Palladium monatomic catalyst, preparation of palladium monatomic catalyst and application of palladium monatomic catalyst in acetylene hydrogenation reaction

A catalyst and atomic technology, applied in the field of palladium single-atom catalyst and its preparation and application in acetylene hydrogenation reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1) Prepare the impregnation solution: dissolve palladium nitrate with nitric acid and deionized water to prepare the impregnation solution; the concentration of palladium nitrate is 80mgPd / mL;

[0037] 2) Equal volume impregnation: Mix the ZnO carrier heat-treated at 120°C for 8 hours with the impregnation solution evenly, and impregnate at room temperature for 30 hours to obtain the catalyst precursor;

[0038] 3) Heat treatment: dry the catalyst precursor in a drying oven at 120°C for 8 hours, then calcinate in a muffle furnace at 400°C for 3 hours, and finally cool to room temperature;

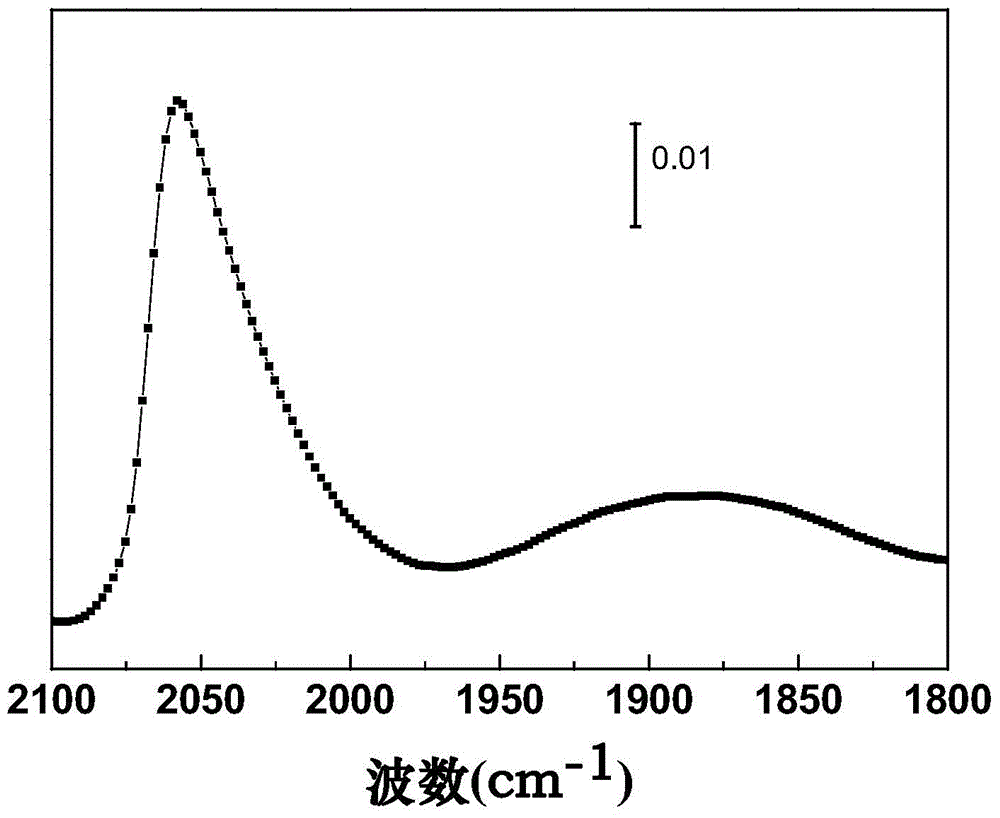

[0039] 4) Reduction activation: at volume content of 10%H 2 / He atmosphere at 300°C for 1 hour to obtain a single-atom catalyst. Infrared spectra of CO adsorbed on the catalyst ( figure 1 ) shows that the catalyst Pd mainly exists in the form of single atoms. (Description: 1890cm -1 with 2060cm -1 The adsorption peaks were assigned to bridge and line adsorption of CO on Pd, resp...

Embodiment 2

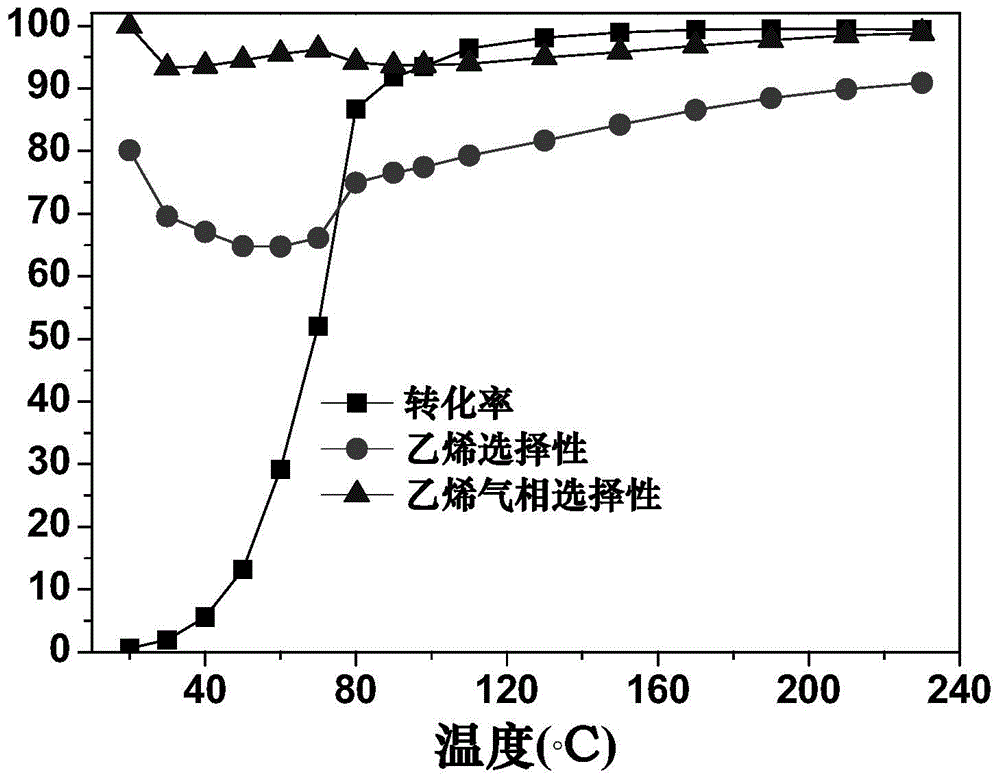

[0041] Carry out acetylene hydrogenation reaction under normal pressure with the catalyst that embodiment 1 obtains, 10mg catalyst mixes with 100mg quartz sand, volume content 10%H 2 / He atmosphere at 300°C for 1h, then lowered to 60°C for acetylene hydrogenation reaction, the raw material gas composition (volume content) is 2%C 2 h 2 ,20%H 2 , He is the balance gas, the gas flow rate is 30mL / min, and the space velocity is 180,000mL / g.h. The raw material gas and product analysis are carried out by Agilent gas chromatography and hydrogen flame detector. The reaction time is 12h, and the reaction results are listed in Table 1.

Embodiment 3

[0043] The difference from Example 2 is that the reaction temperature is changed from 60° C. to 80° C., and the reaction results are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com