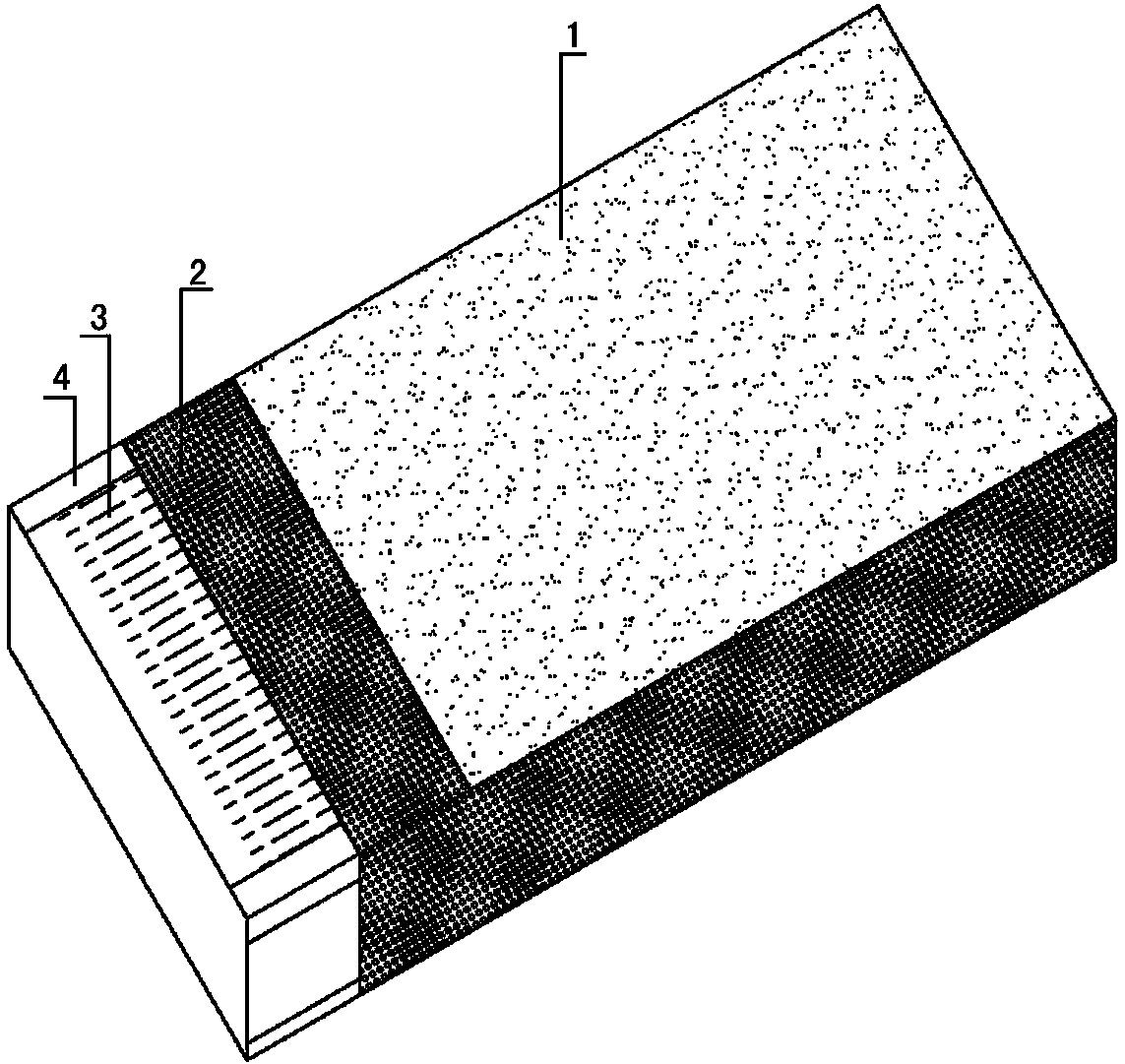

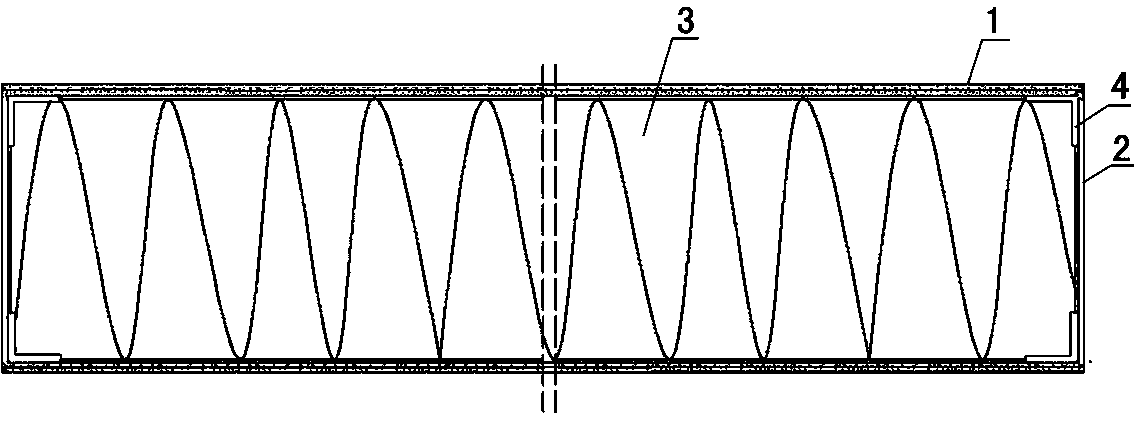

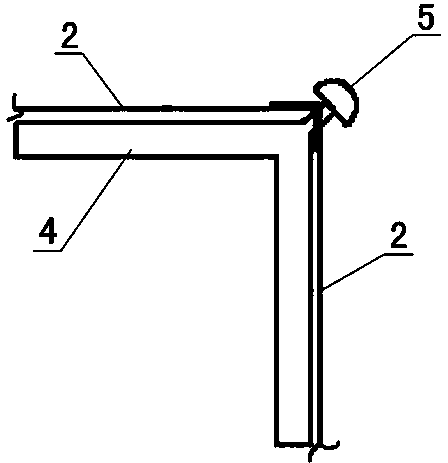

Basalt fiber gridding cloth wrapped rock wool composite heat-preserving plate and manufacturing method thereof

InactiveCN103850353AHigh strengthMeet the technical requirements of thermal insulation constructionHeat proofingFire proofingAdhesive cementPolyvinyl chloride

The invention discloses a basalt fiber gridding cloth wrapped rock wool composite heat-preserving plate and a manufacturing method thereof. The basalt fiber gridding cloth wrapped rock wool composite heat-preserving plate comprises a heat-preserving plate and gridding clothes which wrap the upper and lower surfaces and left and right surfaces of the heat-preserving plate, wherein the heat-preserving plate is formed by splicing a plurality of vertical cotton strips; the fiber direction of each vertical cotton strip is vertical to the upper and lower surfaces of the heat-preserving plate; a PVC (polyvinyl chloride) protecting corner wraps each of the four corner angles of the heat-preserving plate; a row of toothed openings corresponding to gridding cloth meshes in the gridding clothes is formed in the PVC protecting corner on one corner angle of the heat-preserving plate; the gridding clothes are basalt fiber gridding clothes; one end of each basalt fiber gridding cloth is hung to the toothed openings through the gridding cloth meshes; after wrapping around the heat-preserving plate for one circle, the other end of each basalt fiber gridding cloth is also hung to the toothed openings through the gridding cloth meshes. The four surfaces of the heat-preserving plate formed by splicing the vertical cotton strip are wrapped by the basalt fiber gridding clothes, and a hydrophobic bonding adhesive cement is coated on the upper and lower surfaces of the heat-preserving plate, so that the whole tensile strength of the rock wool composite plate is effectively improved.

Owner:河北东华绿源节能科技有限公司

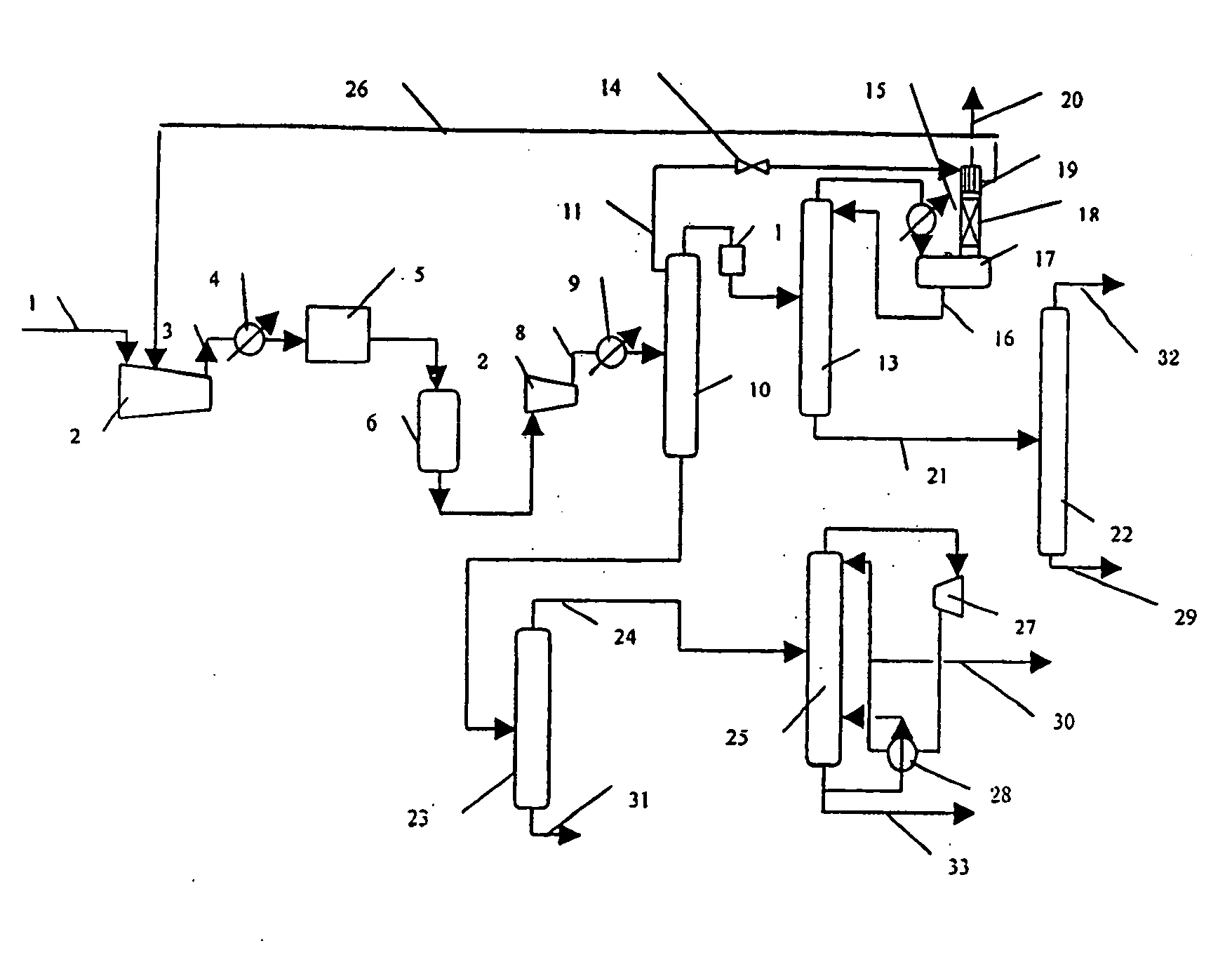

Process for recovering lower carbon olefins from product gas for production of olefins

The present invention concerns a process for recovering lower carbon olefins from MTO or DTO product gas. Said process primarily comprises the product gas compressing, pre-deethanizing, demethanizing and ethylene recovering apparatus, depropanizing column, ethylene rectification column, propylene rectification column and the like. In addition, the process of the present invention needs no independent ethylene cooling system, and the ethylene recovery rate may achieve 99.5%.

Owner:CHINA PETROCHEMICAL CORP +1

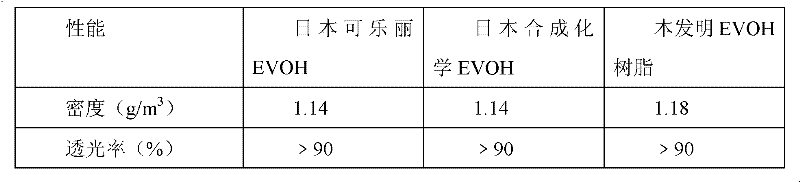

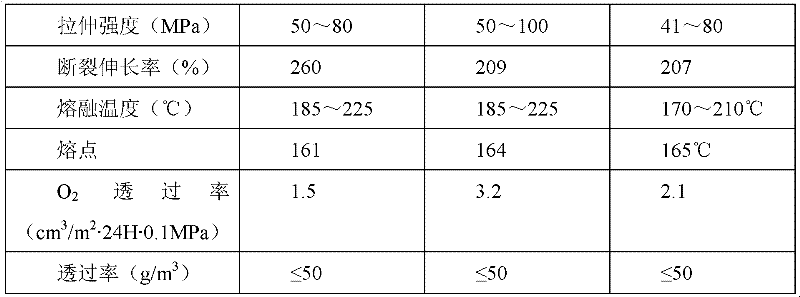

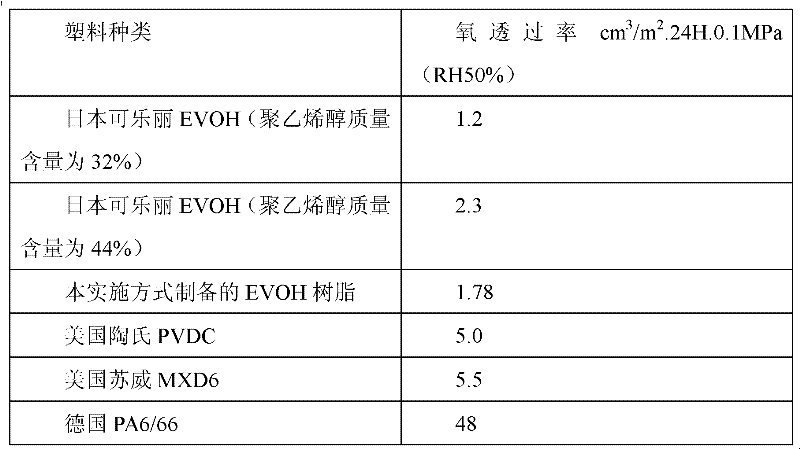

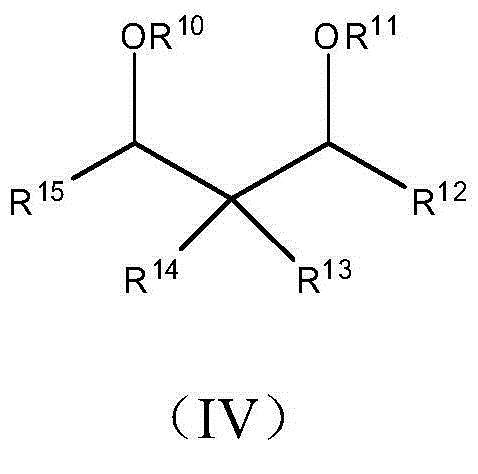

EVOH (ethylene vinyl alcohol) resin and preparation method thereof

The invention discloses an EVOH (ethylene vinyl alcohol) resin and a preparation method thereof and relates to a resin and a preparation method thereof, and the method provided by the invention can be used for solving the problems of complex process for the production of the EVOH resin and large production difficulty in traditional methods. The EVOH resin is prepared through the following steps: stirring polyvinyl alcohol, a plasticizer, an ethylene unsaturated monomer, maleic anhydride graft polypropylene resin, an initiator, a catalyst, an anti-yellowing agent and a surfactant, and then pelletizing the mixture in a double-screw extruder. The method provided by the invention is simple in process and small in equipment investment, and the EVOH resin has the advantage of stable quality.

Owner:WEIFANG HUAWEI MATERIALS TECH CO LTD

Power transmission products having enhanced properties

ActiveUS20060148990A1Improved compositionImprove pillingV-beltsFilm/foil adhesivesElastomerAlpha-olefin

The present invention is directed to the incorporation of functionalized polyethylenes, in amount of about 1% to 95% by weight based upon the weight of the total crosslinkable material, into ethylene alpha olefin elastomers , such as EPDM elastomer compositions, which are crosslinked by peroxides, which results in improved properties, such as hardness and modulus of elongation, and can result in improved higher abrasion resistance, wear resistance, coefficient of friction, tensile strength, and other properties through a broad temperature range, which are beneficial to power transmission products, such as power transmission belts.

Owner:CONTITECH USA INC

Thermoplastic olefin compositions and articles

A thermoplastic olefin (TPO) composition comprises (1) a major amount by weight of (a) a substantially linear homopolymer or copolymer of a C2–C10 α-olefin in major proportion to (b) a long chain branched a linear homopolymer or copolymer of a C2–C10 α-olefin, (2) a minor amount by weight of a cross linkable elastomer, and (3) at least one thermally decomposing free radical generating agent present in an amount sufficient to promote an increase in melt strength of the composition over that of the melt strength of the linear homopolymer or copolymer of a C2–C10 α-olefin alone and insufficient to substantially degrade the α-olefinic polymers. The TPO composition is prepared by melt blending the components at a temperature sufficient to melt said homopolymers or copolymers of a C2–C10 α-olefin and thermally decompose said agent. Articles are thermoformed from the thermoplastic olefin.

Owner:EXOUSIA IP LLC

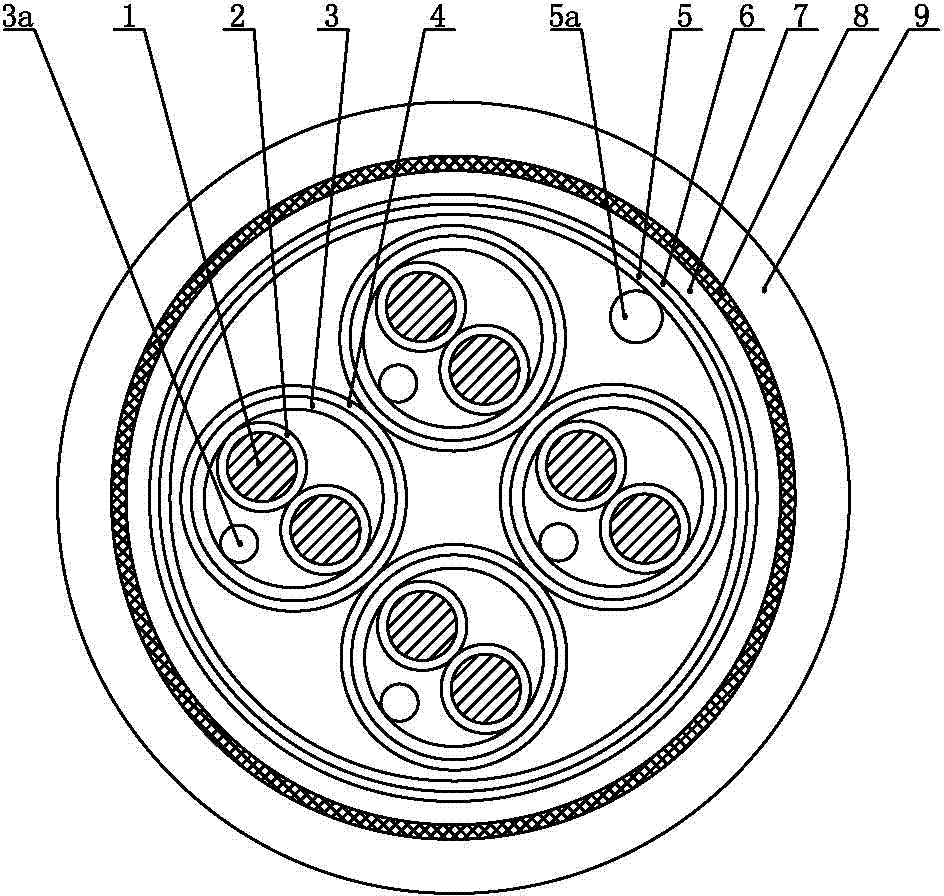

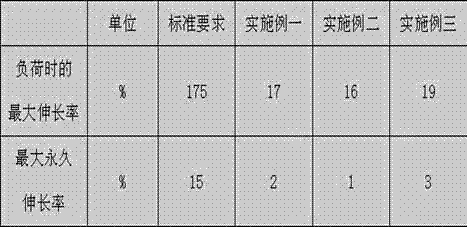

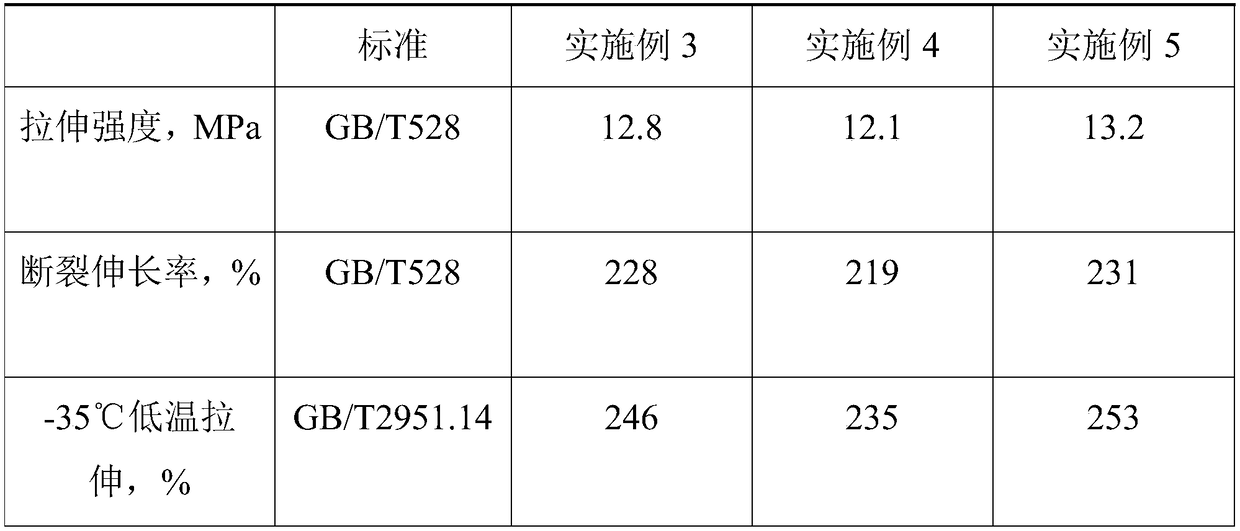

Low-temperature-resistant door/window sealing strip and preparation method thereof

The invention discloses a low-temperature-resistant door / window sealing strip which is formed by mixing a component A and a component B in a mass ratio of 2:1. The component A comprises modified ethylene propylene diene monomer rubber, a filler, a coupling agent, a plasticizer, a vulcanizing agent, a softening agent and an activator. The component B comprises the following components in parts by mass: styrene-butadiene rubber, a filler, a chain extender and an antioxidant. The invention also discloses a preparation method of the low-temperature-resistant door / window sealing strip. The preparation method is simple to operate and easy to implement, and has the advantage of low cost. The door / window sealing strip has the advantages of favorable cold resistance, favorable heat resistance, favorable aging resistance, favorable sealing property and longer service life.

Owner:SUZHOU TONGMING MACHINERY

Modified EPDM composition used in submerged pump cable rubber insulation

InactiveCN103509252AHigh mechanical strength and oil resistanceImprove electrical performanceRubber insulatorsPlastic/resin/waxes insulatorsParaffin oilsStearic acid

The invention relates to a rubber composition, and especially relates to an ethylene-propylene rubber composition used in submerged pump cable rubber insulation. The composition is characterized by comprising, by weight, 100 parts of EPDM, 10-15 parts of polyethylene powder, 5-10 parts of nano-scale zinc oxide, 1-2 parts of stearic acid, 1-1.5 parts of water repellent red lead powder (paint grade), 10-18 parts of paraffin oil 2280, 1.5-2 parts of a silane coupling agent A-172, 100-120 parts of silane-modified calcined clay, and 3.5-4 parts of a peroxide vulcanizing agent. EPDM and polyethylene powder in the above proportion are subjected to open milling; the other materials are added, and the mixture is subjected to mixing and open milling; and gstraining, tabletting, and slicing are carried out, such that the EPDM composition is obtained. With the EPDM composition, various performance requirements of export submerged pump cable can be completely satisfied.

Owner:SHANGHAI QIFAN CABLE CO LTD

High-strength titanium alloy steam turbine blade

InactiveCN108624783ALow costDoes not affect the chemical compositionAntifouling/underwater paintsBlade accessoriesEpoxyTitanium alloy

The invention discloses a high-strength titanium alloy steam turbine blade. The surface of the steam turbine blade is further provided with a protection layer, and the protection layer is prepared from, by mass, 10-15 parts of modified ethylene-propylene-diene monomer rubber, 15-20 parts of methyl phenyl silicone resin, 8-11 parts of organosilicon-modified epoxy resin, 5-7 parts of nanometer SiC powder, 13-15 parts of filler and pigment, 3-5 parts of dispersing agent, 10-15 parts of coupling agent, 13-15 parts of curing agent, 7-9 parts of defoaming agent and 1-3 parts of anti-mildew bactericide. The high-strength titanium alloy steam turbine blade has good strength, and is good in corrosion resistance, simple in preparation process, low in cost and long in service life.

Owner:南京赛达科技有限公司

Marine independent screening instrument cable capable of whitening and resisting ultraviolet and manufacturing method thereof

InactiveCN102969048AExcellent light aging performanceGood physical and mechanical propertiesRubber insulatorsInsulated cablesUltraviolet lightsEngineering

The invention relates to a marine independent screening instrument cable capable of whitening and resisting ultraviolet and a manufacturing method thereof. Whitening and ultraviolet-resisting ethylene propylene rubber insulation layers are extruded at the peripheries of tin-plating annealing stranded copper conductors to form insulation wire cores, every two insulation wire cores are stranded to form a stranded wire pair, a copper foil polyester composite belt screening layer is lapped at the periphery of each group of stranded wire pair, copper foil surfaces are inward, tin-plating stranded steel drainage wires are arranged on the inner sides of the copper foil polyester composite belt screening layers, penetrate through the full length of each stranded pair and cling together with the copper foil surfaces; and a polyester belt is lapped at the periphery of each copper foil polyester composite belt screening layer to form a stranded group; and the all stranded groups are stranded rightwards according to the 16-24 times of stranded node ratio to form a cable core, an inner protecting bush is extruded at the periphery of the cable core, a copper alloy wire knitting armor layer covers the periphery of the inner protecting bush, and an outer protecting bush is extruded at the periphery of the copper alloy wire knitting armor layer. The independent screening instrument cable has the advantages that the color of an insulation layer is white, the mechanical property is good, the performance of resisting aging caused by ultraviolet light is excellent, and the service life is long.

Owner:JIANGSU YUANYANG DONGZE CABLE

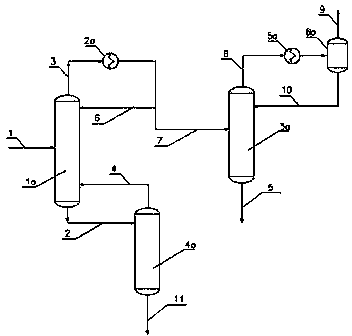

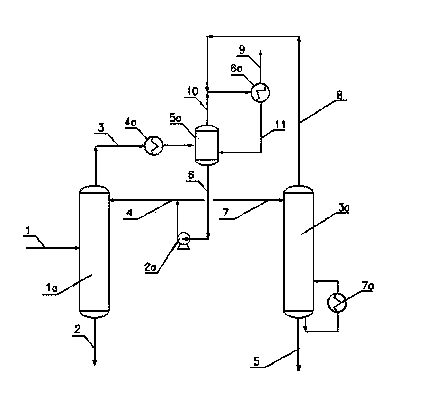

Separation refinement method for ethylene preparation through biomass ethanol dehydration

ActiveCN103420752AHigh yieldEasy to operateDistillation purification/separationGas phaseDistillation

The present invention relates to a separation refinement method for ethylene preparation through biomass ethanol dehydration, wherein problems of product separation and ethylene yield increase in ethylene preparation through ethanol dehydration, especially the technical problem of recovery of ethylene from a light component stream and a heavy component material, are mainly solved with the present invention. According to the present invention, the three tower process technical scheme is adopted, wherein the tower kettle of an ethylene rectification tower separates an ethylene-containing heavy component, the ethylene-containing heavy component enters the top of a steam stripping distillation tower, light component-containing ethylene is separated from the tower top, and is conveyed to the middle portion of a light component tower, the vapor phase on the steam stripping distillation tower top returns to the middle-lower portion of the ethylene rectification tower, a heavy component is discharged from the tower bottom, a stream on the light component rectification tower top is subjected to partial condensation, the liquid phase is refluxed, the gas phase is externally discharged, and the ethylene product is obtained from the tower kettle. With the technical scheme, the problems in the prior art are well solved, and the separation refinement method can be used for industrial production of ethylene preparation through ethanol dehydration.

Owner:CHINA PETROLEUM & CHEM CORP +1

Marine integral screening instrument cable capable of whitening and resisting ultraviolet and manufacturing method thereof

InactiveCN102969056AExcellent light aging performanceGood physical and mechanical propertiesRubber insulatorsInsulated cablesCopper foilScreening instrument

The invention relates to a marine integral screening instrument cable capable of whitening and resisting ultraviolet and a manufacturing method thereof. Whitening and ultraviolet-resisting ethylene propylene rubber insulation layers are extruded at the peripheries of tin-plating annealing stranded copper conductors to form insulation wire cores, every two insulation wire cores are stranded to form a stranded wire pair, the all stranded wire pairs are stranded rightwards according to the 16-24 times of stranded node ratio to form a cable core, a copper foil polyester composite belt screening layer is lapped at the periphery of the cable core, a copper foil surface is inward, a tin-plating stranded steel drainage wire is arranged on the inner side of the copper foil polyester composite belt screening layer, penetrates through the full length of each stranded pair and clings together with the copper foil surface; and a polyester belt is lapped at the periphery of the copper foil polyester composite belt screening layer, an inner protecting bush is extruded at the periphery of the polyester belt, a copper alloy wire knitting armor layer covers the periphery of the inner protecting bush, and an outer protecting bush is extruded at the periphery of the copper alloy wire knitting armor layer. The integral screening instrument cable has the advantages that the color of an insulation layer is white, the mechanical property is good, the performance of resisting aging caused by ultraviolet light is excellent, and the service life is long.

Owner:JIANGSU YUANYANG DONGZE CABLE

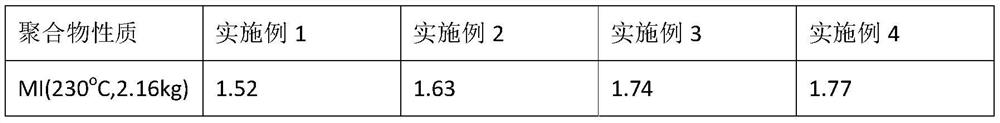

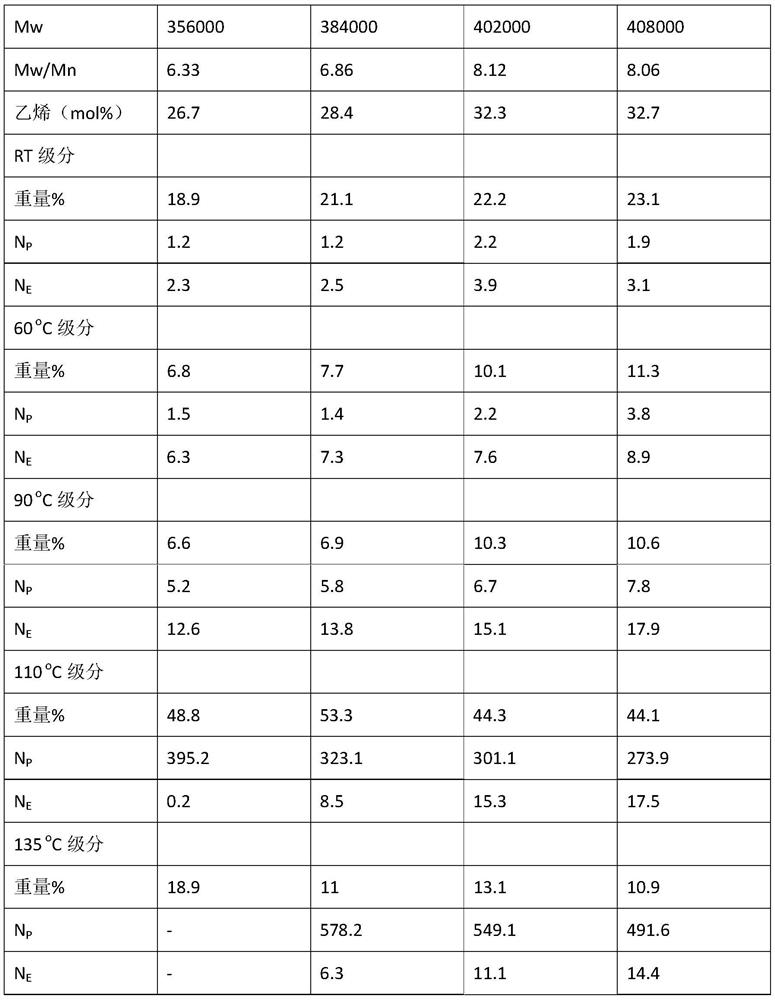

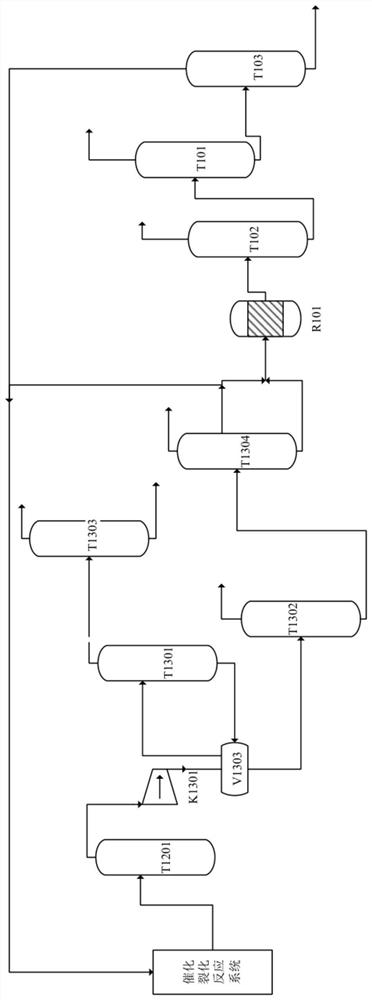

Propylene copolymer and preparation method thereof

ActiveCN104558336AGuaranteed polymerization activityReduce concentrationChemical industryPolymer scienceZiegler–Natta catalyst

The invention discloses a preparation method of a propylene copolymer with low energy consumption and high ethylene content. The method disclosed by the invention adopts a gas phase multi-temperature range technology, a second external electron donor is selectively added under the presence of a highly active ziegler-natta catalyst, so that propylene, or propylene and ethylene can perform propylene homopolymerization and copolymerization in at least three continuous polymerization areas of one or more polymerization reactors. The method disclosed by the invention adopts the gas phase multi-temperature range technology, at a low temperature area, most of polymerization activity of the catalyst is ensured, and at a high-temperature area, the heat exchanger efficiency of a heat exchanger is improved; in addition, the second external electron donor is selectively added, and the second external electron donor is matched with a solid catalyst component, containing titanium, of the ziegler-natta catalyst, so that the reactivity ratio of ethylene in the polyreaction can be effectively increased, the high ethylene content of products is ensured, and besides, the concentration of the ethylene in gas phase composition is reduced; therefore, the energy consumption during production is reduced, and the production capacity of the conventional device is reached.

Owner:CHINA PETROLEUM & CHEM CORP +1

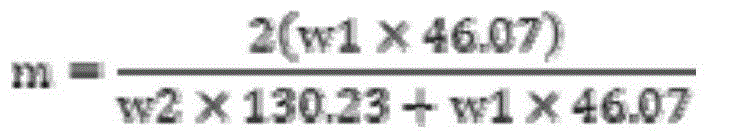

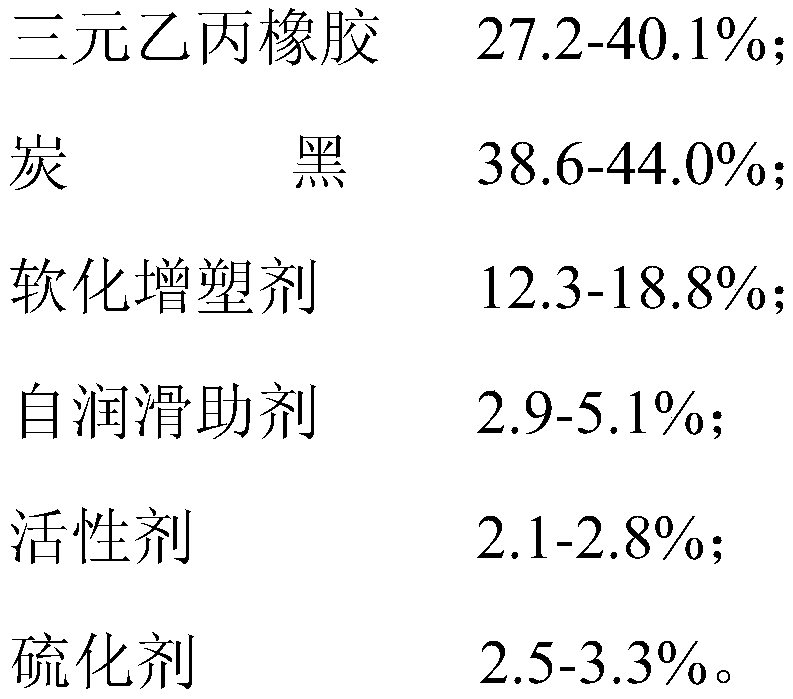

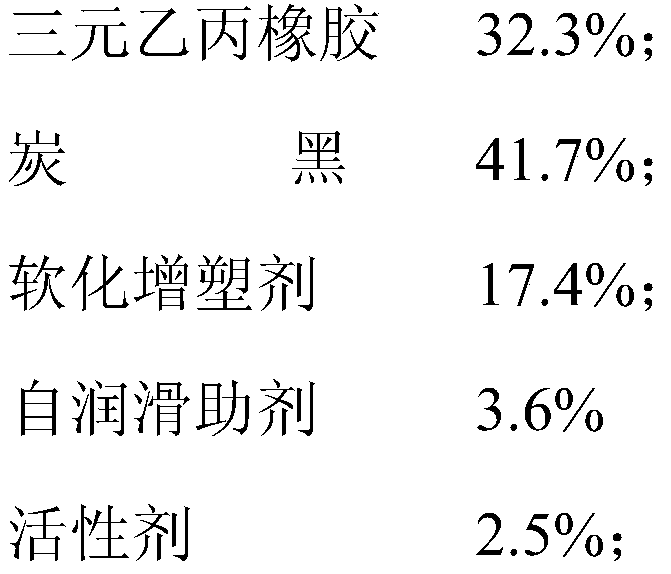

Environmentally-friendly self-lubricating wiring harness sheath EPDM and preparation method thereof

InactiveCN110591237AGood physical and mechanical propertiesMeet the performancePolymer scienceActive agent

The invention discloses environmentally-friendly self-lubricating wiring harness sheath EPDM, which comprises, by weight, 27.2-40.1% of ethylene propylene diene monomer rubber, 38.6-44.0% of carbon black, 12.3-18.8% of a softening plasticizer, 2.1-2.8% of an active agent, 2.9-5.1% of a self-lubricating auxiliary agent, and 2.5-3.3% of a vulcanizing agent. According to the present invention, the environmentally-friendly self-lubricating wiring harness sheath EPDM is an environmentally-friendly wiring harness sheath EPDM rubber material with excellent physical and mechanical properties and extremely low friction coefficient.

Owner:TAICANG GUANLIAN POLYMERIC MATERIAL

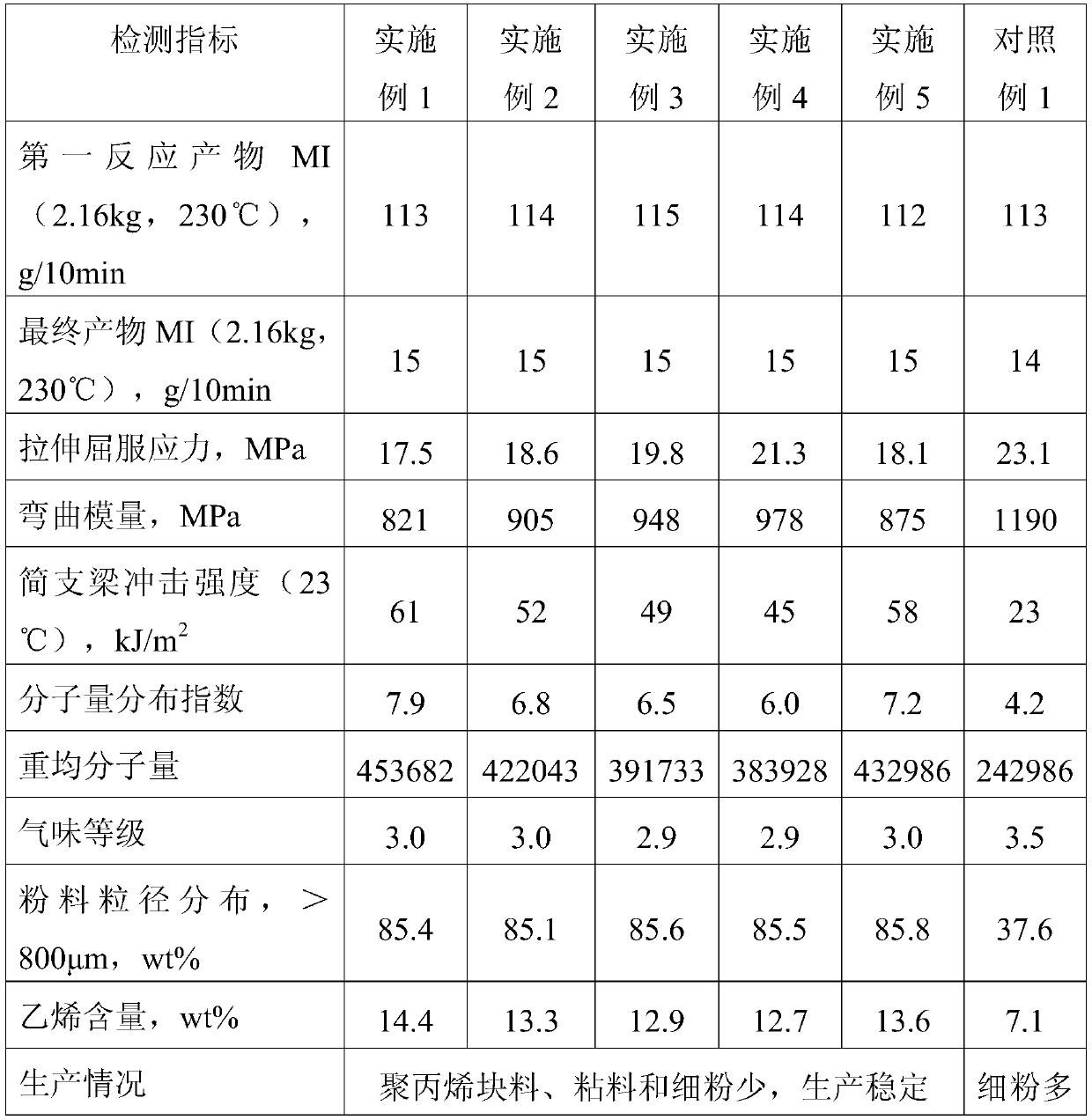

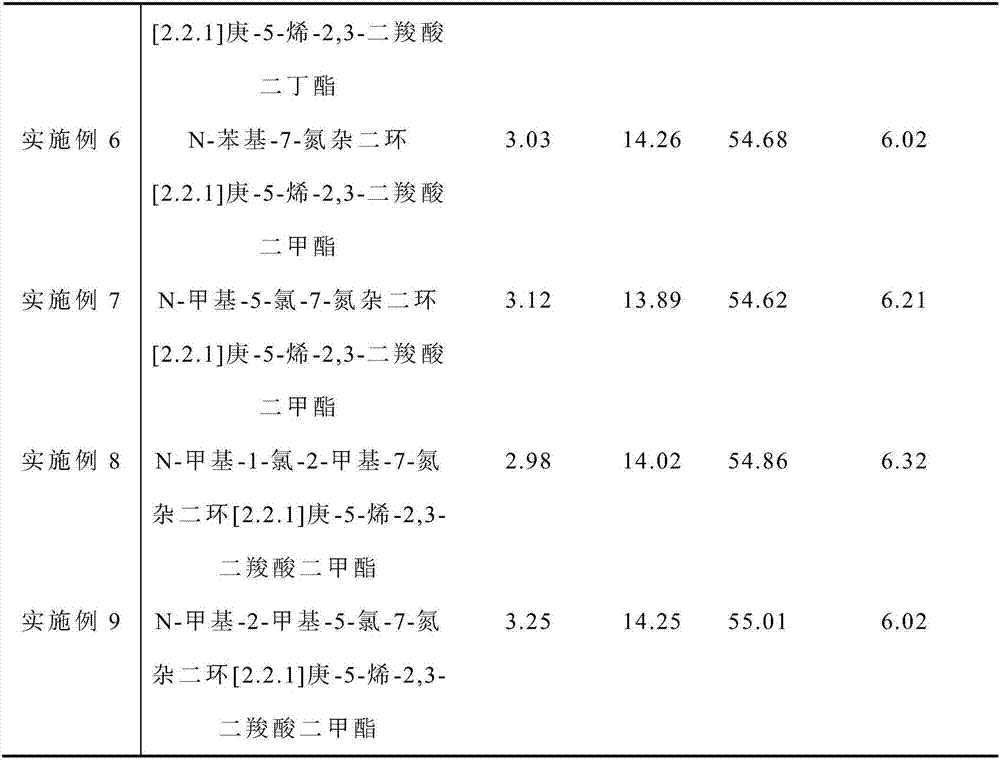

Impact resistant copolymerized polypropylene and preparation method thereof

The invention provides impact resistant copolymerized polypropylene and a preparation method thereof. The preparation method of the impact resistant copolymerized polypropylene includes the steps: adding a main catalyst, a cocatalyst and a modifier into a first gas-phase reactor, introducing propylene and hydrogen into the first gas-phase reactor, and carrying out a first polymerization reaction to obtain a first reaction product; collecting a solid part of the first reaction product, adding the solid part of the first reaction product into a second gas-phase reactor, and introducing ethylene,propylene and hydrogen into the second gas-phase reactor, carrying out a second polymerization reaction, and collecting a solid part of the second reaction product, to prepare the impact resistant copolymerized polypropylene. The activity of the main catalyst is 10000-20000 g / g. The preparation method can ensure the long-term stable production of the impact resistant copolymerized polypropylene,the impact strength of a simply supported beam of the impact resistant copolymerized polypropylene is more than or equal to 45 kJ / m<2>, the melt index is 14-19 g / 10 min, and the odor grade is less than or equal to 3. The impact resistant copolymerized polypropylene with high impact resistance, middle melt index and low odor is prepared.

Owner:PETROCHINA CO LTD

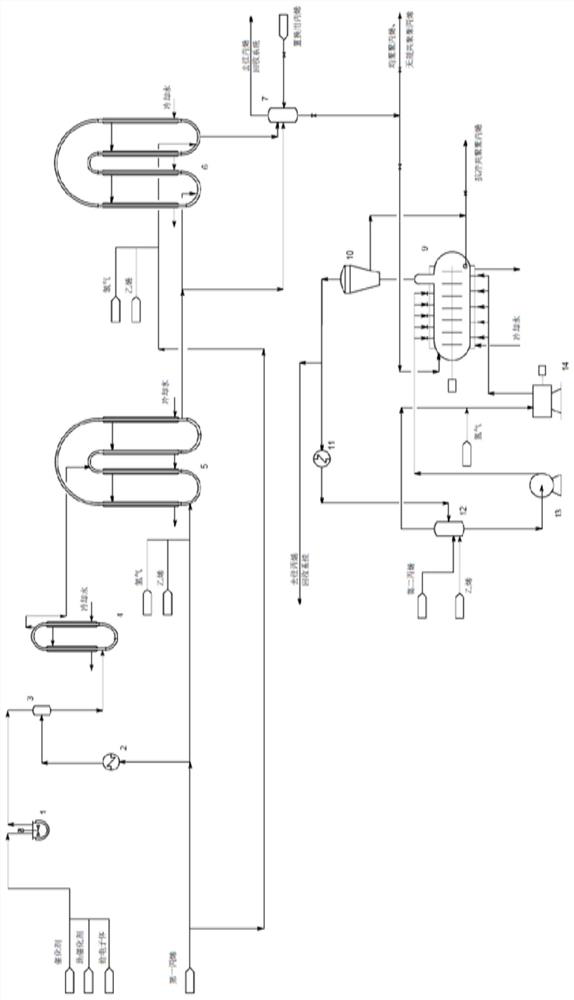

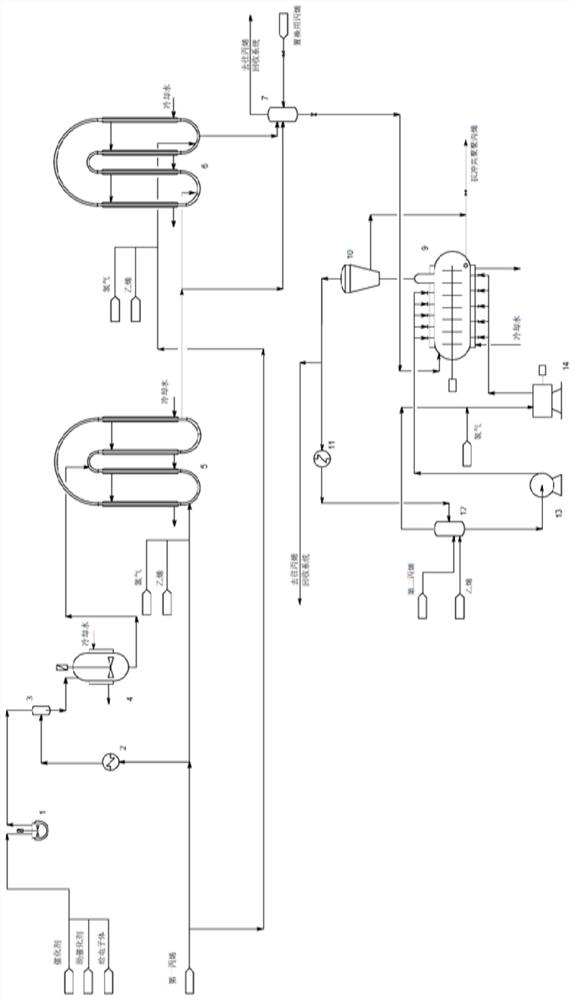

Preparation method of polypropylene

The invention relates to a preparation method of polypropylene. The method comprises the following steps: cooling first liquid-phase propylene, mixing the cooled first liquid-phase propylene with a polypropylene catalyst, and carrying out low-temperature prepolymerization reaction, feeding an obtained slurry containing the low-molecular-weight polypropylene prepolymer into a double-loop reactor, carrying out liquid-phase bulk slurry polymerization on the slurry and supplemented second liquid-phase propylene, hydrogen and ethylene monomers, and feeding part or all of polypropylene slurry flowing out of the first loop reactor into a second loop reactor, carrying out directflash evaporation on the polypropylene slurry flowing out of the second loop reactor to remove non-condensable gas and most of propylene monomers, and carrying out purification and granulationan obtained polypropylene intermediate to obtain the product; or carrying out copolymerization reaction on the polypropylene intermediate, and then carrying out powder purification and granulation to obtain the product. According to the preparation method disclosed by the invention, high-melt-index / high-rigidity and high-rubber-content impact-resistant co-polypropylene can be produced through flexible switching of devices, and meanwhile, high-isotacticity homo-polypropylene and random co-polypropylene can also be produced.

Owner:PETROCHINA CO LTD

Separating and refining method for preparing ethylene by dehydrating biomass ethanol

The invention relates to a separating and refining method for preparing ethylene by dehydrating biomass ethanol, which is mainly used for solving the problems that a process for separating a product in preparation of ethylene from dehydrating ethanol and a way for increasing the yield of the ethylene are not related in the previous literatures, particularly the technical problem of the recovery of the ethylene from light-component material flow and heavy-component materials. According to the separating and refining method disclosed by the invention, the technical scheme of a three-tower flow is adopted to well solve the problems. According to the technical scheme, the method comprises the following steps: separating ethylene-containing heavy components out of the tower kettle of an ethylene refining tower, feeding the ethylene-containing heavy components into the top of a stripping tower, separating ethylene containing light components out of the tower top, and feeding to the middle part of a light-component tower; returning a vapor phase on the top of the stripping tower to the middle lower part of the ethylene refining tower, and discharging heavy components from the tower bottom; and partially condensing top material flow of a light-component refining tower, refluxing a liquid phase, and discharging a gas phase to obtain an ethylene product from the tower kettle. The method can be applied to industrial production of ethylene prepared by dehydrating ethanol.

Owner:CHINA PETROLEUM & CHEM CORP +1

Whitening ultraviolet-proof ethylene-propylene rubber insulation power cable for ships and manufacturing method thereof

InactiveCN102969064AExcellent light aging performanceGood physical and mechanical propertiesPower cablesCable/conductor manufactureCopper conductorInsulation layer

The invention relates to a whitening ultraviolet-proof ethylene-propylene rubber insulation power cable for ships and a manufacturing method thereof. The cable is characterized in that a whitening ultraviolet-proof ethylene-propylene rubber insulation layer is extruded at the periphery of a tin-plated annealed stranded copper conductor to form an insulation wire core; a plurality of insulation wire cores are stranded to the right to form a cable core; and then an inner lining layer is extruded, a copper alloy wire weaving armor layer is coated, and an outer sheath is extruded successively. The insulation layer is prepared from the following raw material components: 12 parts of Keltan5508, 8 parts of Keltan21, 0.4-0.6 parts of TAIC, 0.5-0.8 parts of DCP (Dicumyl Peroxide), 0.3 -0.6 part of Ager MB, 0.1-0.2 parts of anti-aging agent 2246, 0.8-1.2 parts of oxidation zinc, 0.1-0.3 parts of stearic acid; 1-1.5 parts of a rutile-type titanium dioxide, 10-12 parts of lightweight calcium carbonate, 10-12 parts of ultrafine talcum powder, 2-3 parts of 38# cylinder oil, 2-3 parts of vapor-phase-method hydrated silica, 0.05-0.1 parts of ultraviolet absorbent UV-326, and 0.1-0.3 parts of coupling agent A-174. The insulation layer of the cable is white in color, good in mechanical property, excellent in anti-ultraviolet irradiation and anti-aging performance, and long in service life.

Owner:JIANGSU YUANYANG DONGZE CABLE

Olefin disproportionation method

InactiveCN107973686AImprove stabilityExtend your lifeMolecular sieve catalystsMolecular sieve catalystChemistryCost (economic)

The invention relates to an olefin disproportionation method, wherein the used catalyst composition comprises a disproportionation catalyst and an isomerization catalyst, and a mass ratio of the disproportionation catalyst to the isomerization catalyst is (2:1)-(1:15). In the prior art, the technology is single, is only used for the propylene preparation technology through disproportionation of ethylene and butylene, and cannot be flexibly adjusted along with the price fluctuation of the product on the market, and the catalyst is easily deactivated in the propylene disproportionation reaction.A purpose of the present invention is mainly to solve the problems in the prior art. According to the present invention, with the method, the product structure can be flexibly adjusted according to the price fluctuation of the product on the market while the device, the catalyst and the process during the adjusting remain the unchanged states, the economic cost is low, and the method can be usedfor the industrial production of olefin disproportionation reactions.

Owner:CHINA PETROLEUM & CHEM CORP +1

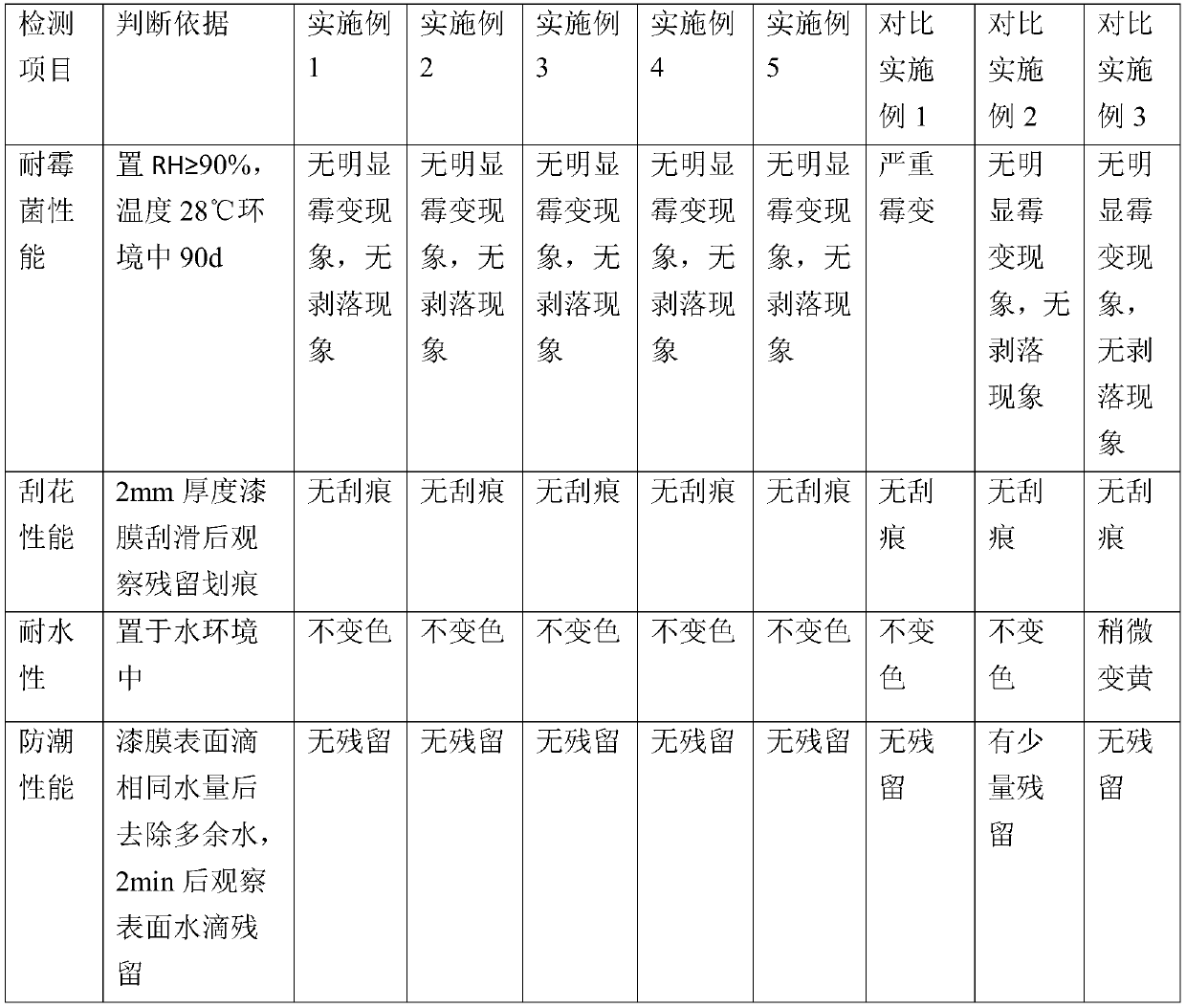

Moisture-proof and mildew-proof dry powder coating

InactiveCN111334102AImprove mildew resistanceImprove scratch resistanceAntifouling/underwater paintsPaints with biocidesCelluloseKaolin clay

The invention discloses moisture-proof and mildew-proof dry powder coating. The coating is prepared from the following raw materials in percentage by weight: 28 to 33% of white cement; 10 to 18% of white stone powder; 15%-17.5% of sepiolite, 8%-10% of diatomite, 7%-10% of titanium dioxide, 8%-10% of calcium oxide, 3%-5% of kaolin, 10%-13% of redispersible latex powder, 0.05%-0.07% of etherified starch, 0.3%-0.5% of a heterocyclic compound mildew preventive, 1.5%-1.8% of a photocatalyst and 0.85%-1% of cellulose. The components of the dry powder coating provided by the invention are matched with each other; the dry powder coating has excellent mildew-proof performance and scratch-proof performance, non-discoloring when meeting water, color stability, capability of adsorbing harmful substances such as indoor formaldehyde effectively, excellent environmental protection performance, and extremely high adsorption performance because the sepiolite and the diatomite are mutually matched and have a synergistic effect; water vapor in air is adsorbed in pores and cannot be adsorbed into water drops on the surface of the coating in the 'Huinan' days, the dryness of the surface of the coatingis guaranteed, people cannot feel uncomfortable, when the temperature rises again, water in the pores evaporates, and the coating has good moisture-proof performance.

Owner:广西正花涂料有限公司

Separation refining method for ethylene preparation through ethanol dehydration

ActiveCN103772102AImprove ethylene yieldReduce energy consumptionDistillation purification/separationHigh energyHydrocarbon

The invention relates to a separation refining method for ethylene preparation through ethanol dehydration, and mainly solves the problems of separation of products in ethylene preparation through ethanol dehydration, especially low ethylene yield and high energy consumption which exist in former literatures. A mixture containing ethylene, ethane and C3 and C3+ hydrocarbons and light components go into an ethylene rectification tower, light component-containing ethylene is separated out at the tower top, the gas phase goes into a light component-removing tower, and a heavy component rich in ethylene is discharged from a tower kettle; after the light component-containing gas-phase ethylene is rectified by the light component-removing tower, a tower top gas phase is congealed to separate out gas-phase light components, the congealed liquid is used as a reflux and returns to the light component-removing tower, a bottom liquid phase in the light component-removing tower is partially used as a reflux and sent to the top of the ethylene rectification tower through compression by a pump, and the rest is an ethylene product; the heavy component rich in ethylene goes into the top of a heavy component steam stripping distillation tower, a tower top gas phase of the steam stripping distillation tower returns to the middle-lower part of the ethylene rectification tower, and a heavy component containing a little ethylene is obtained at the tower bottom. With adopting of the above technical scheme, the problems in the prior art are relatively well solved, and the separation refining method can be used for industrial production of ethylene preparation through ethanol dehydration.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cable sheath rubber material and preparation method thereof

InactiveCN109135074AImprove low temperature resistanceImprove plasticizing effectPlastic/resin/waxes insulatorsParaffin waxRubber material

The invention provides a cable sheath rubber material which comprises, by weight, 70-80 parts of ethylene-propylene-diene monomer rubber, 10-15 parts of butyl rubber, 16-22 parts of ethylene-vinyl acetate copolymer, 3-9 parts of vulcanizing agents, 1-3 parts of accelerators, 4-8 parts of paraffin wax, 8-16 parts of plasticizers, 2-6 parts of lubricating agents, 8-16 parts of carbon black, 5-10 parts of magnesium aluminum hydrotalcite powder and 4-8 parts of fillers. The plasticizers are mainly prepared from polyether silicone oil, butyl oleate, nano-silicon dioxide and silane coupling agents.A preparation method of the cable sheath rubber material includes the steps: placing raw materials into an internal mixer to mix the raw materials; transferring the mixed raw materials into an open mill to thin and roll the raw materials; placing thinned and rolled rubber reels into a three-roller page rolling machine to roll and cut the reels; opening cooling water in a cooling roller; enabling cut rubber sheets to penetrate the cooling roller and then penetrate an isolation powder tank to prepare rubber sheets. The cable sheath rubber material is good in cold resistance and softness and hasexcellent tensile strength and breaking elongation.

Owner:安庆市泽烨新材料技术推广服务有限公司

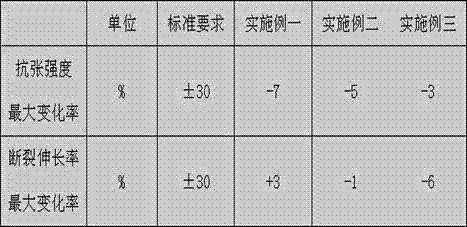

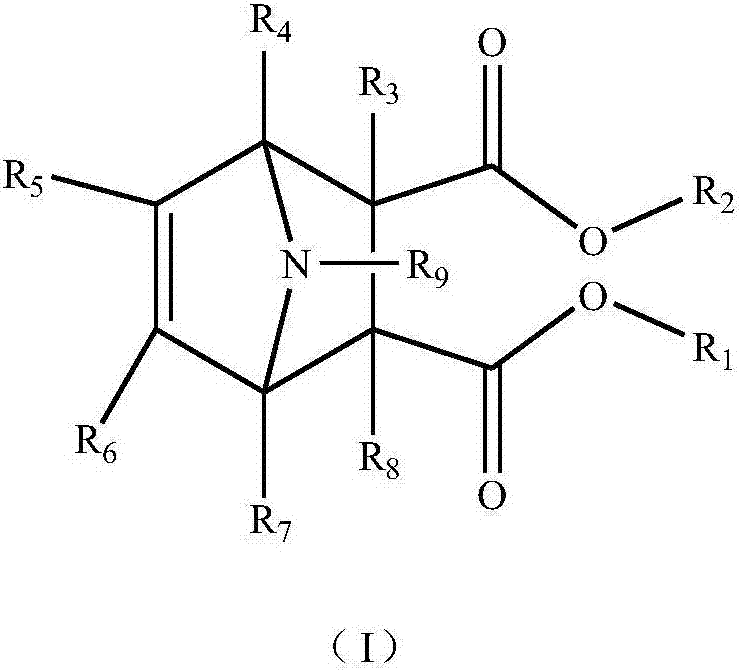

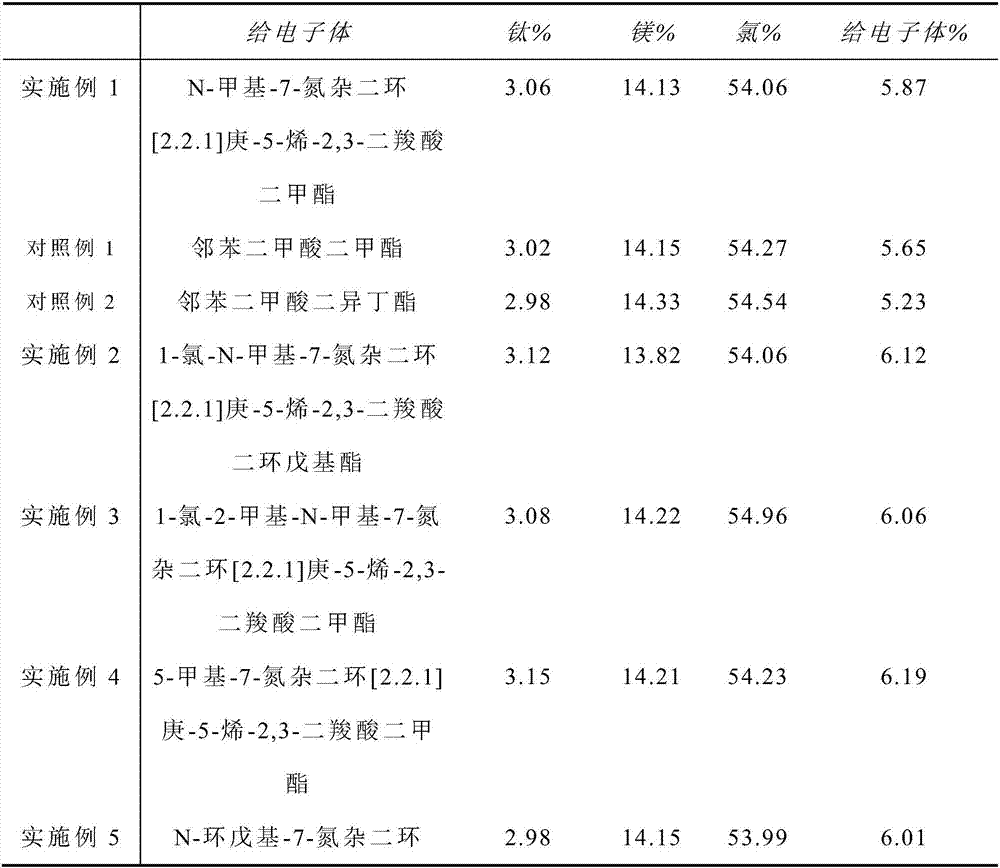

Random copolymer polypropylene catalyst and preparation method thereof

ActiveCN107383256AHigh polymerization activityHigh ethylene contentBulk chemical productionPolypropyleneMagnesium

The invention provides a random copolymer polypropylene catalyst. The random copolymer polypropylene catalyst comprises, by weight, 10-25% of magnesium, 1-15% of titanium, 40-60% of halogens and 1-20% of an internal electron donor. The internal electron donor is a 7-oxabicyclo[2. 2. 1]hepta-5-ene-2, 3-dicarboximide compound. The random copolymer polypropylene catalyst has high catalytic activity and stereoregularity. In olefin polymerization and especially in propylene polymerization, ultra-high polymerization activity of the ether catalyst is kept and the molecular weight distribution of the polypropylene is remarkably improved.

Owner:谢炳

A heterogeneous propylene copolymer and its continuous gas-phase fluidized bed polymerization process

A heterophasic propylene copolymer produced by a continuous gas phase fluidized bed polymerization process which produces a heterophasic propylene copolymer with a high ethylene or rubbery content without fouling and without loss of yield. The heterophasic propylene copolymer obtained by the method has relatively high ethylene content and rubber component content, and exhibits excellent impact resistance and a balance between rigidity and toughness.

Owner:JIUTAI ENERGY ZHUNGEER CO LTD

Catalytic cracking and gasoline hydrogenation combined method

ActiveCN111826198AHigh yieldHigh propylene contentTreatment with hydrotreatment processesHydrocarbon oils treatment productsNaphthaDistillation

The invention provides a catalytic cracking and gasoline hydrogenation combined method which comprises the following steps: carrying out a catalytic cracking reaction on a catalytic cracking raw material, and sequentially carrying out fractionation, separation, desorption, absorption and stabilization to obtain dry gas, liquefied gas, light naphtha, diesel oil and slurry oil; 60-70 wt% of light naphtha and gasoline are sequentially subjected to a gasoline hydrogenation reaction and gasoline hydrogenation separation, and a delivery material and a recycling material are obtained, wherein the distillation range of the light naphtha controls the content of C3 + C4 to be less than 1wt% and the dry point to be 70 DEG C, the distillation range of the recycled material controls the initial boilingpoint to be more than 40 DEG C and the final boiling point to be 90-101 DEG C; 30%-40% of the light naphtha and the recycled material return to continue the catalytic cracking reaction. According tothe method, 30-40% of light naphtha, a recycled material and a catalytic cracking raw material are subjected to a catalytic cracking reaction together so that the yield of liquefied gas and the content of propylene in the liquefied gas are both increased, and the content of ethylene in dry gas is also obviously increased.

Owner:SHANDONG JINGBO PETROCHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com