Method and system for preparing ethylene from powdered coal

A pulverized coal and ethylene technology, applied in the field of coal chemical industry, can solve problems such as long technical process, high carbon emissions, complex process, etc., and achieve the effects of improving economy, reducing process energy consumption, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

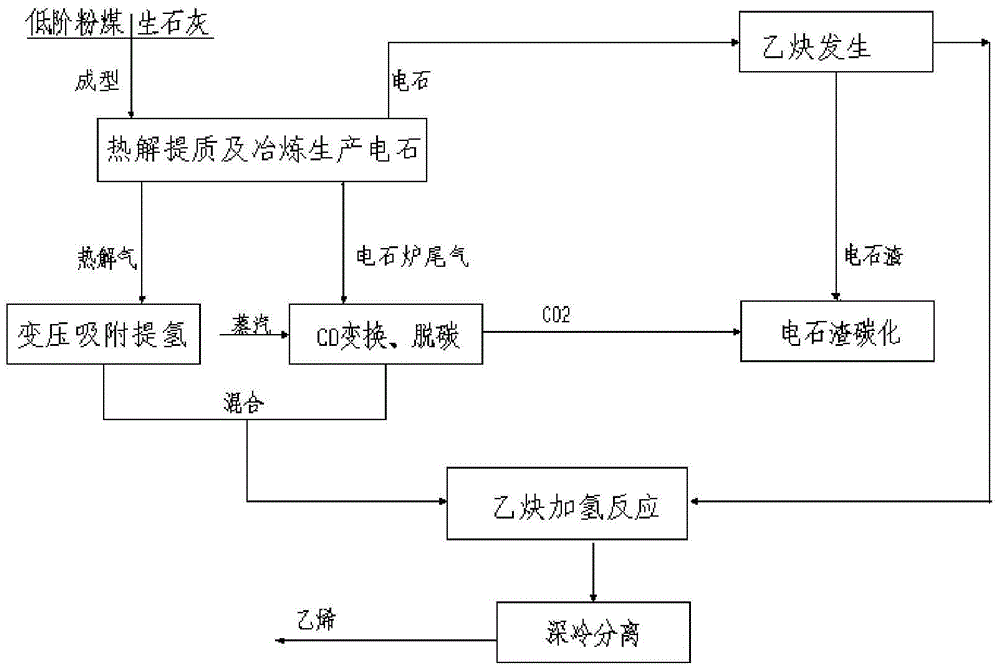

[0048] A method for producing ethylene by using bituminous coal as a raw material using a rotary bottom calcium carbide furnace, such as figure 1 As shown, the specific steps are as follows:

[0049] (1) Pyrolysis upgrading and smelting to produce calcium carbide

[0050] Pretreatment: Finely grind the bituminous coal and quicklime with a particle size of less than 1mm by jet mill, respectively, to obtain bituminous coal powder and quicklime powder with a particle size of less than 30 microns accounting for more than 98.19%, and then according to the fixed carbon and calcium oxide Prepare the mixture with a molar ratio of 2.8:1 and send it to the mill by airflow, add 8wt% binder tar and mill for 10 minutes to obtain the mixed material, and obtain material balls with a particle size of 8 to 30mm through a disc granulator group;

[0051] Pyrolysis: The material pellets are directly transferred by the belt to the feed bin on the roof of the rotary bottom calcium carbide furnace...

Embodiment 2

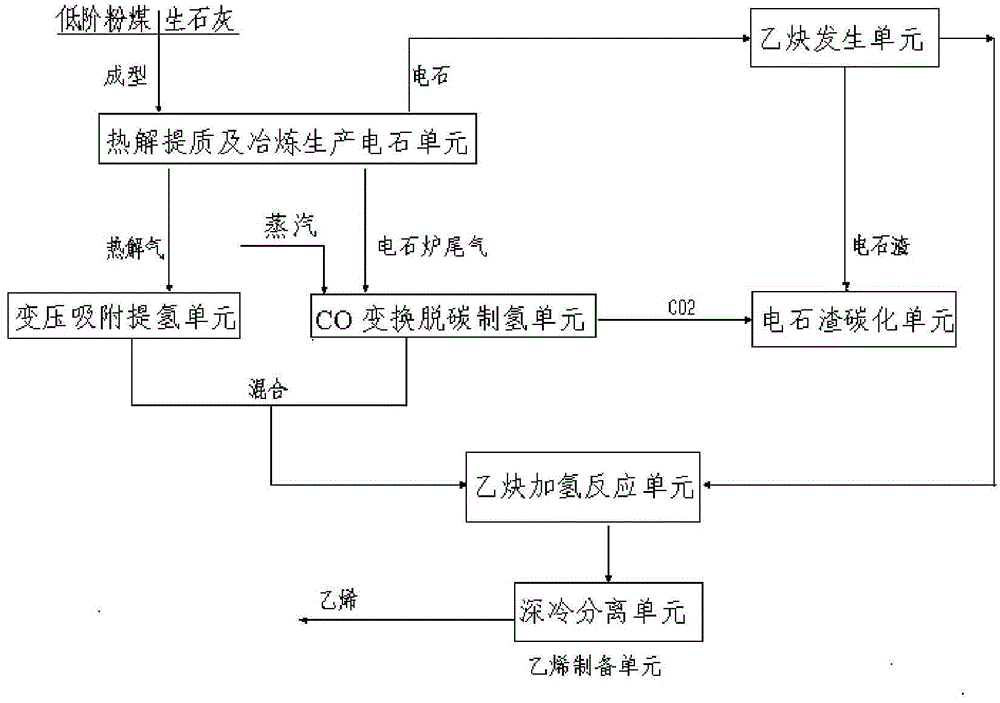

[0068] A system for realizing the method for producing ethylene from pulverized coal described in Embodiment 1, such as figure 2 As shown, it includes pyrolysis upgrading and smelting calcium carbide unit, pressure swing adsorption hydrogen extraction unit, CO shift decarbonization hydrogen production unit, acetylene generation unit, and acetylene hydrogenation reaction unit;

[0069] Wherein, the pyrolysis upgrading and smelting calcium carbide production unit is a rotary bottom calcium carbide furnace, which includes a pyrolysis furnace cavity, a smelting furnace cavity directly connected with the pyrolysis furnace cavity, and a plurality of radiant tube burners; wherein, the A plurality of the radiant tube burners are arranged on the inner wall of the outer peripheral wall of the pyrolysis furnace cavity and above the revolving bottom calcium carbide furnace charge plate;

[0070]The coal gas outlet of the pyrolysis furnace chamber is connected to the inlet pipeline of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com