Acetylene hydrogenation slurry bed reaction as well as catalyst separation device and method

A technology of acetylene hydrogenation and separation device, which is applied in the field of acetylene hydrogenation to ethylene, which can solve the problems of unfavorable development, decreased catalyst activity, low filtration accuracy, etc., to improve the uniformity of radial distribution, promote the smooth progress of the reaction, and uniform materials stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

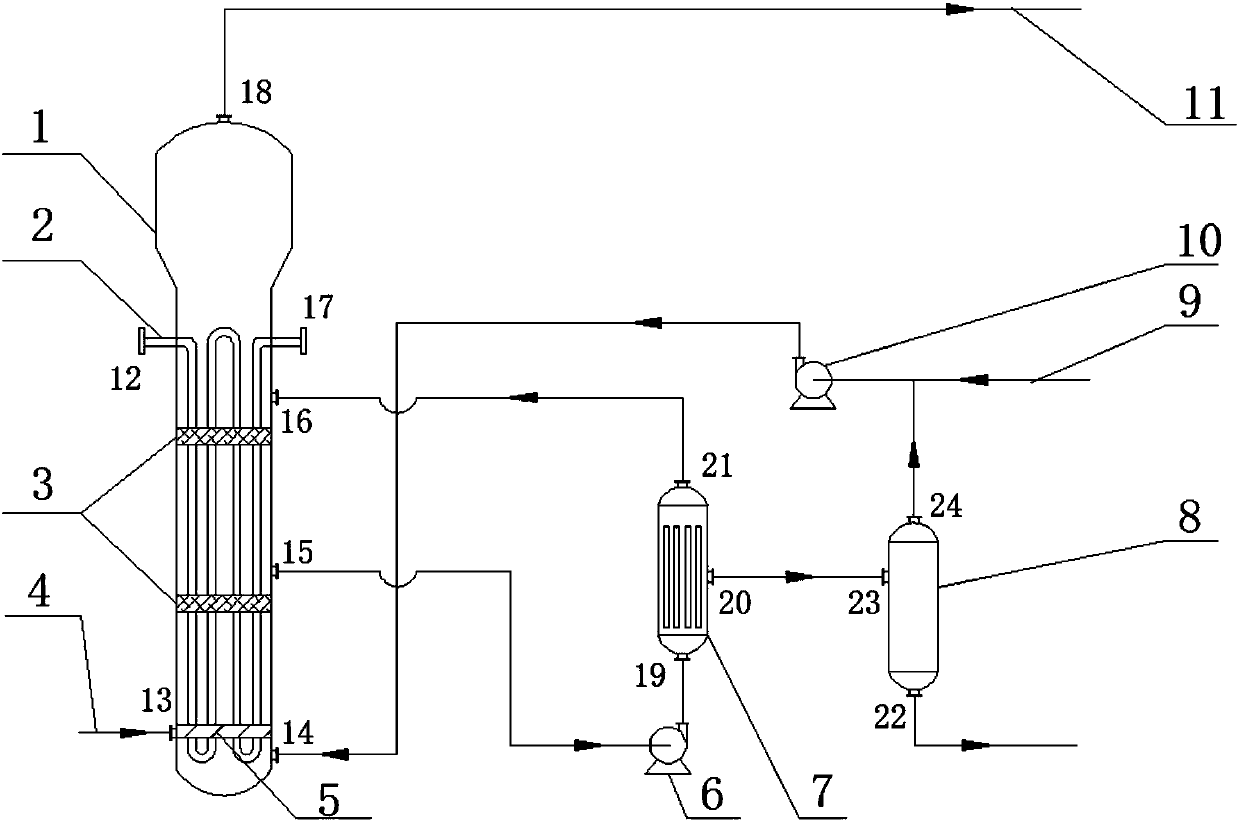

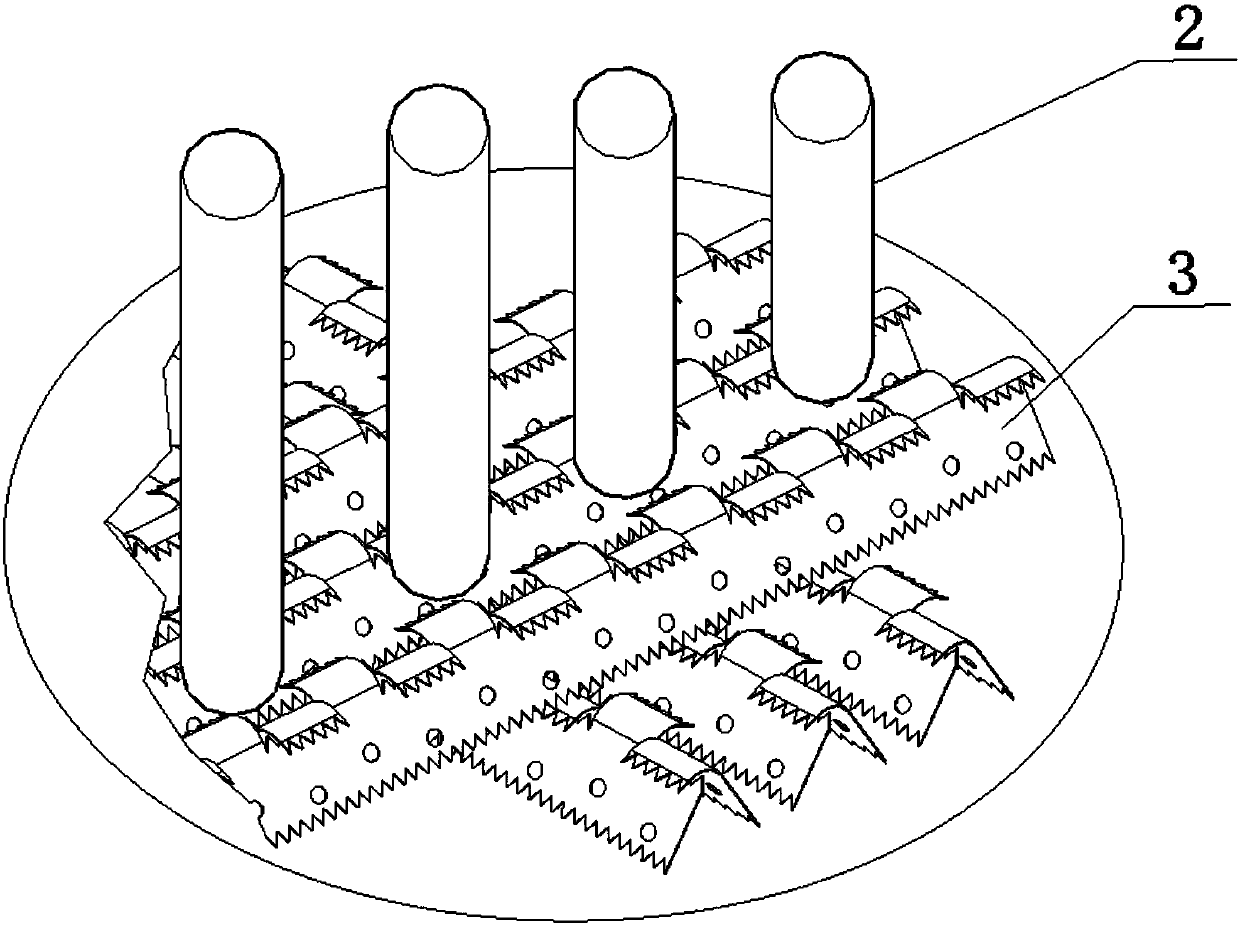

[0053] Acetylene and hydrogen enter the acetylene hydrogenation reactor 1 through the external raw material gas delivery pipeline 4, the raw material gas inlet 13, and the gas distributor 5, and the working fluid whose component is acetone enters the acetylene hydrogenation reactor 1 from the mixed liquid inlet 14 In the process, the catalyst loaded with the active component palladium enters the acetylene hydrogenation reactor 1 from the inlet 17 of the concentrated solution, and the water at about 25°C enters from the heat exchange medium inlet 12 of the built-in heat exchanger 2, and becomes 110°C through heat exchange. Left and right water vapor is discharged through the heat exchange medium outlet 17 of the built-in heat exchanger 2, so that the temperature in the acetylene hydrogenation reactor 1 is controlled at 130°C, and the pressure in the acetylene hydrogenation reactor 1 is controlled at about 3MPaG. 1. Hydrogenation reaction occurs on the surface of the catalyst who...

Embodiment 2

[0057] Acetylene and hydrogen enter the acetylene hydrogenation reactor 1 through the external raw material gas delivery pipeline 4, raw material gas inlet 13, and gas distributor 5, and the working fluid whose component is cyclohexanone enters the acetylene hydrogenation reaction from the mixed liquid inlet 14 In the reactor 1, the catalyst loaded with the active component palladium enters the acetylene hydrogenation reactor 1 from the concentrated solution inlet 17, and the water at about 20°C enters from the heat exchange medium inlet 12 of the built-in heat exchanger 2, and becomes The water vapor at about 120°C is discharged through the heat exchange medium outlet 17 of the built-in heat exchanger 2, so that the temperature in the acetylene hydrogenation reactor 1 is controlled at 140°C, and the pressure in the acetylene hydrogenation reactor 1 is controlled at about 4MPaG , the hydrogenation reaction of acetylene and hydrogen occurs on the surface of the catalyst whose ac...

Embodiment 3

[0061]Acetylene and hydrogen enter the acetylene hydrogenation reactor 1 through the external raw material gas delivery pipeline 4, raw material gas inlet 13, and gas distributor 5, and the working fluid whose component is N-methyl-2-pyrrolidone is from the mixed liquid inlet 14 Entering the acetylene hydrogenation reactor 1, the catalyst loaded with the active component palladium enters the acetylene hydrogenation reactor 1 from the concentrated solution inlet 17, and the water at about 25°C enters from the heat exchange medium inlet 12 of the built-in heat exchanger 2, After heat exchange, it becomes water vapor at about 130°C, and then it is discharged through the heat exchange medium outlet 17 of the built-in heat exchanger 2, so that the temperature in the acetylene hydrogenation reactor 1 is controlled at 150°C, and the acetylene hydrogenation reactor 1 is controlled The internal pressure is about 3.5MPaG, and the hydrogenation reaction of acetylene and hydrogen occurs on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com