Separation method for preparing low-carbon olefin gas through methanol conversion

A low-carbon olefin and methanol conversion technology, applied in the field of petrochemical industry, can solve the problems of ineffective removal and inability to obtain purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

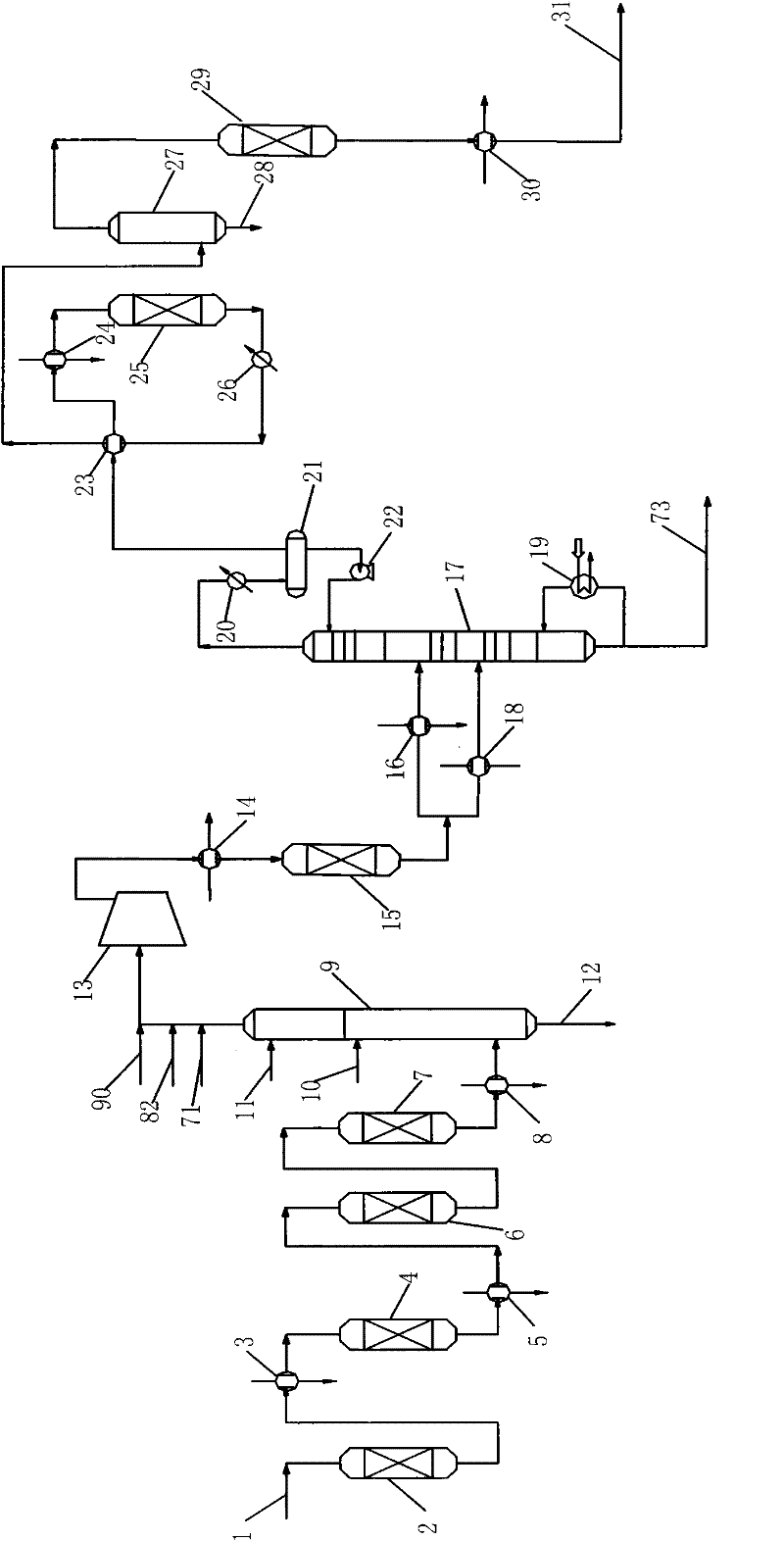

[0096] Such as figure 2 As shown, in addition to ethylene and propylene, it also includes one or more mixtures of hydrogen, oxygen, nitrogen, carbon monoxide, carbon dioxide, methane, ethane, acetylene, propane, cyclopropane, propyne and propadiene as Methanol conversion to produce light olefins gas removal of oxygenates, water and C 4 and C 4 The low-carbon olefins stream after the above hydrocarbons passes through the first dryer 2 (built-in) through the low-carbon olefins stream line 1 Molecular sieve) for primary dehydration (note: water is a small amount of water entrained by the low-carbon olefin stream), and after heat exchange in the first heat exchanger 3, it enters the carbon monoxide removal tank 4 (built-in carbon monoxide removal copper-based catalyst, such as C18 catalyst) to remove large amounts of carbon monoxide. Part of the carbon monoxide, the low-carbon olefin stream after the cooling of the first cooler 5 enters the second dryer 6 (built-in Molecular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com