Catalyst for preparing ethylene by selective hydrogenation of acetylene, preparation method and application

A catalyst and selective technology, applied in catalyst activation/preparation, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of high cost and high energy consumption, and achieve the effects of long service life, low cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

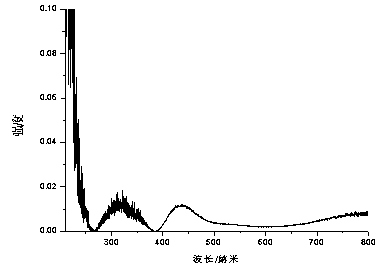

Image

Examples

Embodiment 1

[0024] Dissolve a certain amount of soluble nickel salt (nitrate) in water to obtain a nickel salt solution, then fully stir with an organic amine (diethylenetriamine) complexing agent for 30 minutes, and then follow the H 2 0:Si0 2 =20, Ni:Si0 2 =0.08, NaOH:Si0 2 =0.7, Al:Si0 2 The ratio of =0.1 was added sequentially to sodium metaaluminate, sodium hydroxide and silica sol and fully stirred for 100 minutes to obtain an initial gel.

[0025] Put the initial gel into the autoclave, statically crystallize at 120°C for 100h, cool to room temperature, filter and wash the product until neutral, dry it in an oven at 100°C for 12h, and then bake it in a muffle furnace at 550°C for 6h .

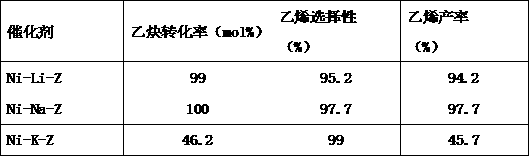

[0026] Put the calcined samples into 1mol / L lithium nitrate, sodium nitrate and potassium nitrate solutions respectively, conduct ion exchange for 12 hours in a water bath at 80°C, dry and calcinate to obtain Ni-Li-silicon-aluminum molecular sieves (named as Ni- Li-Z), Ni-Na-silicon-alumina mol...

Embodiment 2

[0035] The catalyst used in this example is Ni-Na-Z. The influence of the continuous reaction time on the selective hydrogenation activity of Ni-Na-Z catalyst in acetylene was investigated. The catalytic performance evaluation is shown in Table 2:

[0036] Table 2 Effect of continuous reaction time on the activity of Ni-Na-Z in the selective hydrogenation of acetylene

[0037]

[0038] The results of catalytic performance evaluation show that within a certain time range, as the continuous reaction time increases, the conversion rate of acetylene and the selectivity of ethylene can remain relatively stable, and when the reaction time reaches 40h, the catalytic activity decreases slightly, indicating that Ni- The catalyst of Na-Z system has excellent catalytic stability.

Embodiment 3

[0040] The catalyst used in this example is Ni-Na-Z. The influence of different ratios of hydrogen and acetylene on the Ni-Na-Z catalyst's selective hydrogenation activity of acetylene was investigated. The catalytic performance evaluation is shown in Table 3:

[0041] Table 3 Effects of different hydrogen-alkyne ratios on the activity of Ni-Na-Z in the selective hydrogenation of acetylene

[0042]

[0043] The results of catalytic performance evaluation showed that with the increase of hydrogen-alkyne ratio, the conversion of acetylene gradually increased and then stabilized, while the selectivity of ethylene showed a trend of first increasing and then decreasing. Therefore, considering comprehensively, when the ratio of hydrogen to acetylene is 15:1, the yield of ethylene reaches 97.7%, which is an ideal reaction condition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com