High-dispersion palladium-doped sulfur active carbon catalyst, and preparation method and application thereof

A technology of sulfur activated carbon and highly dispersed palladium, which is applied in the field of highly dispersed palladium-sulfur-doped activated carbon catalysts and its preparation, can solve the problems of easy excessive hydrogenation and low ethylene selectivity, and achieve difficult agglomeration and loss, high catalyst activity, The effect of increasing the utilization rate of atoms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

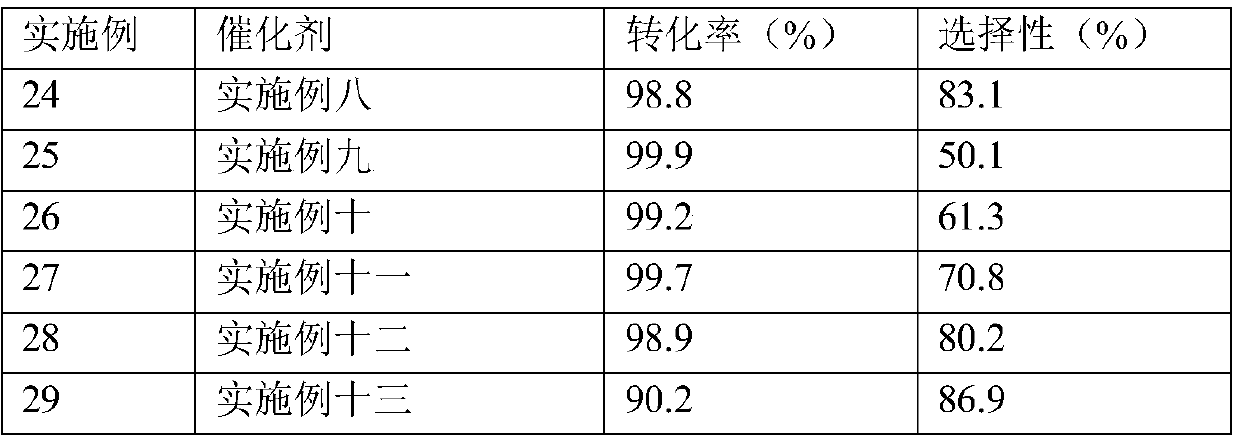

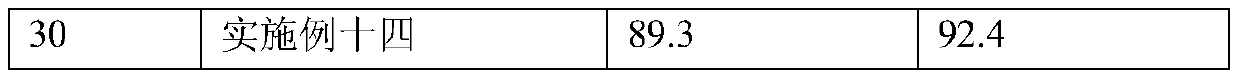

Examples

Embodiment 1

[0028] Weigh Na 2 S·9H 2 Dissolve 3.8218g of O in 50mL of deionized water, mix well with 5g of activated carbon, and stir magnetically at a stirring rate of 1000r / min in a water bath at 40°C for 60min. Then transfer to a high-pressure hydrothermal reactor for hydrothermal treatment at 180°C for 40 hours; filter after cooling to room temperature, obtain a filter cake by suction filtration, dry in vacuum at 80°C for 8 hours, and transfer to a quartz boat. Place the quartz boat in a tube furnace under N 2 Under the atmosphere, the temperature was raised to 800°C at a rate of 3°C / min and maintained for 2h. After being cooled to room temperature, it was taken out to obtain sulfur-doped activated carbon. Then spread 1 g of the above-mentioned sulfur-doped activated carbon on a watch glass, and add the chloropalladium acid solution dropwise according to the loading amount of 0.1 wt % until the carrier is just wetted, and stir slightly. After the catalyst uniformly wetted by the c...

Embodiment 2

[0030] Weigh Na 2 S·9H 2 O 3.0580g was dissolved in 50mL of deionized water, mixed evenly with 5g of activated carbon, and magnetically stirred at a stirring rate of 600r / min in a 60°C water bath for 40min. Then transfer to a high-pressure hydrothermal reaction kettle for hydrothermal treatment at 250°C for 30h; filter after cooling to room temperature, and obtain a filter cake by suction filtration, vacuum-dry at 60°C for 10h and transfer to a quartz boat. The quartz boat was placed in a tubular heating furnace, and the temperature was raised to 700 °C at a rate of 3 °C / min under He atmosphere, and maintained for 3 h. After being cooled to room temperature, it was taken out to obtain sulfur-doped activated carbon. Then spread 1 g of the above-mentioned sulfur-doped activated carbon on a watch glass, add palladium acetate solution dropwise according to the load of 0.08 wt% until the carrier is just wet, and stir slightly. After the catalyst uniformly wetted by the chloropal...

Embodiment 3

[0032] Weigh Na 2 S·9H 2 Dissolve 1.9123g of O in 50mL of deionized water, mix well with 5g of activated carbon, and stir magnetically at a stirring rate of 300r / min in a water bath at 80°C for 50min. Then transfer to a high-pressure hydrothermal reactor for hydrothermal treatment at 200°C for 24 hours; filter after cooling to room temperature, and obtain a filter cake by suction filtration, vacuum-dry at 50°C for 12 hours, and then transfer to a quartz boat. The quartz boat was placed in a tubular heating furnace, and the temperature was raised to 600 °C at a rate of 3 °C / min under Ar atmosphere, and maintained for 4 h. After being cooled to room temperature, it was taken out to obtain sulfur-doped activated carbon. Then spread 1 g of the above-mentioned sulfur-doped activated carbon on a watch glass, and add the chloropalladium acid solution dropwise according to the loading amount of 0.05 wt % until the carrier is just wetted, and stir slightly. After the catalyst unifor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com