Process and system for preparing ethylene from powdered coal by two-stage calcium carbide furnace

A two-stage, calcium carbide furnace technology, applied in the field of coal chemical industry, can solve the problems of high carbon emission, long technical process, complex process, etc., to achieve the effect of less floor space, improved economic benefits, and reduced environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

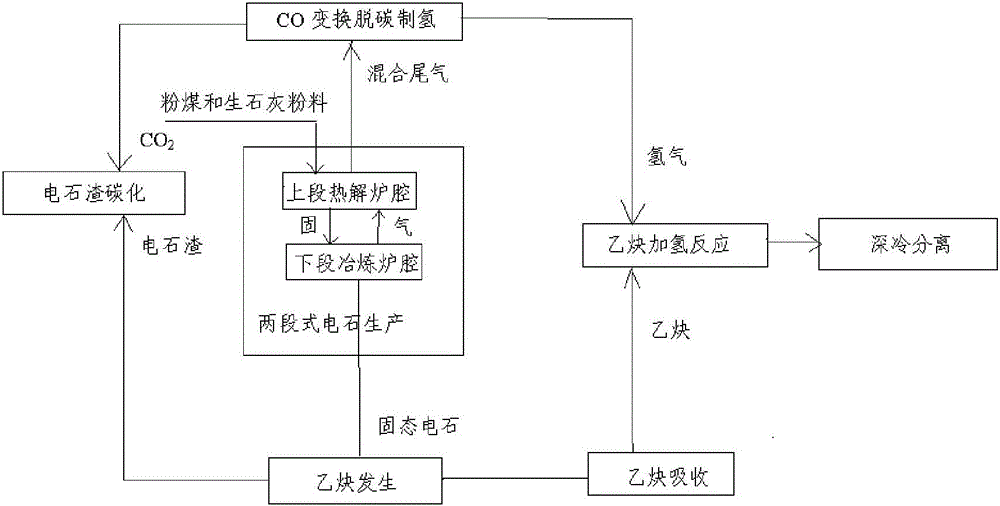

[0049] A two-stage calcium carbide furnace pulverized coal to ethylene process, such as figure 1 As shown, including the following steps:

[0050] (1) Two-stage calcium carbide production

[0051] The coal is crushed step by step to 20-100μm, quicklime is ground to 20-100μm, 20-100μm pulverized coal, quicklime powder and binder are fully mixed and extruded, and then sent to the upper section of the two-stage calcium carbide furnace for pyrolysis The furnace cavity undergoes medium-high temperature pyrolysis, the upper temperature is 600-1000℃; the solid obtained after pyrolysis is about 800℃, and it enters the lower smelting cavity (gas melting furnace) of the two-stage calcium carbide furnace to produce calcium carbide and calcium carbide tail gas; the resulting calcium carbide tail gas Then enter the upper section of the two-stage pyrolysis furnace and the upper section of the two-stage calcium carbide furnace to exchange heat with the formed solid raw materials;

[0052] Wherein,...

Embodiment 2

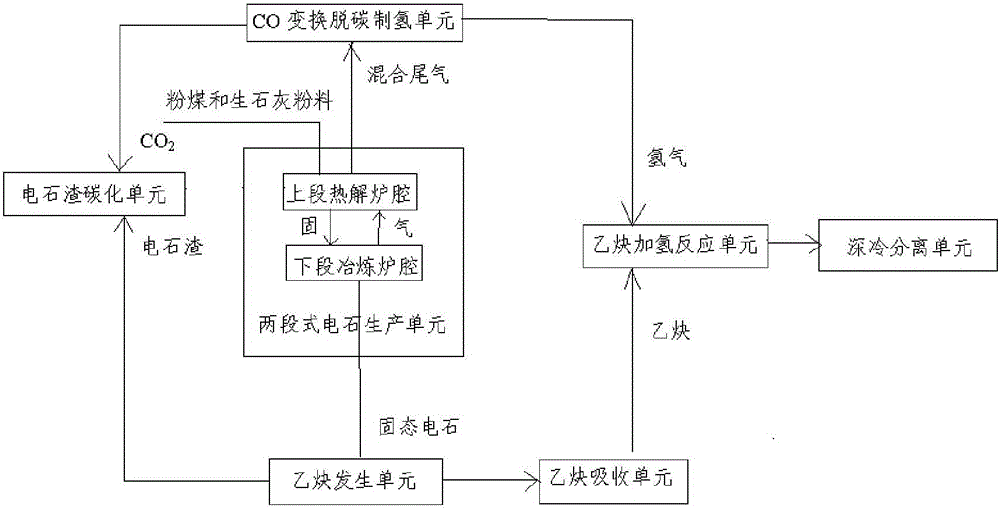

[0067] A system for implementing the two-stage calcium carbide furnace pulverized coal to ethylene process described in Example 1, such as figure 2 As shown, it includes a two-stage calcium carbide production unit, a CO shift decarbonization hydrogen production unit, an acetylene generation unit, an acetylene absorption unit, and an acetylene hydrogenation reaction unit;

[0068] Wherein, the two-stage calcium carbide production unit is a two-stage calcium carbide furnace, the two-stage calcium carbide furnace includes an upper pyrolysis furnace cavity and a lower smelting furnace cavity that are connected, and a heating device is provided in the lower smelting furnace cavity;

[0069] The gas outlet of the two-stage calcium carbide production unit is connected with the gas inlet pipe of the CO shifting and decarbonization hydrogen production unit, and the calcium carbide outlet of the two-stage calcium carbide production unit is connected with the inlet pipe of the acetylene gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com