Device and method for producing ethylene through hydrogenation of high concentration acetylene

A technology for acetylene hydrogenation and ethylene production, which is applied in the petrochemical field, can solve problems such as complex reaction process, and achieve the effects of simple process, avoiding multi-column rectification and separation, and advanced process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

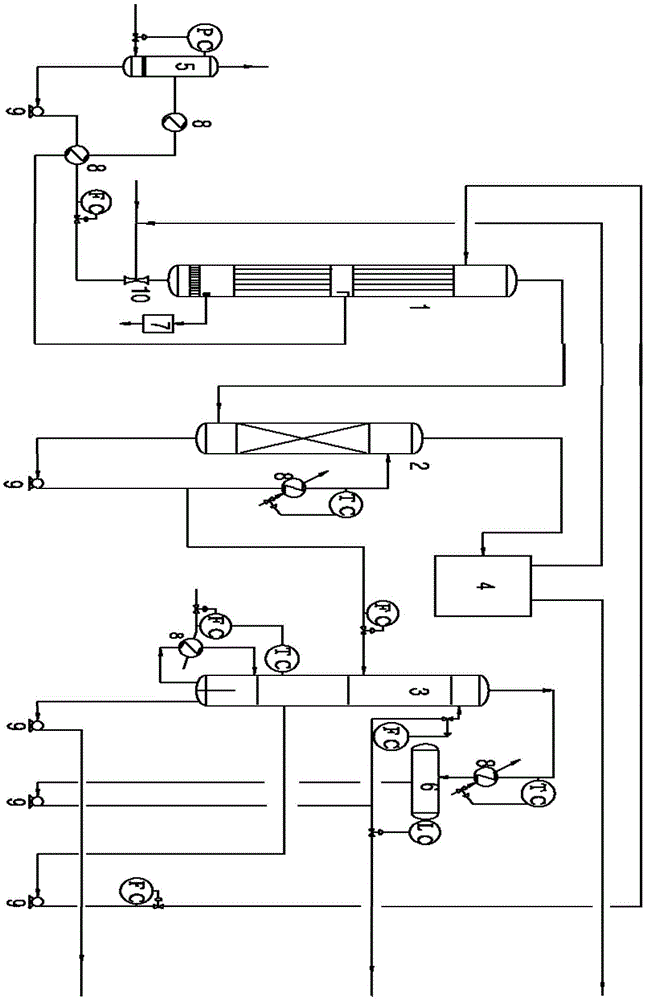

Image

Examples

Embodiment 1

[0064] Acetylene from outside enters the acetylene tank, the pressure of acetylene entering the acetylene tank is 0.02-0.2MPaG, preferably 0.15MPaG in this example, and the temperature is -20-40°C, preferably 10°C in this example. Mix with the solvent in the acetylene tank and dissolve completely in the solvent. The solvent is one or more combinations of N-methylpyrrolidone, dimethylformamide, dimethyl sulfoxide, monomethylamine and acetone. In this example, N - Methylpyrrolidone. The flow ratio of solvent to acetylene is 2-20:1 (mass ratio), preferably 10:1 in this example. The solvent carrying acetylene is boosted by a pump, heated by a heat exchanger, and then sent to the acetylene hydrogenation reactor. Hydrogen is mixed with acetylene at the inlet of the acetylene hydrogenation reactor and sent into the hydrogenation reactor together. The hydrogen feed temperature is 20-200°C, preferably 40°C in this example. The feed pressure is 0.2-2.0MPaG, preferably 1.5MPaG in this...

Embodiment 2

[0075] Acetylene from outside enters the acetylene tank, the pressure of acetylene entering the acetylene tank is 0.02-0.2MPaG, preferably 0.15MPaG in this example, and the temperature is -20-40°C, preferably -10°C in this example. Mix with the solvent in the acetylene tank and completely dissolve in the solvent. The solvent is one or more combinations of N-methylpyrrolidone, dimethylformamide, dimethyl sulfoxide, monomethylamine and acetone. In this case, acetone is preferred . The flow ratio of solvent to acetylene is 2-20:1 (mass ratio), preferably 5:1 in this example. The solvent carrying acetylene is boosted by a pump, heated by a heat exchanger, and then sent to the acetylene hydrogenation reactor. Hydrogen is mixed with acetylene at the inlet of the acetylene hydrogenation reactor and sent into the hydrogenation reactor together. The hydrogen feed temperature is 20-200°C, preferably 40°C in this example. The feed pressure is 0.2-2.0MPaG, preferably 0.45MPaG in this e...

Embodiment 3

[0082] Acetylene from outside enters the acetylene tank, the pressure of acetylene entering the acetylene tank is 0.02-0.2MPaG, preferably 0.15MPaG in this example, and the temperature is -20-40°C, preferably -10°C in this example. Mix with the solvent in the acetylene tank and completely dissolve in the solvent. The solvent is one or more combinations of N-methylpyrrolidone, dimethylformamide, dimethyl sulfoxide, monomethylamine and acetone. In this case, acetone is preferred . The flow ratio of solvent to acetylene is 2-20:1 (mass ratio), preferably 5:1 in this example. The solvent carrying acetylene is boosted by a pump, heated by a heat exchanger, and then sent to the acetylene hydrogenation reactor. Hydrogen is mixed with acetylene at the inlet of the acetylene hydrogenation reactor and sent into the hydrogenation reactor together. The hydrogen feed temperature is 20-200°C, preferably 40°C in this example. The feed pressure is 0.2-2.0MPaG, preferably 0.45MPaG in this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com