Cable sheath rubber material and preparation method thereof

A technology of rubber materials and cable sheaths, applied in circuits, electrical components, plastic/resin/wax insulators, etc., can solve problems affecting escape and fire extinguishing, loss of flame retardant properties, serious occurrence, etc., to achieve high ethylene content, Low water absorption and good plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of plasticizer comprises the following steps:

[0028] 1) Calculated in parts by weight, weigh 30 parts of polyether silicone oil, 25 parts of butyl oleate, 10 parts of nano silicon dioxide and 0.5 parts of silane coupling agent KH602 for use;

[0029] 2) First, polyether silicone oil and nano-silica are added to butyl oleate for stirring and dispersing to obtain a dispersion;

[0030] 3) Warm up the dispersion liquid in step 2) to 80°C, add silane coupling agent KH602, stir and mix well, keep it warm for 4 hours, and then cool down to room temperature.

Embodiment 2

[0032] The preparation method of plasticizer comprises the following steps:

[0033] 1) Calculated according to parts by weight, weigh 40 parts of polyether silicone oil, 15 parts of butyl oleate, 20 parts of nano silicon dioxide and 2.5 parts of silane coupling agent KH540 for later use;

[0034] 2) First, polyether silicone oil and nano-silica are added to butyl oleate for stirring and dispersing to obtain a dispersion;

[0035] 3) Warm up the dispersion liquid in step 2) to 90°C, add silane coupling agent KH540, stir and mix well, keep it warm for 3 hours, and then cool down to room temperature.

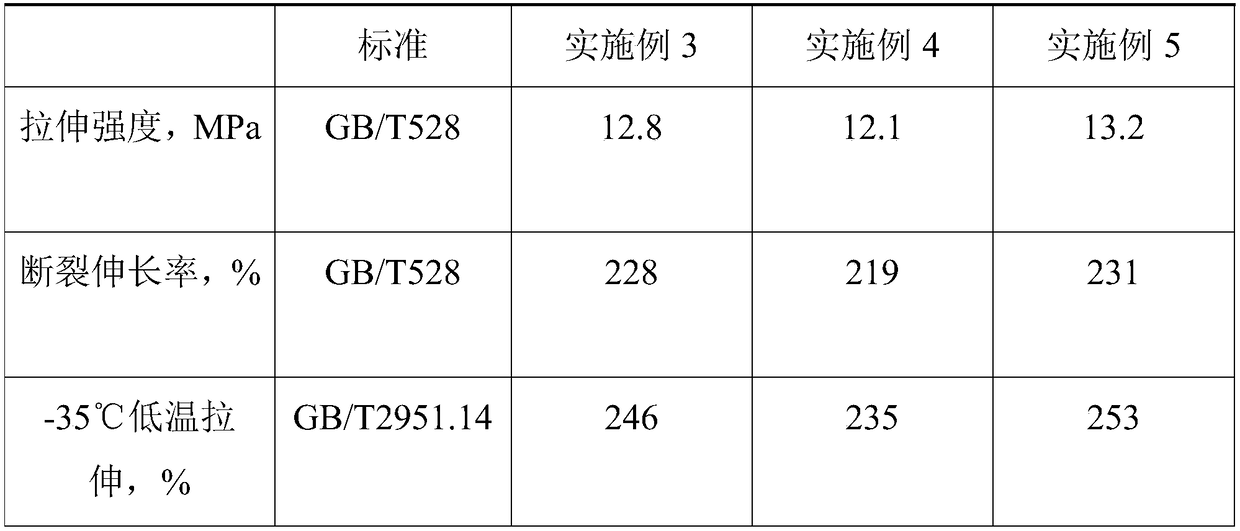

Embodiment 3

[0037] A cable sheath rubber material, comprising the following raw materials:

[0038] 76 parts of EPDM rubber, 12 parts of butyl rubber, 19 parts of ethylene-vinyl acetate copolymer, 5 parts of ethoxylated trimethylolpropane triacrylate, 2 parts of tetramethylthiuram disulfide, paraffin wax 6 parts, 12 parts of plasticizers of Example 1, 4 parts of polyethylene wax, 12 parts of carbon black, 8 parts of magnesium aluminum hydrotalcite powder and 6 parts of clay.

[0039] Preparation method of cable sheath rubber material:

[0040] 1) Weigh EPDM rubber, butyl rubber, ethylene-vinyl acetate copolymer, ethoxylated trimethylolpropane triacrylate, tetramethylthiuram disulfide, paraffin wax, according to the proportioning ratio 1 plasticizer, polyethylene wax, carbon black, magnesium aluminum hydrotalcite powder and clay for subsequent use;

[0041] 2) primary mixing: add EPDM rubber, butyl rubber, ethylene-vinyl acetate copolymer, paraffin wax, polyethylene wax and the plasticiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com