A heterogeneous propylene copolymer and its continuous gas-phase fluidized bed polymerization process

A technology of propylene copolymer and comonomer, applied in the field of heterophasic propylene copolymer, can solve the problems such as insufficient material residence time, limited control range of production process, and difficulty in meeting the requirements of the rubber phase content of impact-resistant polypropylene products. , to achieve excellent impact resistance and the effect of rigidity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

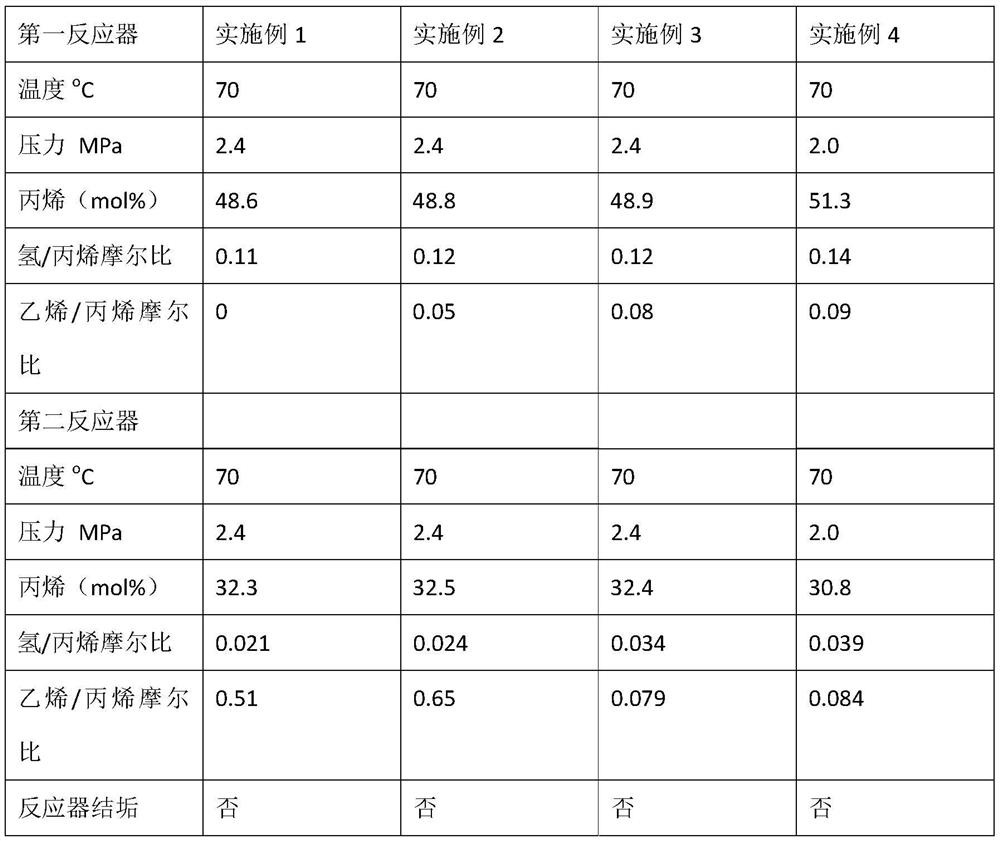

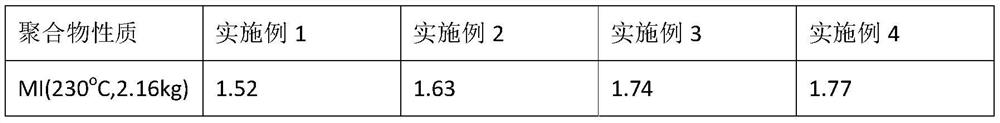

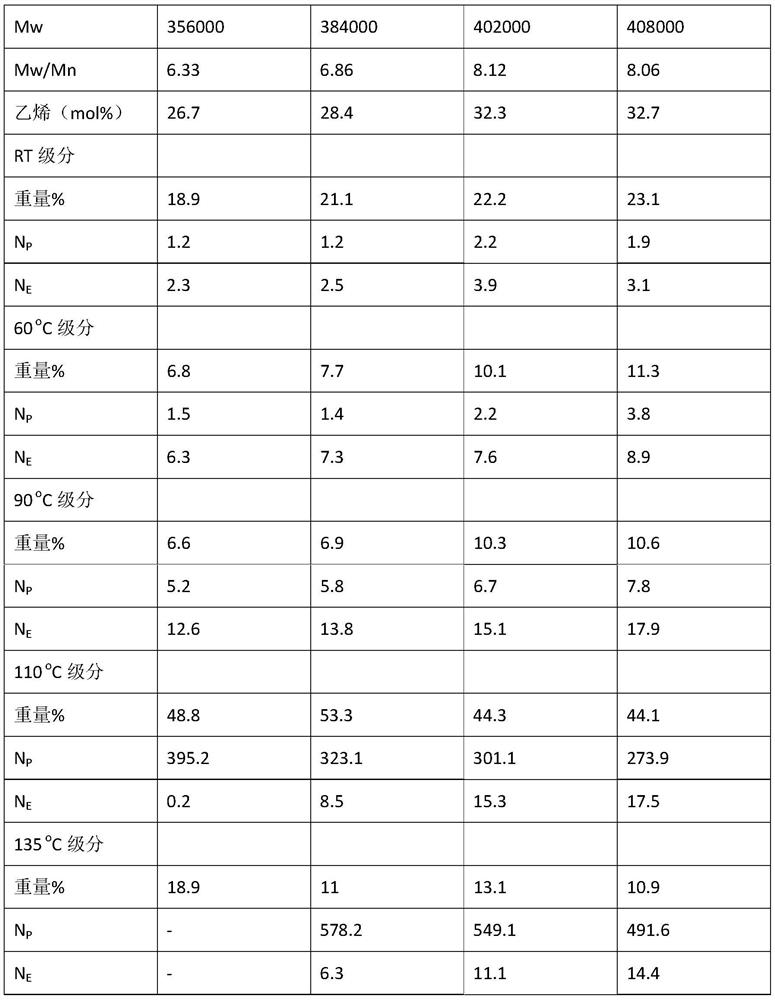

[0059]In the titanium-containing solid catalyst component used in the examples, Ti is 2.6 wt%, Mg is 17.0 wt%, and internal electron donor dibutyl phthalate is 15.2 wt%. In the first gas-phase fluidized bed reactor, add titanium-containing solid catalyst components, triethylaluminum, external electron donor diisopropyldimethoxysilane, propylene, and optionally ethylene to carry out polymerization. Wherein, the feeding rate of titanium-containing solid catalytic component is respectively 0.66g / hr, Al / Ti (mol / mol)=168.33, Al / Si (mol / mol)=6.21; Reactor material level 90%, polymerization time 90 minutes, obtain crystalline propylene polymer;

[0060] In the second gas-phase fluidized bed reactor, in the presence of a crystalline propylene polymer, ethylene and propylene are fed for polymerization. The material level in the reactor was 45%, and the polymerization time was 50 minutes to obtain a heterophasic propylene copolymer. The specific process conditions are shown in Table 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com