Vinyl acetylene hydrogenation catalyst and preparation method and applications thereof

A technology of vinyl acetylene and hydrogenation catalyst, which is applied in the fields of hydrogenation to hydrocarbons, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. It can solve the problems of butadiene supply risks and achieve cost reduction. Low, highly selective, less time-consuming effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

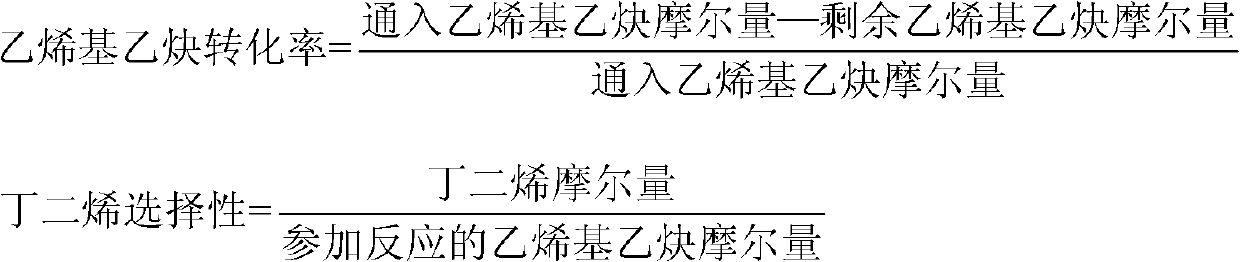

Image

Examples

Embodiment 1

[0032] Use deionized water to make palladium nitrate and copper nitrate into 3.73×10 -3 mol / L solution, and then according to the ratio of pd%=50%, Cu%=50%, the two solutions are made into a mixed metal salt solution. Measure 30ml of mixed metal salt solution, slowly add 10g of carrier α-Al 2 o 3 In a ceramic cell, stir with a glass rod while adding, in order to obtain a paste precursor. Next, the resulting paste precursor was left to stand for 3 hours to carry out co-impregnation of the carrier, and then it was put into a muffle furnace for roasting, so as to prepare a vinyl acetylene catalyst, wherein the temperature control program of the muffle furnace is: use 30min The temperature was raised to 100°C, held at this temperature for 1 h, then raised to 500°C over 1 h and held for 4 h, and finally lowered to 30°C over 3 h.

Embodiment 2

[0034] According to the preparation method of Example 1, a vinyl acetylene hydrogenation catalyst was prepared. Wherein, the difference from Example 1 is that the mixed metal salt used in the catalyst preparation is palladium, silver and copper nitrate, and its composition is pd%=60%, Cu%=20%, Ag%=20%.

Embodiment 3

[0036] According to the preparation method of Example 1, a vinyl acetylene hydrogenation catalyst was prepared. Wherein, the difference from Example 1 lies in that the mixed metal salt solution used in the preparation of the catalyst is a nitrate solution of palladium and silver, and its composition is pd%=60%, Ag%=40%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com