Lignin amine modified aqueous polyurethane material, preparation method and application

A technology of water-based polyurethane and lignin amine, which is applied in the field of natural polymer materials, can solve the problems that the excellent properties of lignin cannot be reflected, the chemical activity of industrial lignin is low, and the direct reaction of isocyanate, etc., to achieve excellent anti-aging performance and solve the problem of dissolution The effect of low solubility and increasing solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

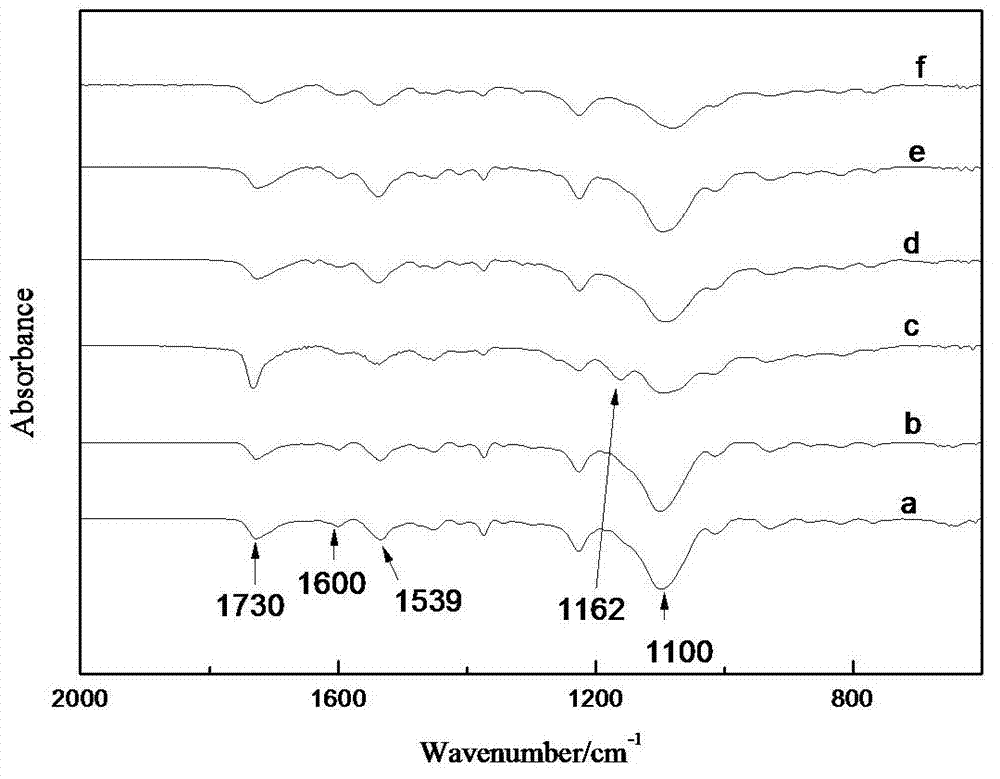

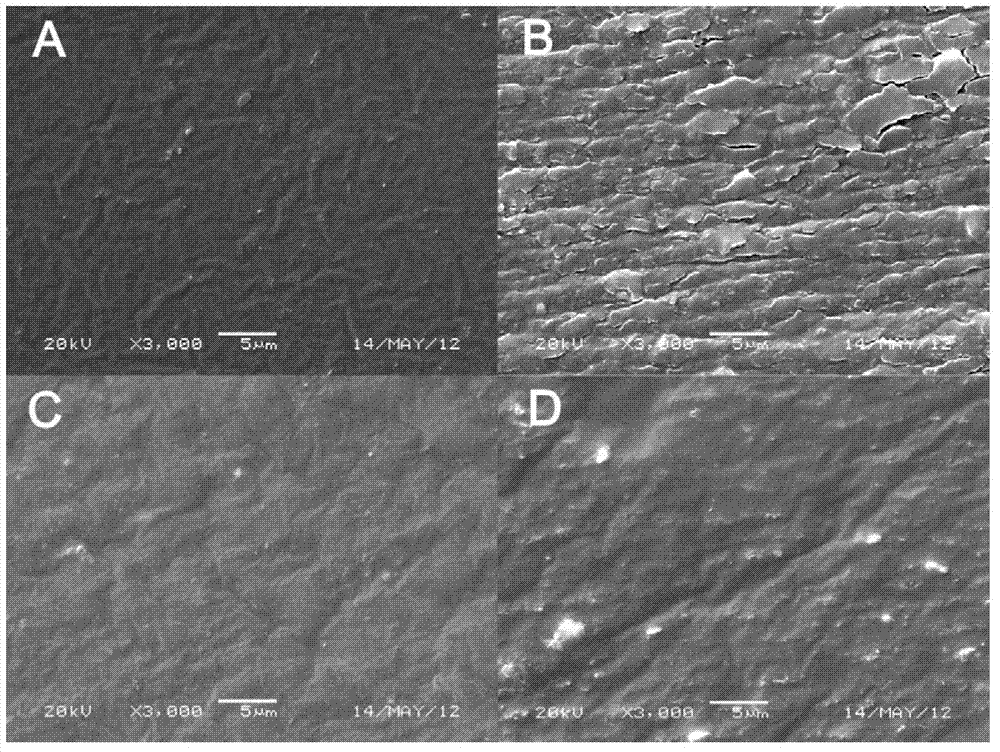

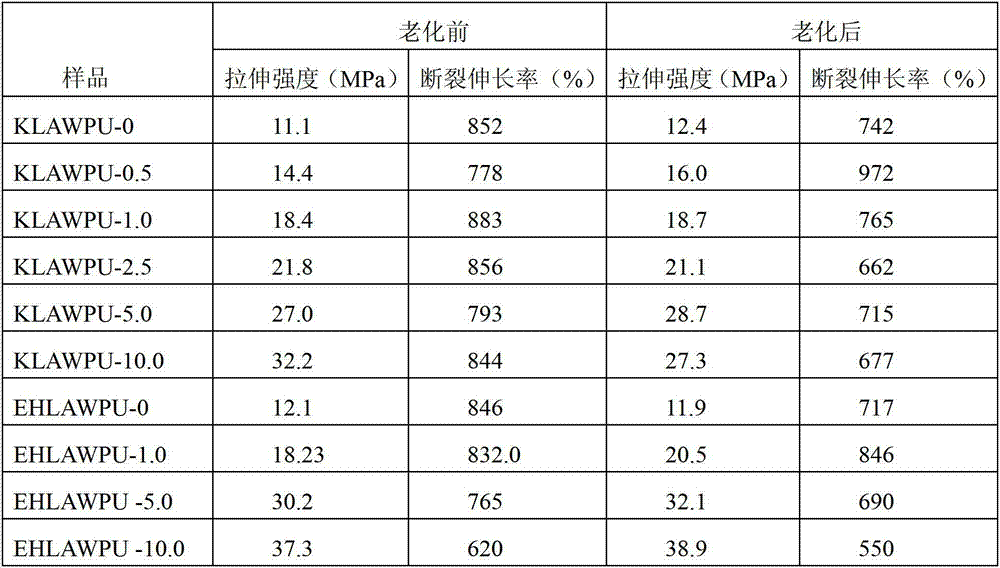

[0036] (1) Dissolve 60 parts by weight of enzymatically hydrolyzed lignin with a molecular weight of 5000 and 50 parts by weight of diethylenetriamine in 0.6L of distilled water, adjust pH to 10.5 with 1.0M hydrochloric acid and 1.0M sodium hydroxide, and mix well at room temperature Add 20 parts by weight of 37wt% formaldehyde solution dropwise, stir for 0.5h after dropping, and react at 50°C for 5h to obtain a reaction solution; at room temperature, the reaction solution and isopropanol are precipitated at a volume ratio of 1:5, and filtered by suction. The precipitate was washed 3 times with isopropanol and dried under vacuum at 40°C for 10 hours to obtain enzymatically hydrolyzed ligninamine (EHLA) as a brown-yellow powder;

[0037] (2) After 100 parts by weight of polypropylene glycol polyol with a molecular weight of 1500 is dehydrated under reduced pressure at 100°C, 50 parts by weight of diphenylmethane diisocyanate are added under nitrogen protection, reacted at 65°C for ...

Embodiment 2

[0043] (1) Dissolve 100 parts by weight of sulfate lignin with a molecular weight of 7000 and 80 parts by weight of diethanolamine in 1.0L of distilled water, adjust pH=10.2 with 0.5M hydrochloric acid and 0.5M sodium hydroxide, mix well at room temperature and add 70 parts by weight A portion of 37wt% formaldehyde solution was added dropwise and stirred for 0.6h, reacted at 45°C for 8h to obtain a reaction solution; the reaction solution and isopropanol were precipitated at a volume ratio of 1:3 at room temperature, filtered with suction, and the obtained precipitate Washed with propanol 3 times, dried at 50°C under vacuum for 8 hours to obtain brown powdery sulfate ligninamine (KLA);

[0044] (2) After 80 parts by weight of polybutylene glycol with a molecular weight of 1000 is dehydrated at 80°C under reduced pressure, 35 parts by weight of toluene diisocyanate are added under nitrogen protection, reacted at 55°C for 3 hours, and then 4 parts by weight of dimethylol propylene a...

Embodiment 3

[0050] (1) 50 parts by weight of alkali lignin with a molecular weight of 3000 and 40 parts by weight of triethylenetetramine are dissolved in 0.5L of distilled water, 0.1M hydrochloric acid and 0.1M sodium hydroxide are adjusted to pH=10.5, mixed evenly at room temperature, and then 50 weight parts are added dropwise A portion of 37wt% formaldehyde solution was added dropwise and stirred for 0.2h, reacted at 75°C for 3h to obtain a reaction solution; at room temperature, the reaction solution and isopropanol were precipitated at a volume ratio of 1:5, and filtered with suction. Washed with propanol 3 times, dried in vacuum at 60°C for 6 hours to obtain brown powdery alkali ligninamine (ALA);

[0051] (2) After 50 parts by weight of polypropylene glycol polyol with a molecular weight of 2000 is dehydrated at 100°C under reduced pressure, 25 parts by weight of toluene diisocyanate are added under nitrogen protection, reacted at 75°C for 2h, and then 2 parts by weight of dimethylol ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com