Method for preparing ethylene by heterogeneous reaction

A multiphase reaction, ethylene technology, applied in the fields of hydrogenation to hydrocarbons, organic chemistry, etc., can solve the problems of difficult bed heat transfer, decreased ethylene yield, increased side reactions, etc., to increase the gas-liquid contact surface area and reduce the yield. , the effect of low saturated vapor pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

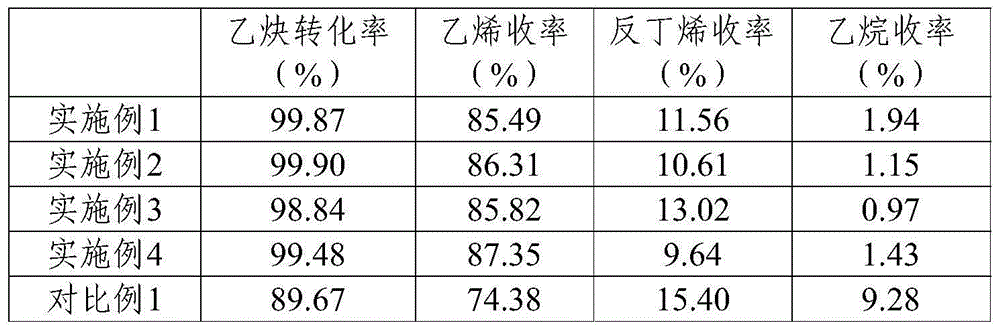

Examples

Embodiment 1

[0036] (1) Mix hydrogen and other gases to form gas phase materials;

[0037] The other gases include: CO 0ppm, CO 2 0ppm, CH 4 50ppm, C 2 H 6 500ppm, C 3 H 8 200ppm, butadiene 200ppm;

[0038] (2) Under the condition of 2.0MPa, use a liquid phase solvent with a surface tension of 0.01 mN / m to absorb acetylene to form a liquid phase material;

[0039] The liquid phase solvent is composed of the following components: N-methylpyrrolidone, fatty alcohol polyoxyethylene ether, p-methoxyphenol with a concentration of 500ppm, and composite silicone with a concentration of 800ppm;

[0040] (3) Provide a heterogeneous reaction system uniformly composed of the liquid phase material, the gas phase material and the hydrogenation catalyst; the selective hydrogenation catalyst is a Pd / Al 2 O 3 It is a solid particle catalyst of the active component, the catalyst particle size is 75-100μm;

[0041] The reaction temperature of the multiphase reaction system is 110° C., and the reaction pressure is 5 M...

Embodiment 2

[0044] (1) Mix hydrogen and other gases to form gas phase materials;

[0045] The other gases include: CO 50ppm, CO 2 50ppm, CH 4 20ppm, C 2 H 6 300ppm, C 3 H 8 100ppm, butadiene 100ppm;

[0046] (2) Under the condition of 2.0MPa, use a liquid phase solvent with a surface tension of 0.001 mN / m to absorb acetylene to form a liquid phase material;

[0047] The liquid phase solvent is composed of the following components: tetrahydrofuran, petroleum carboxylate, phenothiazine with a concentration of 300 ppm, and ionic liquid [BMIM] Br with a concentration of 600 ppm;

[0048] (3) Provide a heterogeneous reaction system uniformly composed of the liquid phase material, the gas phase material and the hydrogenation catalyst; the selective hydrogenation catalyst is a solid particle catalyst with Pd-Ag / ZSM-5 as the active component , The catalyst particle size is 0.1~1μm;

[0049] The reaction temperature of the multiphase reaction system is 140°C, and the reaction pressure is 7.5 MPa;

[0050] (...

Embodiment 3

[0052] (1) Mix hydrogen and other gases to form gas phase materials;

[0053] The other gases include: CO 20ppm, CO 2 20ppm, CH 4 20ppm, C 2 H 6 100ppm, C 3 H 8 80ppm, butadiene 100ppm;

[0054] (2) Under the condition of 2.0 MPa, use a liquid phase solvent with a surface tension of 0.08 mN / m to absorb acetylene to form a liquid phase material;

[0055] The liquid phase solvent is composed of the following components: N-methylpyrrolidone, sodium dodecylbenzene sulfonate, benzoquinone with a concentration of 800ppm, and ionic liquid [BMIM]Cl with a concentration of 800ppm;

[0056] (3) Provide a heterogeneous reaction system uniformly composed of the liquid phase material, the gas phase material and the hydrogenation catalyst; the selective hydrogenation catalyst is a solid monolithic catalyst with Pd-Ag-Pt as the active component;

[0057] The reaction temperature of the multiphase reaction system is 185°C, and the reaction pressure is 4.0 MPa;

[0058] (4) According to the molar ratio o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com