Atomic-scale dispersed palladium-based nanometer diamond/graphene composite material catalyst, preparation method and applications thereof

A nano-diamond and composite material technology, which is applied in the field of atomically dispersed palladium-based nano-diamond/graphene composite material catalyst and its preparation, can solve problems such as loss and environmental pollution, and achieve good stability, environmental friendliness and high stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Put 200mg of nanodiamond / graphene carrier in a 100mL round bottom flask with 30mL of water, and after ultrasonic dispersion, adjust the pH value to 10 with 0.25mol / L sodium carbonate solution to obtain nanodiamond / graphene carrier dispersion. Calculate the amount of palladium nitrate solution according to the loading capacity of 0.1wt%, then weigh the required amount of palladium nitrate solution and adjust the pH value to 7 with 0.25mol / L sodium carbonate solution, then add the palladium nitrate solution to the nanodiamond / graphene carrier solution in an oil bath at 100° C. for 1 hour, then cooled to room temperature, suction filtered, and washed to obtain a palladium-based nanodiamond / graphene composite catalyst precursor. Then 30 mg of palladium-based nano-diamond / graphene composite catalyst precursor was placed in a quartz tube, and treated with a mixed gas of hydrogen and helium (hydrogen and helium volume ratio 1:1) at a flow rate of 20 mL / min at 150 ° C for 1 hour...

Embodiment 2

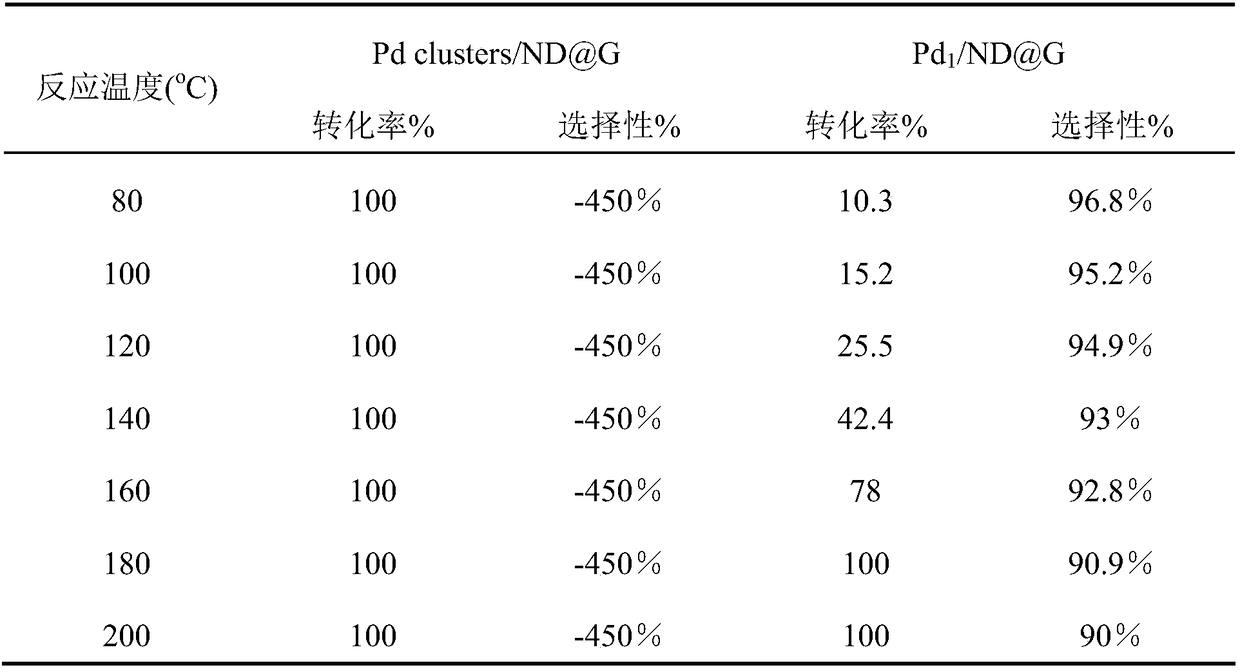

[0038]The catalysts obtained in Example 1 and Comparative Example 1 were added to the fixed-bed reactor. The mixed raw material gas is: 1% acetylene, 10% hydrogen, 20% ethylene, helium as the balance gas, the space velocity is 60000mL / g h, and the percentage is volume percentage, catalyzing the hydrogenation of acetylene to generate ethylene, the catalyst The use temperature is 80°C-200°C; the reaction product is detected by gas chromatography analysis. Among them, Pd clusters / ND@G has no ethylene catalytic selectivity, while atomically dispersed Pd 1 / ND@G has 100% acetylene conversion and 90% ethylene selectivity at 180°C. The performance of the catalyst does not decrease significantly when it is continuously used for 30 hours, indicating that the atomically dispersed nano-diamond / graphene catalyst prepared by the method of the present invention can obviously obtain higher acetylene catalytic reaction activity and ethylene selectivity.

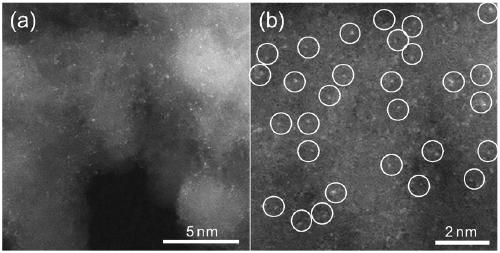

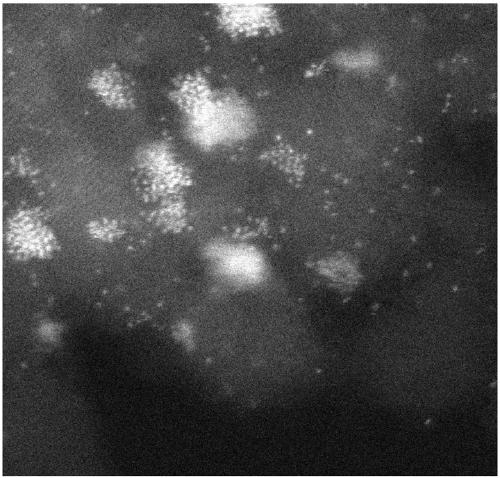

[0039] Correct the transmission ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com