Process and equipment for producing copper-aluminum compound busbar

A copper-aluminum composite and production process technology, applied in the direction of roll speed control, electrical components, circuits, etc., can solve the problems of composite interface bonding strength influence, large difference in hardness and ductility, and low interface bonding strength, so as to ensure the copper layer Volume ratio, high interface bonding strength, and the effect of avoiding material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

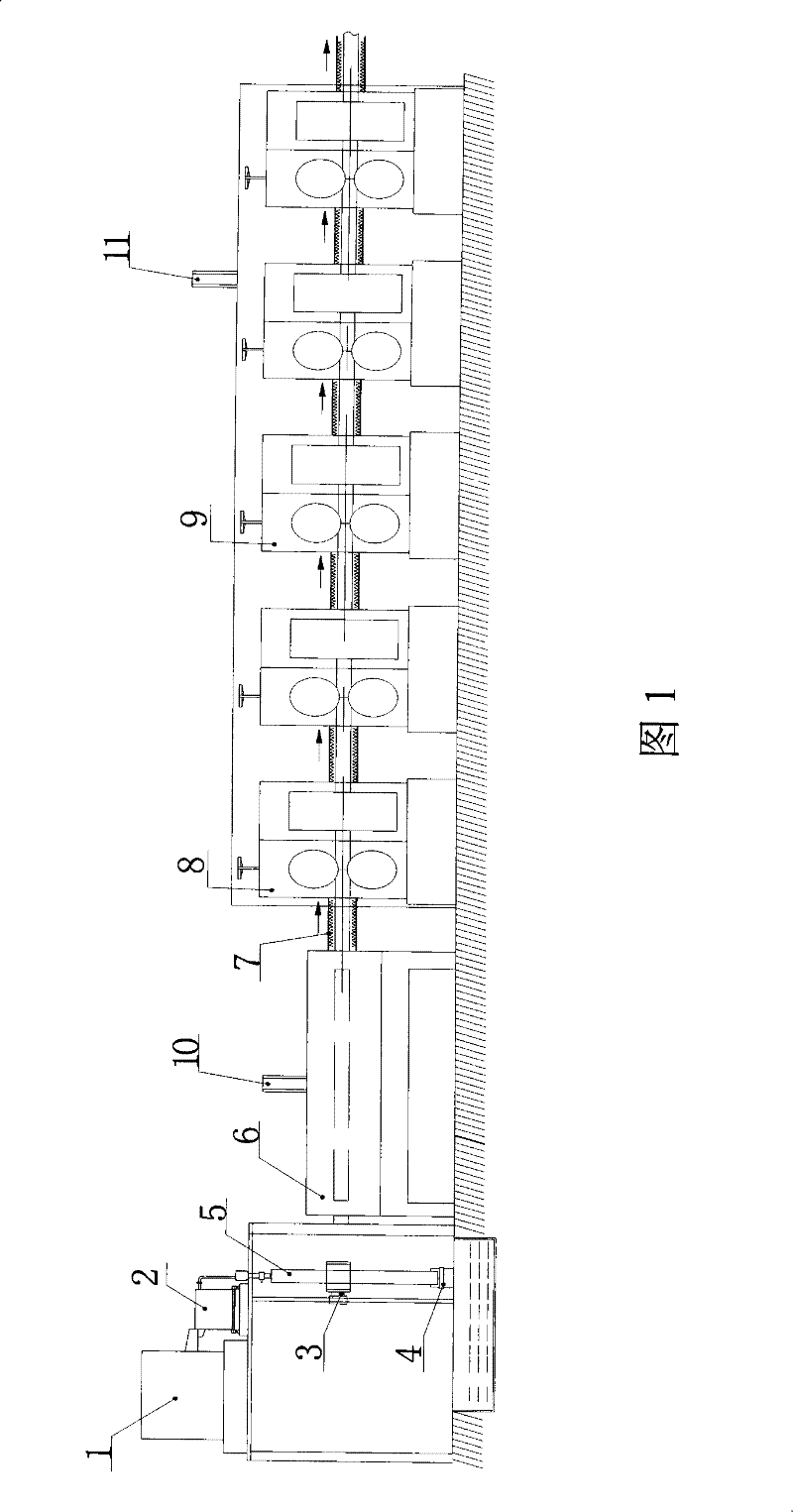

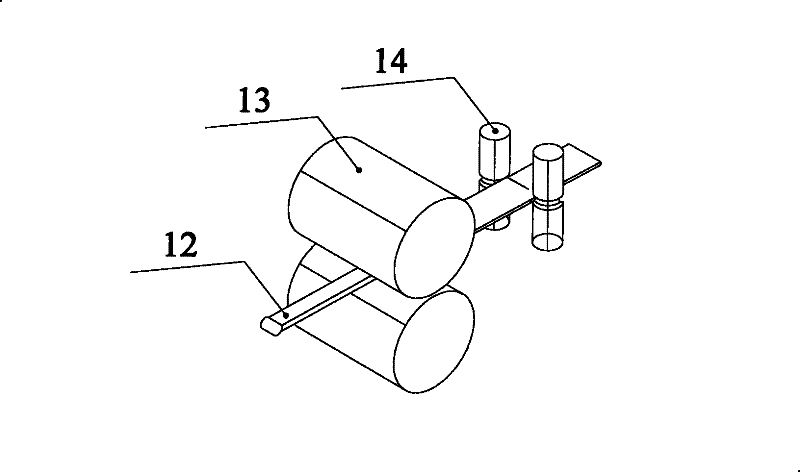

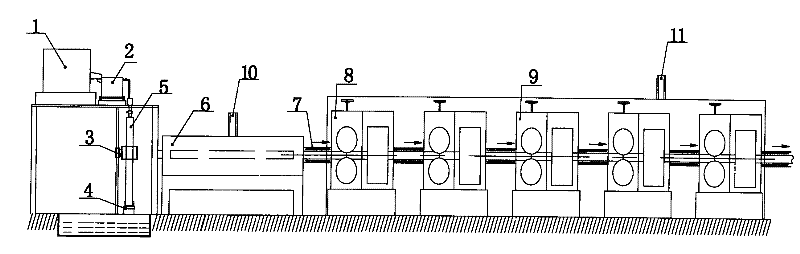

[0021] The main technological process of producing copper-aluminum composite busbars using the copper-aluminum composite busbar production equipment provided by the present invention is as follows: put aluminum into a melting furnace to melt, and then pour it into a sealed holding furnace with a quantitative pouring system. The holding furnace can Keep warm at 700°C-800°C, then pour quantitatively into the already formed special-shaped copper tube, and become a copper-aluminum composite ingot under the cooling effect of a cooler that can rise around the special-shaped copper tube at a uniform speed, and then use the heat The rolling device processes the copper-aluminum composite ingot into a copper-aluminum composite busbar. The copper-aluminum composite ingot can be a common specification in the technical field, and its appearance can be circular or oval. Taking a circular shape as an example, the outer diameter can be 30-200mm, and the thickness of the copper layer can be 2-4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com