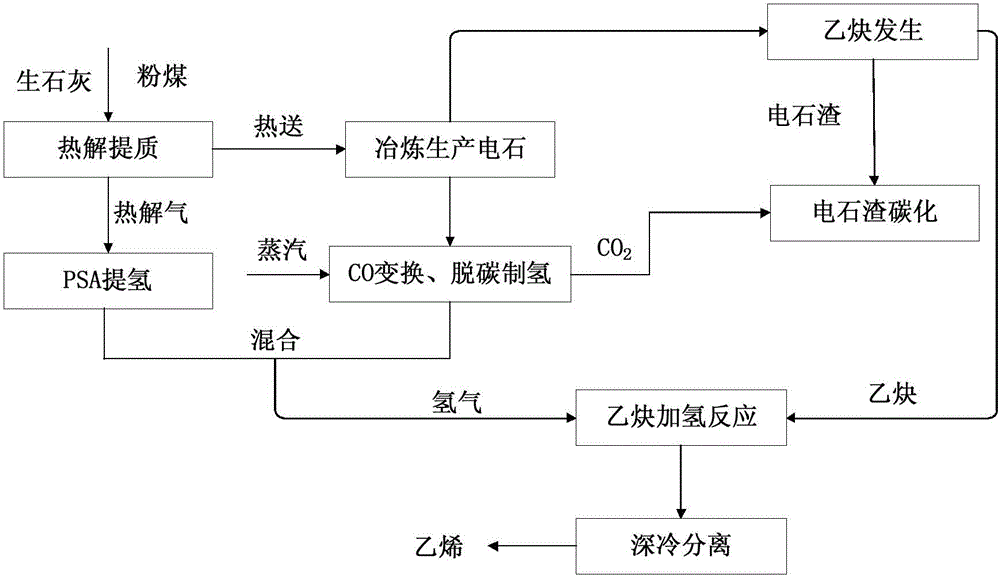

A method and system for producing ethylene from pulverized coal

A technology for pulverized coal and ethylene, applied in the field of coal chemical industry, can solve the problems of high volatile matter, high water content, low carbon content, etc., and achieve the effects of short process, low energy consumption and less floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

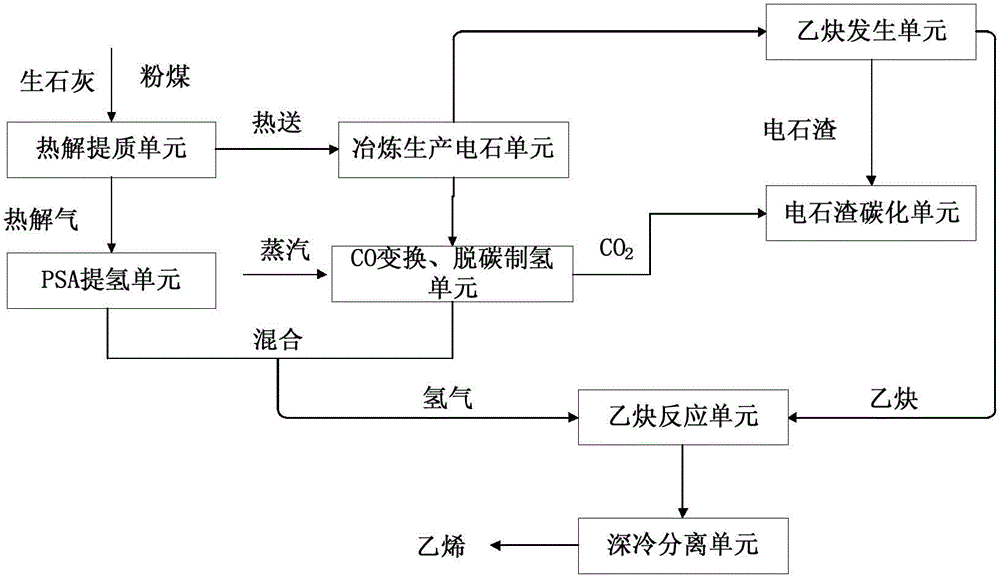

[0060] See figure 2 , a system for producing ethylene from pulverized coal, including pyrolysis upgrading unit, PSA hydrogen extraction unit, smelting and production of calcium carbide unit, CO conversion decarbonization hydrogen production unit, acetylene generation unit, acetylene hydrogenation reaction unit, cryogenic separation unit and carbide slag carbonization unit;

[0061] The pyrolysis upgrading unit includes a pyrolysis device, the outlet of the pyrolysis device is connected to the calcium carbide furnace; the top of the pyrolysis device is provided with a pyrolysis gas outlet, and the pyrolysis gas outlet is connected to the A pressure swing adsorption hydrogen extraction unit; the pressure swing adsorption hydrogen extraction unit is provided with a hydrogen outlet; the pyrolysis device is provided with a fuel inlet, and the gas phase residual outlet of the pressure swing adsorption hydrogen extraction unit is connected to the fuel inlet of the pyrolysis device. ...

Embodiment 2

[0067] Adopt the system of embodiment 1, the technique of preparing ethylene with pulverized coal:

[0068] Pulverized coal is long-flame coal, which is crushed and screened to 3-5mm, and then ground to 50μm. Quicklime is crushed and screened to 3-5mm, and then ground to 50μm, and becomes powdered quicklime, pulverized coal and quicklime powder Mix according to the mass ratio of 1.06:1.

[0069] 1) Pyrolysis upgrading

[0070] Long-flame coal and quicklime powder are fully mixed and then extruded into raw material rods of 30mm*25mm*13mm. The raw material rods are sent to the pyrolysis device at 900°C. The gas phase products produced by pyrolysis include tar and pyrolysis gas; After decomposition, the solid product with a temperature of 800°C is sent to the calcium carbide furnace; the volume ratio of hydrogen in the pyrolysis gas is 42%. If quicklime powder is not added under the same process conditions, the pyrolysis gas The volume ratio of hydrogen in the coal is 30%. It c...

Embodiment 3

[0089] Adopt the system of embodiment 1, the technique of preparing ethylene with pulverized coal:

[0090] Pulverized coal is long-flame coal, which is crushed and screened to 3-5mm, and then ground to 100μm. Quicklime is crushed and screened to 3-5mm, and then ground to 100μm, and becomes powdered quicklime, pulverized coal and quicklime powder Mix according to the mass ratio of 1.16:1.

[0091] 1) Pyrolysis upgrading

[0092] Fine coal and quicklime are fully mixed and then extruded into pellets with a diameter of 30 mm. The pellets are sent to a pyrolysis device at 900 ° C. The gas phase products produced by pyrolysis include tar and pyrolysis gas; after pyrolysis, the temperature is 780 The solid product at ℃ is sent to the calcium carbide furnace; the volume ratio of hydrogen in the pyrolysis gas is 38%. The volume ratio is 30%. It can be seen that the addition of quicklime powder can significantly increase the hydrogen production rate in the coal pyrolysis process.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com