On-line measuring method for one section outlet acetylene concentration of acetylene hydrogenation reaction chamber

A technology of acetylene hydrogenation and reactor, which is applied in the direction of measuring devices, specific gravity measurement, instruments, etc., and can solve problems such as not being able to work in the optimal operating state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further elaborated below in conjunction with embodiment:

[0019] Implementation example

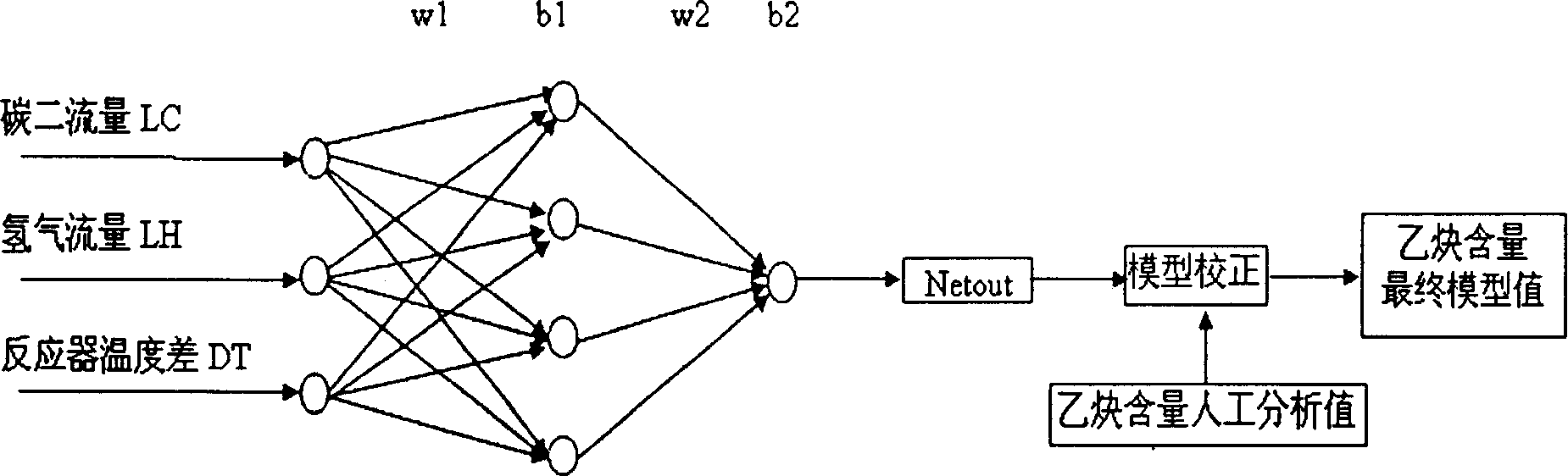

[0020] Firstly, the main process operating parameters that affect the concentration of acetylene at the outlet of the first stage of the hydrogenation reactor are obtained in the DCS: the flow rate of carbon distillate in the feed, the amount of hydrogen in the first stage, the temperature difference of the reactor, and the concentration of acetylene at the outlet of the first stage of the hydrogenation reactor at the corresponding time. Analyze the values and normalize these data to the range [0.2, 0.8], the normalization method is as follows:

[0021] x=(X-a) / ((b-a)×0.6+0.2

[0022] Among them, X is the input variable, [a, b] is the range of X, and x is the normalized input. The range of the carbon distillate flow in the feed is taken as [50000, 80000], the range of hydrogen in the first stage is taken as [500, 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com