Patents

Literature

113 results about "Acetylene hydrogenation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acetylene hydrogenation is a very important step in most olefins plant operations along the process flow path of achieving on-specification ethylene and propylene production.

Process and catalyst for selective hydrogenation of dienes and acetylenes

InactiveUS20060173224A1Eliminate needReduce the amount requiredHydrocarbon purification/separationHydrocarbonsRheniumPtru catalyst

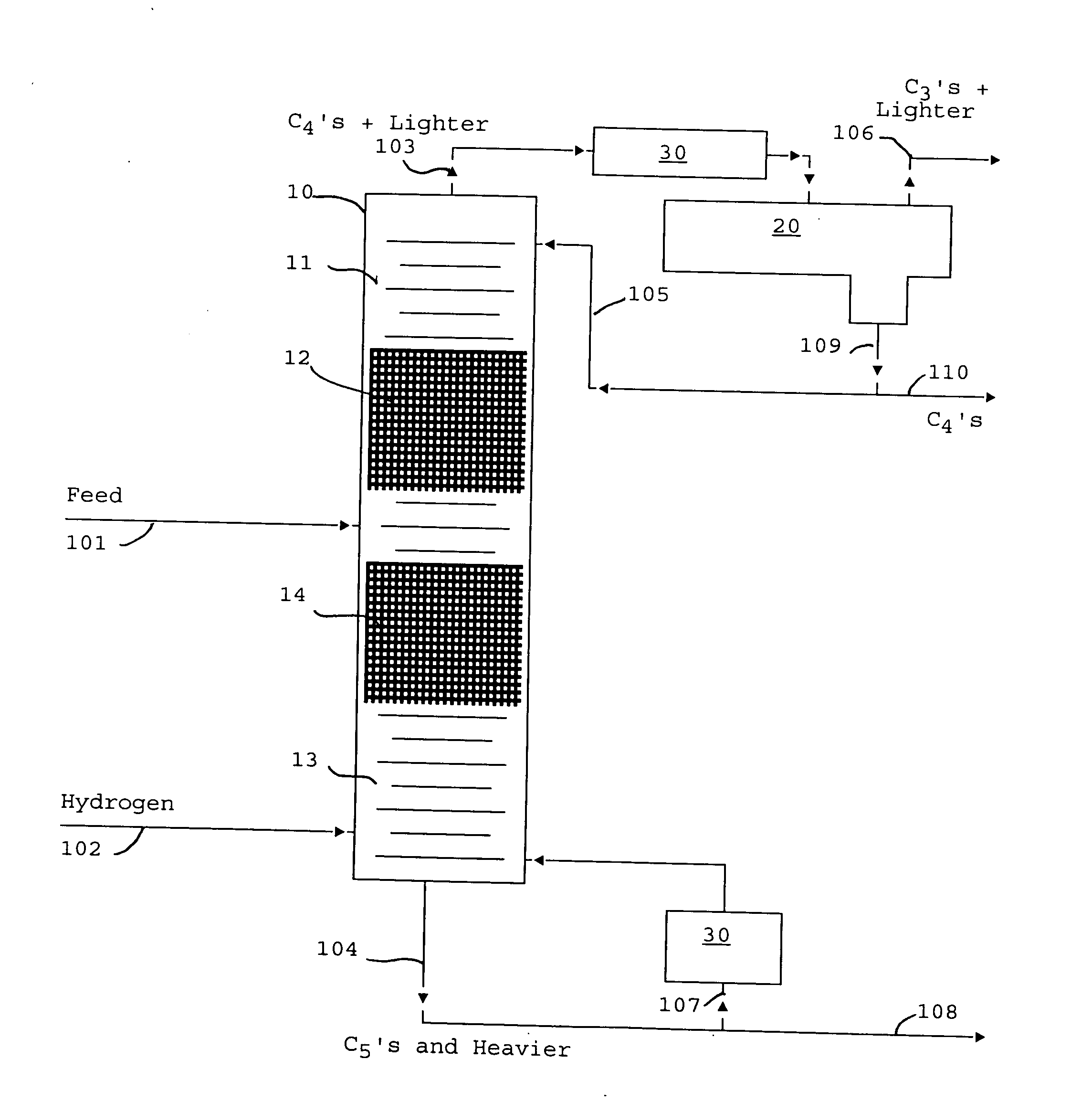

A process for the selective hydrogenation of dienes and acetylenes in a mixed hydrocarbon stream from a pyrolysis steam cracker in which a front end a one step acetylene hydrogenation is carried out using catalyst comprising (A) 1 to 30 wt. % based on the total weight of the catalyst of a catalytic component of nickel only or nickel and one or more elements selected from the group consisting of copper, rhenium, palladium, zinc, gold, silver, magnesium, molybdenum, calcium and bismuth deposited on (B) a support having the a BET surface area of from 1 to about 100 m2 / gram, total nitrogen pore volume of from 0.2 to about 0.9 cc / gram and an average pore diameter of from about 110 to 450 Å under conditions of temperature and pressure to selectively hydrogenate acetylenes and dienes. The process hydrogenates the dienes and acetylenes to olefins without loss of ethylene and propylene in the light and heavy products which eliminates the need for further processing of the heavier stream. In addition the amount of polymerization in the lower part of the distillation column reactor is reduced.

Owner:CHEM RES & LICENSING CO

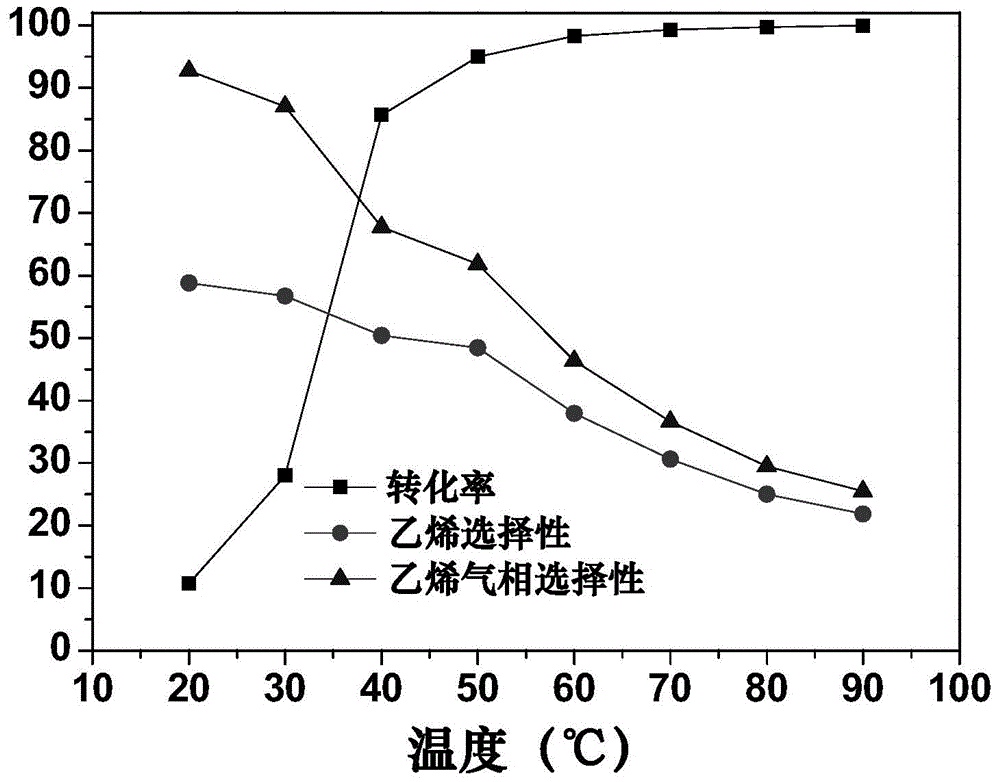

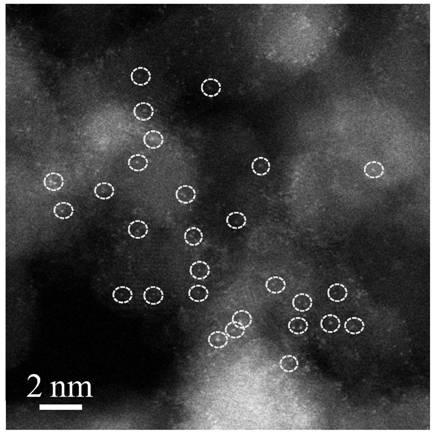

Palladium monatomic catalyst, preparation of palladium monatomic catalyst and application of palladium monatomic catalyst in acetylene hydrogenation reaction

InactiveCN104689816AImprove catalytic performanceHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsActive componentSpace velocity

The invention discloses a palladium monatomic catalyst, preparation of the palladium monatomic catalyst and application of the palladium monatomic catalyst in acetylene hydrogenation reaction. The palladium monatomic catalyst is prepared by the following steps: with Pd as the active component and ZnO as a carrier, dipping, and carrying out high-temperature reduction to form an alloyed monatomic catalyst. Under the conditions of low temperature, wide temperature range (60-300 DEG C) and high space velocity (such as 180000mL / g.h) and in pure acetylene atmosphere and acetylene atmosphere with a great amount of acetylene, a small amount of the catalyst (such as 10mg) has excellent activity, selectivity and stability. The invention provides a preparation method of the palladium monatomic catalyst. The preparation method is simple and feasible, very good catalytic performance is shown in preparation of acetylene by selectively hydrogenating in the acetylene and the industrial application prospect is good.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

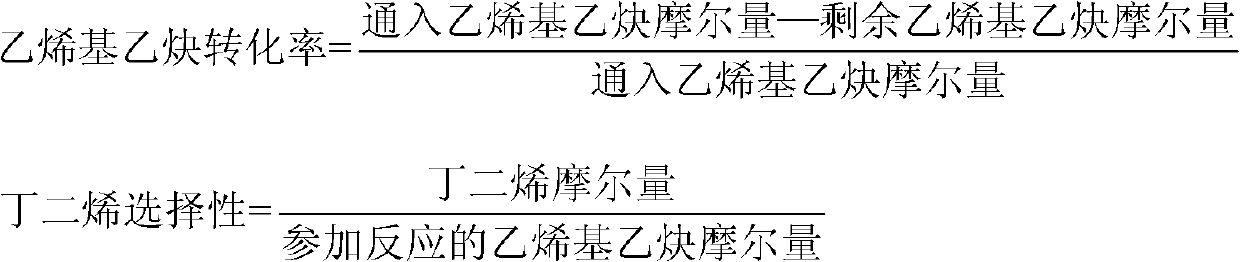

Vinyl acetylene hydrogenation catalyst and preparation method and applications thereof

InactiveCN103285876AStrong hydrogenation activityHigh selectivityHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsVinylacetyleneActive component

The invention provides a vinyl acetylene hydrogenation catalyst and a preparation method and applications thereof, wherein the vinyl acetylene hydrogenation catalyst comprises the following compositions in parts by weight: 0.01-30 parts of active component, 40-99.989 parts of carriers and catalyst promoter, wherein the mole ratio of the catalyst promoter to the active component is (0.1-10):1. According to the vinyl acetylene hydrogenation catalyst, the acetylene hydrogenation activity and butadiene selectivity are high, the vinyl acetylene hydrogenation catalyst can be effectively used in vinyl acetylene hydrogenation reaction so as to further efficiently prepare butadiene.

Owner:TSINGHUA UNIV

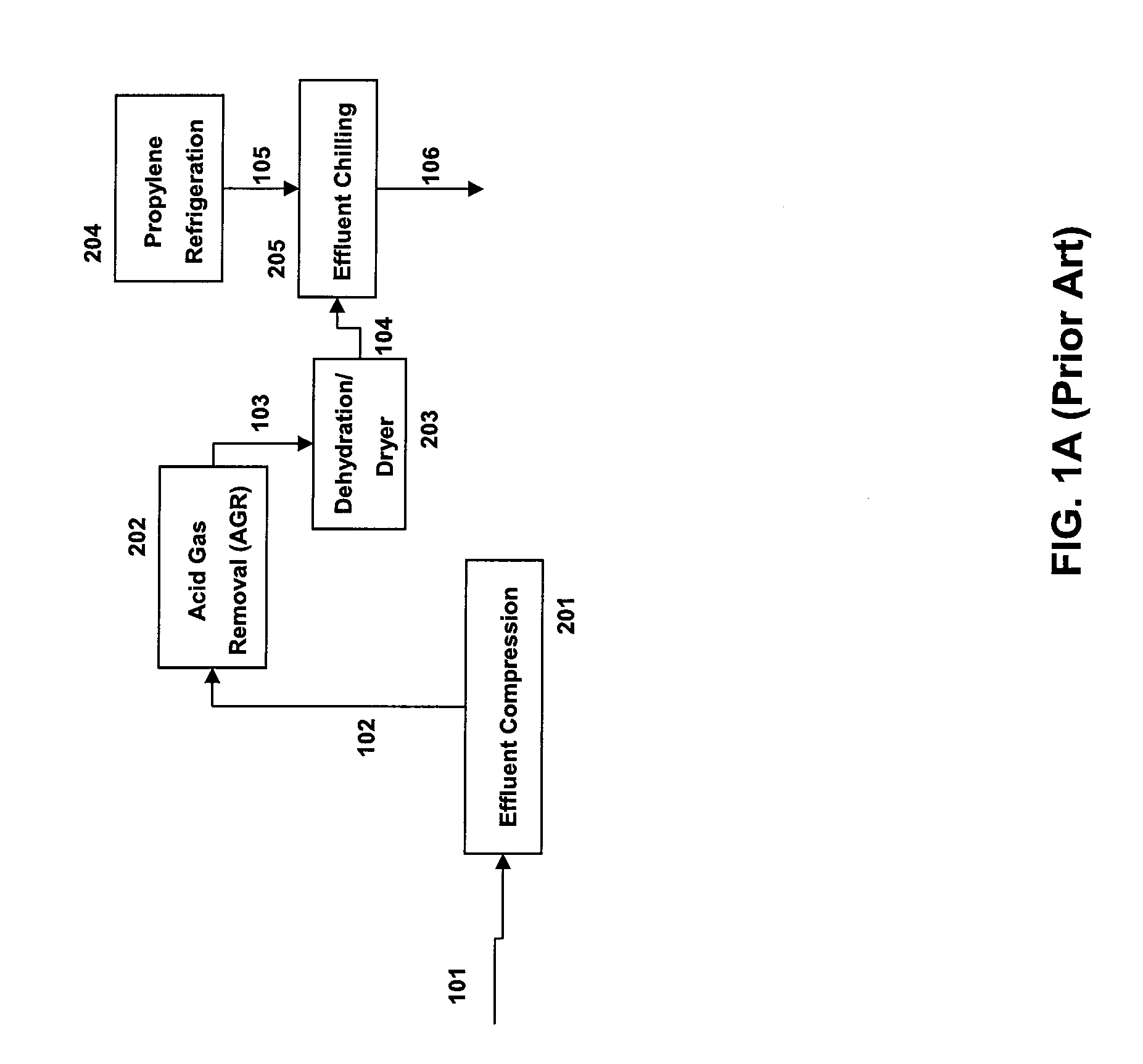

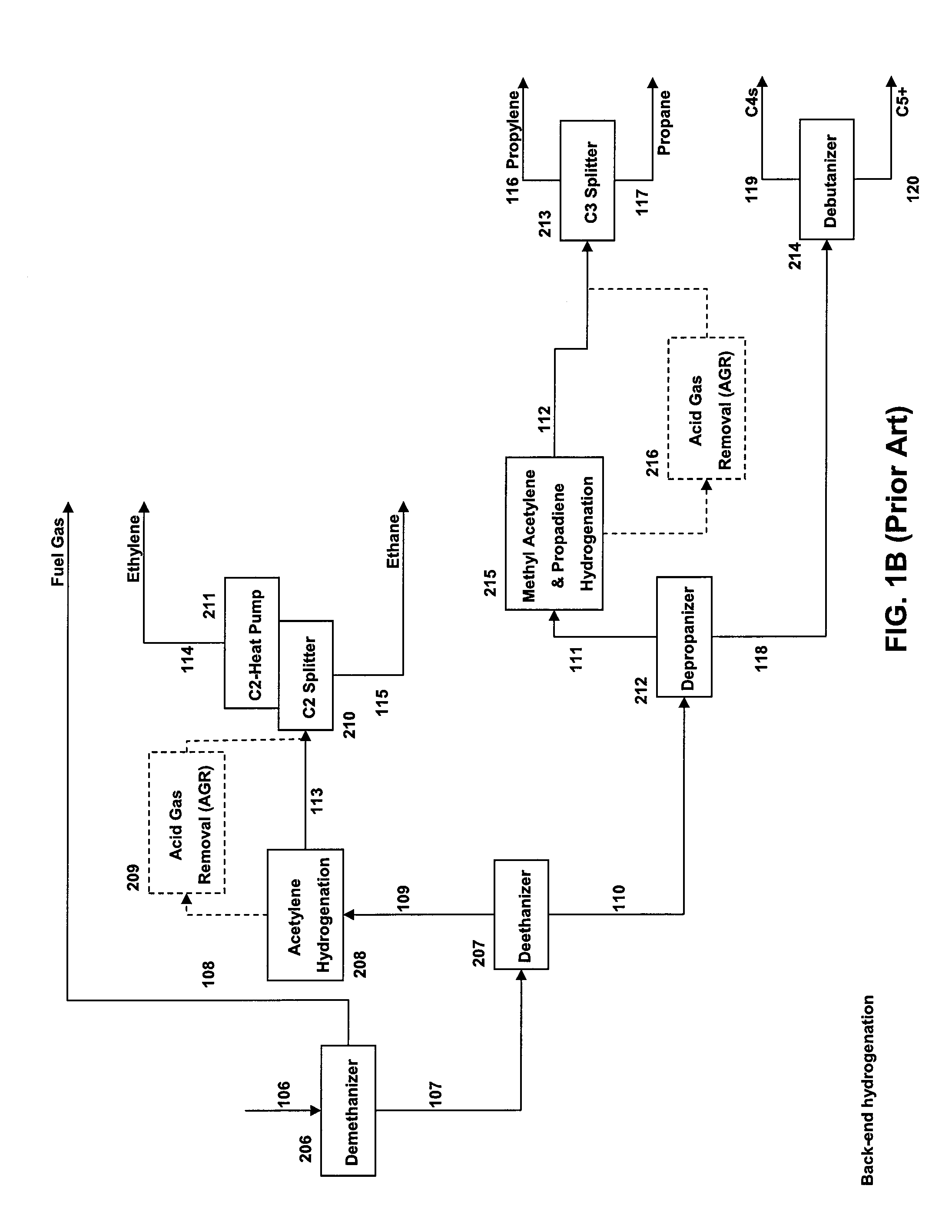

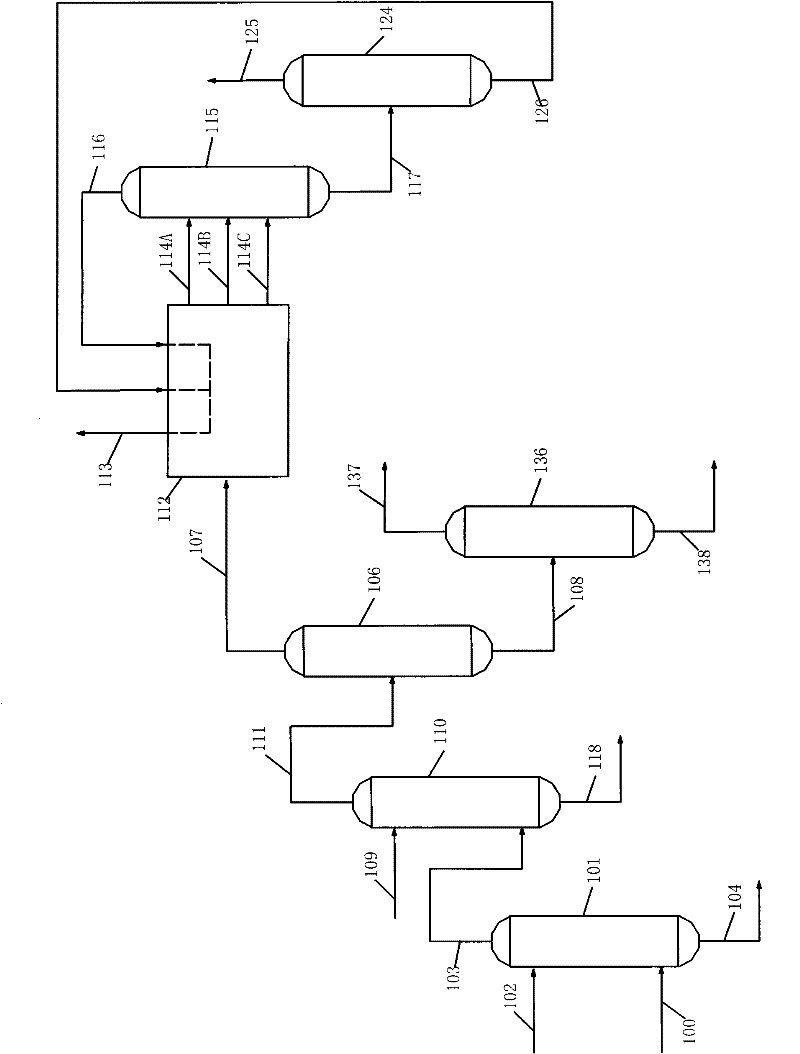

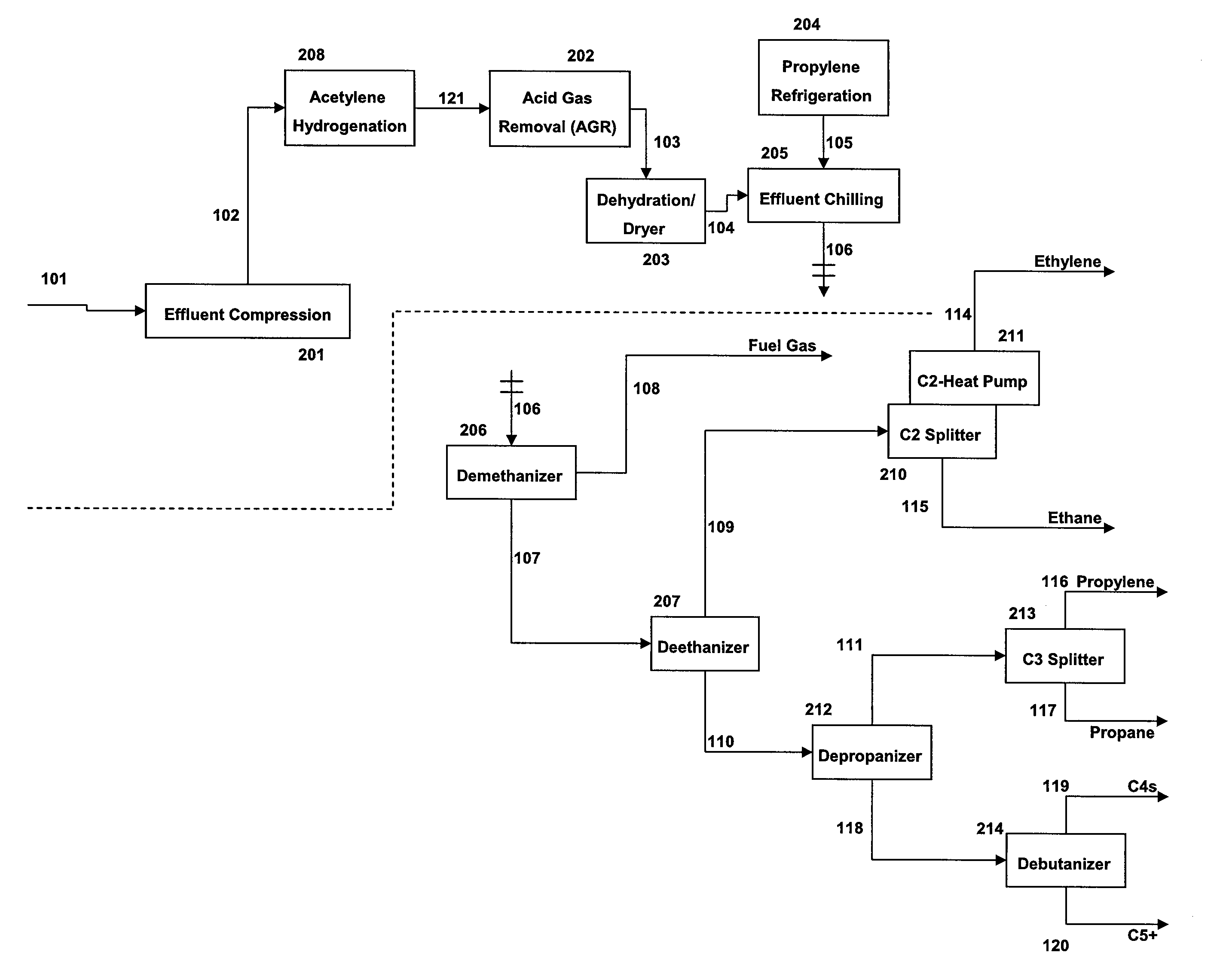

Method for contaminants removal in the olefin production process

ActiveUS20110144397A1Reduce in quantityHydrocarbon by hydrogenationHydrocarbon purification/separationReactor systemDistillation

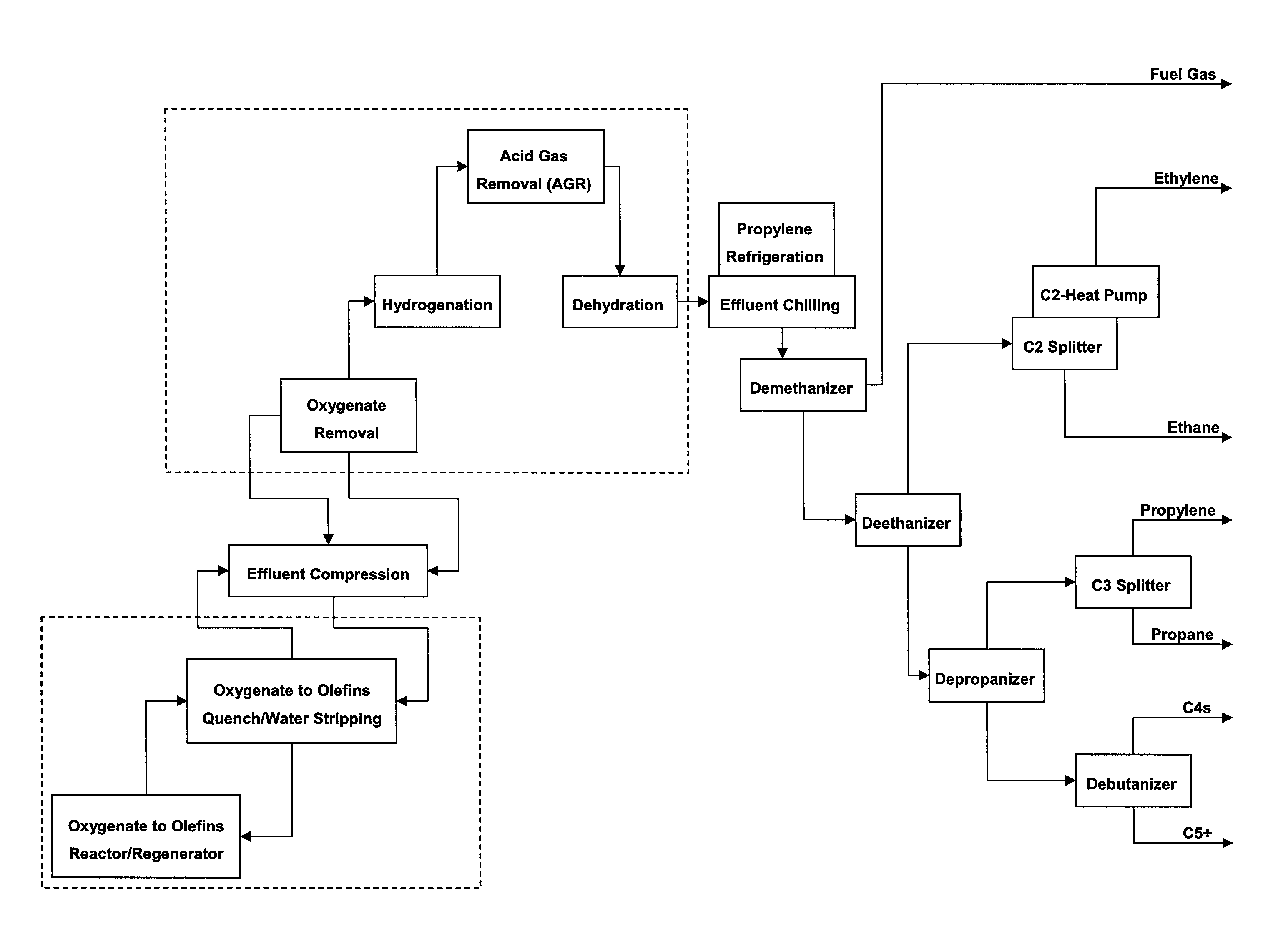

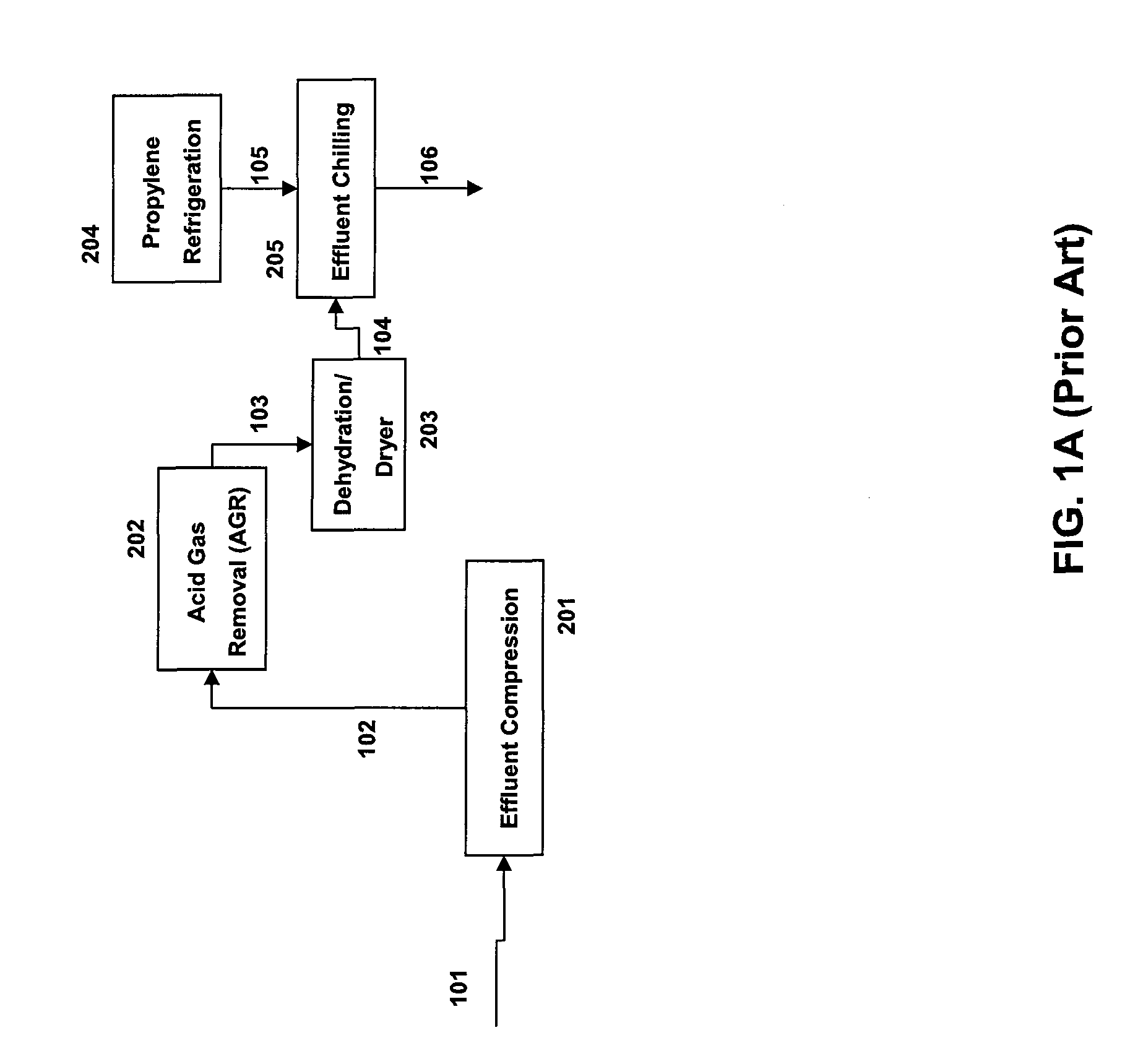

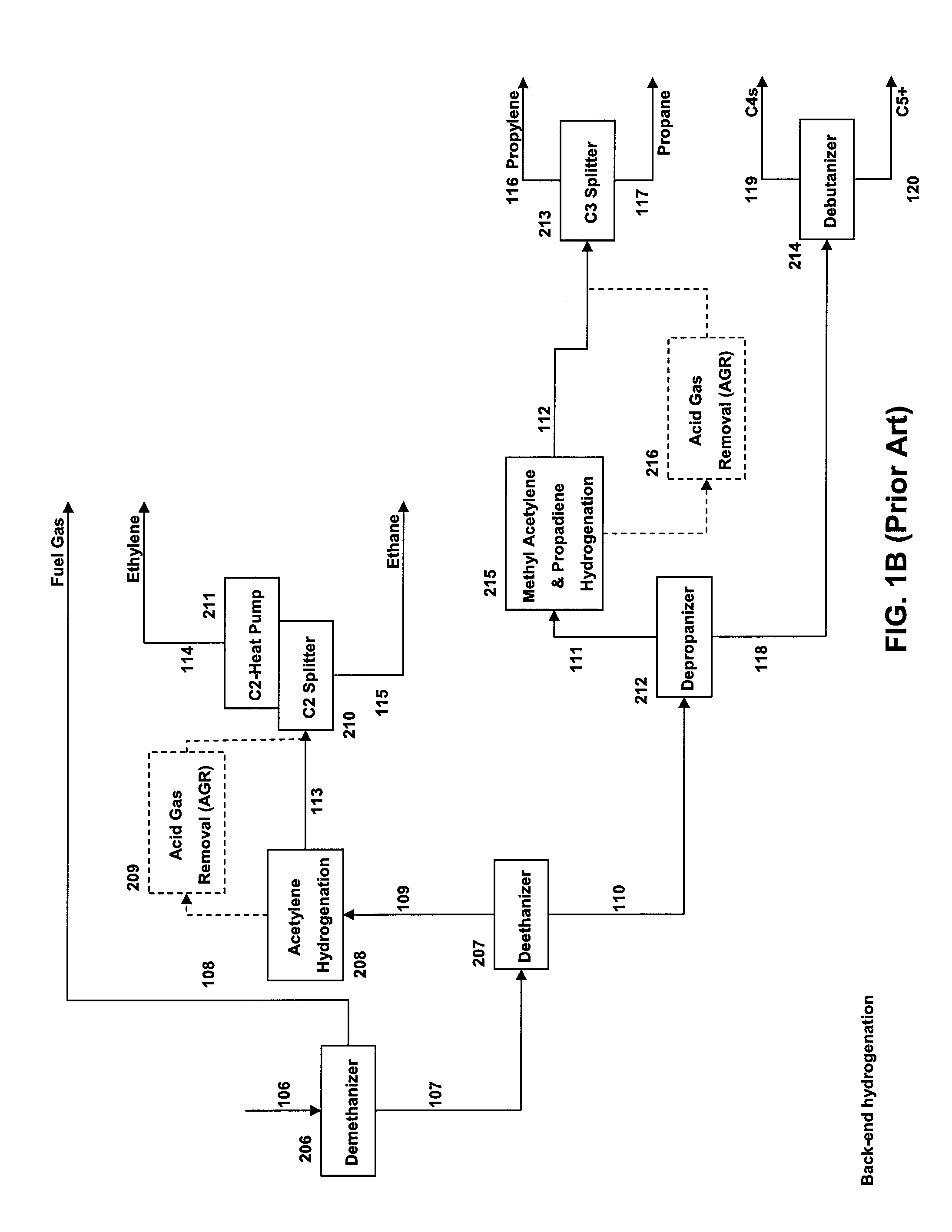

The present invention provides a method and reactor system for hydrogenating acetylenes present in the olefin stream derived from the following streams, alone or in combination: petroleum catalytic cracking process and / or oxygenate-to-olefin reactor, such as methanol-to-olefin (MTO) reactor, in an olefin production plant before the distillation steps, wherein the acetylene hydrogenation occurs before or just after the acid gas removal step.

Owner:STONE & WEBSTER PROCESS TECH

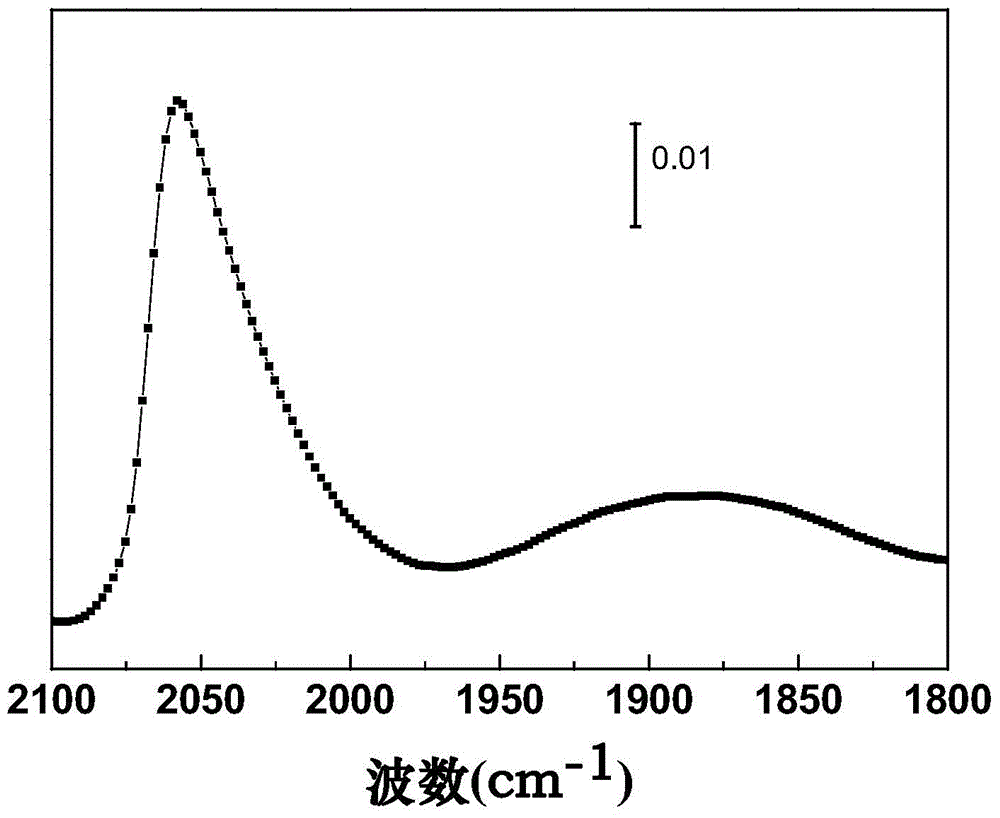

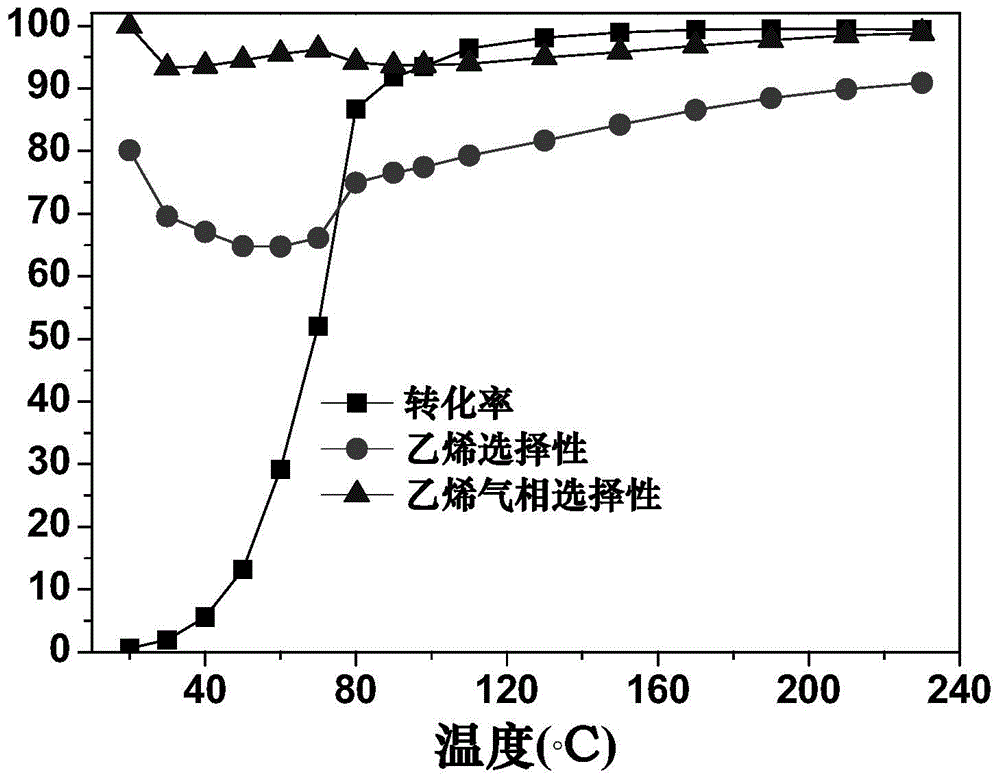

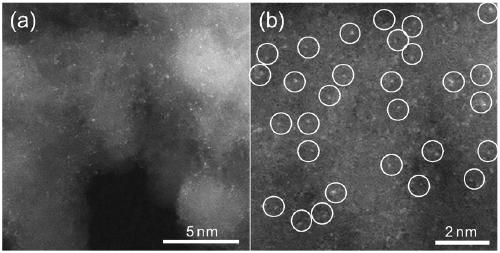

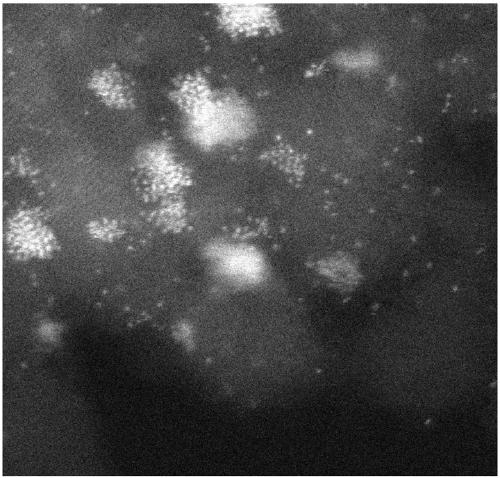

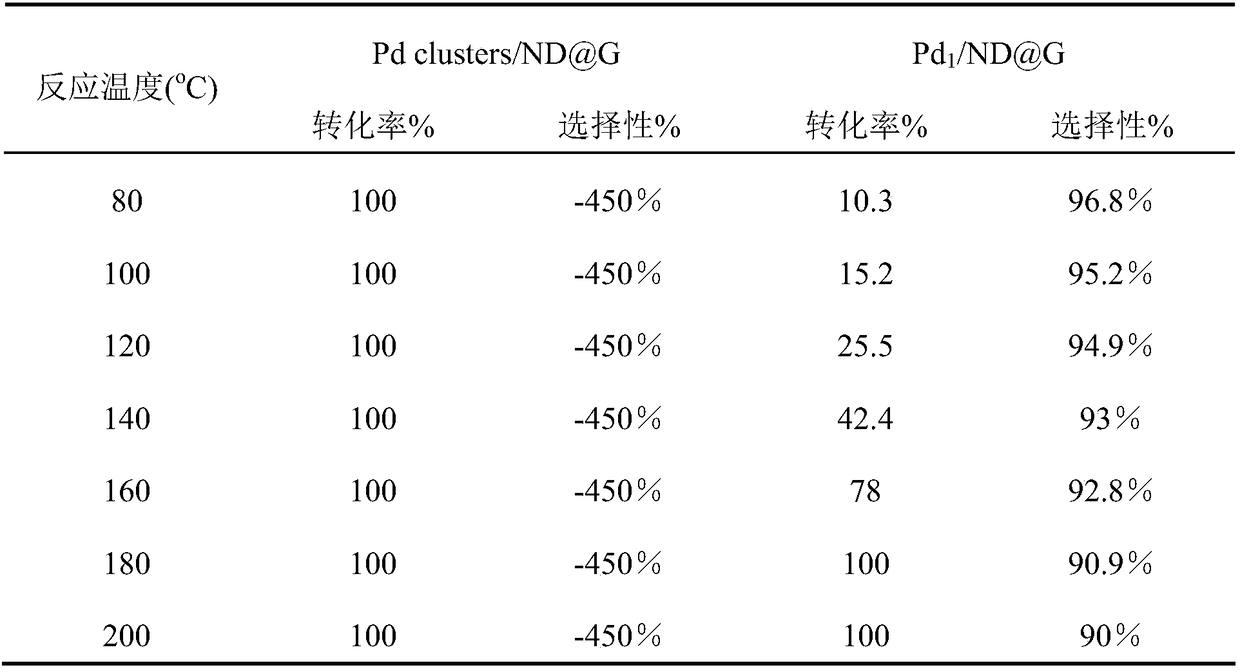

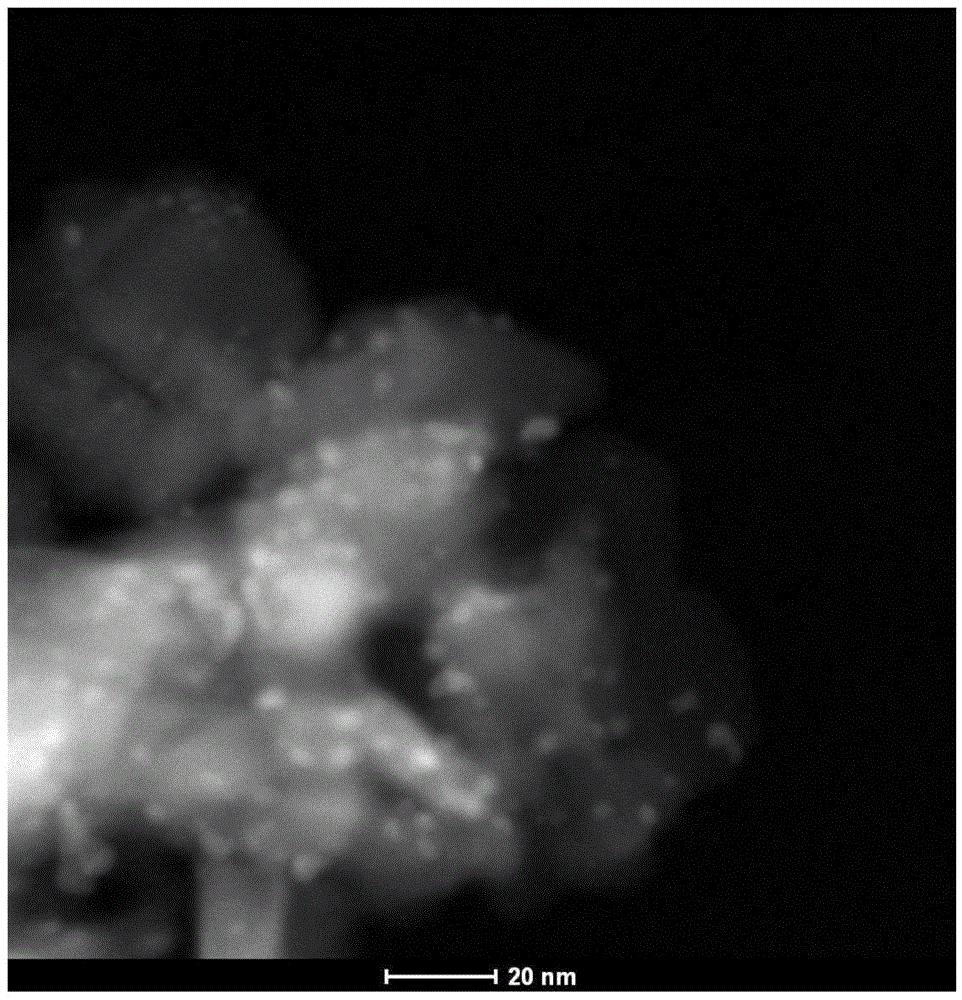

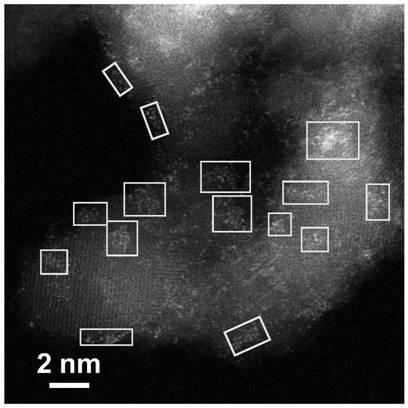

Atomic-scale dispersed palladium-based nanometer diamond/graphene composite material catalyst, preparation method and applications thereof

ActiveCN109174085AConducive to loadWide variety of sourcesHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsHydrogenation reactionPalladium catalyst

The invention discloses an atomic-scale dispersed palladium-based nanometer diamond / graphene composite material catalyst, a preparation method and applications thereof, and belongs to the technical field of catalysts for selective hydrogenation reactions of acetylene, wherein nanometer diamond is subjected to high temperature calcination treatment in an inert atmosphere to obtain a nanometer diamond / graphene structure carbon material, and palladium is dispersed and fixed in the graphene shell layer in an atomic form. According to the present invention, the catalyst hydrogenates acetylene to generate ethylene in a mixed raw material gas, wherein the use temperature of the catalyst is 80-200 DEG C; by dispersing palladium on the nanometer diamond / graphene material in an atomic scale manner,the atomic-scale dispersed palladium-based nanometer diamond / graphene composite material catalyst can effectively catalyze the conversion of acetylene into ethylene and has significantly improved acetylene hydrogenation selectivity compared to the traditional palladium-based carbon materials and the commercial palladium catalysts, has good stability, and is not easily deactivated during the reaction.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

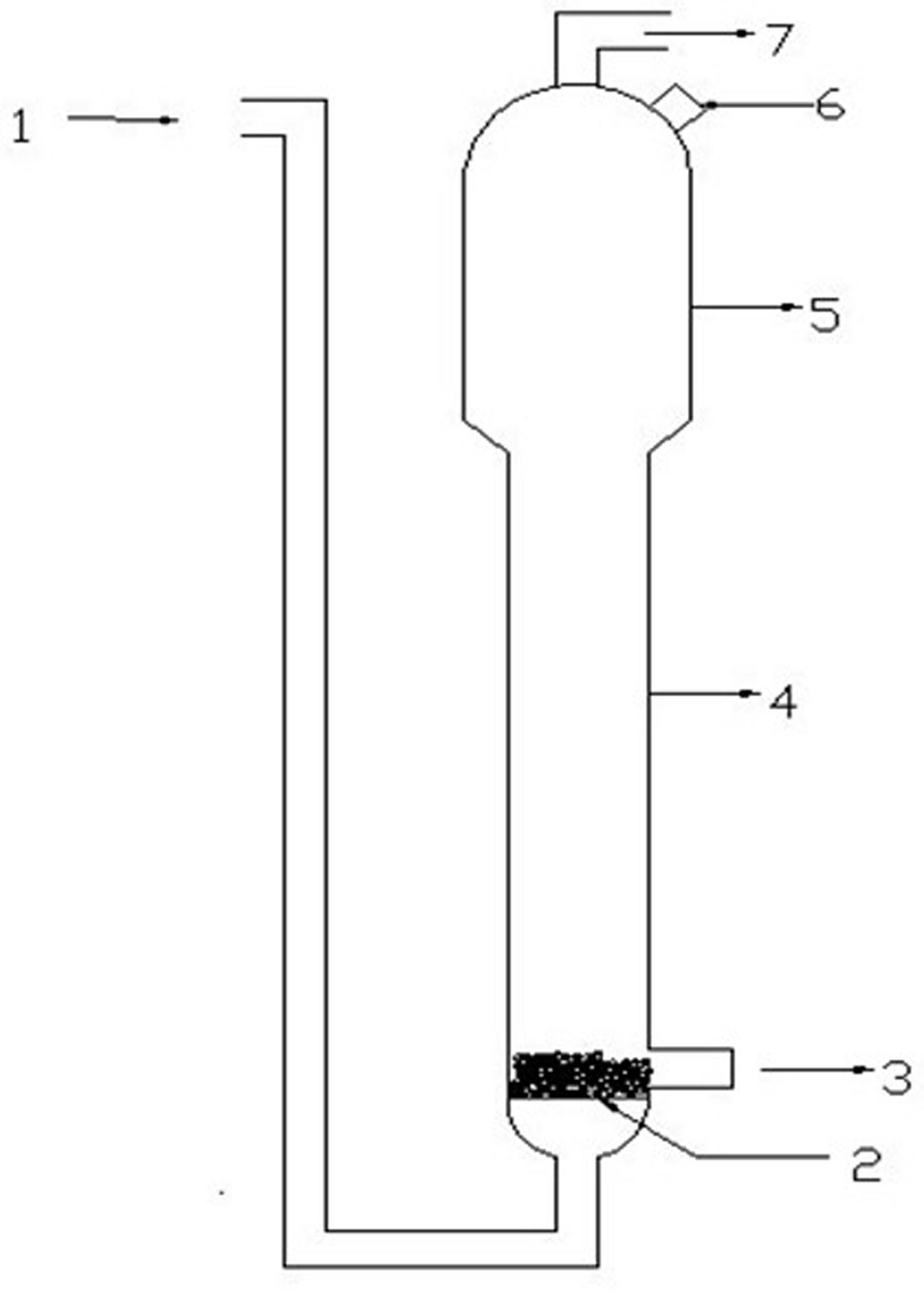

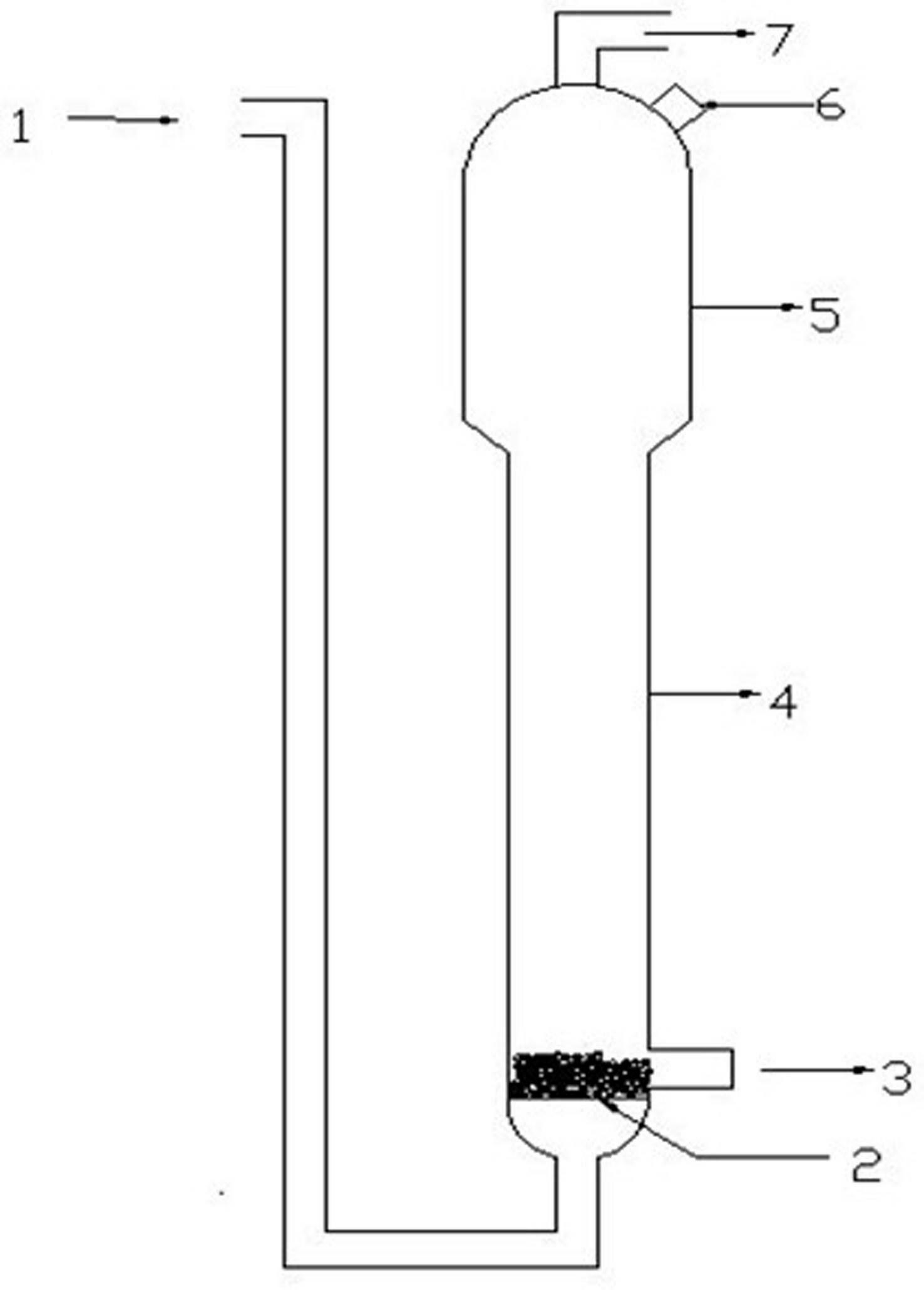

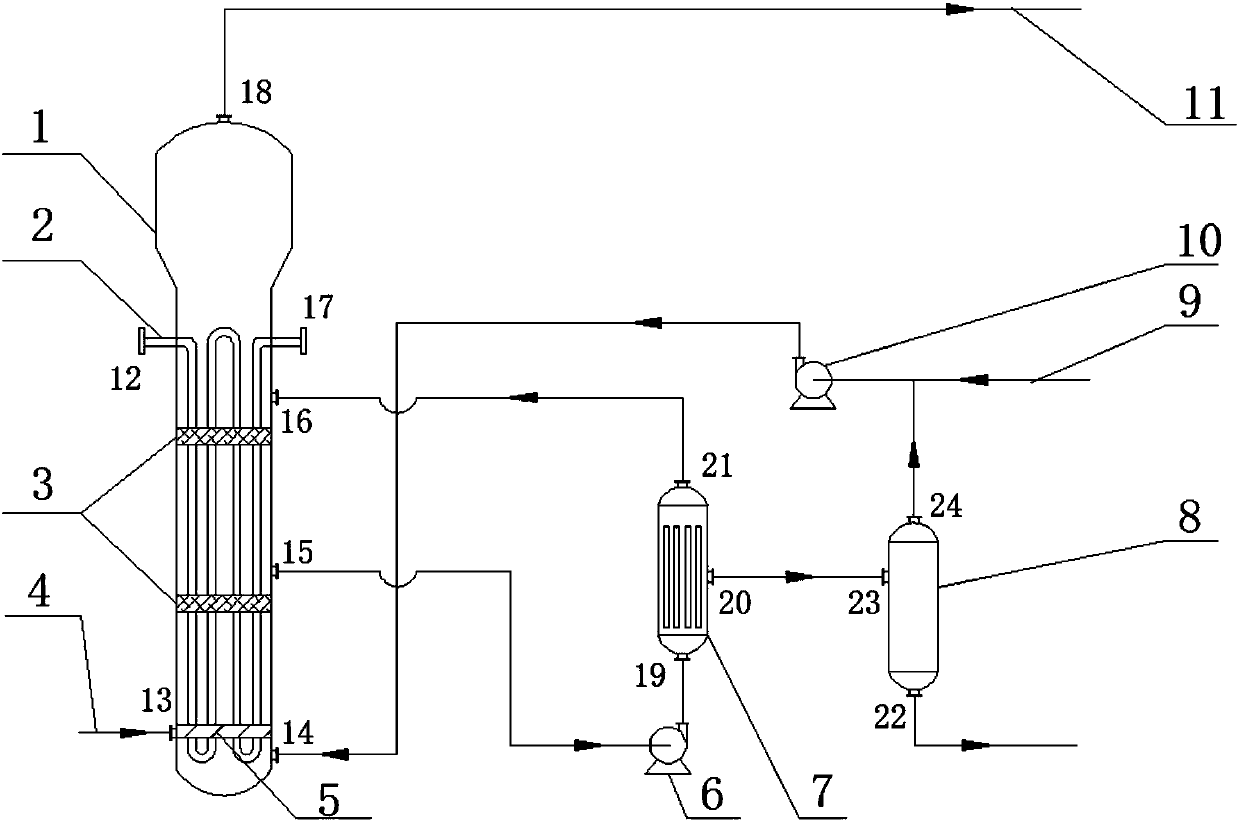

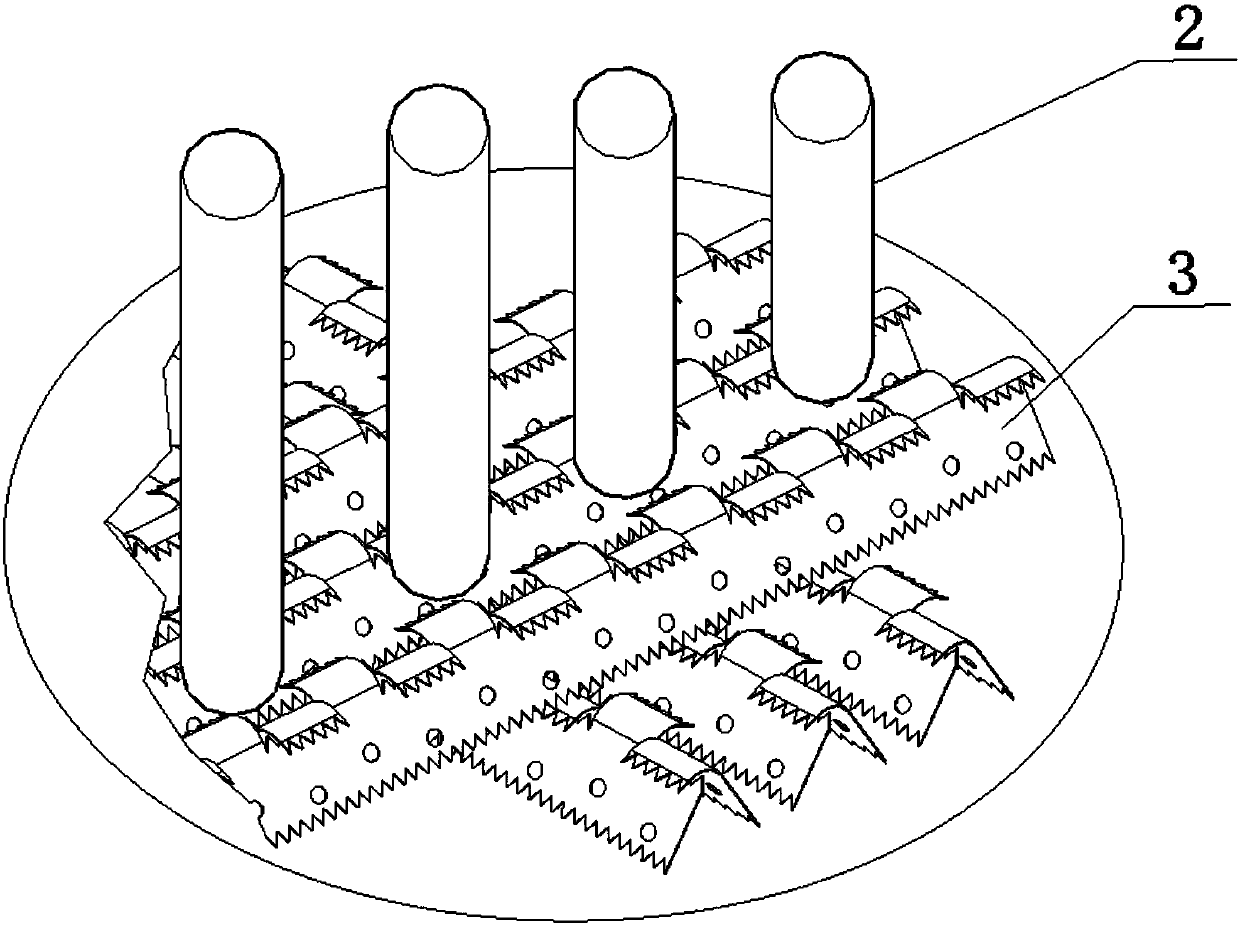

Slurry bubble column technology for preparing ethylene through acetylene hydrogenation and device thereof

InactiveCN102489225AExpand downstream fine chemical productsAvoid overwritingHydrocarbon by hydrogenationChemical/physical processesPtru catalystFixed bed

Provided are slurry bubble column technology for preparing ethylene through acetylene hydrogenation and a device thereof. The slurry bubble column technology includes adding water and then catalyst into a reactor, filling inert gases for replacing, heating, leading gas mixture of acetylene and hydrogen to enter in the reactor for reacting from the bottom of the reactor through a gas distributor, finally exhausting reaction products and unreacted feed gases from the top of the reactor, and separating to obtain the ethylene. The unreacted feed gases and the feed gases are mixed and then enter the reactor again for reacting. The reactor comprises a reaction gas inlet at the bottom, the gas distributor and a material liquid exhaust port, a reactor barrel body is arranged on an expended section on the upper portion of a slurry bubble column reactor, and a catalyst feeding port and a gas outlet are arranged at the top of the reactor. The slurry bubble column for preparing the ethylene through the acetylene hydrogenation is simple in structure, overcomes the phenomenon of temperature runaway in a fixed bed reactor and improves the conversion rate and selectivity of the reaction, and the operation is easy to control.

Owner:TAIYUAN UNIV OF TECH

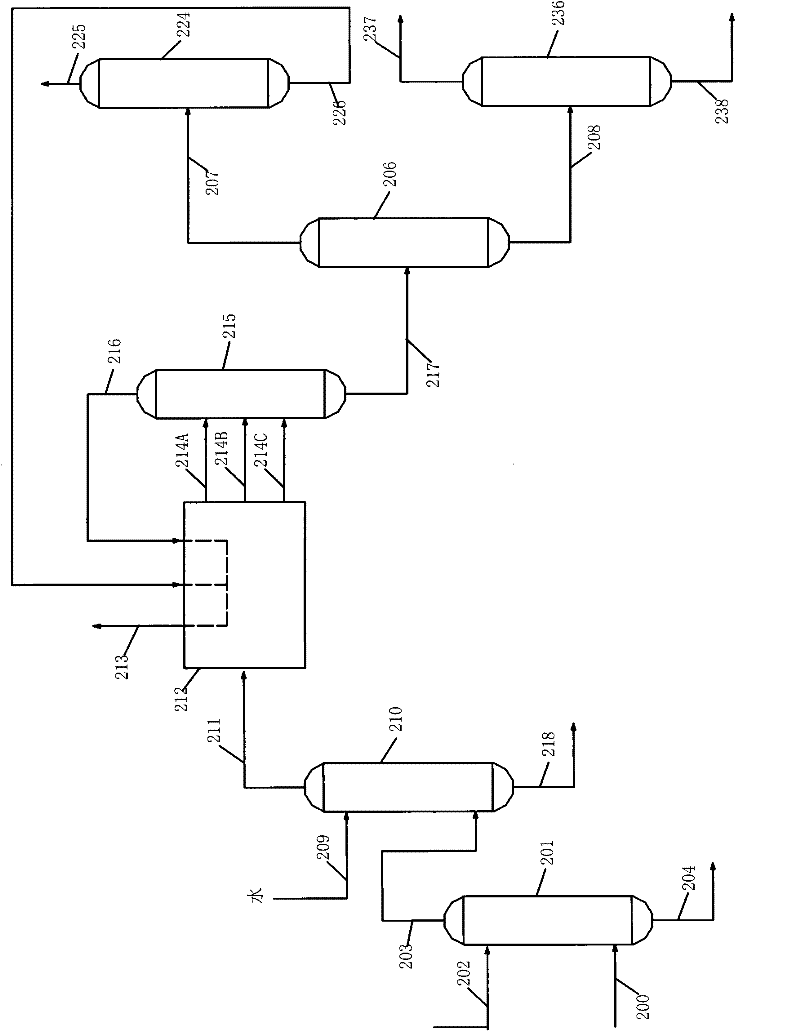

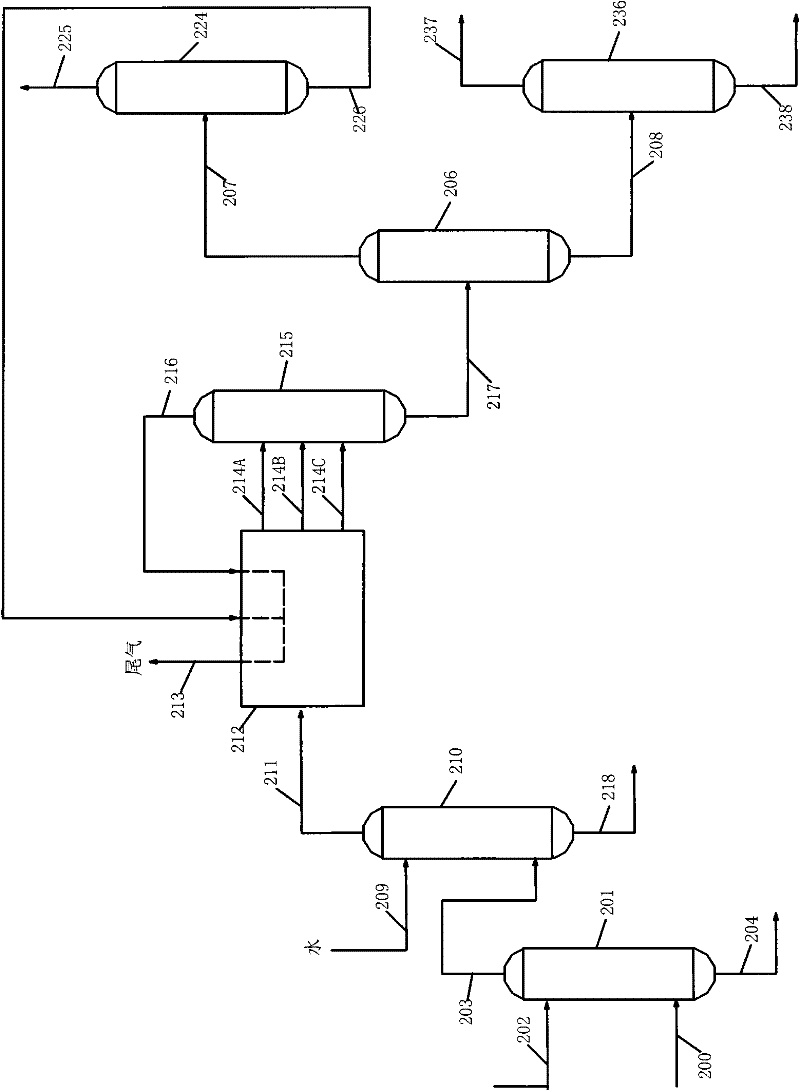

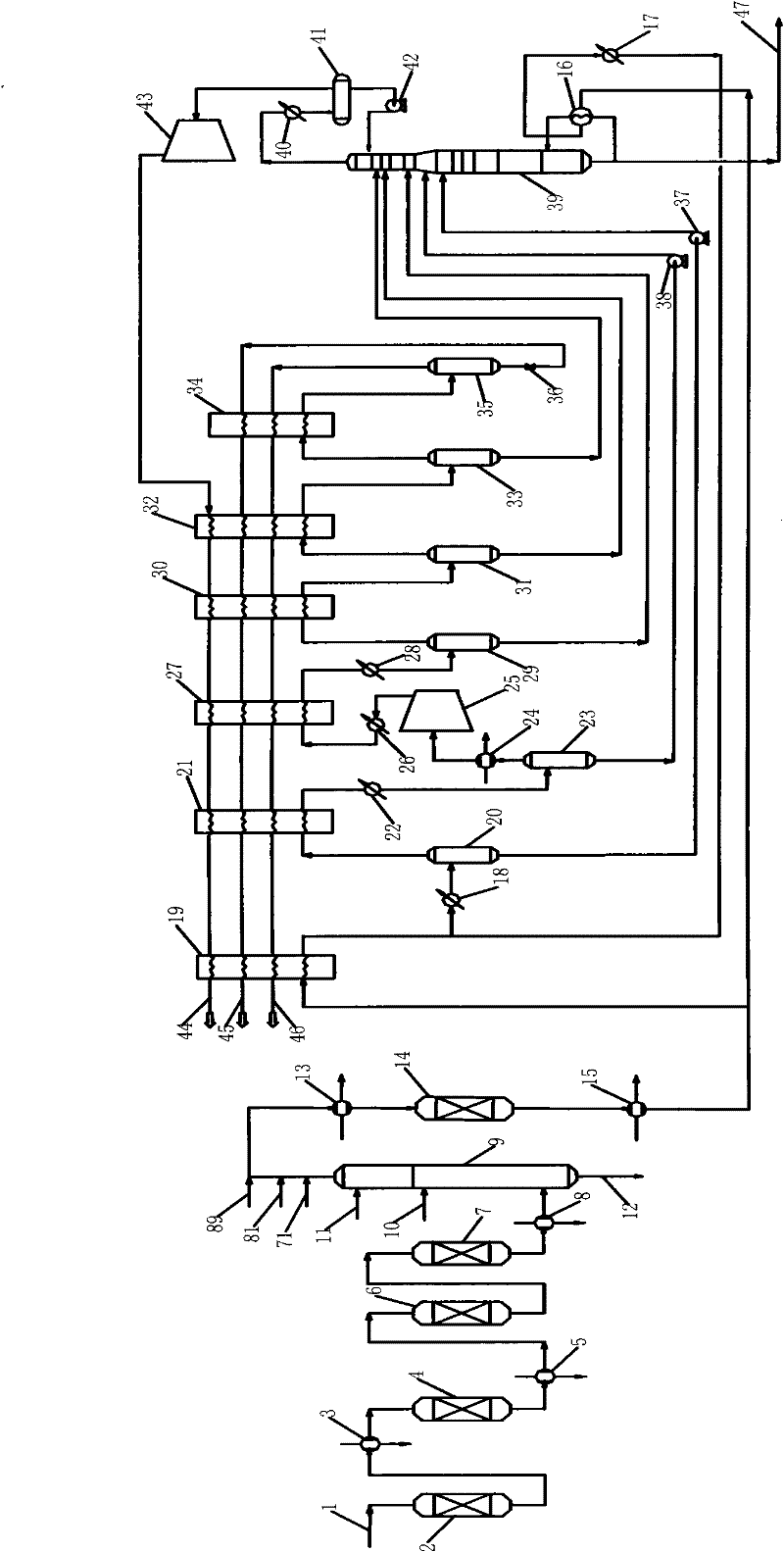

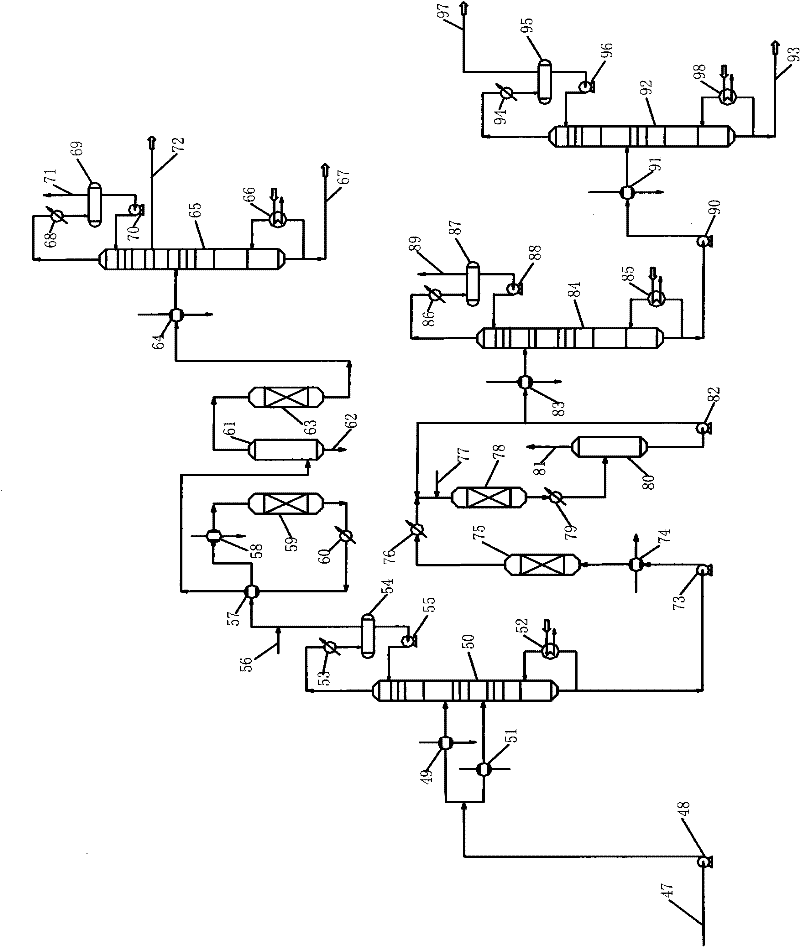

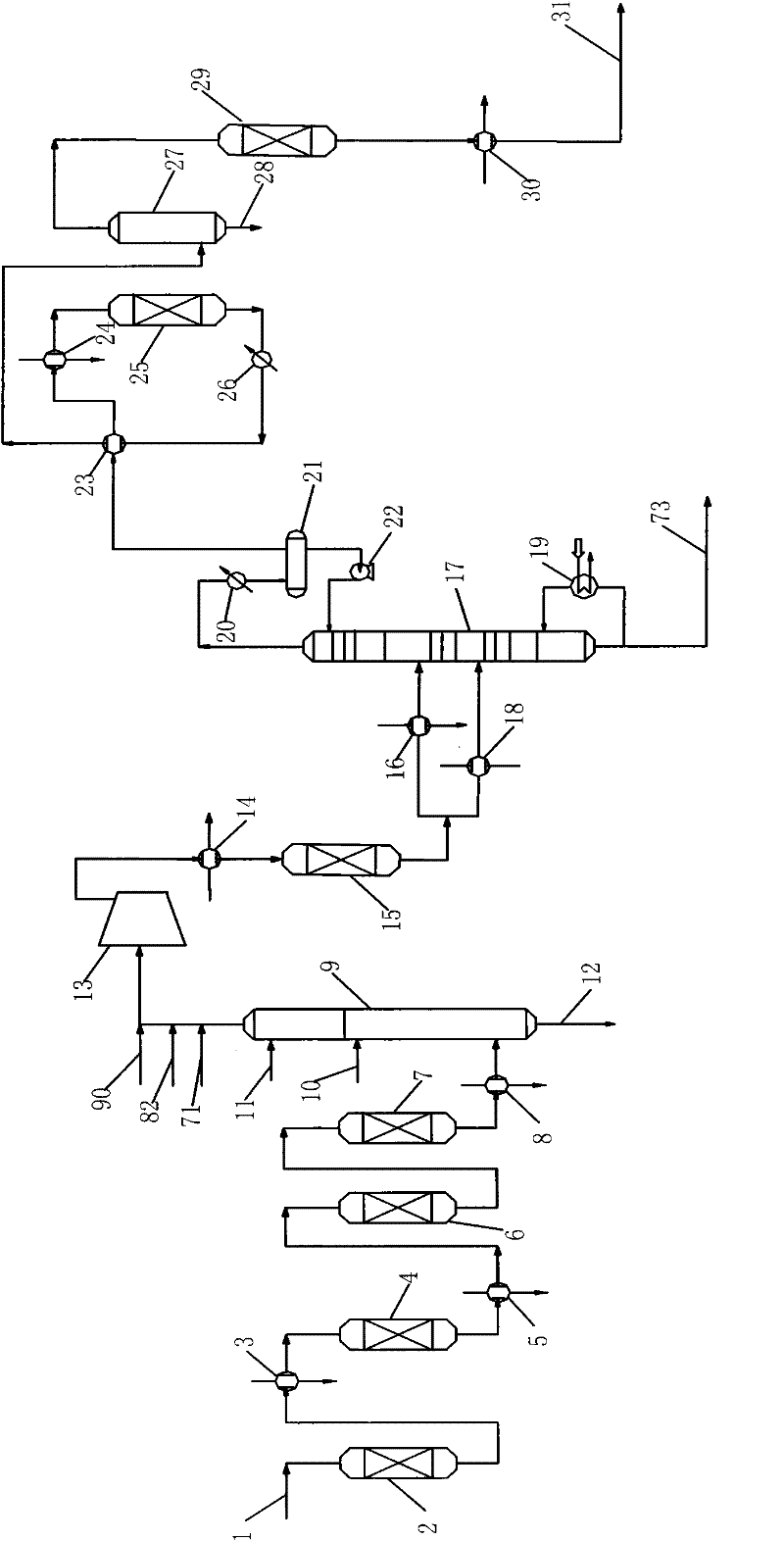

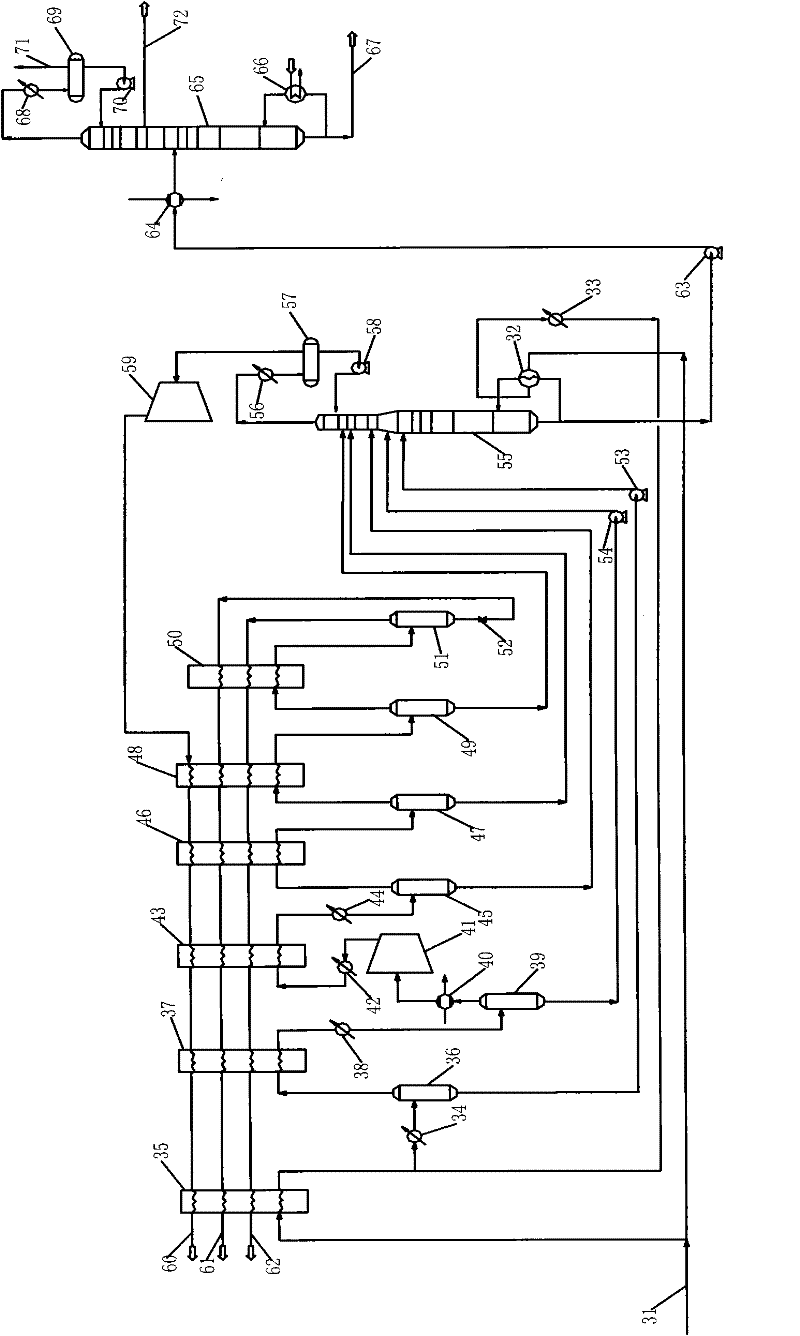

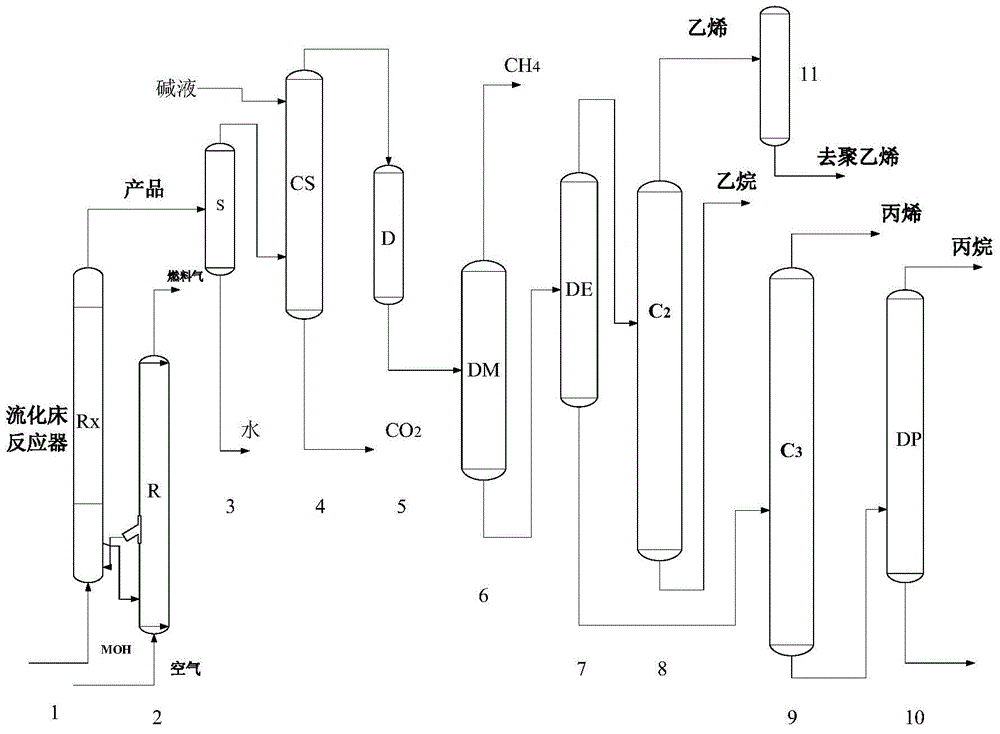

Separation process for preparing low-carbon alkene gases through conversion of methanol

The invention discloses a separation process for preparing low-carbon alkene gases through conversion of methanol and aims to solve the problems that high-purity products such as hydrogen, methane, ethane and propane cannot be obtained and oxygen and carbon monoxide in dimethyl ether and gas impurities cannot be effectively eliminated in the prior art. According to the alkene gas streams through conversion of methanol, eliminating steps of oxygen and carbon monoxide are added, the alkene gas streams through conversion of methanol after elimination of oxygen and carbon monoxide sequentially passes six knockout drums and then enters a low-pressure demethanizer, a deethenizer, an acetylene hydrogenation reactor, an ethylene rectification tower, an allylene hydrogenation reactor and a propylene rectification tower for separation, the liquid from the bottoms of the first four knockout drums sequentially enter the middle-upper portion of the demethanizer, and the liquid from the bottom of the fifth knockout drum enters the upper portion of the demethanizer or returns to a section of a compressor. The separation process for preparing the low-carbon alkene gases through conversion of methanol can obtain products such as polymer grade ethylene, propylene, and the high-purity products such as hydrogen, methane, ethane and propane.

Owner:CHINA PETROLEUM & CHEM CORP +1

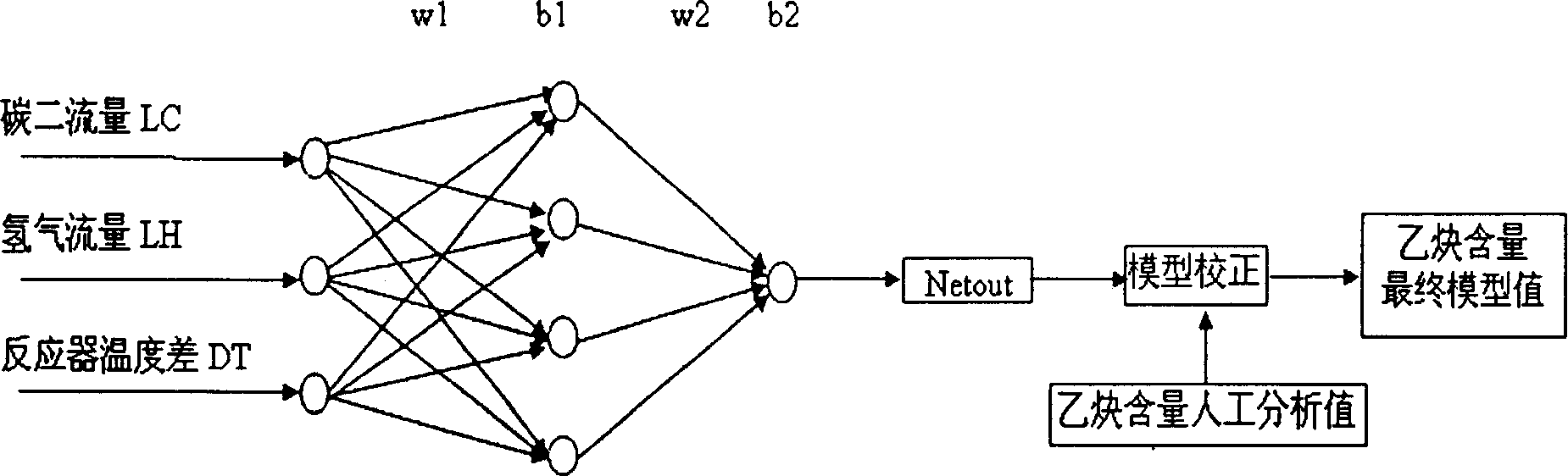

On-line measuring method for one section outlet acetylene concentration of acetylene hydrogenation reaction chamber

InactiveCN1693892ASpecial data processing applicationsSpecific gravity measurementNerve networkHydrogenation reaction

The invention discloses an on-line method for measuring the density of acetylene from a outlet of the ethylene device hydrogenation reactor. It chooses some critical variables which impact this kind of density: the quantity of carbon 2 passed into the reactor, the input variables including the quantity of hydrogen and the temperature difference of the reactor, which are used for the soft measure model. The invention makes use of the nerve network model on the DCS system platform of ethylene producing device, collects samples continuously and calculates in time to measure the density of ethine from an exit of the ethylene device hydrogenation reactor by online.

Owner:EAST CHINA UNIV OF SCI & TECH

Separation process for preparing low-carbon olefin gas through methanol conversion

The invention discloses a separation process for preparing low-carbon olefin gas through methanol conversion, aiming at overcoming the defects that products such as high-purity hydrogen, methane, ethane and propane cannot be obtained, dimethyl ether and oxygen and carbon monoxide in flue gas impurities are not effectively removed and the like in the prior art. A carbon monoxide and oxygen removal step is added in the process. Methanol-to-olefin gas with the carbon monoxide and the oxygen being removed passes through six separation tanks and then enters a high-pressure demethanation tower, a deethanization tower, an acetylene hydrogenation reactor, an ethylene rectifying tower, an allylene hydrogenation reactor, a propylene rectifying tower and the like for separation, wherein liquid which comes out from the bottoms of the first five separation tanks sequentially enters the middle-to-upper part of the demethanation tower. By adopting the separation process, polymer-grade ethylene and propylene products can be obtained and products such as high-purity hydrogen, methane, ethane and propane can also be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

Separation method for preparing low-carbon olefin gas through methanol conversion

ActiveCN102675025AHigh purityReduce usageLiquid hydrocarbon mixture productionAbsorption purification/separationOlefiant gasOxygen

The invention discloses a separation method for preparing low-carbon olefin gas through methanol conversion, and aims to solve the problems that products with high purity such as hydrogen, methane, ethane and propane which cannot be obtained in the prior art and oxygen, carbon oxide and the like in dimethyl enther and gas impurities cannot be effectively removed. According to the method, a step of removing the carbon oxide and the oxygen is increased, a methanol prepared olefin gas material flow from which the carbon oxide and the oxygen are removed enters a deethanizing column; the material flow on the top of the deethanizing column flows through an acetylene hydrogenation reactor, six separation tanks, a demethanizing column, an ethylene rectifying column and the like in sequence to separate to obtain ethylene and ethane products; and the material flow at the bottom of the deethanizing column flows through a propyne hydrogenation reactor, a methane stripping column, a propylene rectifying column and the like in sequence to separate to obtain propene and propane products. By using the separation method, polymer grade ethylene and propene products can be obtained, and products with high purity such as hydrogen, methane, ethane and propane can also be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for contaminants removal in the olefin production process

ActiveUS8309776B2Hydrocarbon by hydrogenationHydrocarbon purification/separationReactor systemDistillation

Owner:STONE & WEBSTER PROCESS TECH

Method using acetylene hydrogenation to produce ethylene

InactiveCN105152836ADoes not cause hydrogenation side reactionsNot prone to deteriorationHydrocarbon by hydrogenationChemical recyclingOrganic solventHydrogenation reaction

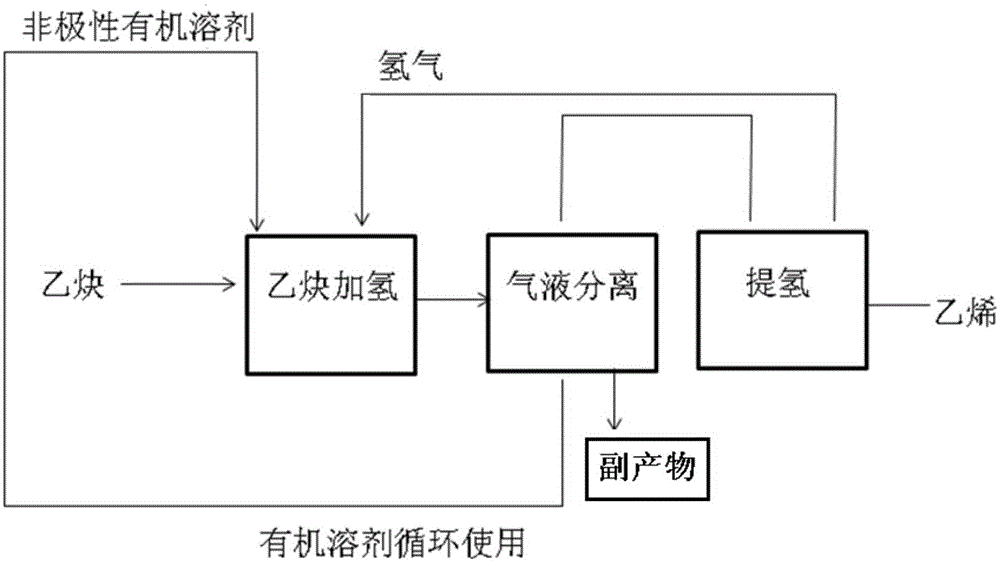

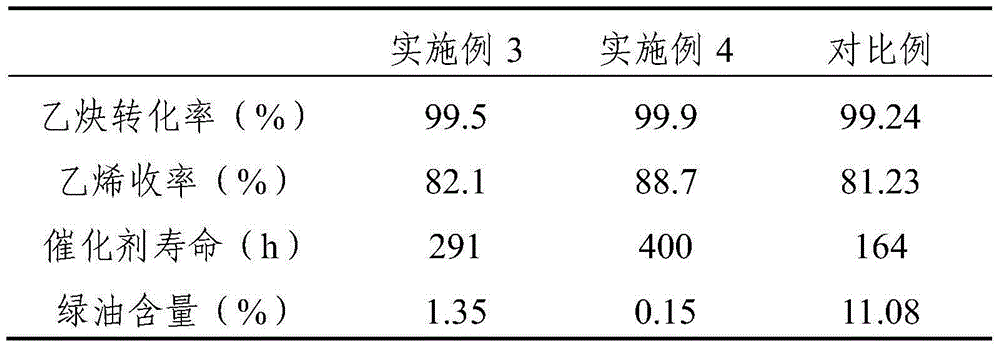

The invention relates to a method using acetylene hydrogenation to produce ethylene. The method includes the steps of firstly, performing acetylene hydrogenation; secondly, performing gas-liquid separation; thirdly, extracting hydrogen. The method has the advantages that non-polarity organic solvent is added into a reactor with a rotary catalyst bed, so that phase change of the formed liquid film can be achieved, part of reaction heat can be taken away, side reaction occurrence in the acetylene hydrogenation reaction is reduced, bed temperature stability is guaranteed, and catalyst bed temperature runaway is avoided; the solvent recycled by separating reaction products can be reused directly, and the method is simple, and convenient to operate.

Owner:BEIJING HUAFU ENG

Reaction system and method for preparing ethylene through acetylene hydrogenation

ActiveCN105152842AImprove conversion rateAvoid overwritingHydrocarbon by hydrogenationBulk chemical productionGas solidGas phase

The invention relates to a reaction system for preparing ethylene through acetylene hydrogenation. The reaction system is a gas phase-liquid phase two-phase contact reaction system. By means of the system, a traditional solid catalyst can be replaced by a liquid-phase catalyst, so that a traditional gas-solid two phase or gas-liquid-solid three-phase contact reaction is changed into a gas-liquid contact reaction, and coverage of the catalyst activity center by produced green oil is avoided; meanwhile, the hydrogenation activity of the liquid-phase catalyst is under the suitable condition through regulation of proportions of different kinds of complexation metals in the liquid-phase catalyst, the high conversion rate of acetylene is guaranteed, production of the green oil due to self-polymerization of acetylene is avoided, and production of ethane through deep acetylene hydrogenation can be inhibited. The invention further relates to a method for preparing the ethylene with the reaction system. By means of the method, the selectivity of production of the ethylene through acetylene hydrogenation is improved and the yield of the ethylene in product gas is increased.

Owner:北京锦泰诚瑞科技发展有限公司

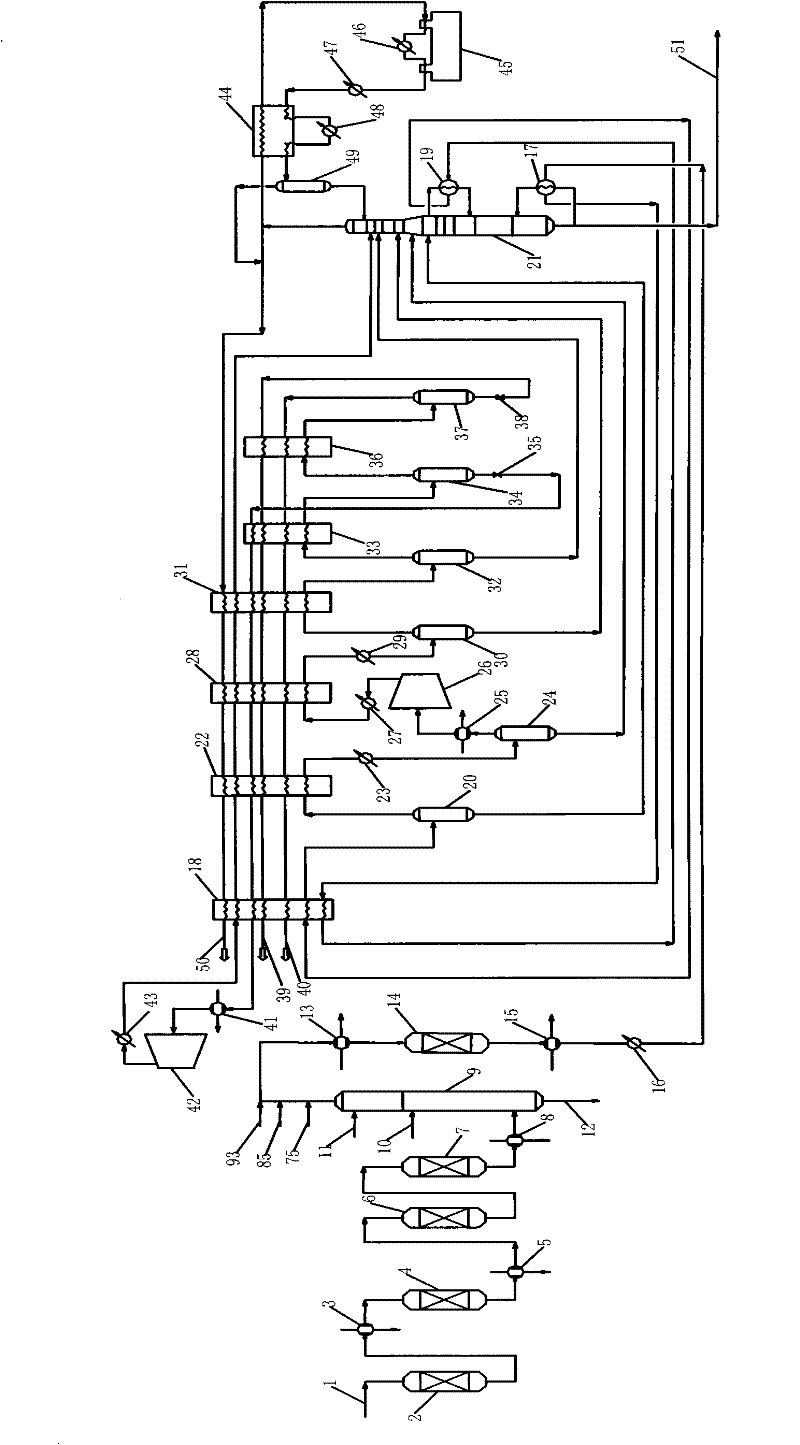

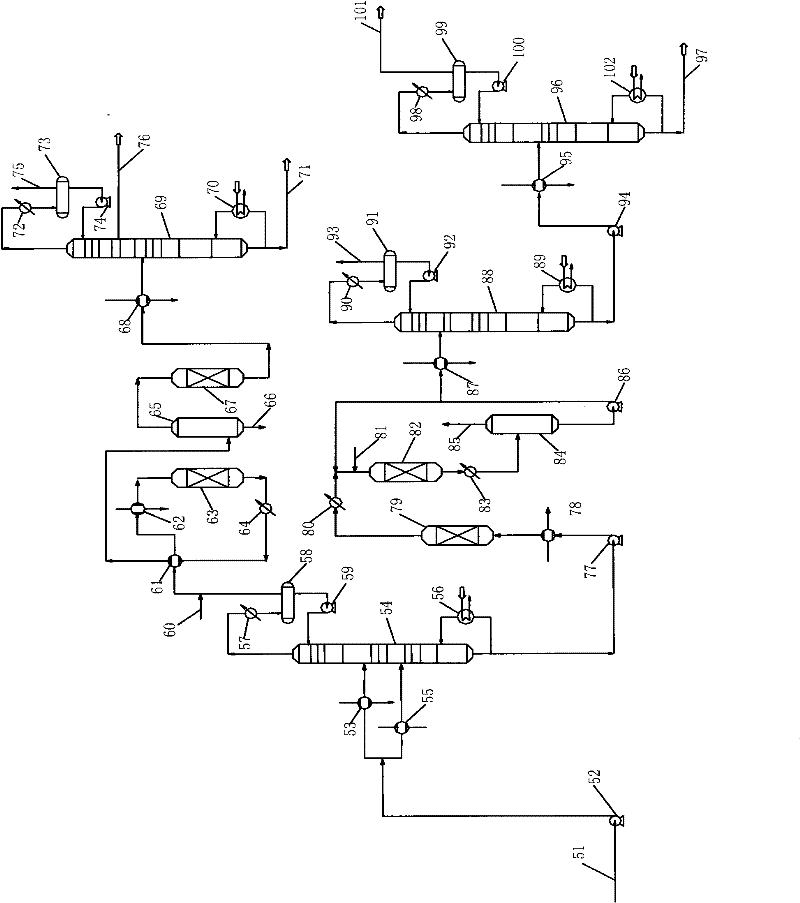

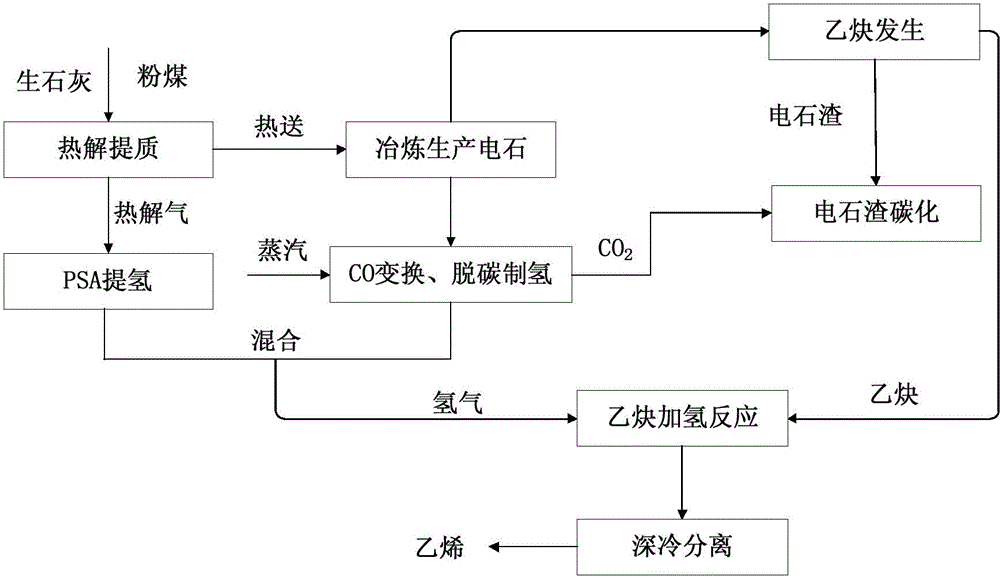

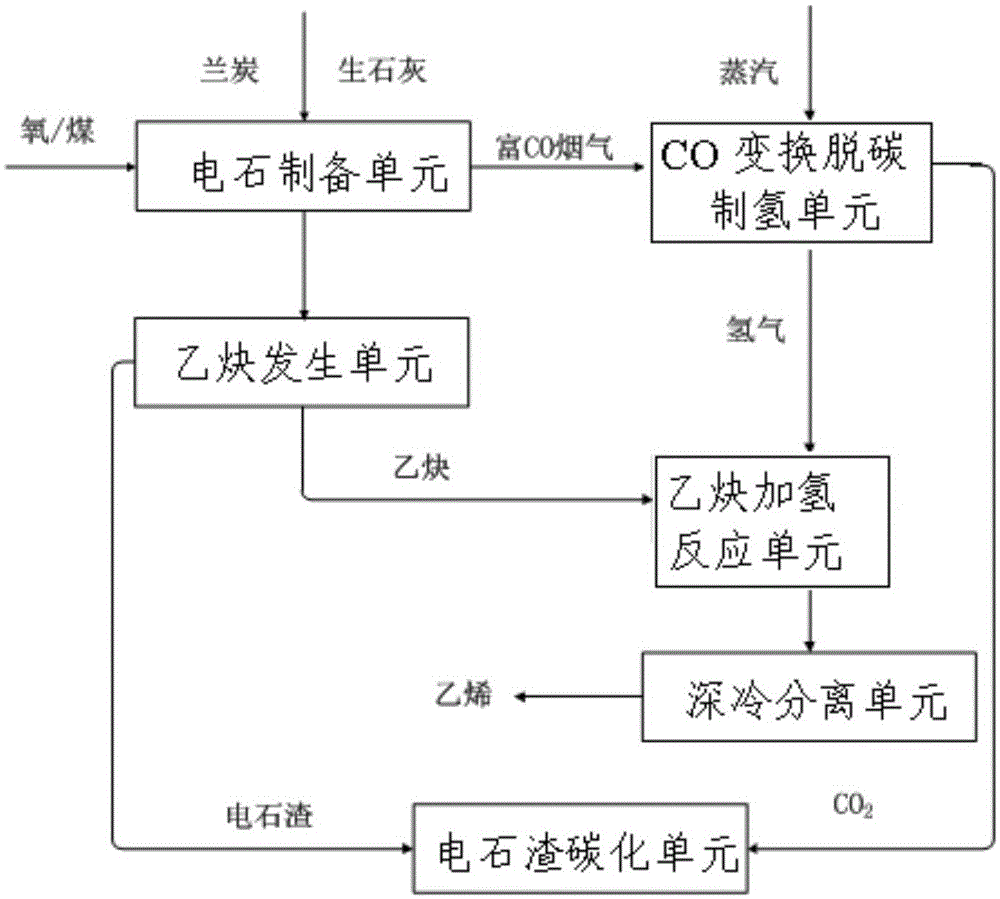

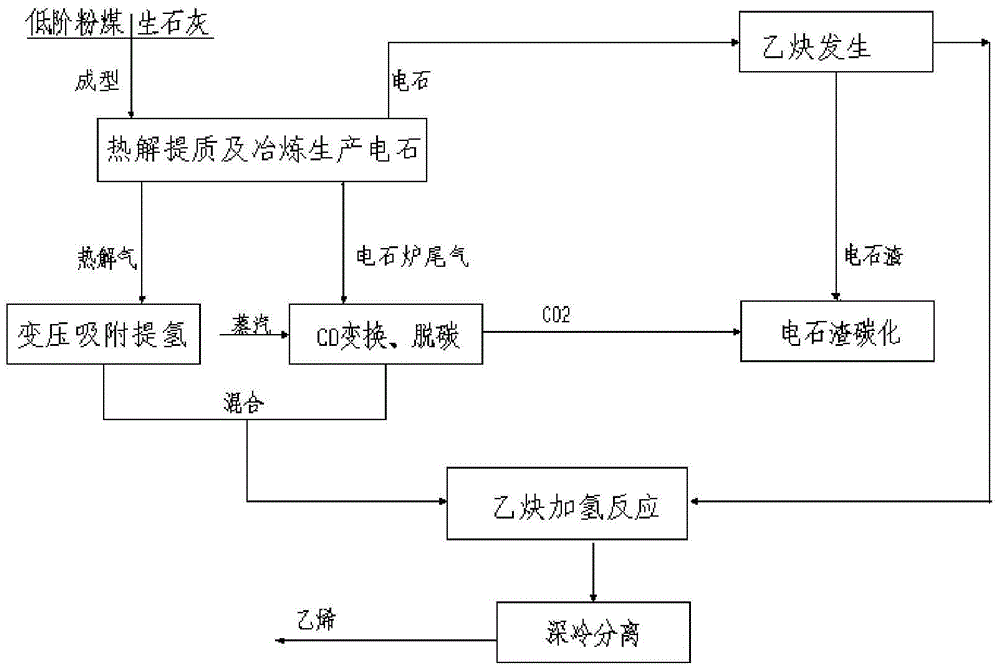

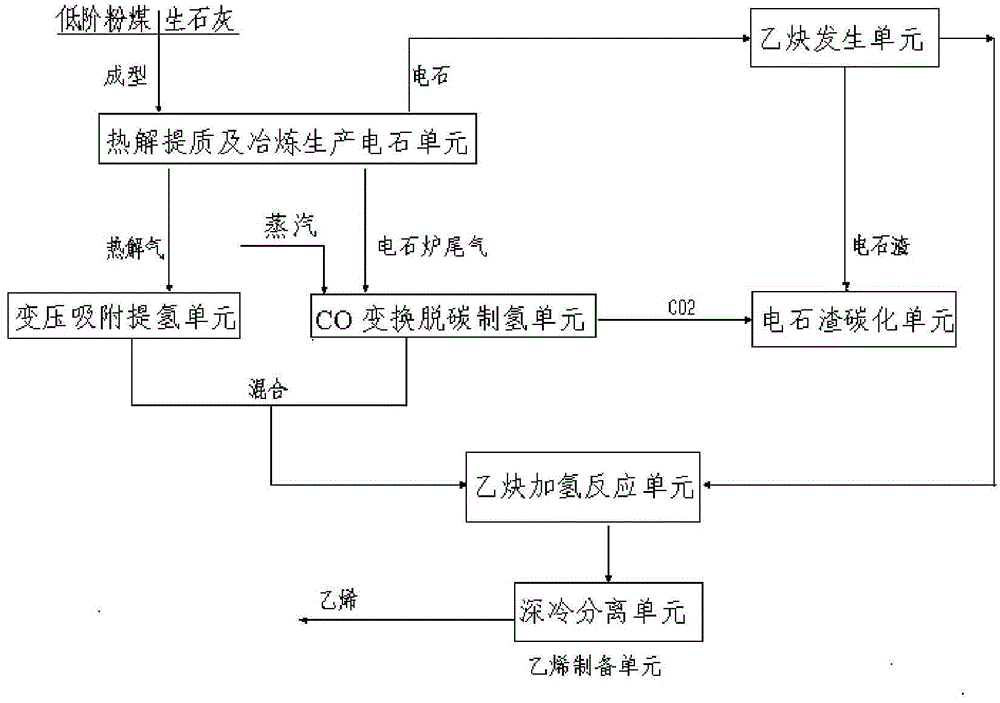

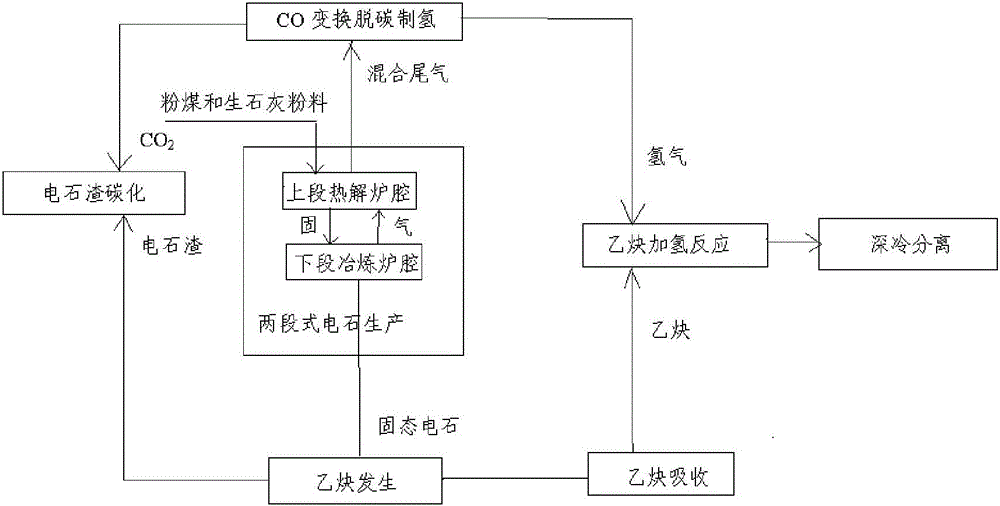

Method and system for producing ethylene by utilizing pulverized coal

ActiveCN104803819AShort processSmall footprintCalcium/strontium/barium carbonatesHydrocarbon by hydrogenationDecarburizationRaw material

The invention belongs to the field of coal chemical industry and provides a method for producing ethylene by utilizing pulverized coal. The method comprises the steps of (1) pyrolysis upgrading, (2) pressure swing adsorption and hydrogen extraction, (3) smelting production of calcium carbide, (4) CO conversion decarburization and hydrogen production, (5) acetylene generation, (6) acetylene hydrogenation reaction and (7) cryogenic separation so as to obtain the ethylene and other hydrocarbon products. According to the method, high-quality resources such as blocky coke, semi-coke and anthracite which are high in price are replaced with medium-low-order raw pulverized coal which is low in price, the medium-low-order raw pulverized coal serves as a raw material for producing the calcium carbide, the process energy consumption is low, high value-added tar and pyrolysis gas byproducts are obtained in the pyrolysis process, and the overall economy of the process is improved; a pyrolyzed solid product adopts a hot delivery process, the sensible heat is fully utilized, and the power consumption of a calcium carbide furnace is reduced; hydrogen obtained by the pressure swing adsorption of a pyrolysis gas product and hydrogen obtained by the tail gas conversion of the calcium carbide furnace are used for the acetylene hydrogenation reaction, another product of the calcium carbide furnace reacts with CO2 to generate nano calcium carbonate, and the environmental pollution is reduced.

Owner:SHENWU TECH GRP CO LTD

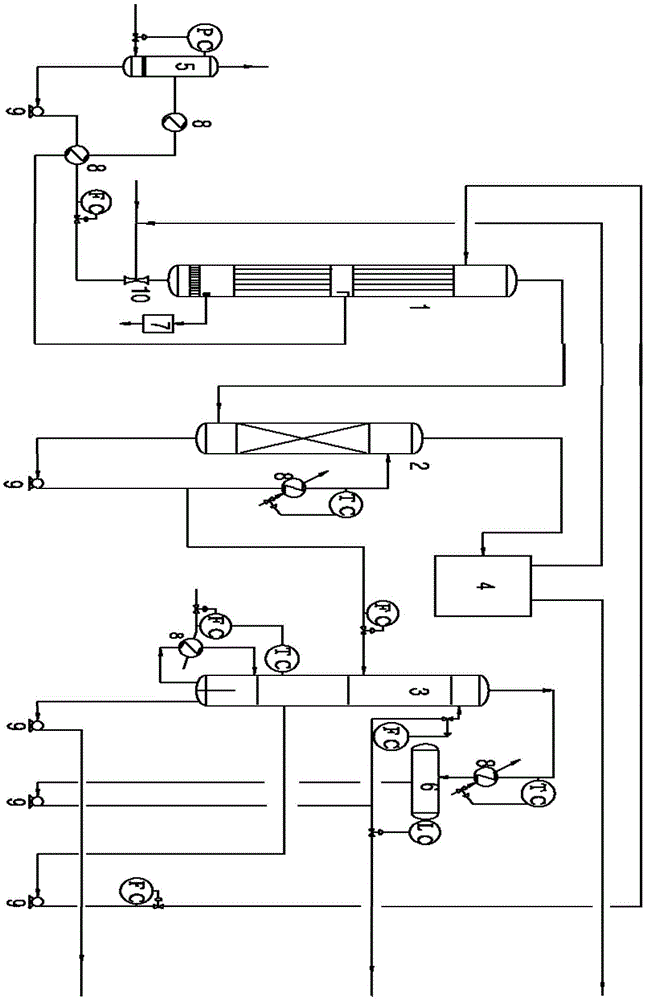

Device and method for producing ethylene through hydrogenation of high concentration acetylene

InactiveCN105418352AOvercoming stress limitsSimple structureHydrocarbon by hydrogenationChemical recyclingHigh concentrationGas phase

The invention provides a device and method for producing ethylene through hydrogenation of high concentration acetylene. The device comprises an acetylene hydrogenation reactor, a solvent absorbing tower, and an ethylene condensing device. The structure of the device is simple. An acetylene feed pipeline is connected to the acetylene hydrogenation reactor through an acetylene solvent tank; acetylene is dissolved into a solvent and then introduced into the acetylene hydrogenation reactor; through liquid phase pressurization, the pressure limitation of acetylene is overcome, thus hydrogenation of acetylene can be carried out under a pressure of 1.5 MPaG or more; the acetylene hydrogenation reactor is connected to the solvent absorbing tower, after the acetylene hydrogenation, the obtained gas phase is absorbed by the solvent, the multi-tower rectification separation in the conventional technology is not needed therefore, and the energy consumption is low. The provided device and method can utilize the excess calcium carbide product, greatly relieves the demand on ethylene in our country, and has an important meaning for the sustainable development of acetylene industry of our country, energy saving, and emission reduction.

Owner:BEIJING HUAFU ENG

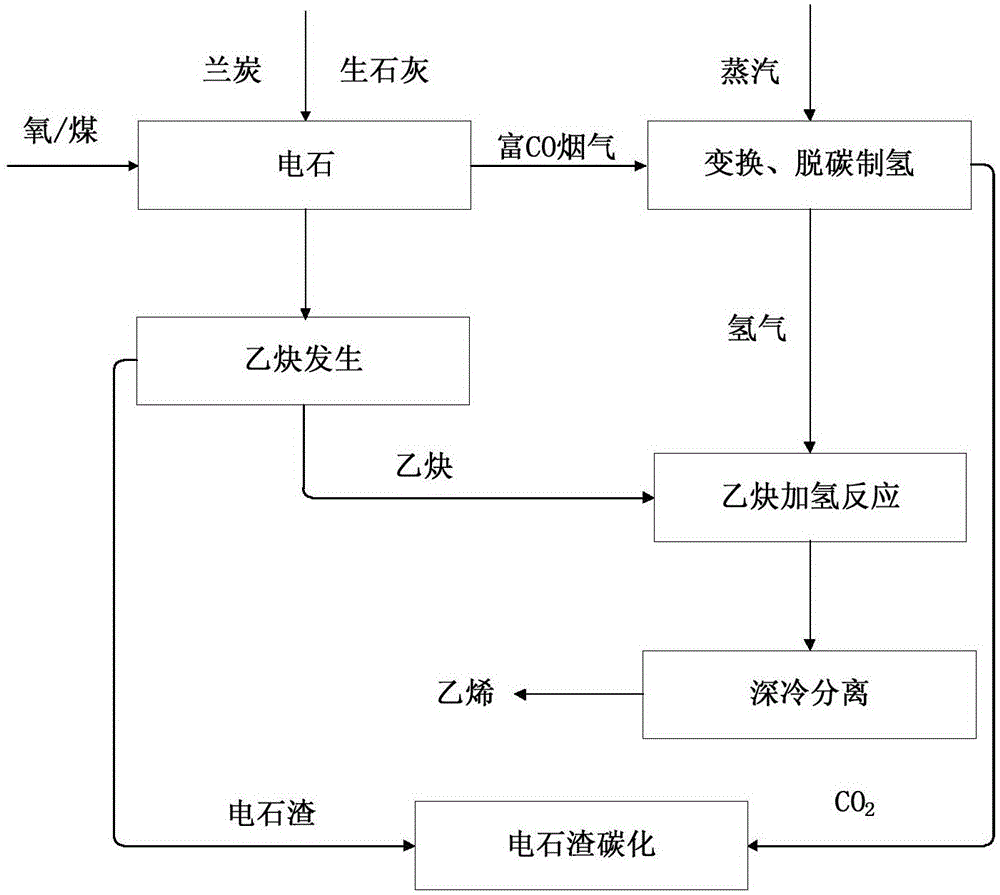

Process and system of preparing calcium carbide and ethylene through oxygen/coal injection

ActiveCN105129800AImprove uniformityReduce usageHydrocarbon by hydrogenationHydrocarbon purification/separationUranium carbideElectric consumption

The invention relates to a process and a system of preparing calcium carbide and ethylene through oxygen / coal injection, wherein the process includes following steps: (1) preparation of calcium carbide; (2) CO conversion and decarburization and hydrogen production; (3) acetylene generation; (4) acetylene hydrogenation reaction; and (5) cryogenic separation. In the invention, oxygen and coal powder are injected during a calcium carbide smelting process. Because that heat generated from incomplete combustion of oxygen and coal can radiate to a position which is difficult to reach by arc light, the process, compared with a conventional calcium carbide furnace method, is more uniform in heat distribution in furnace, thereby reducing electric consumption in the calcium carbide furnace and calcium carbide production period. The injected coal powder can replace a part of coke, so that the process can reduce production cost of the calcium carbide. Meanwhile, the process fully utilizes calcium carbide smelting tail gas being rich in CO, which is used for preparing hydrogen through the CO conversion to prepare the hydrogen source in the acetylene hydrogenation reaction, so that not only is environment pollution reduced but also economic benefit is improved greatly.

Owner:SHENWU TECH GRP CO LTD

Method for preparing ethylene by heterogeneous reaction

ActiveCN104829406AReduce surface tensionLow yieldHydrocarbon by hydrogenationSlurry reactorGas phase

The invention relates to a method for preparing ethylene by heterogeneous reaction. The method comprises the following steps: (1) providing a hydrogen-containing gas-phase material; (2) absorbing acetylene with a liquid-phase solvent with the surface tension of at most 1mN / m to form a liquid-phase material; (3) providing a heterogeneous reaction system uniformly composed of the liquid-phase material, the gas-phase material and a hydrogenation catalyst, wherein the reaction temperature of the heterogeneous reaction system is 110-185 DEG C, and the reaction pressure is 2.5-7.5 MPa; and (4) introducing the gas-phase material and the liquid-phase material into the heterogeneous reaction system to perform continuous reaction according to the hydrogen / acetylene mole ratio of (3-9):1 at the operation air speed of 30000-90000 mL / (gcat.h), and separating the gas-phase product to obtain the product. The method provided by the invention overcomes the defects of temperature runaway, difficulty in transfer of reaction heat and great bed pressure drop in the fixed bed, and the detects of low reaction pressure, low productivity, lower ethylene selectivity and catalyst deactivation due to high tendency to producing green oil in the slurry reactor in the traditional methods for preparing ethylene by high-purity acetylene hydrogenation.

Owner:BEIJING HUAFU ENG

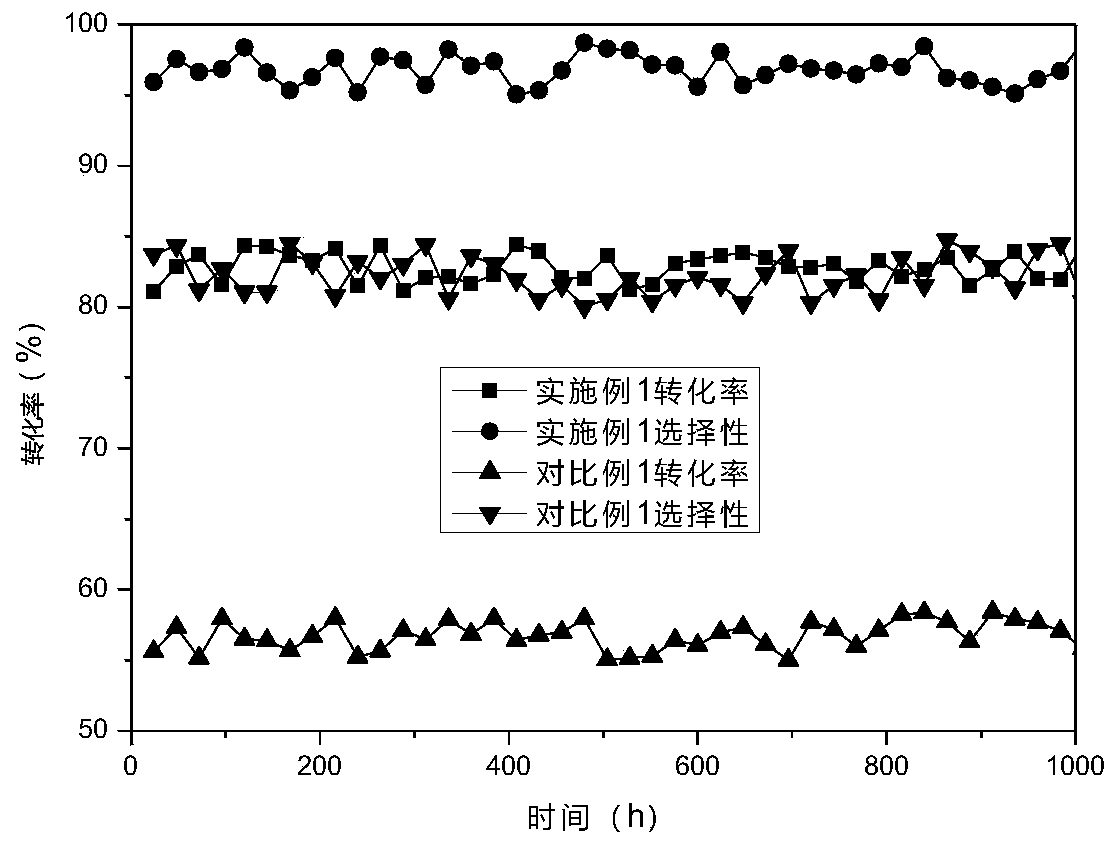

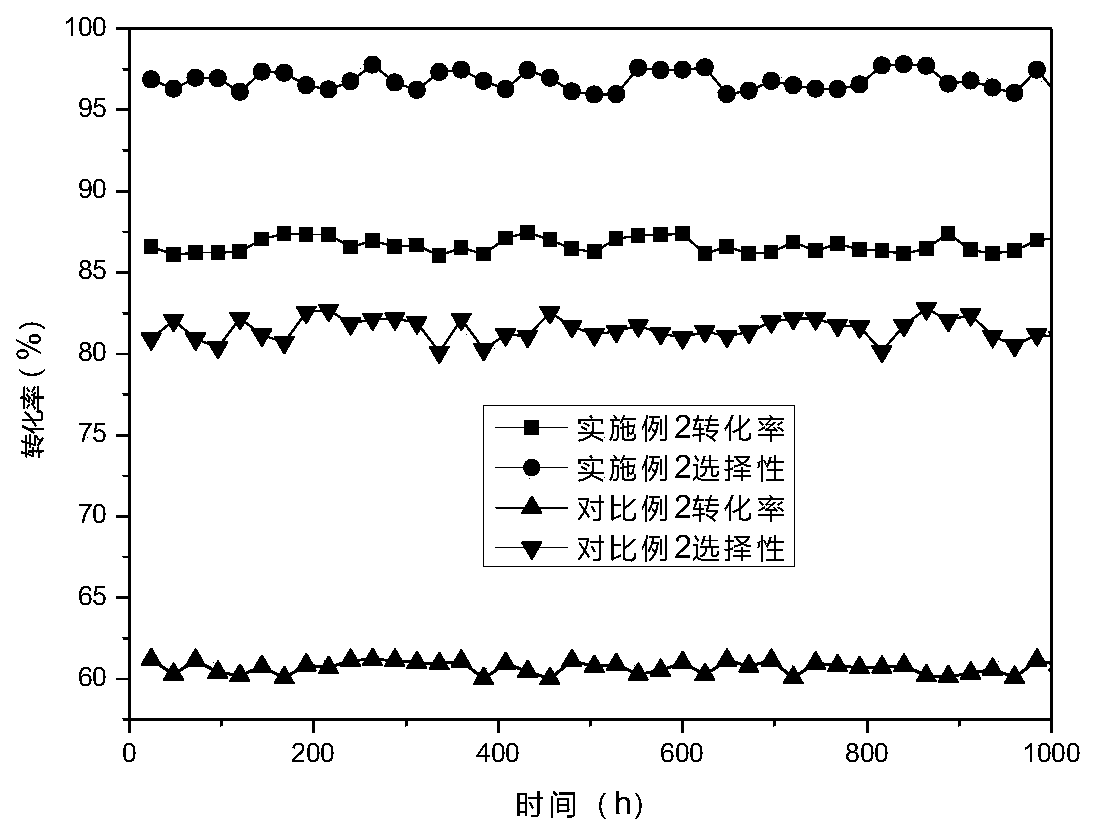

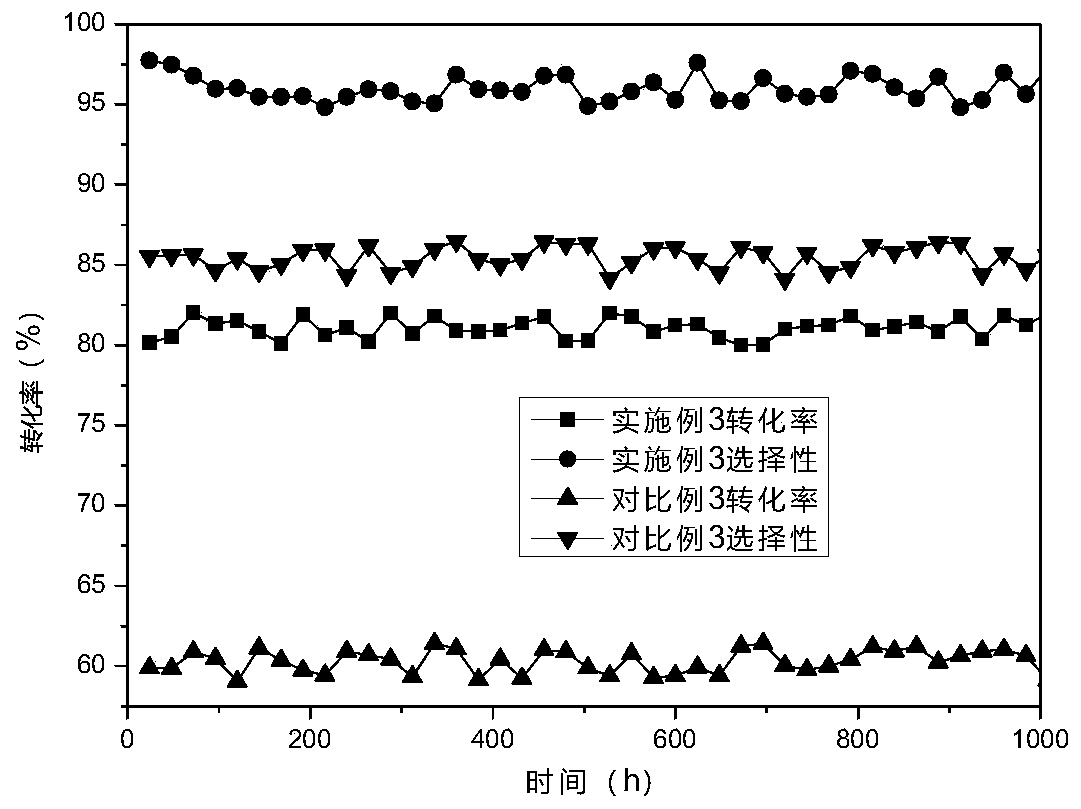

Acetylene hydrogenation catalyst and preparation method thereof

ActiveCN106622223AGood dispersionImprove stabilityHydrogen separationCatalyst activation/preparationActive componentWork in process

The invention relates to an acetylene hydrogenation catalyst and a preparation method thereof. The preparation method comprises the following steps: 1) using an alkaline solution to process a carrier, then calcining the carrier to obtain a carrier Z; 2) loading a main active component palladium to the carrier Z to obtain a catalyst semi-finished product; and 3) mixing the catalyst semi-finished product and a solution containing a free-radical scavenger and contacting, and then performing ionizing radiation on the catalyst semi-finished product to reduce palladium to a simple substance. The prepared catalyst has good dispersibility and stability, can obviously increase the catalyst hydrogenation performance, especially increases the capability for removing microscale acetylene from CO and H2-rich gas mixture, and has good industrial application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

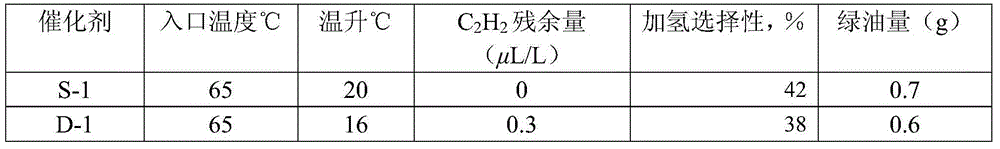

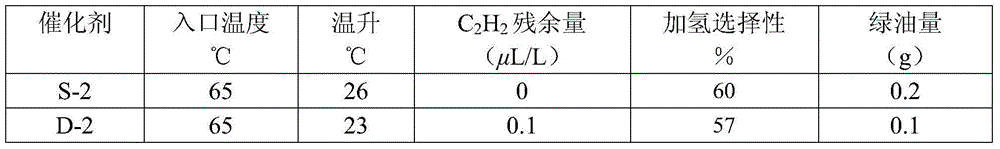

Selective hydrogenation method of trace amount of acetylene in methanol to olefin (MTO) apparatus

ActiveCN105732264AImprove hydrogenation activityImprove stabilityHydrocarbon purification/separationHydrocarbonsImpurityHydroxy compound

A selective hydrogenation method of trace amount of acetylene in a methanol to olefin (MTO) apparatus. In the method, a C2 material from the top of a deethanizing column in the MTO apparatus is fed into an adiabatic bed reactor to perform selective hydrogenation. A Pd-Ni-series catalyst is arranged in the adiabatic bed reactor and is prepared with Al2O3 or a mixture of the Al2O3 with other oxides as a carrier. During preparation of the catalyst, the carrier is combined with hydroxylbipyridine, wherein a metal complex is formed from the hydroxyl bipyridine combined on the carrier and active components. The reaction conditions include: inlet temperature of the adiabatic bed reactor is 45-150 DEG C, reaction pressure is 2.0-3.5 MPa and space velocity is 2000-7000 / h. The method, when being used for the selective hydrogenation, improves activity and selectivity of the catalyst significantly and improves the stability of the catalyst. The catalyst has excellent anti-impurity interference capability and is especially used in a trace amount acetylene hydrogenation apparatus being high in impurity content, such as sulfur and arsenic.

Owner:PETROCHINA CO LTD

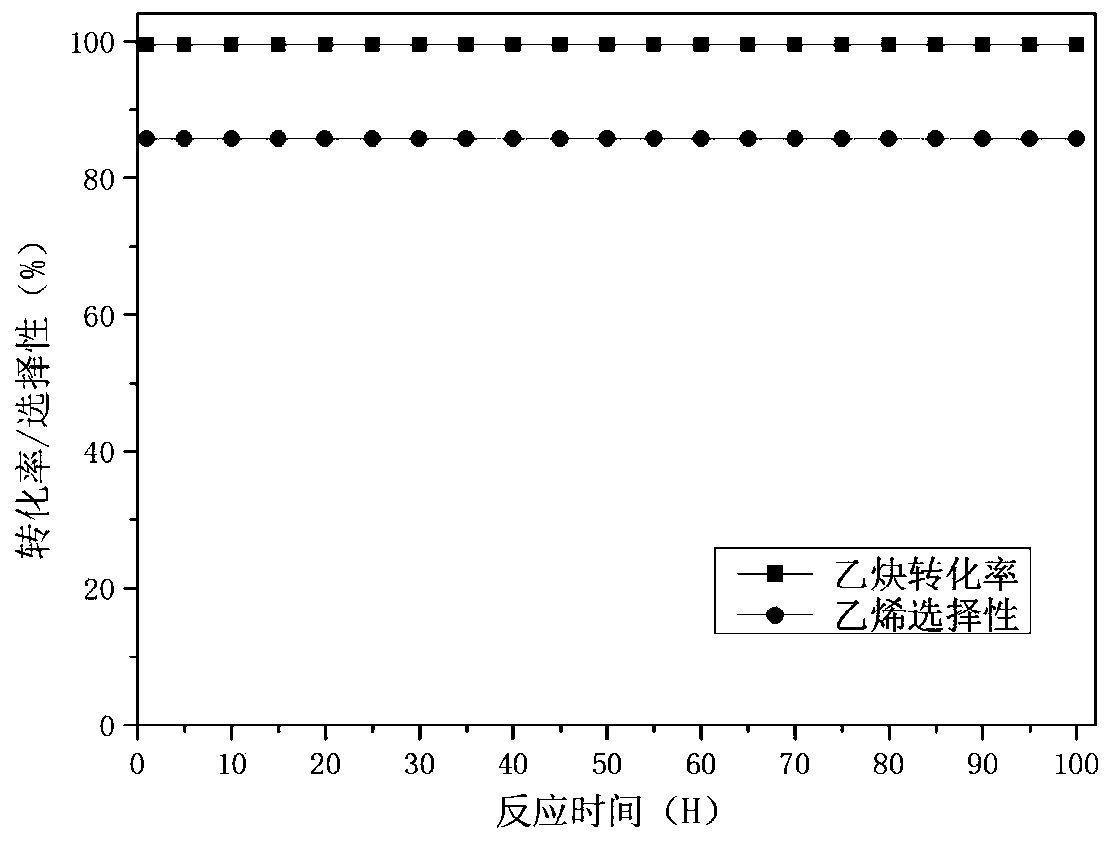

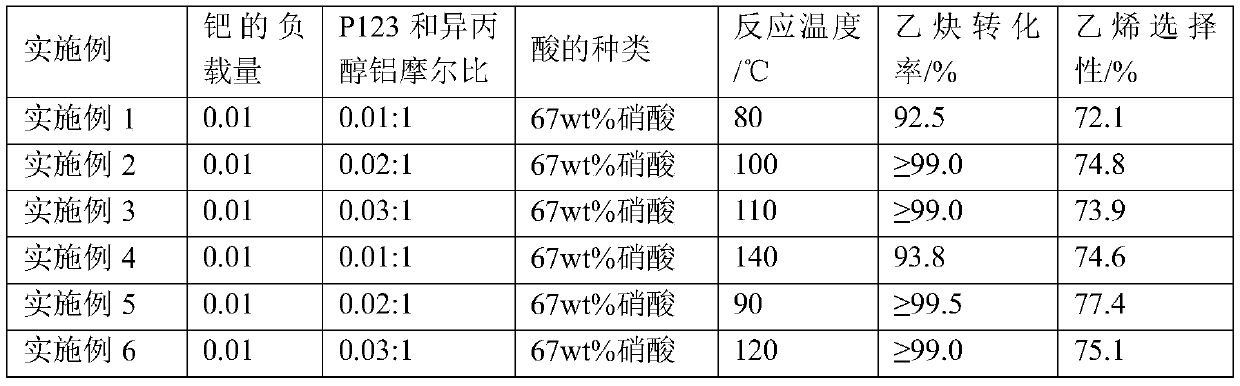

In-situ monatomic Pd/mesoporous Al2O3 catalyst as well as preparation method and application thereof

ActiveCN110508278AImprove catalytic performanceHigh activityHydrocarbon by hydrogenationCatalystsMuffle furnaceChemistry

The invention provides an in-situ monatomic Pd / mesoporous Al2O3 catalyst as well as a preparation method and application thereof. The catalyst is prepared by the following method: dissolving P123 intoabsolute ethyl alcohol; adding an acid and aluminum isopropoxide, dropwise adding a palladium solution while stirring, continuously stirring until the palladium solution is completely dissolved, thendrying at 50-80 DEG C to obtain a spongy sample, putting the sample into a muffle furnace, heating to 300-700 DEG C, and roasting for 4-9 hours to obtain the in-situ monatomic Pd / mesoporous Al2O3 catalyst. Palladium single atoms on the surface of a carrier can be better anchored through strong chemical bonds by an in-situ synthesis method; the catalyst has the advantages of reduction of highly dispersed metal atom aggregation, improvement of the atom efficiency, maximum utilization of precious metals, reduction of the cost of the catalyst, maintenance of a high acetylene conversion rate in anacetylene hydrogenation process, and great improvement of the selectivity and the stability of ethylene in the reaction.

Owner:ZHEJIANG UNIV OF TECH

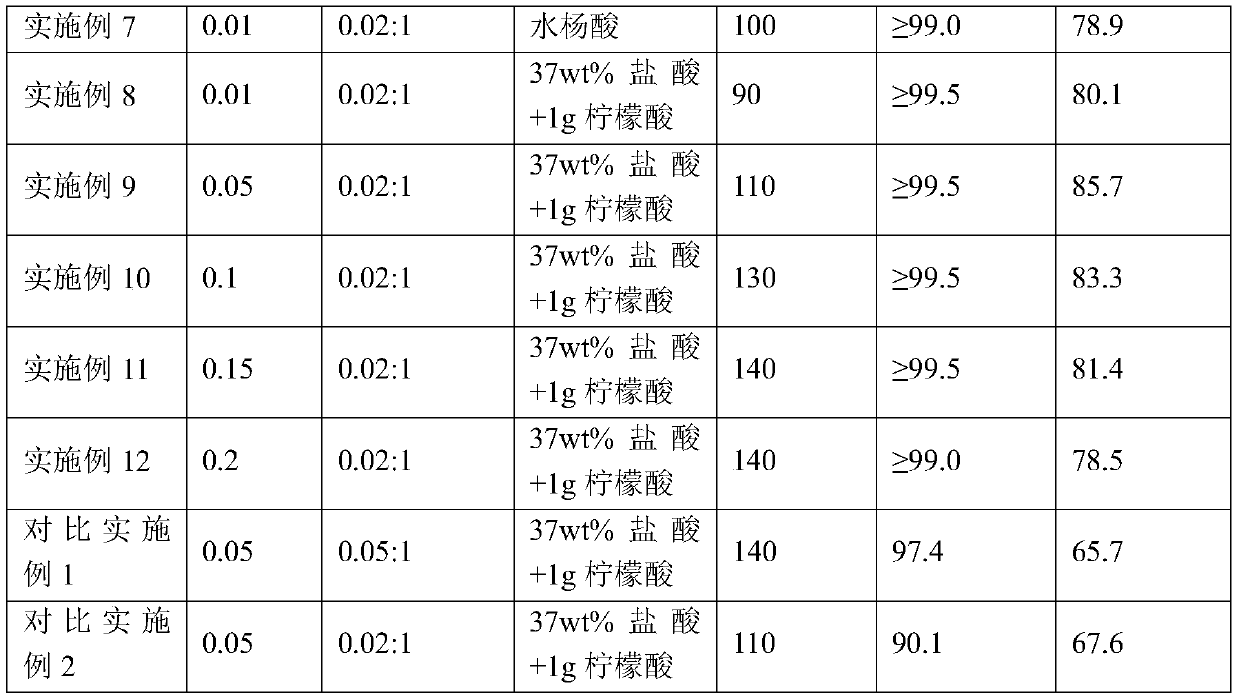

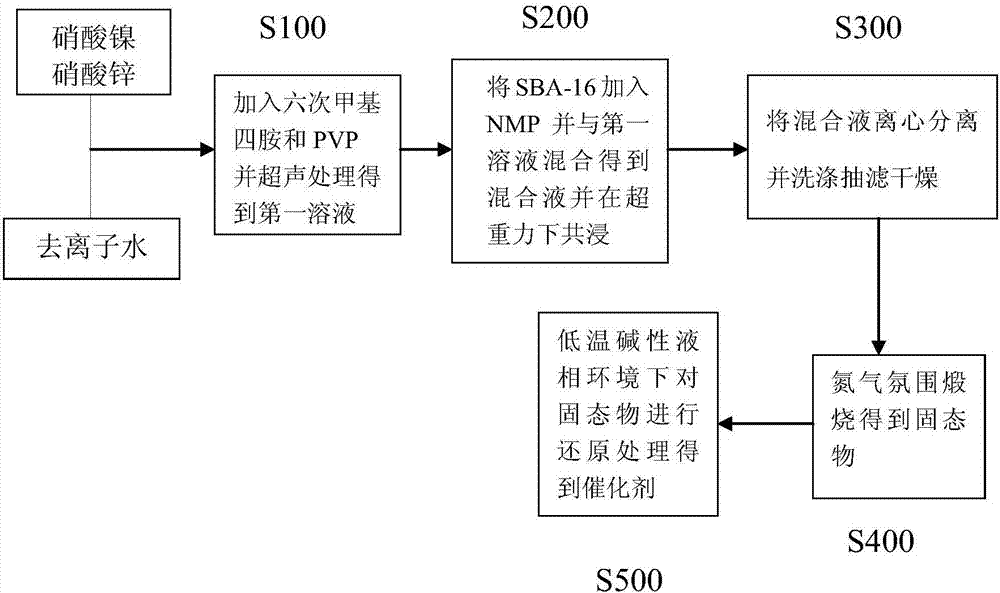

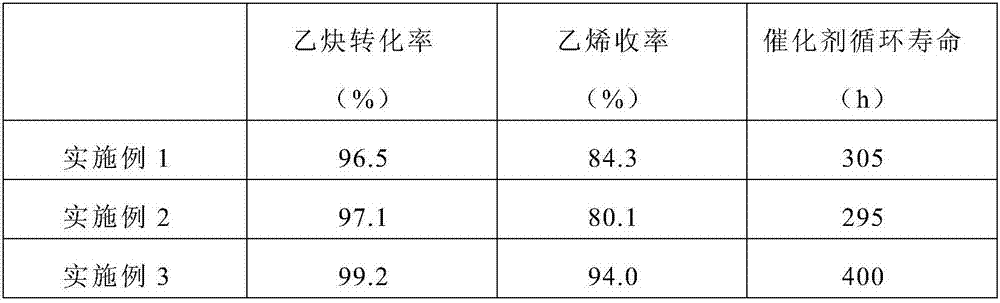

Method for preparing catalyst applied to preparation of ethylene by hydrogenation of acetylene through super-gravity process and application of catalyst

PendingCN106925332AAvoid restore operationsEasy to operateMolecular sieve catalystsHydrocarbon by hydrogenationReduction treatmentHexamethylenetetramine

The present application discloses a method for preparing a catalyst for hydrogenation of acetylene to ethylene by a high gravity method, which comprises the following steps: dissolving nickel nitrate and zinc nitrate in deionized water, adding hexamethylenetetramine and PVP for ultrasonic treatment Obtain the first solution, then add mesoporous molecular sieve SBA-16 into NMP and mix with the first solution to obtain a mixed solution, then move to a high-gravity rotating packed bed for co-immersion, and centrifuge the mixed solution to obtain a solid substance After drying, it was calcined under a nitrogen atmosphere and naturally lowered to room temperature and then subjected to reduction treatment in a weakly alkaline liquid phase environment to obtain a Ni-Zn / SBA-16 catalyst. The present application also provides an application method of the catalyst prepared by the above method. The catalyst prepared by the above method has a significantly longer cycle life than the catalyst prepared by the traditional method in industrial applications, and can be directly used for the reaction after being reduced by sodium borohydride before use, without the need for high-temperature hydrogen reduction, which is more beneficial to simplify gas-liquid ‑Process flow of solid three-phase catalytic system.

Owner:SHENWU TECH GRP CO LTD

Diacetylene hydrogenation catalyst

ActiveCN105312058AImprove stabilityIncreased hydrogenation conversionHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsAlkaneAlkaline earth metal

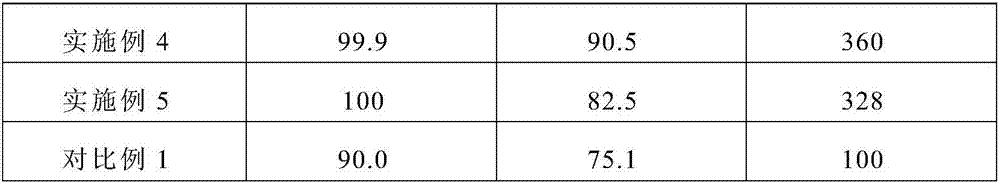

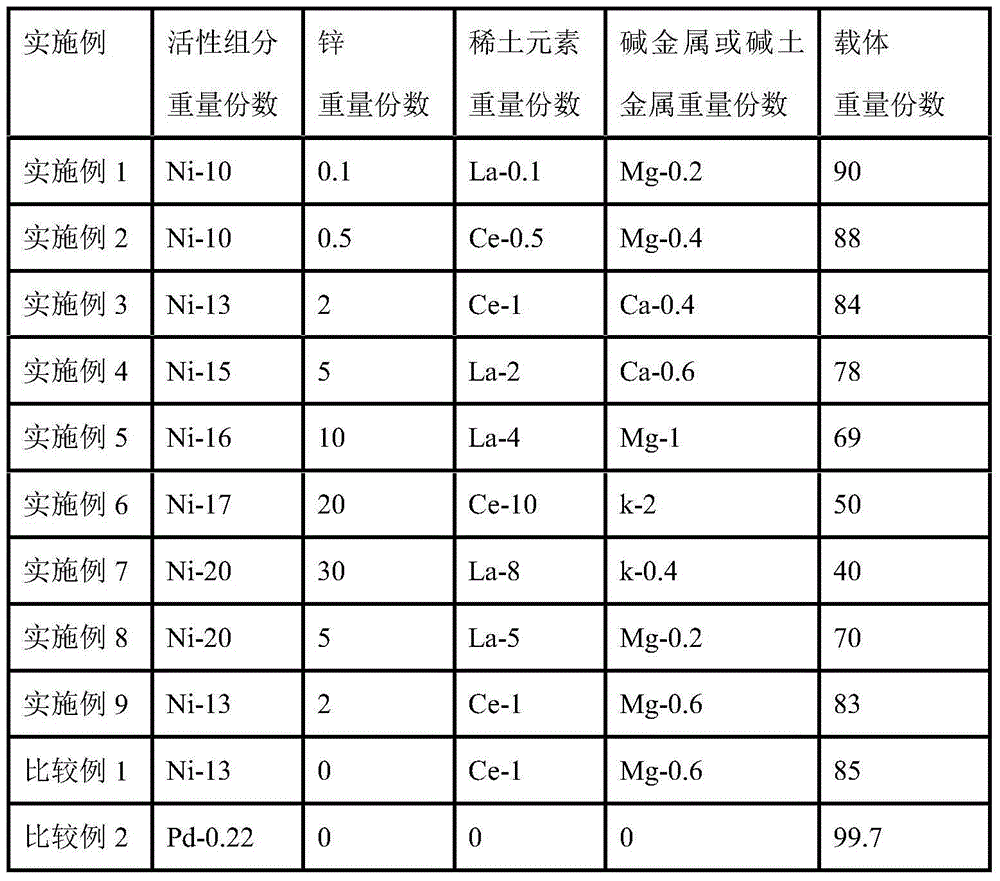

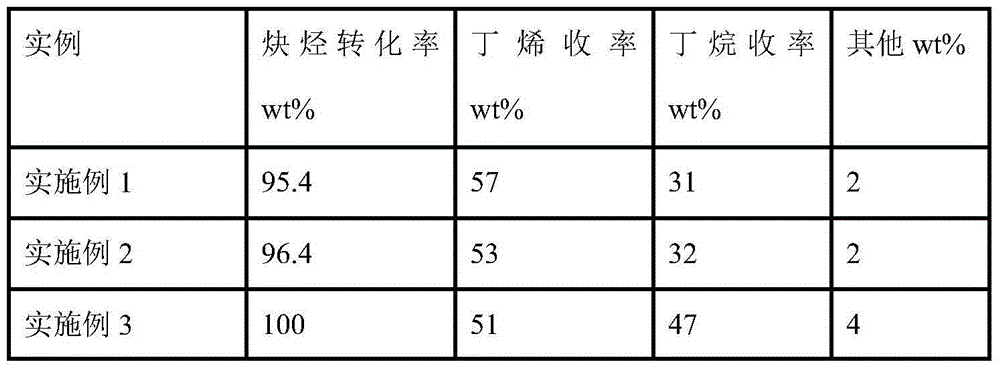

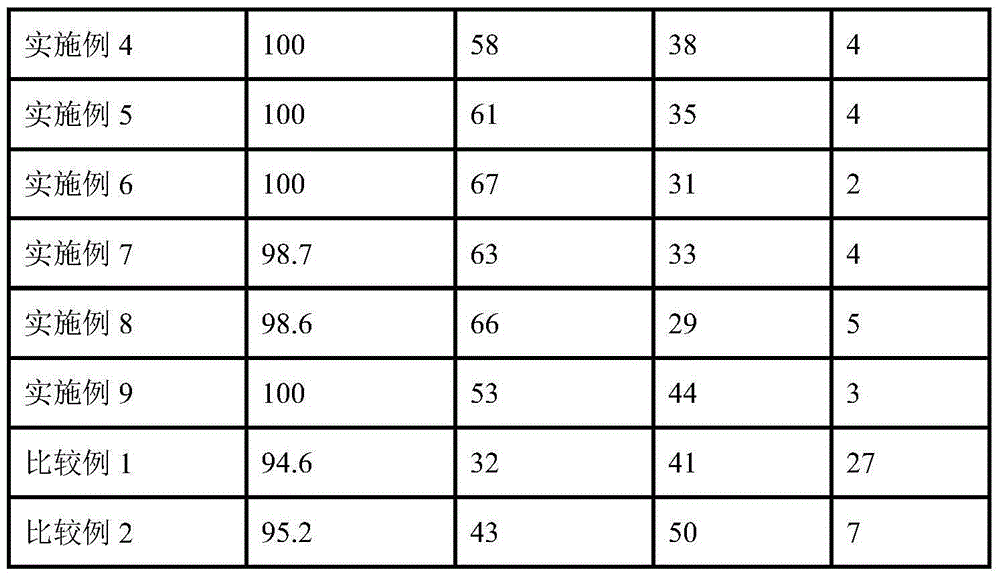

The invention relates to a diacetylene hydrogenation catalyst and mainly solves the technical problems of high catalyst cost and poor stability in the prior art. In the invention, by means of a fixed bed reactor, a material containing the diacetylene and hydrogen are employed as raw materials and are contacted with a catalyst bed layer through the reactor to convert the diacetylene into monoalkene or alkane. The catalyst used in the reactor comprises the following components, on the basis of the weight part of the catalyst: (a) 10-20 parts of metal nickel or an oxide thereof, (b) 0.1-10 parts of at least one element of cerium or lanthanum or an oxide thereof; (c) 0.1-30 parts of zinc or an oxide thereof, (d) 0-2 parts of alkali metal or alkali earth metal, and (e) 38-90 parts of aluminum oxide. The technical scheme solves the technical problem well. The diacetylene hydrogenation catalyst is used in industrial production of high-order acetylene hydrogenation in a device of partially oxidizing natural gas to produce acetylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-dispersion palladium-doped sulfur active carbon catalyst, and preparation method and application thereof

InactiveCN110560086AEffective dispersionGood dispersionHydrocarbon purification/separationCatalystsPalladium nanoparticlesHigh selectivity

The invention provides a high-dispersion palladium-doped sulfur active carbon catalyst, and a preparation method and application thereof. According to the preparation method, sulfur doping is carriedout by adopting a method of carrying out a hydrothermal process first and then carrying out roasting, and the doped sulfur can more stably exist on the surface of a carbon material by the method. A method for loading noble metal by an impregnation method is simple and convenient, and cost is low. In the high-dispersion palladium-doped sulfur active carbon catalyst, doped sulfur on the surface of the carrier exerts an anchoring effect, so that high dispersion and size regulation and control of palladium nanoparticles can be realized, and the atom utilization rate of a noble metal is effectivelyimproved. Strong interaction between sulfur and the metal ensures high stability of the catalyst, so that the metal nanoparticles are not easily agglomerated or lost in an acetylene hydrogenation reaction process, and the service life of the catalyst is prolonged. The catalyst disclosed by the invention has high selectivity to ethylene in an acetylene hydrogenation reaction, and acetylene can becompletely converted. In addition, the use condition is mild, stability is good, the usage amount of the catalyst is small, and the service life of the catalyst is long.

Owner:ZHEJIANG UNIV OF TECH

Silver modified raney copper catalyst, preparation method thereof and method for selective acetylene hydrogenation of C-4 fraction

ActiveCN106552647AHigh selectivityHigh catalytic efficiencyHydrocarbon purification/separationHydrocarbonsAlloyCopper

The invention relates to the field of acetylene hydrogenation and discloses a silver modified raney copper catalyst, a preparation method thereof and a method for selective acetylene hydrogenation of C-4 fraction. The preparation method of the silver modified raney copper catalyst comprises the following steps that copper-aluminum alloy and a solution containing caustic alkali are mixed, and the raney copper catalyst is obtained; and then the raney copper catalyst and a solution containing silver ion are contacted for reacting. The silver modified raney copper catalyst provided by the invention is high in selectivity and catalytic efficiency, and the space velocity can be remarkably improved when the silver modified raney copper catalyst provided by the invention is used for selective acetylene hydrogenation of the C-4 fraction.

Owner:CHINA PETROLEUM & CHEM CORP +1

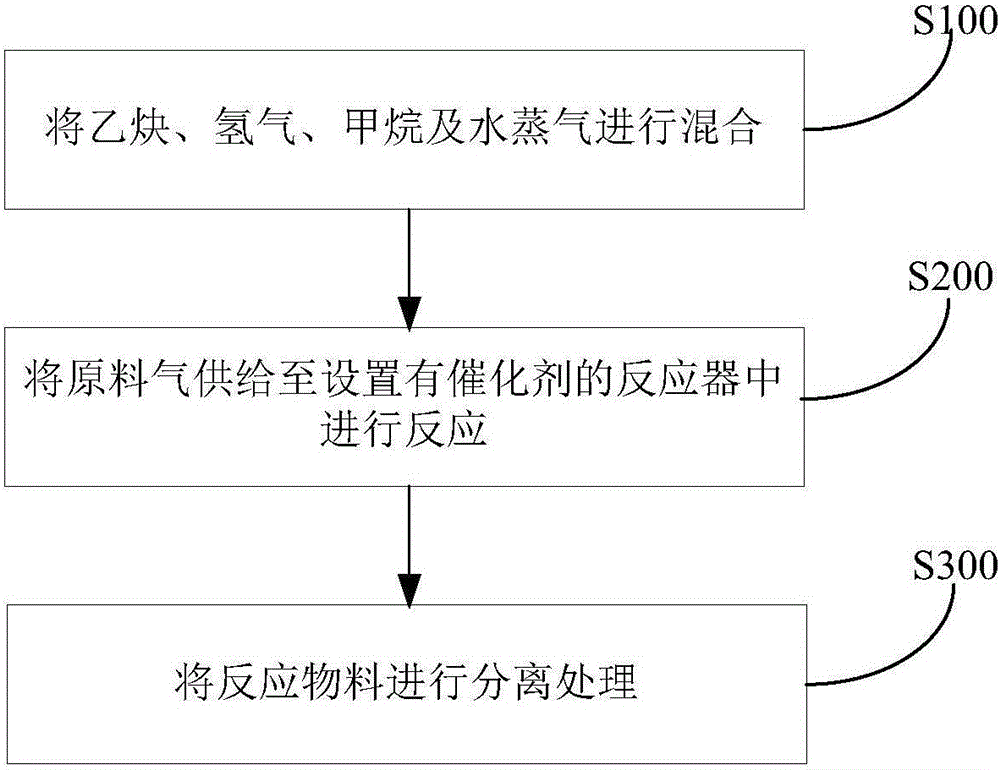

Method for preparing benzene and co-producing ethylene from acetylene

InactiveCN105967972AOvercoming inactivation problemsSimple processHydrocarbon by hydrogenationHydrocarbonsHigh concentrationWater vapor

The invention discloses a method for preparing benzene and co-producing ethylene from acetylene. The method comprises the following steps: (1) mixing the acetylene, hydrogen, methane and steam to obtain feed gas; (2) supplying the feed gas to a reactor with a catalyst for reaction; (3) performing separation treatment on a material obtained by reaction in step (2) to obtain the benzene and the ethylene. According to the method, multiple reactions are coupled, so that the shortcomings of complexity in catalyst preparation, poor selectivity, harsh process conditions, high carbon deposition rate and requirements on use of a toxic solvent during alkyne aromatization reaction are overcome, the problem of high catalyst deactivation rate caused by heat transfer difficulty and high green oil production rate of a high-concentration acetylene hydrogenation process is solved, and the benzene and the ethylene can be prepared at the same time; moreover, the method has the advantages of simple process, easiness for temperature control and product selectivity adjustability, and is suitable for large-scale production.

Owner:BEIJING HUAFU ENG

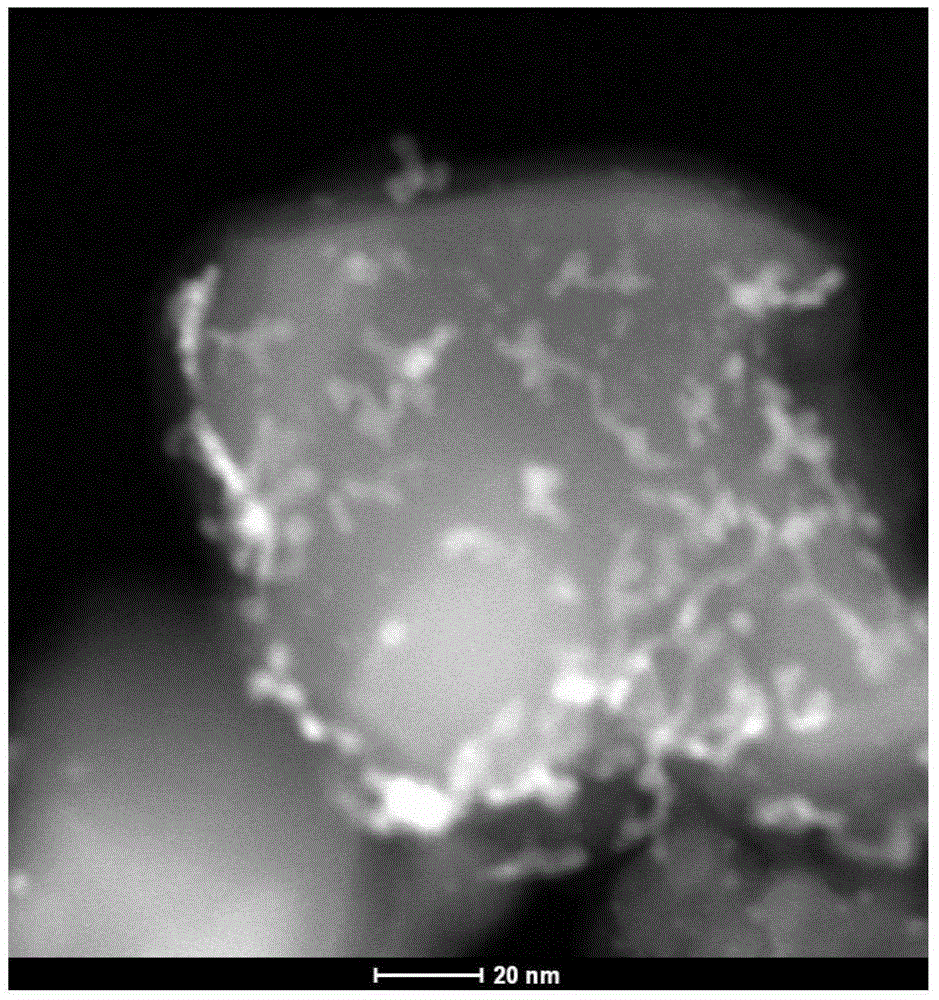

Nano-carbon loaded atomic-scale dispersion copper-based catalyst, and preparation method and application thereof

PendingCN109806867AWide variety of sourcesLow costHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsHydrogenation reactionPalladium catalyst

The invention discloses a nano-carbon loaded atomic-scale dispersion copper-based catalyst, and a preparation method and application thereof, and belongs to the technical field of catalysts applied toacetylene selective hydrogenation reaction. Acetylene is subjected to hydrogenation to generate ethylene in mixed feed gas through the atomic-scale dispersion copper-based catalyst, and the using temperature of the catalyst is 100-200 DEG C; and copper is dispersed on a nano-carbon material in an atomic-scale mode, compared with a traditional palladium-based carbon material and a commercial palladium catalyst, the nano-carbon loaded atomic-scale dispersion copper-based catalyst can effectively catalyze the acetylene to be converted into the ethylene, and acetylene hydrogenation selectivity isobviously improved. The nano-carbon loaded atomic-scale dispersion copper-based catalyst is low in cost, good in stability performance and not prone to inactivation in the reaction process.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

High-dispersion Pd-Ag supported acetylene hydrogenation catalyst and preparation method thereof

InactiveCN110841635ASolving activitySolve the problem of selectivityHydrocarbon by hydrogenationCatalystsCarboxyl radicalPtru catalyst

The invention discloses a high-dispersion Pd-Ag alloy catalyst, and belongs to the field of chemical catalysts. Active components of the catalyst are Pd and Ag as auxiliary components, a carrier is Al2O3 or a composite oxide carrier containing the Al2O3, and the catalyst is characterized in that the content of the Pd in the catalyst is 0.01-0.1% by mass, wherein the content of the Ag is 0.03-1.0%,the catalyst is an alloy type bimetallic catalyst, and in the preparation process, a carboxyl-containing compound is adopted to be matched with the Pd for site-specific loading, so that Pd, high dispersion and Pd-Ag alloy formation are facilitated. The method solves the problems of large active metal particle size, non-uniform dispersion, low catalyst active metal utilization rate, unsatisfactoryactivity and selectivity, easy coking of the catalyst and fast deactivation rate caused by the preparation of the catalyst by an impregnation method in the industry at present. The catalyst providedby the invention can be used in the selective hydrogenation process of C2 fraction.

Owner:天津金玺科技发展有限公司

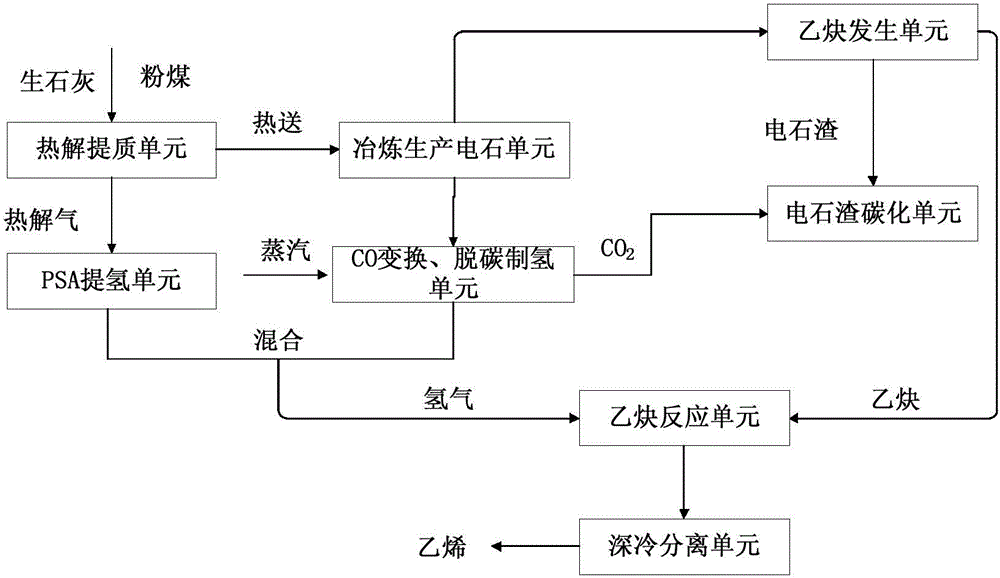

Method and system for preparing ethylene from powdered coal

ActiveCN104945215AGuaranteed volume ratioReduce pollutionCalcium/strontium/barium carbonatesHydrocarbon by hydrogenationCoalDecarburization

The invention relates to a method and system for preparing ethylene from the raw material of powdered coal. The method includes the steps of pyrolysis upgrading and smelting production of calcium carbide, pressure-swing adsorption hydrogen extraction, CO conversion, decarburization hydrogen production, acetylene generation, acetylene hydrogenation reaction and cryogenic separation. The method has the advantages that technical energy consumption is lowered, hydrogen sources are broadened and by-products are recycled, environmental pollution is easily reduced, the ethylene production cost is lowered, the economic benefits are greatly increased, and the method can be better applied to large-scale industrial production.

Owner:SHENWU TECH GRP CO LTD

Acetylene hydrogenation slurry bed reaction as well as catalyst separation device and method

PendingCN107774203AImprove conversion rateHigh yieldHydrocarbon by hydrogenationChemical/physical processesHydrogenation reactionSlurry

The invention belongs to the field of preparing ethylene through acetylene hydrogenation, and relates to acetylene hydrogenation slurry bed reaction as well as a catalyst separation device and method.The method comprises the following steps of enabling acetylene and hydrogen gas to be subjected to hydrogenation reaction in a hydrogenation reactor which contains a catalyst and a working solution,discharging crude ethylene after reaction, separating a working slurry solution with a membrane separator to obtain a concentrated solution and a clear solution, conveying the concentrated solution directly to the hydrogenation reactor to be recycled, enabling the obtained clear solution to be subjected to gas-liquid separation, and then enabling gas and a fresh working solution to return into thehydrogenation reactor to be continuously used. The hydrogenation reactor is internally provided with an angle gear-shaped gas redistribution device, the gas volume fraction in the working solution can be improved, the radial distribution uniformity of the gas in the reactor is improved, the conversion rate of acetylene and ethylene yield are improved; an airtight membrane separator is adopted toperform solid-liquid separation on the working slurry liquid, the separation process can be guaranteed to be safe and stable, a by-product 'green oil' can be timely extracted, the activity of the catalyst is guaranteed, and the reaction can be promoted to be successfully performed.

Owner:河北美邦工程科技股份有限公司

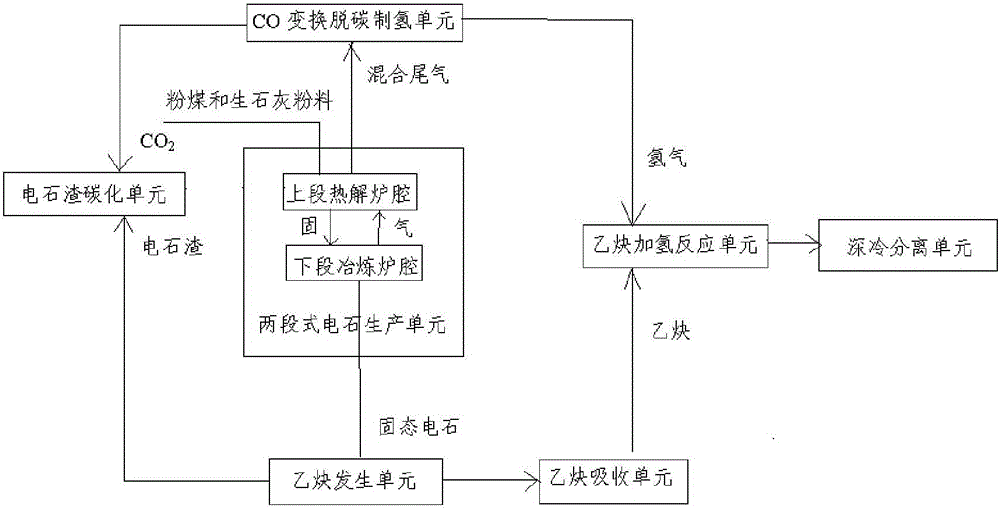

Process and system for preparing ethylene from powdered coal by two-stage calcium carbide furnace

ActiveCN104987275AGuaranteed volume ratioReduce pollutionHydrocarbon by hydrogenationDistillation purification/separationHigh pressureSolvent

The invention relates to a process and a system for preparing ethylene from powdered coal by a two-stage calcium carbide furnace. The process includes (1) two-stage calcium carbide furnace production; (2) carbon monoxide transformation and decarburization for hydrogen production; (3) acetylene generation; (4) acetylene hydrogenation reaction; and (5) cryogenic separation. According to the invention, the upper and lower two-stage calcium carbide furnace is adopted, the pyrolysis process and the calcium carbide production process are combined, the continuous calcium carbide production process and the effective utilization of heat energy are realized, so that the energy consumption of calcium carbide production is effectively reduced; and middle and low order pulverized coal with low costs is adopted as carbon materials, the costs are reduce, the raw material surface area is increased, the reactivity is increased, the calcium carbide smelting temperature is reduced, and the energy consumption is effectively reduced. Tar and pyrolysis gas by-products with high added values are obtained in the pyrolysis process, so that the overall economy of the process is improved, and in addition, the process adopts a liquid solvent to absorb acetylene, avoids the acetylene polymerization explosion hazard, and realizes high pressure reaction, so as to improve the production capacity of the device.

Owner:SHENWU TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com