Process and system of preparing calcium carbide and ethylene through oxygen/coal injection

A calcium carbide and process technology, applied in the field of coal chemical industry, can solve the problems of uneven heat distribution in the furnace, high cost of calcium carbide, large amount of raw coke, etc., to reduce power consumption and calcium carbide production cycle, reduce calcium carbide production cost, Small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

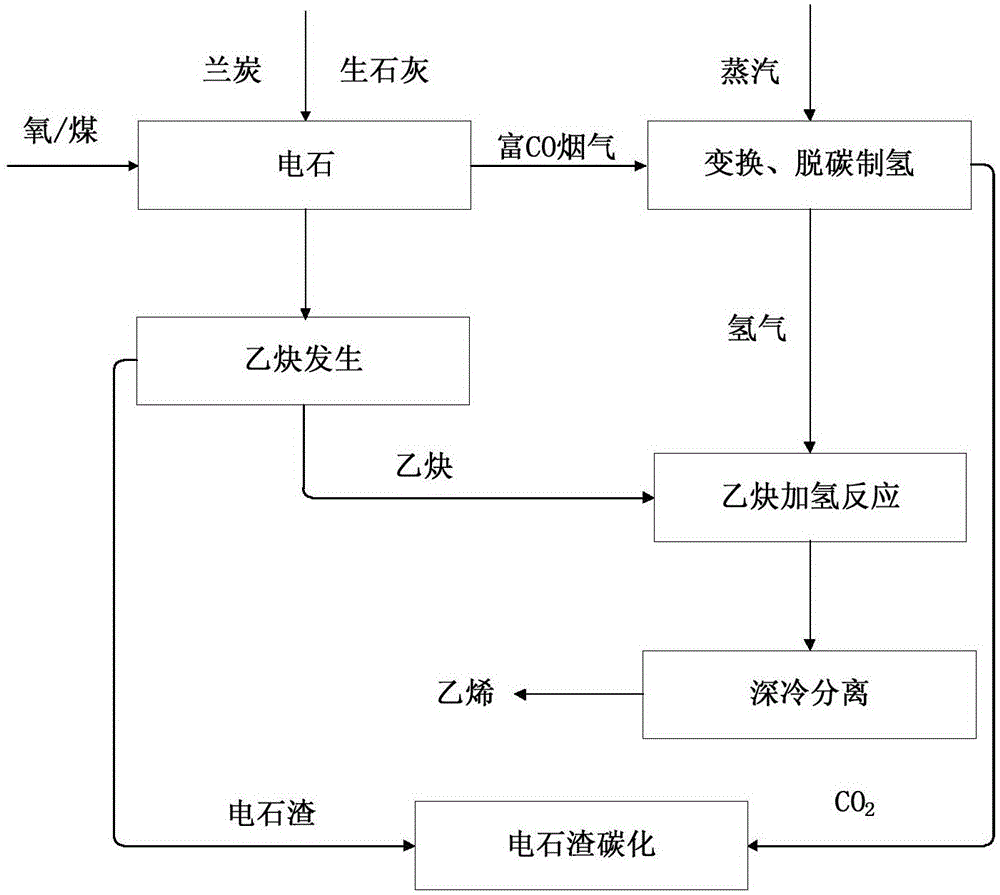

[0039] A process for preparing calcium carbide and ethylene by oxygen / coal injection, such as figure 1 shown, including the following steps:

[0040] (1) Calcium carbide preparation

[0041] Transport the coke and lime with qualified particle size to the calcium carbide production plant, enter the calcium carbide furnace through the feeder and the furnace material storage hopper, and use the blowing gun installed on the side wall or furnace top of the calcium carbide furnace to spray into the furnace while the arc is being fed. Oxygen / coal powder mixture, the combustion of oxygen and coal powder produces a large amount of heat, wherein the injection amount of oxygen is 95Nm 3 / t of calcium carbide, the input of anthracite powder is 130kg / t of calcium carbide; when the temperature of the molten pool is heated to 2000-2200°C, coke and lime are reduced and melted in the calcium carbide furnace under the action of arc heat, resistance heat and reaction heat Calcium carbide flows...

Embodiment 2

[0056] This example adopts the same process as that of Example 1 to prepare ethylene, the difference is that the heat of the calcium carbide smelting tail gas can be used to raise the temperature of the acetylene hydrogenation reactor before the CO shift reaction. Specifically, a gas-liquid heat exchange unit is set up in the acetylene hydrogenation reaction, and the heat transfer oil in the jacket of the acetylene hydrogenation reactor is exchanged with the tail gas of calcium carbide smelting in the gas-liquid heat exchange unit, and the heat transfer oil heats up after heat exchange. To 140-220 ℃, so as to make full use of the heat in the tail gas of calcium carbide smelting.

Embodiment 3

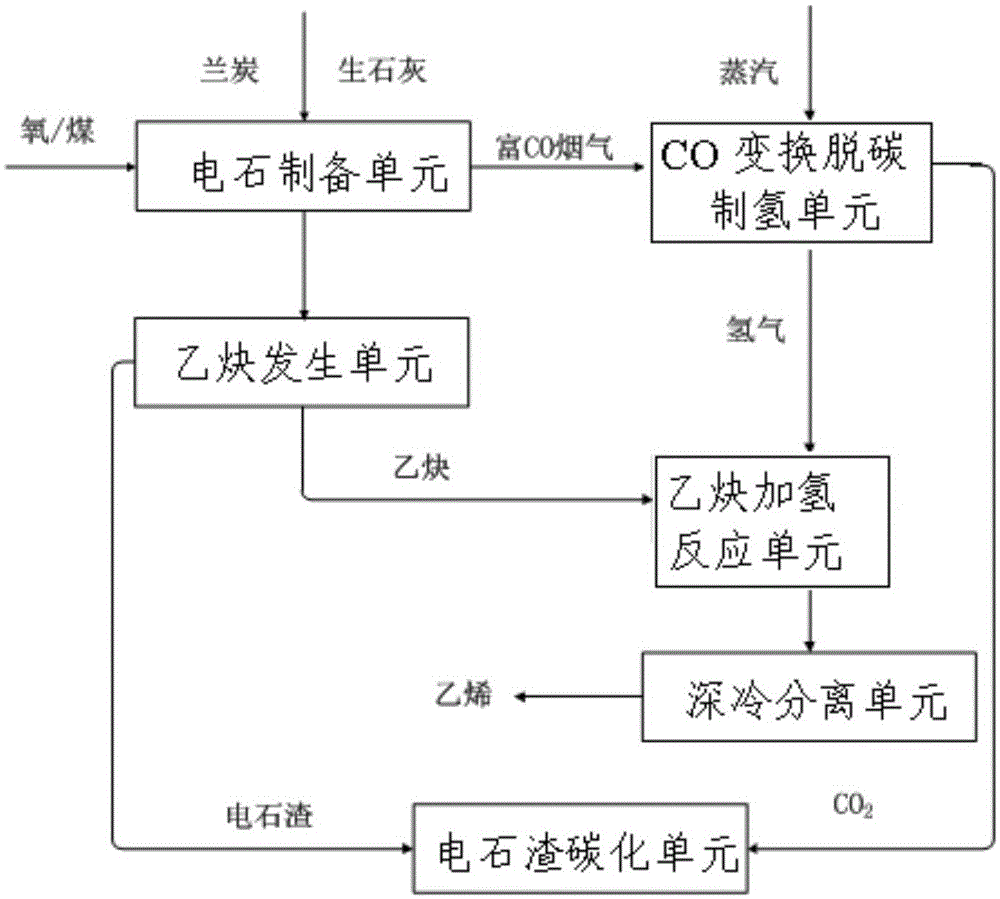

[0058] A system for realizing the process of preparing calcium carbide and ethylene by oxygen / coal mixed injection described in embodiment 1, such as figure 2 As shown, it includes a calcium carbide preparation unit, an acetylene generating unit, an acetylene hydrogenation reaction unit, and a cryogenic separation unit connected in sequence;

[0059] Among them, a CO conversion decarbonization hydrogen production unit is also included, the inlet of which is connected to the outlet pipe of the calcium carbide smelting tail gas of the calcium carbide preparation unit, and the hydrogen outlet is connected to the pipe of the acetylene hydrogenation reaction unit.

[0060] Wherein, the calcium carbide preparation unit is an electric arc calcium carbide furnace, including a furnace body, a furnace cover, a feed inlet and a calcium carbide furnace gas outlet, wherein, the top wall and / or side wall of the furnace body are embedded with a plurality of vertically adjustable Oxygen / coal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com