Boron-containing catalytic cracking catalyst for increasing ethylene yield, preparation method and application method thereof

A catalytic cracking and catalyst technology, used in carbon compound catalysts, including molecular sieve catalysts, physical/chemical process catalysts, etc., can solve the problems of high activation energy, decreased conversion rate of heavy oil, and increased coke yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0050] According to the preparation method of catalytic cracking catalyst provided by the present invention, one embodiment, the method for preparing boron-aluminum composite oxide comprises the following steps:

[0051] (1) mixing the alumina precursor with water to obtain a mixture 2;

[0052] (2) mixing the precursor of boron and water to prepare mixture 3;

[0053] (3) mix mixture 3 and mixture 2, and then acidify by adding an appropriate amount of acid to form mixture 1;

[0054] (4) The mixture 1 obtained in step (3) is dried and calcined.

[0055] According to the preparation method of catalytic cracking catalyst provided by the present invention, in the preparation method of boron-aluminum composite oxide, in step (1), a mixture containing alumina precursor and water is formed, which is called mixture 2 in the present invention. Usually, the precursor of alumina is mixed with water and beaten, and the solid content of the mixture is preferably 10-18% by weight, such ...

Embodiment 1

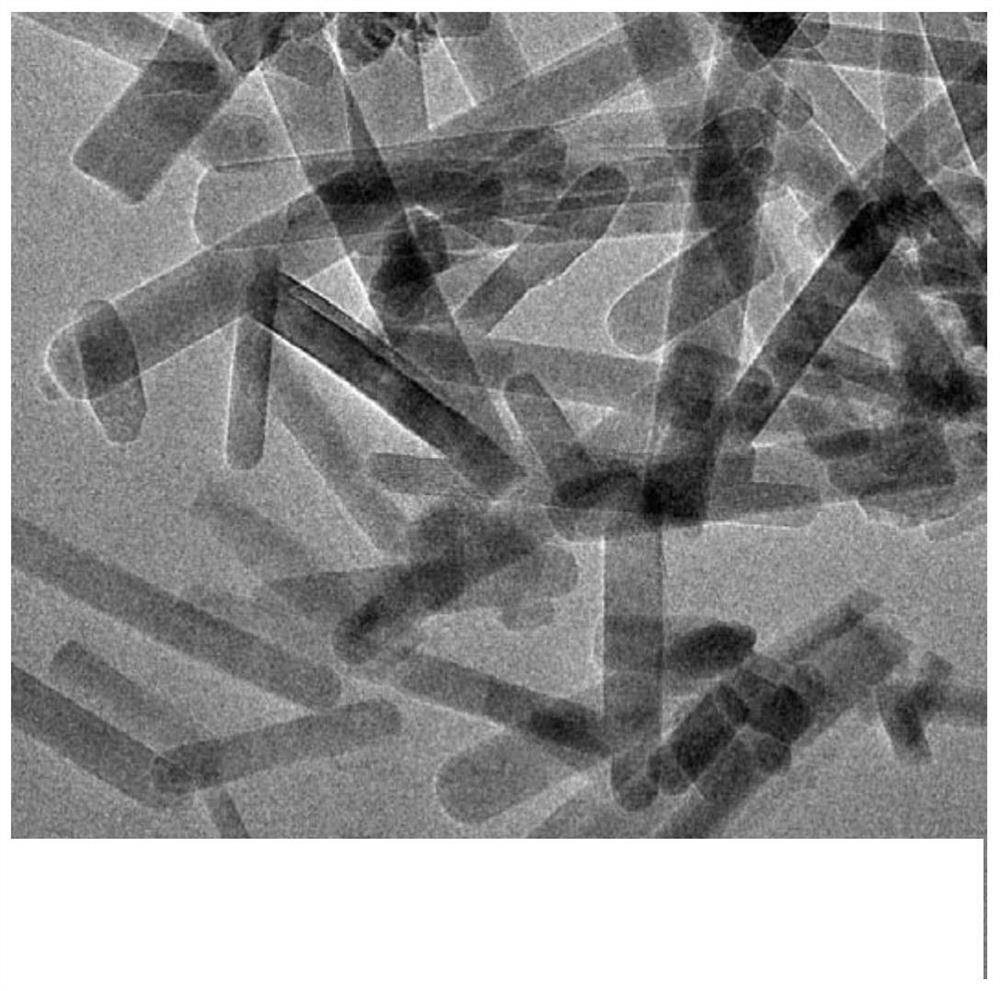

[0077] (1) Preparation of boron-aluminum composite oxide: add 670g of deionized water to the beaker, then add 130g of SB powder, disperse in the homogenizer for 30min, then add 53g of boric acid, disperse in the homogenizer for 20min, and finally add hydrochloric acid 20g was acidified to obtain mixture 1 with a pH value of 1.0; the mixture 1 was dried at 120°C for 12 hours, and calcined at 650°C for 4 hours to obtain a boron-aluminum composite oxide, denoted as BA1. The composition of the boron-aluminum composite oxide: B 2 o 3 The content is 23.5% by weight, the content of alumina is 76.5% by weight, it has a rod-like structure, the minimum size of the shortest side of the grain is 10nm, the pore volume is 0.31ml / g, and the pore distribution: diameter 2-2 / g.

[0078] (2) Catalyst preparation: first add 188g of kaolin to be beaten with water to obtain a slurry with a solid content of 40% by weight, add 74g of aluminum sol for beating to obtain a kaolin slurry containing alu...

Embodiment 2

[0081] (1) Preparation of boron-aluminum composite oxide: add 369g deionized water to a beaker, then add 130g of pseudoboehmite dry powder, disperse in a homogenizer for 30min; add 300g deionized water to another beaker, and then Add 53g of boric acid, heat it at 80°C for 30min to dissolve it; then mix the two solutions, disperse them in a homogenizer for 20min, and finally add 20g of hydrochloric acid to acidify to obtain mixture 2, whose pH value is 2.41, and the mixture Dry at 100°C for 24h, and bake at 800°C for 2h to obtain boron-aluminum composite oxide BA2. The composition of the boron-aluminum composite oxide: B 2 o 3 The content is 23.5% by weight, the content of alumina is 76.5% by weight, it has a rod-like structure, the shortest side of the grain is 11nm, the pore volume is 0.23ml / g, and the pore distribution: diameter 2-2 / g.

[0082] (2) Catalyst preparation: first mix kaolin 188g with water and make a slurry to obtain a slurry with a solid content of 40% by we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com