High-dispersion Pd-Ag supported acetylene hydrogenation catalyst and preparation method thereof

An acetylene hydrogenation catalyst and a technology for acetylene hydrogenation, which are used in catalyst activation/preparation, carbon compound catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of poor dispersion of active metals, influence on catalyst activity, and unfavorable scale. production and other problems, to achieve the effect of high dispersion, low cost, excellent selectivity and anti-coking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

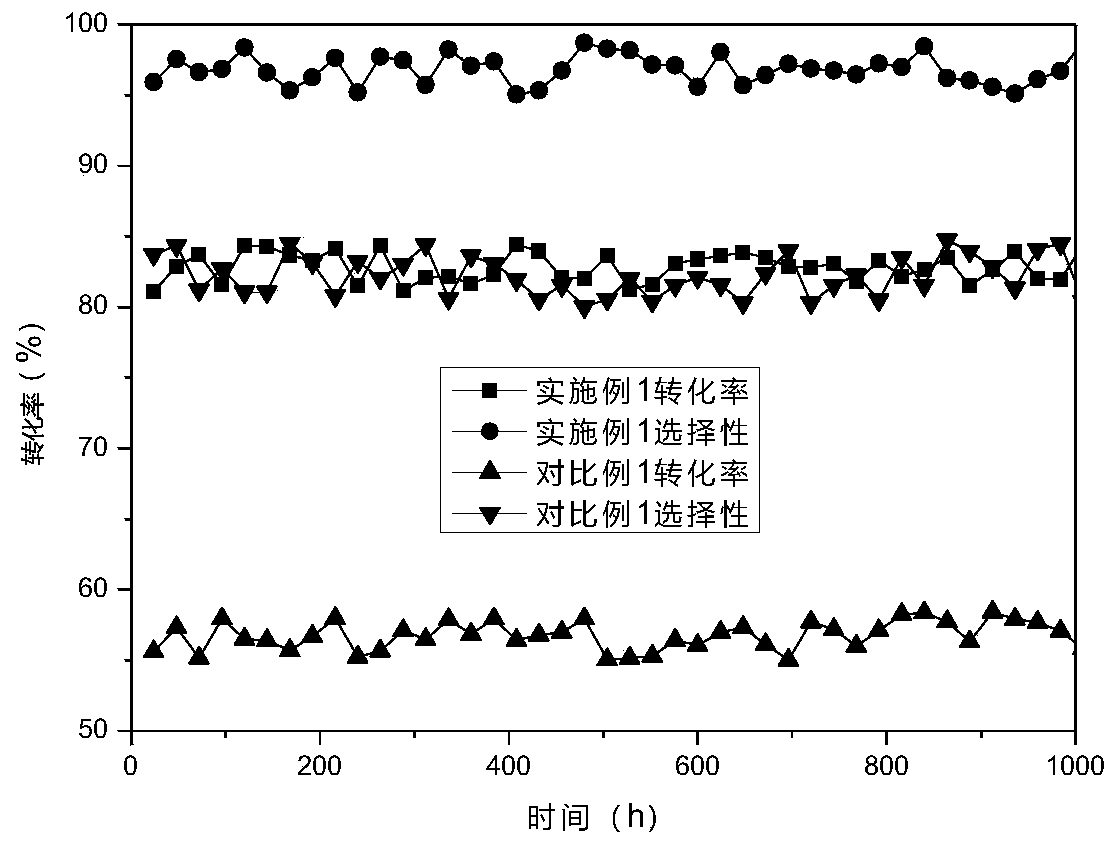

Embodiment 1

[0043] Commercially available alumina balls with a diameter of 4mm were fired at 1300°C for 4h to obtain α-Al 2 o 3 Carrier, measure carrier bulk ratio, pore size, specific surface area, water absorption.

[0044] Weigh 100 g of the carrier for catalyst preparation, and weigh a certain amount of water according to the water absorption rate of the carrier. Using silver nitrate as a precursor, silver nitrate was weighed according to the loading capacity of 0.10% Ag, completely dissolved in the weighed water, and the pH value of the solution was adjusted to 2.0. The solution was slowly impregnated onto the weighed carrier, and aged at room temperature for 30 min. Then it was dried at 120°C for 240 minutes, and then calcined at 500°C for 240 minutes to obtain an impregnated catalyst.

[0045] Prepare 100mL of PMA aqueous solution with a concentration of 1mmol / L, adjust the pH of the solution to 1.8 with dilute nitric acid, place the prepared one-impregnated catalyst in the solu...

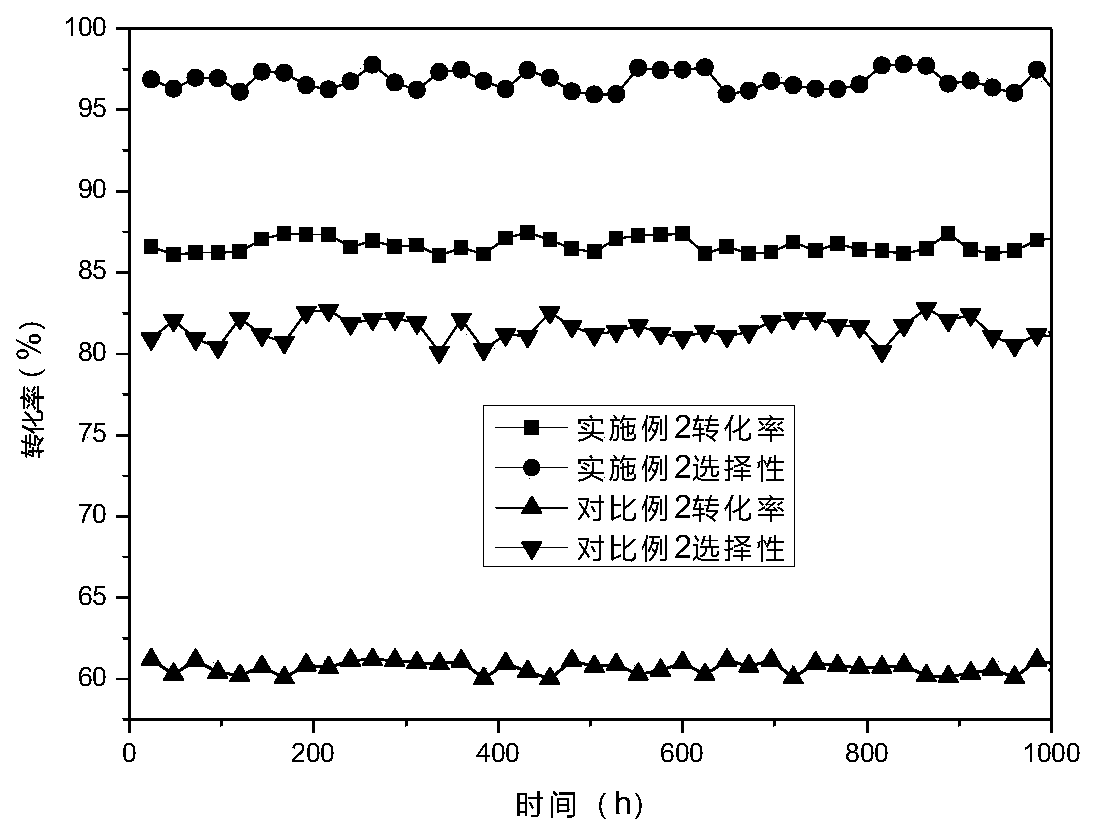

Embodiment 2

[0054] Use commercially available high-purity alumina balls with a particle size of Cylinder, calcined at 1250°C for 4h to obtain α-Al 2 o 3 Carrier, measure the carrier bulk ratio, pore size, specific surface, water absorption.

[0055] Weigh 100 g of the carrier for catalyst preparation, and weigh a certain amount of water according to the water absorption rate. Using silver nitrate as a precursor, silver nitrate was weighed according to the loading capacity of 0.04% Ag, completely dissolved in the weighed water, and the pH value of the solution was adjusted to 2.2. The solution was slowly impregnated onto the weighed carrier, and aged at room temperature for 30 min. Then it was dried at 120°C for 240 minutes, and then calcined at 500°C for 240 minutes to obtain an impregnated catalyst.

[0056] Prepare 100mL of PMA aqueous solution with a concentration of 3mmol / L, adjust the pH of the solution to 4.2 with ammonia water, place the prepared one-immersion catalyst in the ...

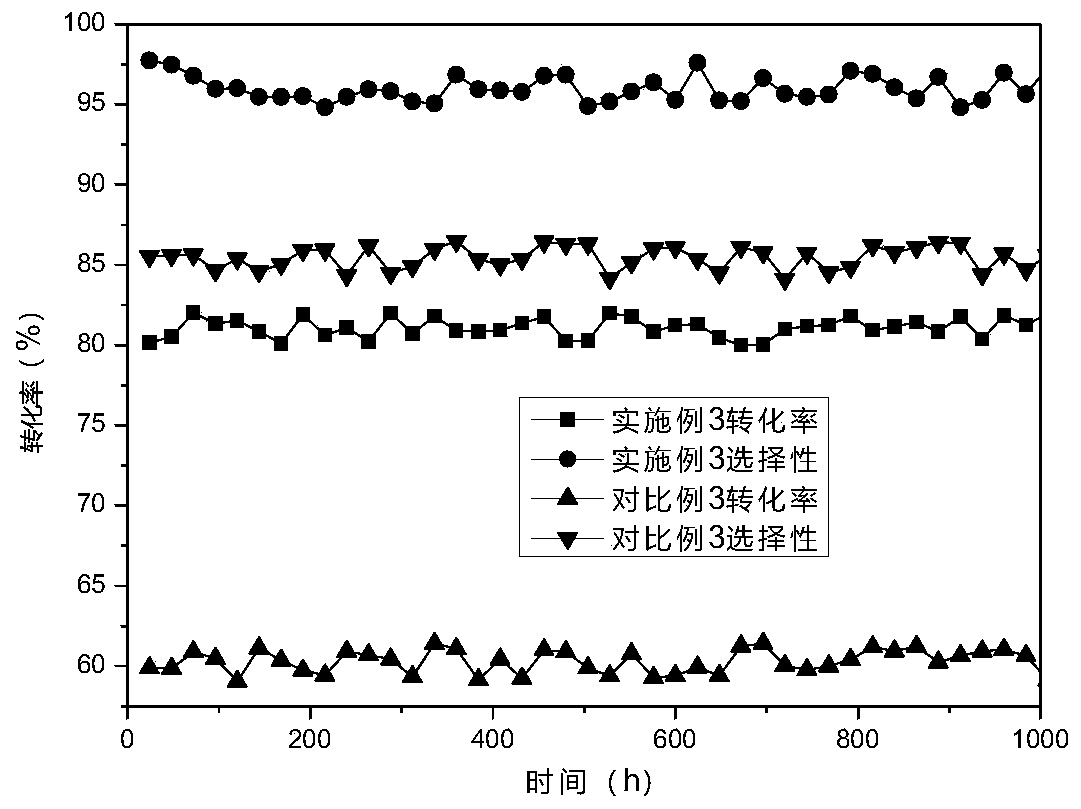

Embodiment 3

[0066] Use commercially available high-purity alumina balls with a size of Hollow cylindrical support, calcined at 1200°C for 4h to obtain α-Al 2 o 3 Carrier, measure the carrier bulk ratio, pore size, specific surface, water absorption.

[0067] Weigh 100 g of the carrier for catalyst preparation, and weigh a certain amount of water according to the water absorption rate. Using silver nitrate as a precursor, silver nitrate was weighed according to the loading capacity of 0.13% Ag, completely dissolved in the weighed water, and the pH value of the solution was adjusted to 2.8. The solution was slowly impregnated onto the weighed carrier, and aged at room temperature for 40 min. Then it was dried at 100°C for 240 minutes, and then calcined at 500°C for 240 minutes to obtain an impregnated catalyst.

[0068] Prepare 100mL of PMA water+ethanol (water:ethanol=2:1) solution with a concentration of 8.6mmol / L, adjust the pH of the solution to 8.0 with ammonia water, place the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com