Separation refining method for ethylene preparation through ethanol dehydration

A technology of ethanol dehydration and refining method, applied in the direction of distillation purification/separation, organic chemistry, etc., which can solve the problems of high energy consumption, complicated process, low recovery efficiency, etc., and achieve improved ethylene yield, good technical effect, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

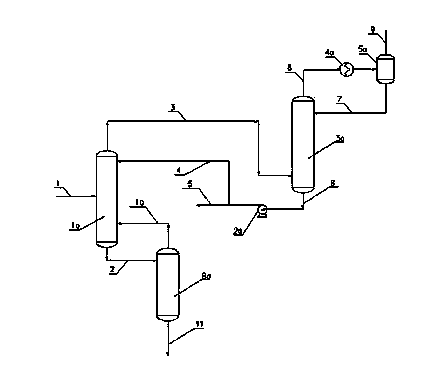

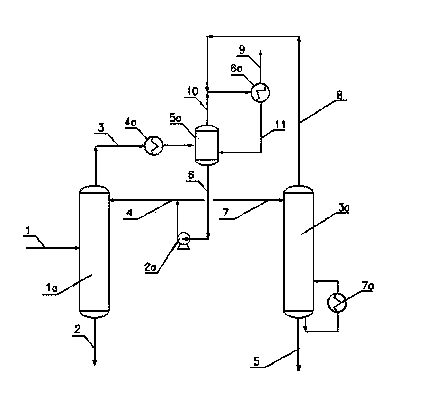

Method used

Image

Examples

Embodiment 1

[0019] Crude ethylene from the ethylene drying system enters the ethylene rectification tower for separation, ethylene containing light components is separated at the top of the tower, and heavy components are separated at the bottom of the tower. The flow rate of each component of crude ethylene is: hydrogen 0.070 kg / h, methane 0.070 kg / h, carbon monoxide 0.557 kg / h, ethylene 1274.518 kg / h, ethane 7.060 kg / h, propane 1.555 kg / h, acetaldehyde 0.113 kg / h Hours, ether 5.631 kg / hour, heavy component 33.957 kg / hour. The weight fraction of the ethylene rectification tower still is 83.977 kg / h, of which ethylene is 18.618 kg / h. The vapor phase at the top of the ethylene rectification tower enters the bottom of the light component removal tower with a flow rate of 5060.536 kg / h. The temperature at the top of the ethylene rectification tower is -24.8°C, the pressure is 2.15MPaG, the temperature at the bottom of the tower is 9.5°C, the number of theoretical plates in the whole tower i...

Embodiment 2

[0025] Same as Example 1, only change the theoretical number of stages of the ethylene rectification tower: the number of theoretical plates in the whole column is 92, the feeding position is in the middle and lower part, and the others are the same as Example 1. The weight fraction of the ethylene rectifying tower still is 84.035 kg / h, of which ethylene is 18.631 kg / h. The vapor phase flow rate at the top of the ethylene rectification tower is 5061.121 kg / h, the top temperature of the ethylene rectification tower is -24.8°C, the pressure is 2.15MPaG, and the temperature at the bottom of the tower is 9.5°C.

[0026] The material mainly containing ethylene steamed from the top of the stripping distillation tower is recycled into the lower part of the ethylene rectification tower with a flow rate of 34.036 kg / h, and the discharge from the bottom of the tower mainly contains ethane and C 3 + The mixture, the flow rate is 50.0 kg / hour, which contains 1.686 kg / hour of ethylene. T...

Embodiment 3

[0031] Same as embodiment 1, only change the theoretical number of stages of the stripping distillation tower: the theoretical plate number of the whole tower is 20, others are the same as embodiment 1. The weight fraction in the bottom of the ethylene distillation tower is 82.667 kg / h, of which ethylene is 18.327 kg / h. The vapor phase flow rate at the top of the ethylene rectification tower is 5059.727 kg / h, the temperature at the top of the ethylene rectification tower is -24.8°C, the pressure is 2.15MPaG, and the temperature at the bottom of the tower is 10.0°C.

[0032] The material mainly containing ethylene steamed from the top of the stripping distillation tower is circulated into the lower part of the ethylene rectification tower with a flow rate of 32.667 kg / h, and the discharge from the bottom of the tower mainly contains ethane and C 3 + The mixture, the flow rate is 50.0 kg / hour, which contains 1.691 kg / hour of ethylene. The temperature at the top of the strippin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com