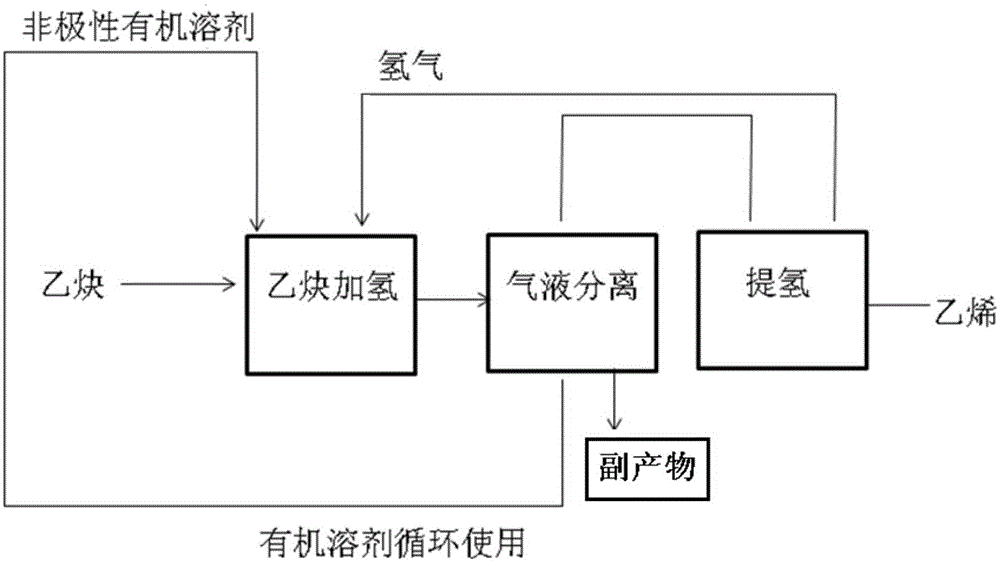

Method using acetylene hydrogenation to produce ethylene

A technology for acetylene hydrogenation and ethylene production, which is applied in the field of acetylene hydrogenation to ethylene, which can solve the problems of difficult recovery, wear and tear of catalyst loss, easy blockage of equipment, etc., and achieve the effect of simple operation and reduced crushing and loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for producing ethylene by hydrogenation of acetylene, comprising the steps of:

[0031] (1) Hydrogenation of acetylene

[0032] The non-polar organic solvent, acetylene and hydrogen enter the reactor through the spray device for selective hydrogenation reaction to obtain a gas-liquid mixture containing ethylene, unreacted acetylene, unreacted hydrogen, by-products, and non-polar organic solvent ; Wherein, the catalyst bed is in a rotating state;

[0033] Among them, the pressure of acetylene raw material gas is 0.2MPa, and the flow rate is 6Nm 3 / h;

[0034] Among them, the hydrogen raw material gas pressure is 0.2MPa, the flow rate is 24Nm 3 / h;

[0035] Among them, N-methylpyrrolidone (NMP rich solution) is pumped into the reactor, the outlet pressure of the pump is 0.2MPa, and the flow rate is 0.8m 3 / h.

[0036] Wherein, the temperature of the catalyst bed is controlled at 150° C., and the rotation speed of the catalyst bed is controlled to be 500 rpm...

Embodiment 2

[0043] Adopt the method for embodiment 1 to prepare ethylene, difference is:

[0044] 1. The non-polar organic solvent is replaced by a mixture of tetrahydrofuran and acetone;

[0045] 2. Bed speed is 600rpm;

Embodiment 3

[0047] Adopt the method for embodiment 1 to prepare ethylene, difference is:

[0048] 1. The non-polar organic solvent is replaced by a mixture of NMP and acetone;

[0049] 2. The bed speed is 800rmp;

[0050] Using the above examples to carry out the reaction of acetylene hydrogenation to ethylene, the results of acetylene conversion and ethylene selectivity are shown in the table below.

[0051] Example

[0052] It has been verified by experiments that the method of the invention is used to prepare ethylene, no overheating phenomenon occurs in the reaction process, the ethylene yield is high, the catalyst is not easy to be lost in the reaction process, and regeneration is easy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com