Reaction system and method for preparing ethylene through acetylene hydrogenation

A reaction system, a technology for acetylene hydrogenation, applied in the fields of hydrogenation to hydrocarbons, bulk chemical production, organic chemistry, etc., can solve the problems of declining ethylene yield and catalyst deactivation, and achieve the effect of improving selectivity and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

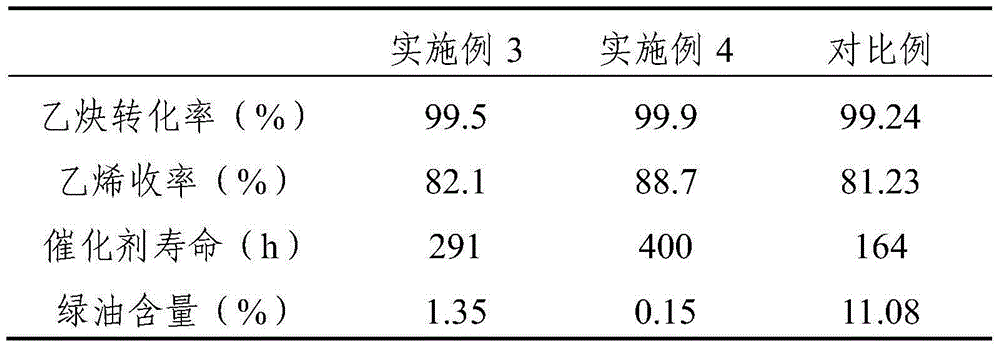

Examples

Embodiment 1

[0022] Provide a "gas-liquid phase" two-phase contact reaction system; the two-phase contact reaction system is composed of a liquid phase and a gas phase;

[0023] Hydrogen and acetylene are contained in the gas phase;

[0024] The liquid phase is composed of the following raw materials: 98 g of N-methyl-2-pyrrolidone, a non-polar solvent, and 2 g of complexed palladium prepared with nitrilotriacetic acid as a complexing agent.

Embodiment 2

[0026] Provide a "gas-liquid phase" two-phase contact reaction system; the two-phase contact reaction system is composed of a liquid phase and a gas phase;

[0027] Hydrogen and acetylene are contained in the gas phase;

[0028] The liquid phase is composed of the following raw materials: 95 g of non-polar solvent N-methyl-2-pyrrolidone, 3 g of palladium complexed with ethylenediaminetetraacetic acid as a complexing agent, and ethylenediaminetetraacetic acid as a complexing agent 1g of complexed manganese and 1g of complexed iron configured with ethylenediaminetetraacetic acid as complexing agent.

Embodiment 3

[0030] Ethylene is prepared as follows:

[0031] Hydrogen and acetylene are composed of gas phase raw materials at a molar ratio of 4:1, and are passed into the reaction system provided in Example 1 from the bottom at a flow rate of 1000mL / min, with an operating pressure of 0.2MPa, continuous reaction at 140°C, and separation and outflow from the top The gas phase product is the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com