Coal tar recovery method and system

A recovery method and recovery system technology, applied in the field of coal tar recovery, can solve the problems of high cost, poor economy, poor quality of washing oil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

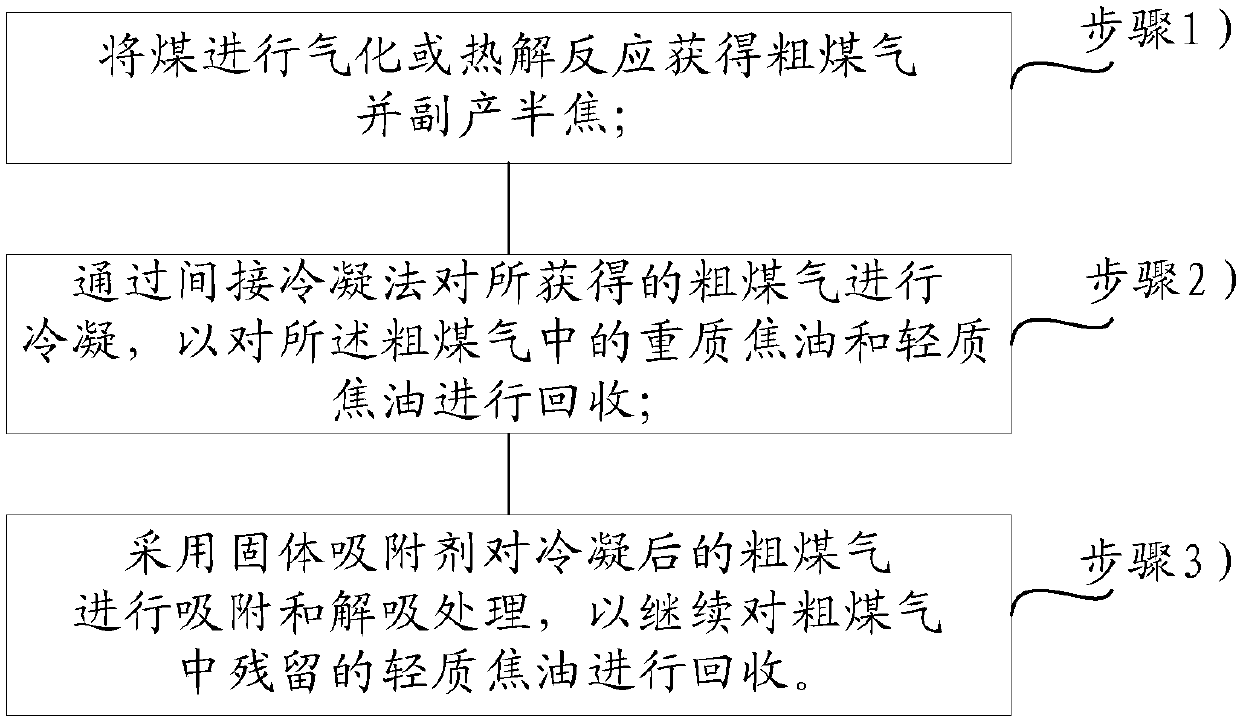

Method used

Image

Examples

Embodiment

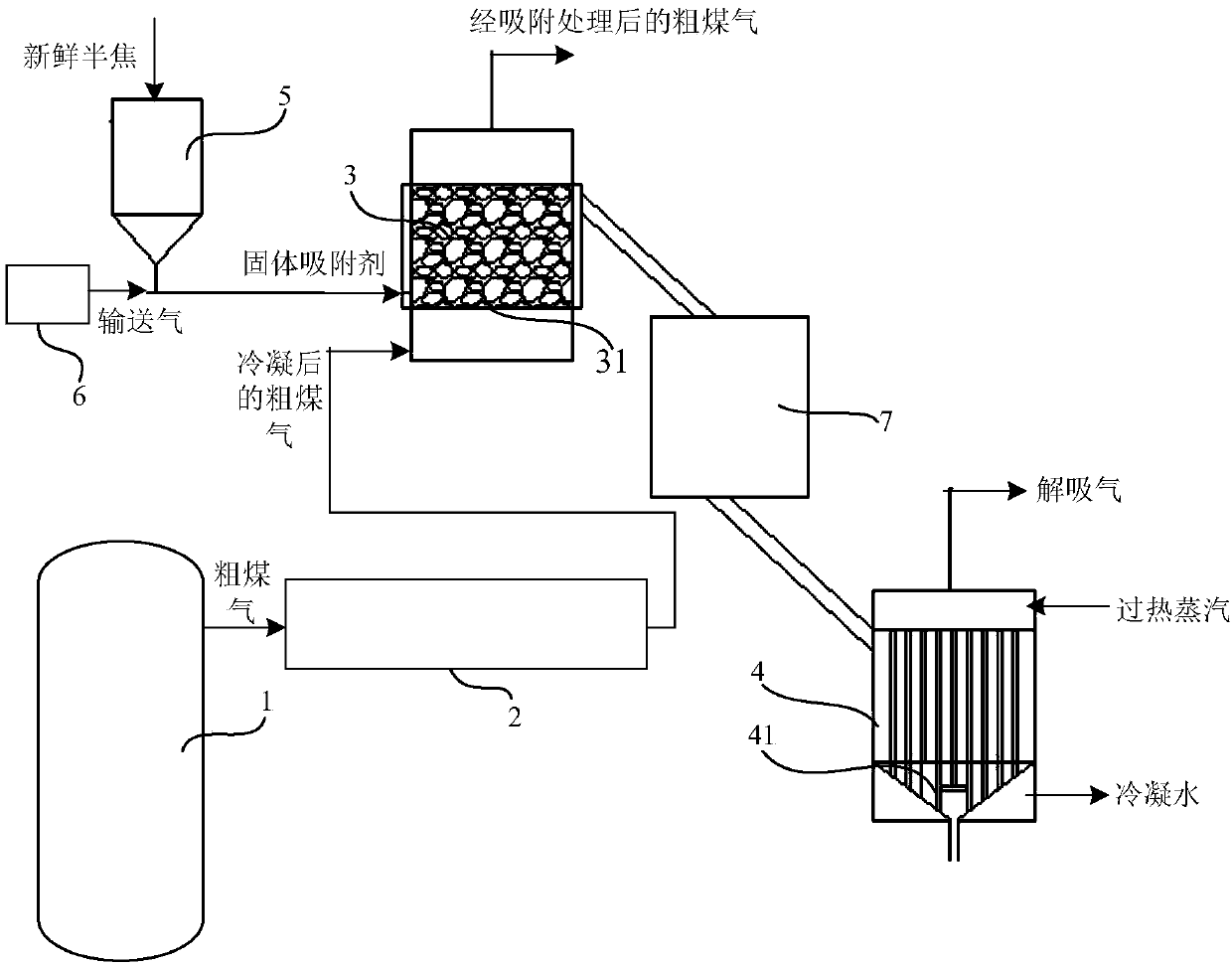

[0084] 1) Under the conditions of temperature 850-1000°C and pressure 5-10MPa, the coal hydrogasification reaction is carried out to generate crude gas and semi-coke as a by-product; among them, it is found through detection that: the semi-coke obtained from the coal hydrogasification reaction Volatile content 3 , specific surface>150m 2 / g; the yield of the tar in the obtained crude gas is >10%, the benzene content in the tar composition is >60%, and the pyrene oil content is >15%.

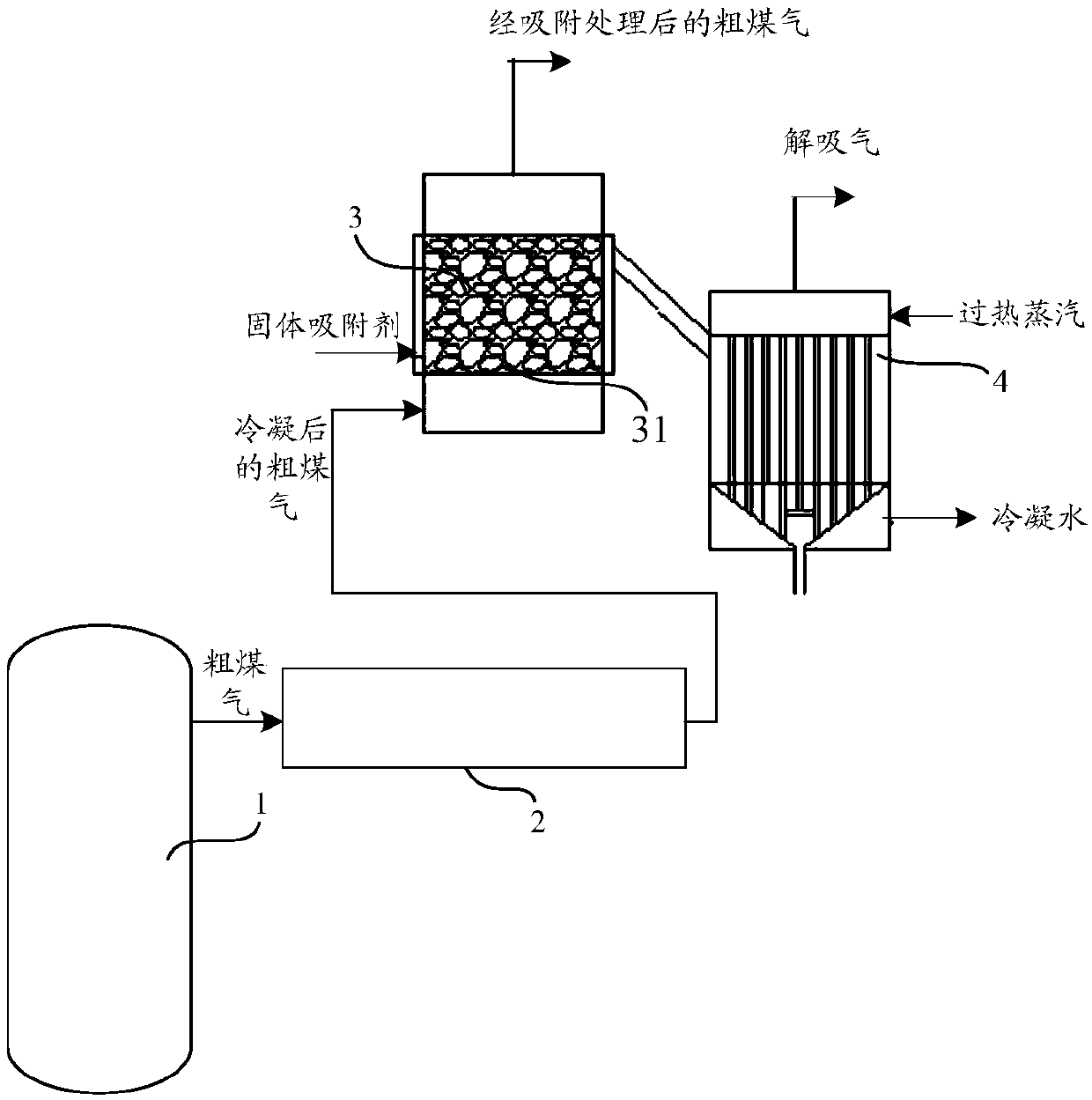

[0085] 2) The obtained crude gas is subjected to dust removal and heat recovery treatment respectively, and the dust content of the crude gas is reduced to 10mg / m 3 , after the temperature drops to 150-220°C, feed the raw gas into the Figure 4 Indirect condensation is performed in the shown indirect condensing device 2, and the tars condensed by the first condensing device 21 and the second condensing device 22 are respectively collected. Among them, it is found through detection that the tetra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com