Patents

Literature

30results about How to "High propylene content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalytic conversion method for petroleum hydrocarbon

ActiveCN102344832AHigh yieldHigh selectivityTreatment with hydrotreatment processesExtraction purification/separationGasolineReaction temperature

The invention relates to a catalytic conversion method for petroleum hydrocarbon. According to the method, raw oil contacts a catalyst in a reactor to carry out a reaction, wherein the catalyst is rich in mesoporous zeolite; a cracking reaction is performed under the following conditions: a reaction temperature is 500-750 DEG C, weight hourly space velocity is 100-800 h<-1>, reaction pressure is 0.10-1.0 MPa, a weight ratio of the catalyst to the raw oil is 1:100, a weight ratio of water vapour to the raw oil is 0.05:1.0; the spent catalyst and the reaction oil gas are separated; the spent catalyst is subjected to regeneration, and returns to the reactor, the reaction oil gas is separated to obtain a product, wherein the product comprises ethylene, propylene, propane, butane and arene-rich catalytic gasoline; the catalytic gasoline is subjected to selective hydrogenation, and enters an arene extraction apparatus to separate to obtain the target product of light arene; the raffinate oil, the propane and the butane are subjected to steam cracking to further produce ethylene and propylene. With the method provided by the present invention, the yields of the ethylene and the propylene are respectively 20.31 wt% and 31.67 wt%, the yield of BTX is 24.39 wt%.

Owner:CHINA PETROLEUM & CHEM CORP +1

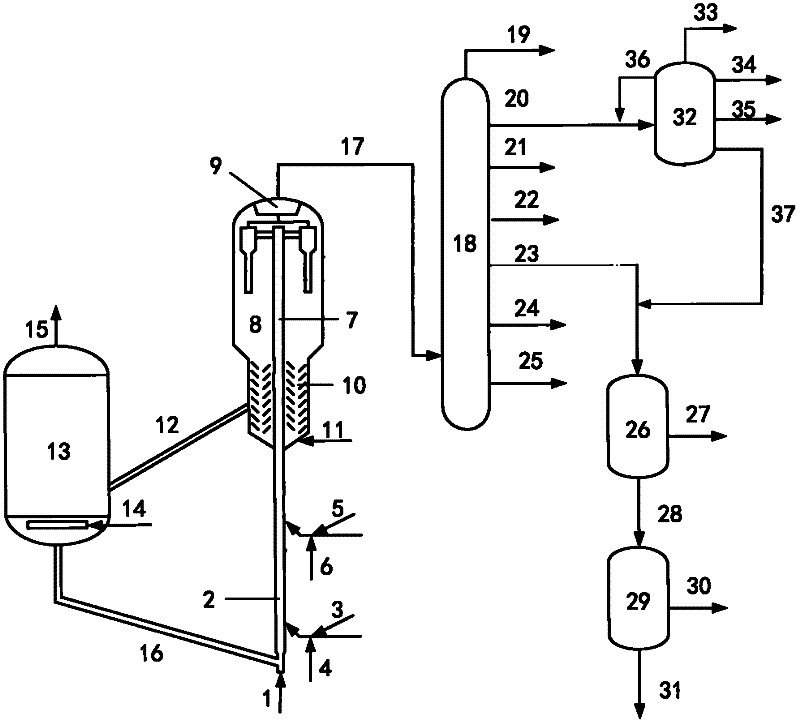

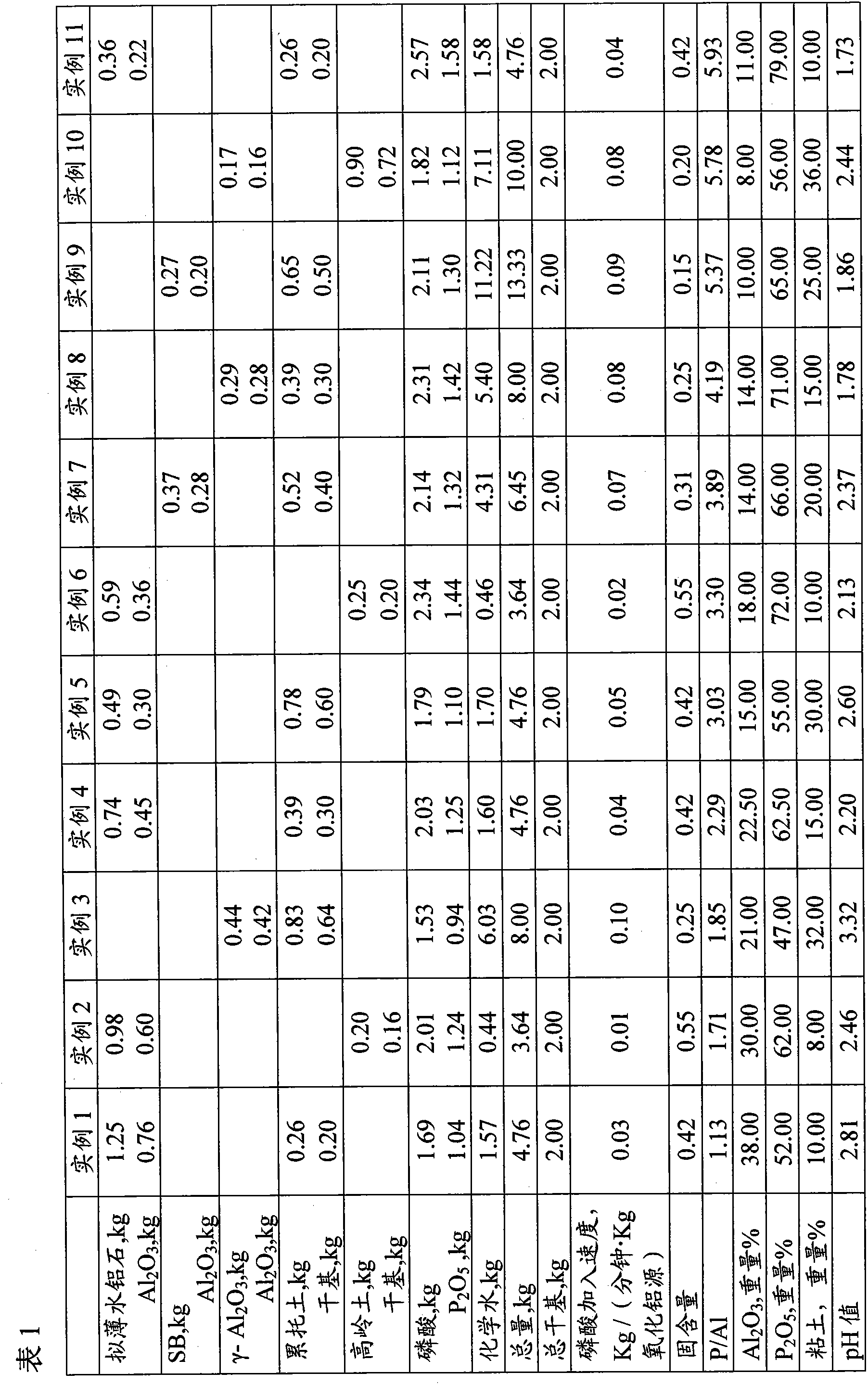

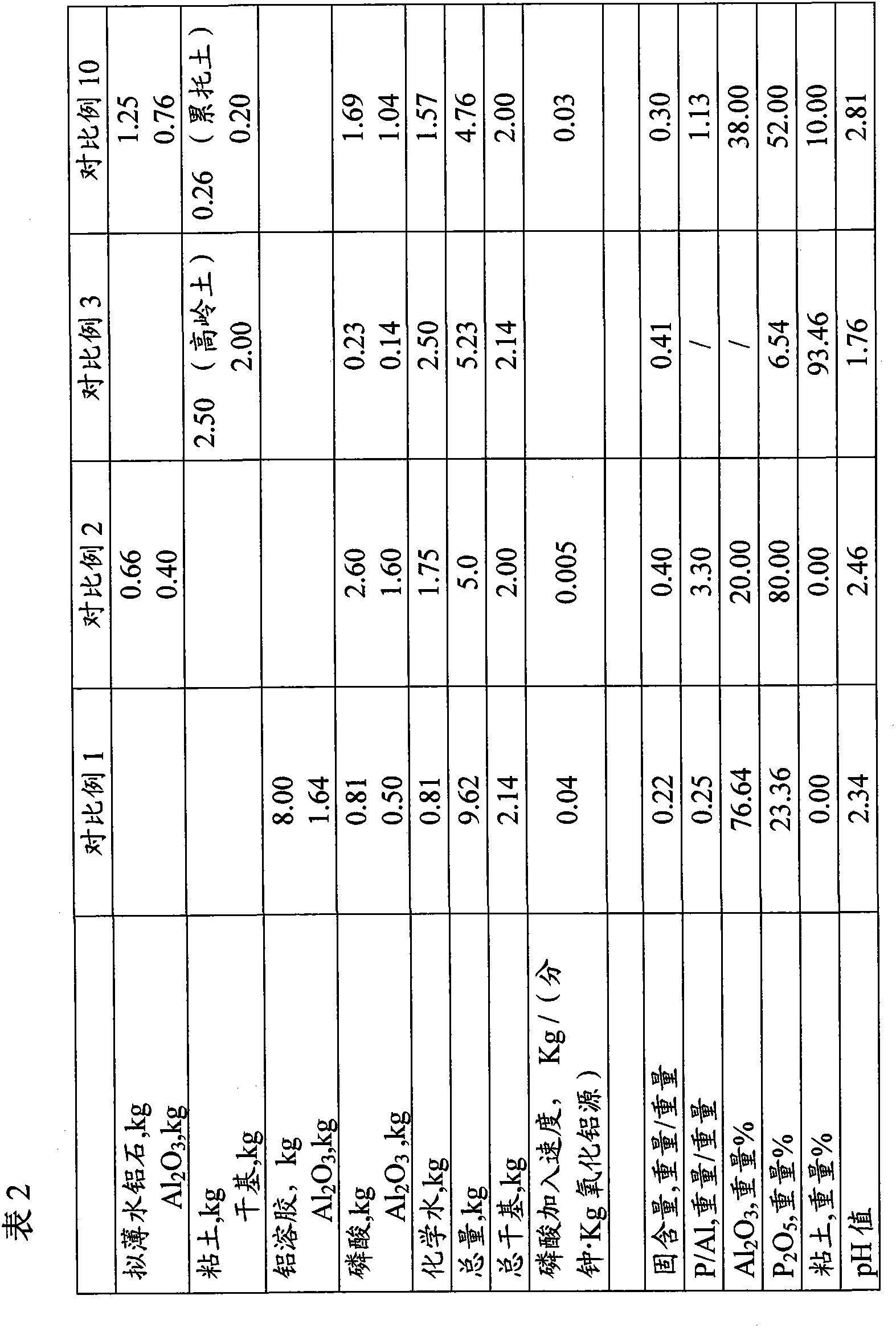

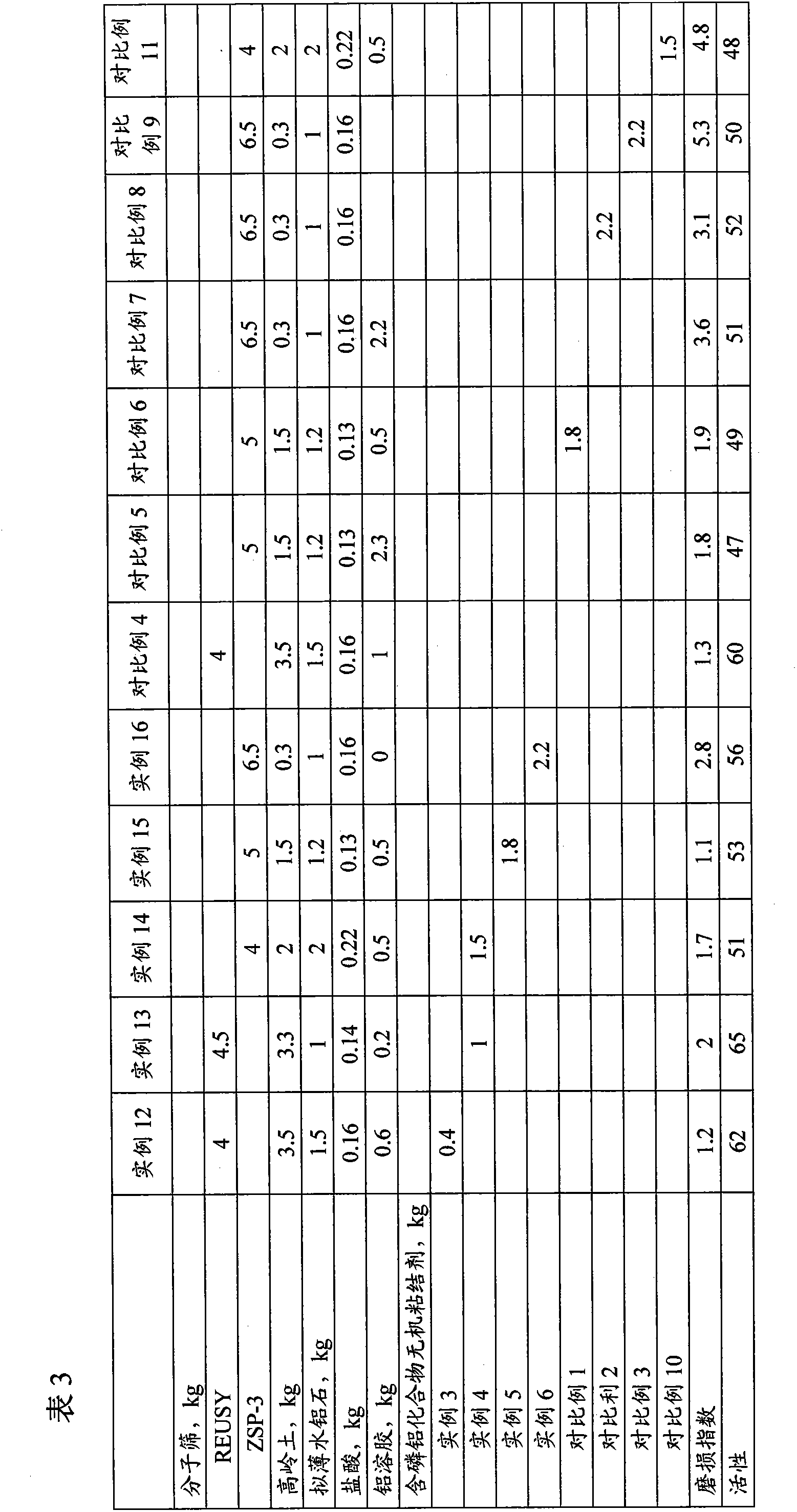

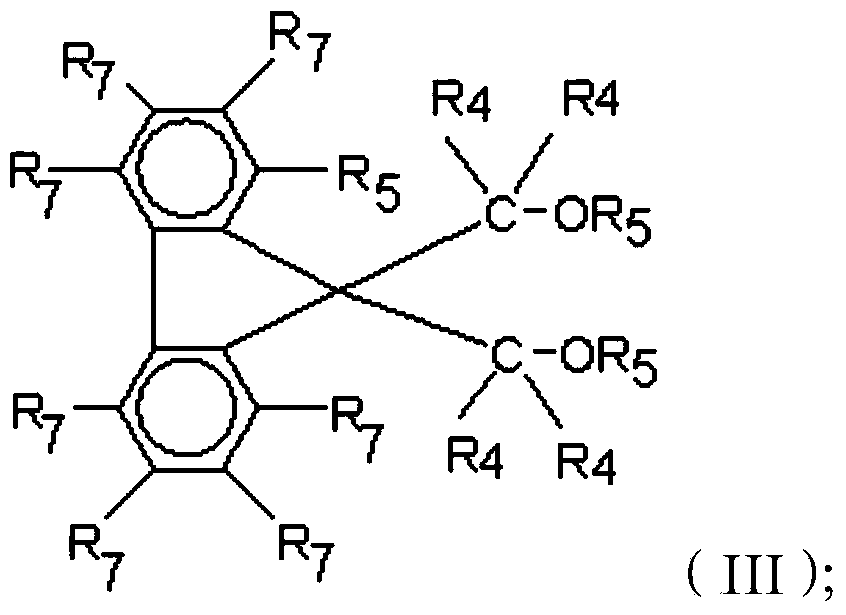

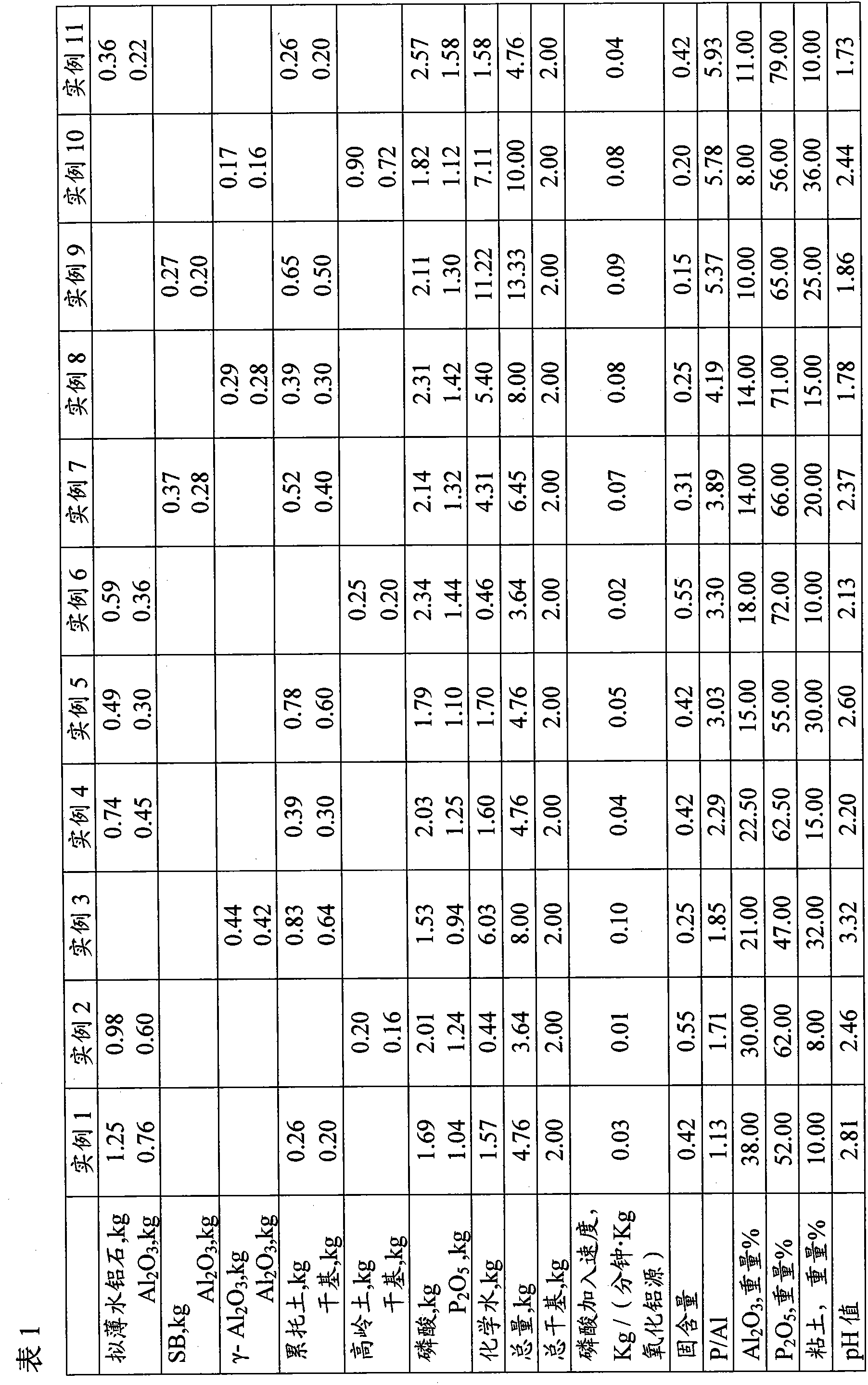

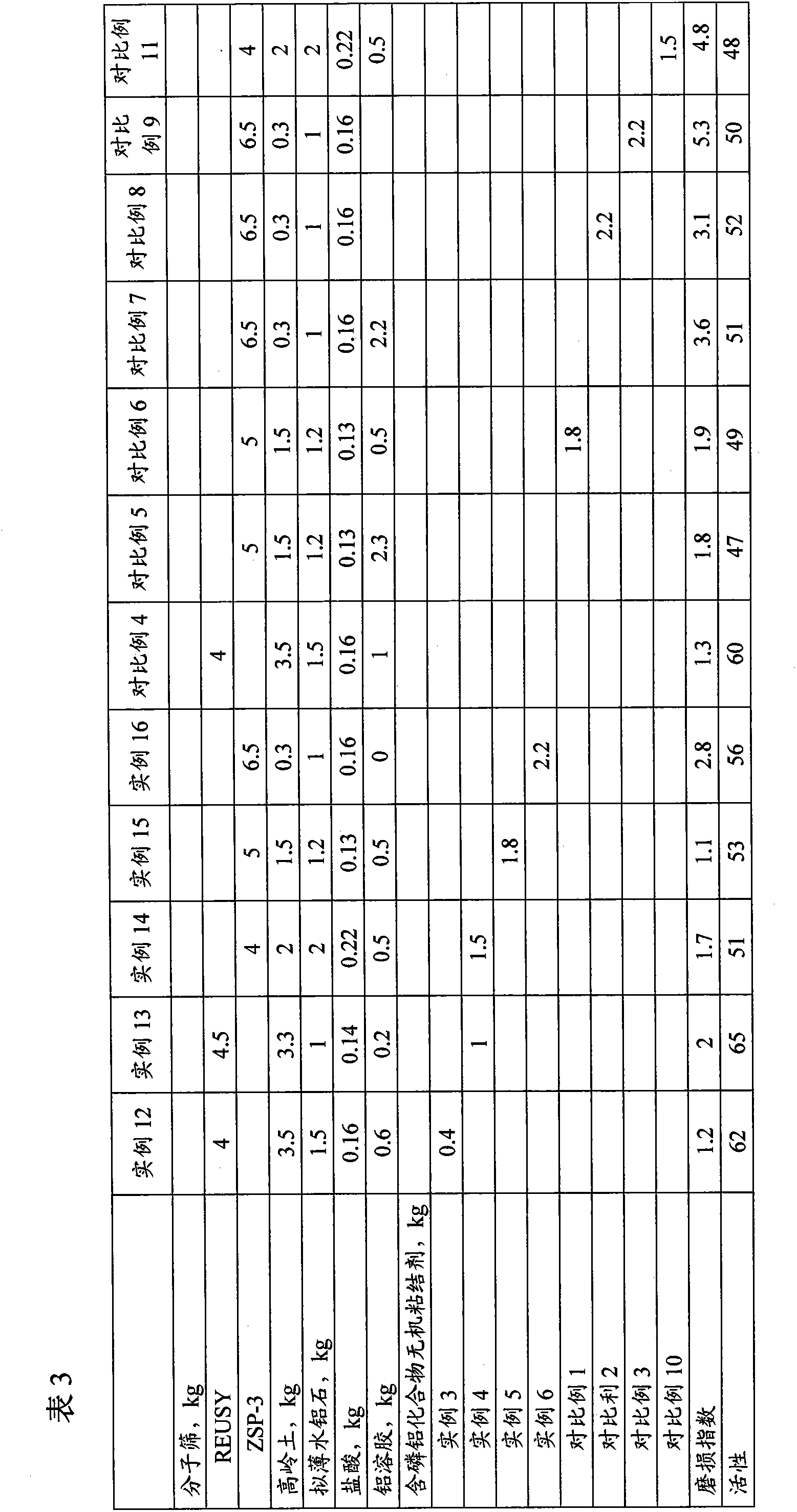

Inorganic binder containing phosphorus and aluminum compounds

ActiveCN102847547APrevent curingIncrease the feeding speedCatalytic crackingMolecular sieve catalystsAluminium hydroxidePhosphoric acid

The inventive inorganic binder containing phosphorus and aluminum compounds comprises (by weight percentages) alumina 15-40, phosphorus pentoxide 45-80, and clay 1-40. The binder has P / Al weight ratio of 1-6, pH of 1-3, and solid content of 15-60 wt%. The preparation method includes mixing acid-soluble aluminum hydroxide and / or alumina, clay and deionized water; pulping into pulp having solid content of 15-45%; adding concentrated phosphoric acid into the pulp under stirring at P / Al weight ratio of 1-6; and reacting at 50-99 DEG C for 15-90 min. The preparation method can avoid binder solidification due to overheat caused by heat release of non-uniform local instantaneous intensive reaction of materials. The binder can improve wear resistance, activity and selectivity of FCC catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

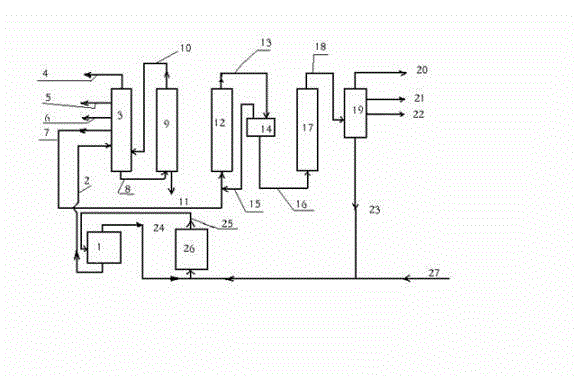

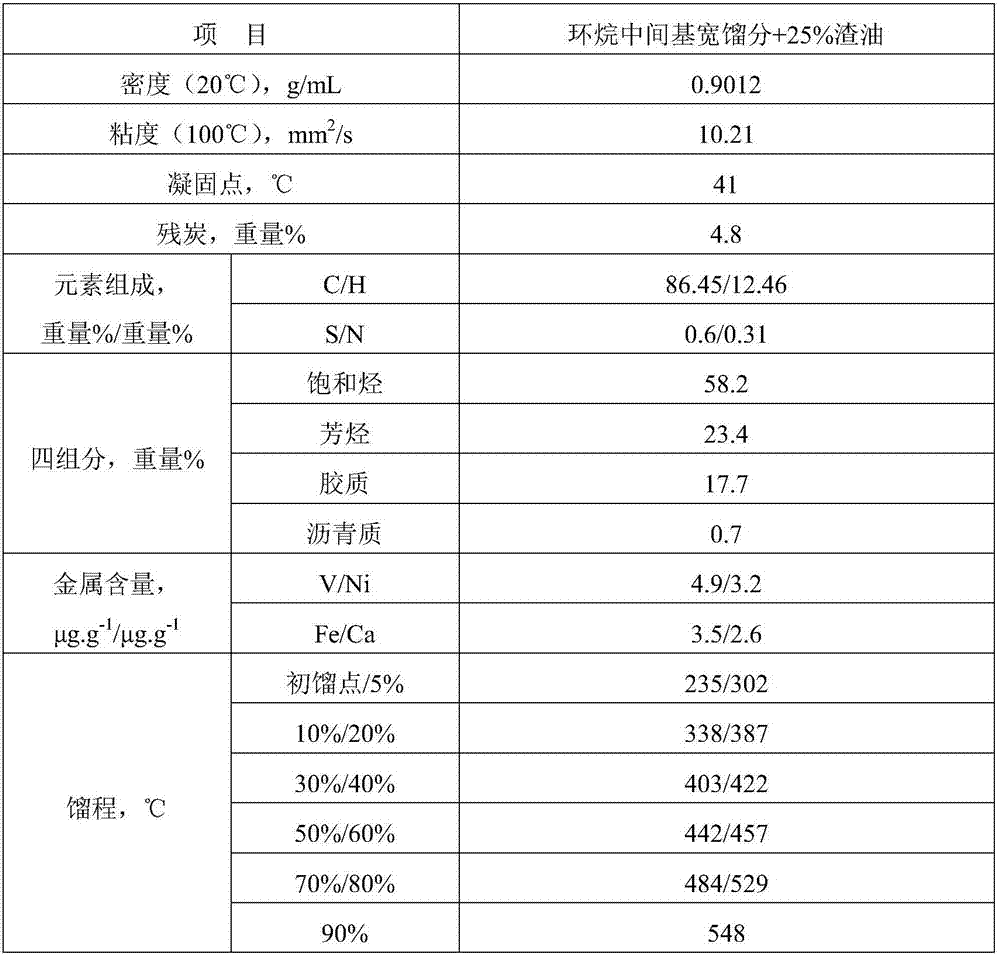

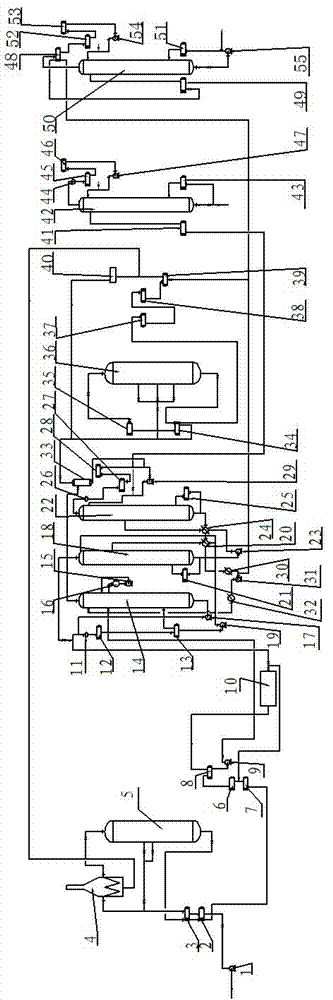

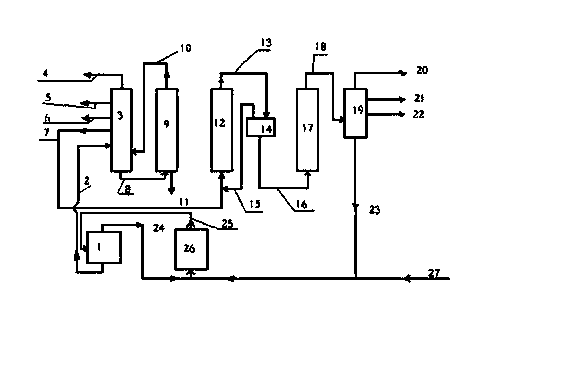

Combined process for treating residual oil

ActiveCN103059998ALess investmentHydrogenation Depth ModerationTreatment with hydrotreatment processesEngineeringHydrogen treatment

The invention discloses a combined process for treating residual oil. Boiling bed residual oil hydrotreatment, delayed coking, wax oil hydrotreatment and catalytic cracking are organically combined in the method. The method concretely comprises the following steps of: enabling a liquid-phase product obtained after residual oil raw materials are subjected to boiling bed hydrotreatment to directly enter a coking fractional distillation column to be in countercurrent contact with oil gas generated through coking, and then, carrying out fractional distillation to obtain a wax oil fraction, and enabling the wax oil fraction to enter a wax oil hydrotreatment device, wherein the liquid-phase product is not subjected to fractional distillation; enabling the obtained liquid-phase product as a raw material to enter a catalytic cracking unit for treating; enabling circulating oil obtained through the fractional distillation of the coking fractional distillation column to return to a delayed coking unit; generating gasoline and diesel products by the coking fractional distillation column; and carrying out catalytic cracking and fractional distillation to obtain liquefied gas, gasoline and diesel products. Compared with the prior art, the combined process has the advantages that a hydrogenization fractional distillation column can be omitted, the investment cost can be reduced, the coking and catalytic cracking raw material sources are expanded, and the coked and catalyzed light oil yield is increased; and meanwhile, the reaction heat energy is sufficiently utilized, and the production energy consumption is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

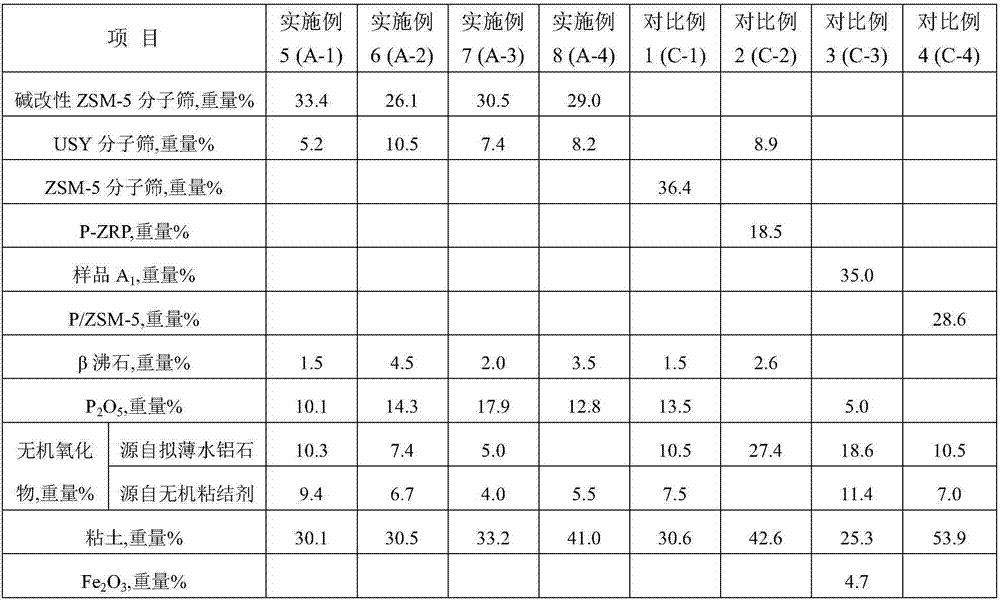

Catalytic cracking additive for increasing yield rates of propylene and isopentene as well as preparation method and application thereof

ActiveCN107185586AHigh yieldFacilitates shape-selective cracking reactionsCatalytic crackingMolecular sieve catalystsMolecular sieveGasoline

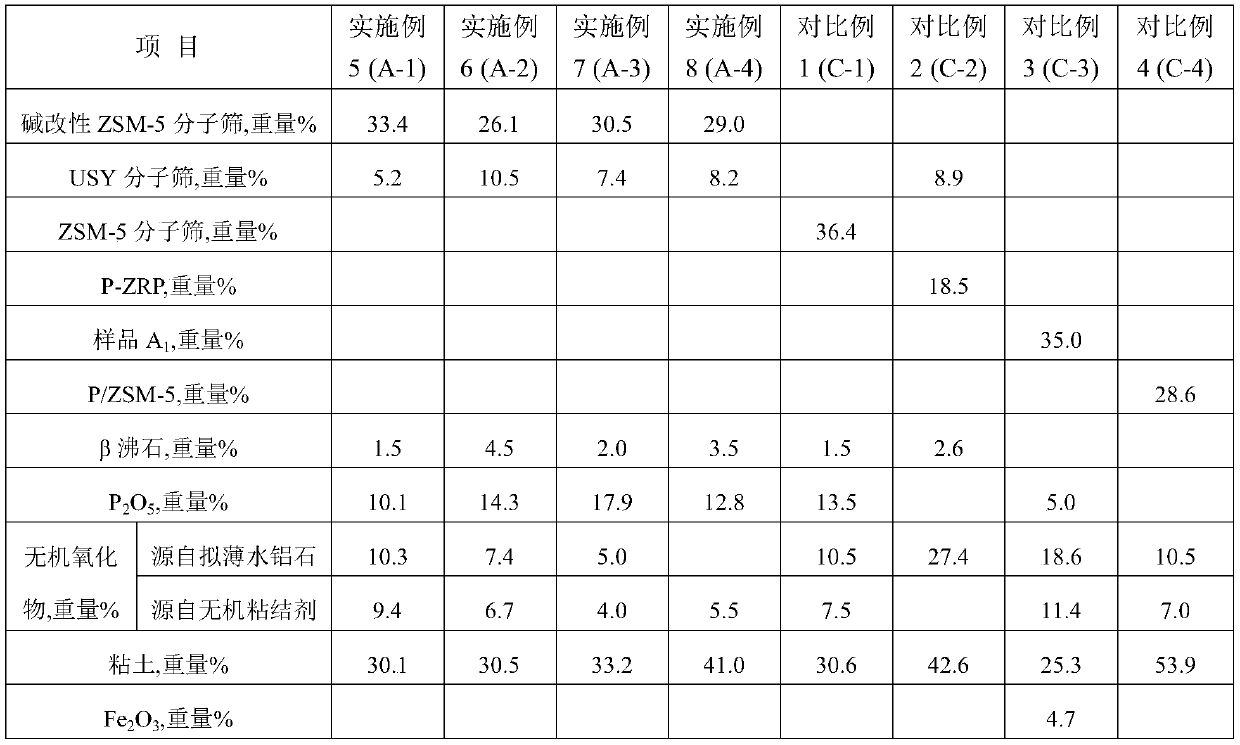

The invention relates to a catalytic cracking additive for increasing yield rates of propylene and isopentene as well as a preparation method and application thereof. The catalytic cracking additive for the increasing yield rates of propylene and isopentene is prepared from the following components in percentage by weight based on the dry basis: 15 to 45 wt% of alkaline-modified ZSM-5 molecular sieve, 1 to 20 wt% of USY molecular sieve, 1 to 10 wt% of beta-zeolite, 3 to 25 wt% of P2O5 (phosphorus pentoxide), 3 to 25 wt% of inorganic oxide, and the balance of clay. The catalytic cracking additive for increasing the yield rates of propylene and isopentene has the advantages that the selective heterogenous cracking reaction of C8 or above gasoline components in gasoline can be promoted to catalyze and crack, the yield rates of propylene and isopentene are synchronously increased, the content of propylene (delta propylene / delta liquefied gas) in the liquefied gas increment is increased, and the gasoline with high octane number is jointly produced.

Owner:李瑛

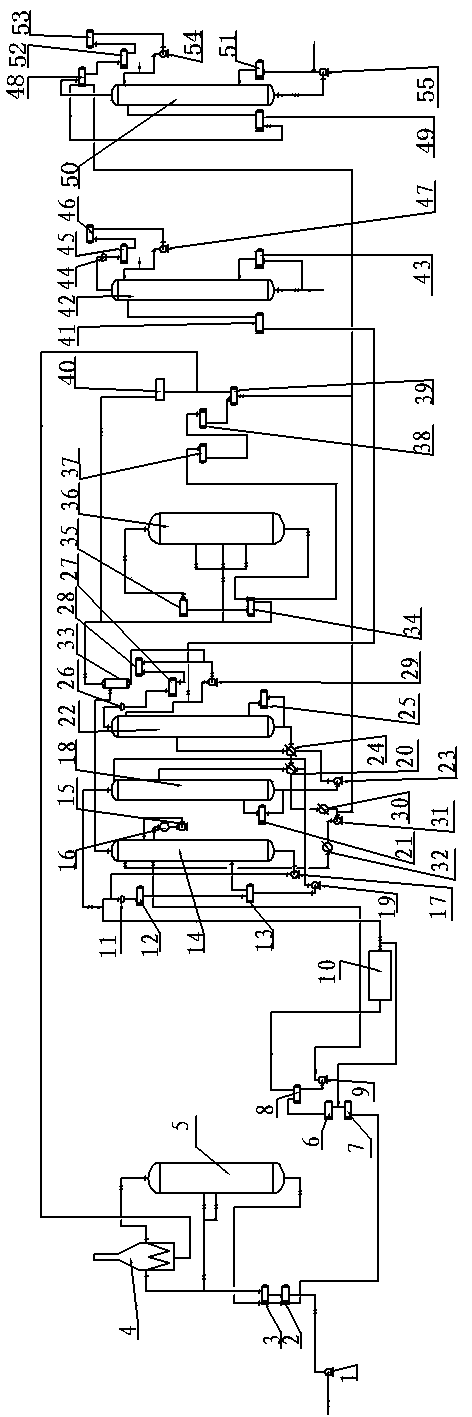

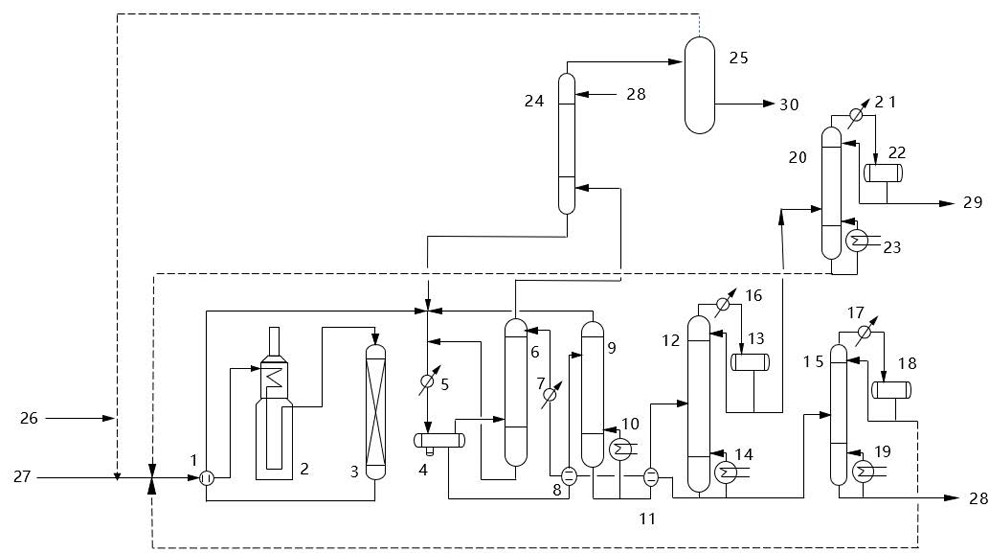

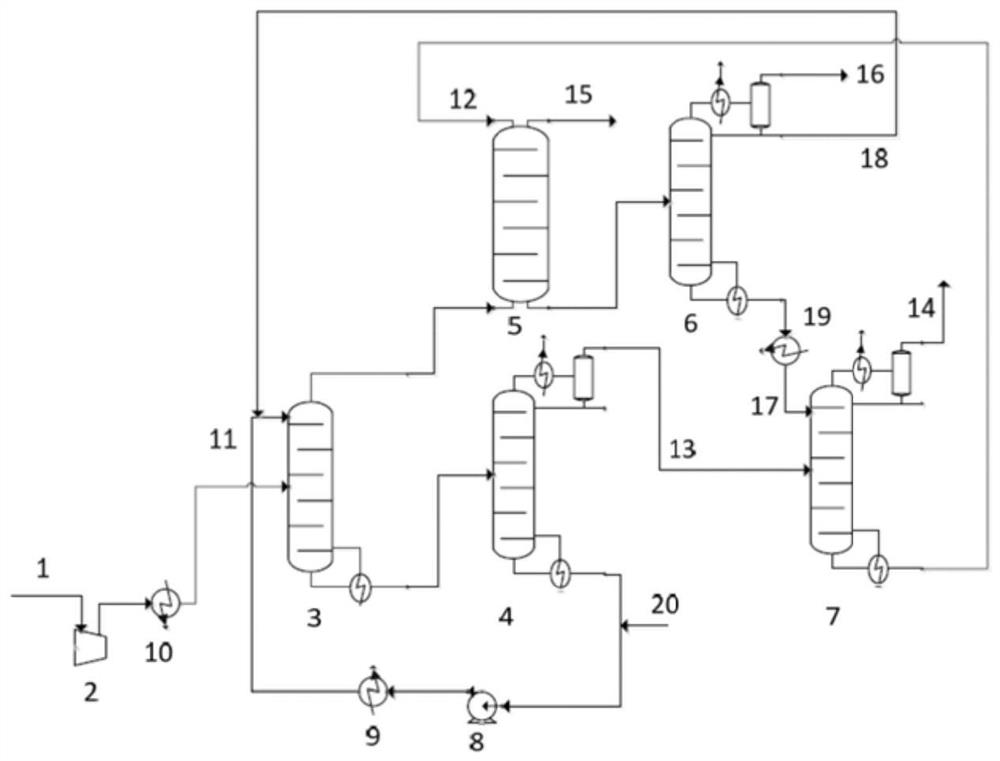

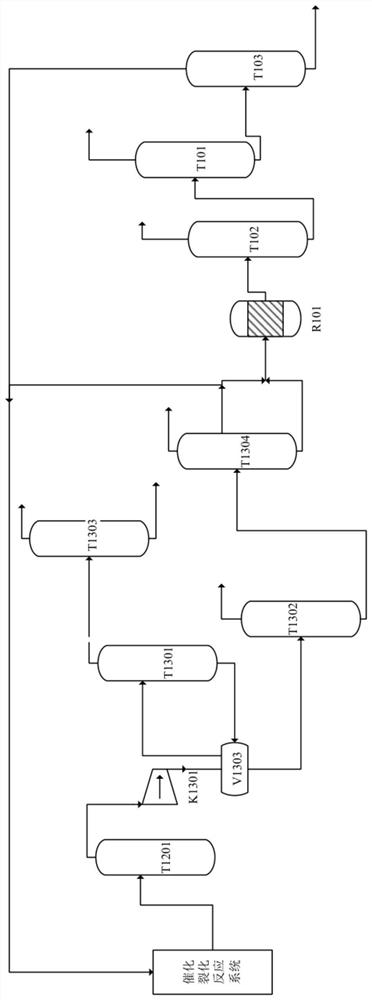

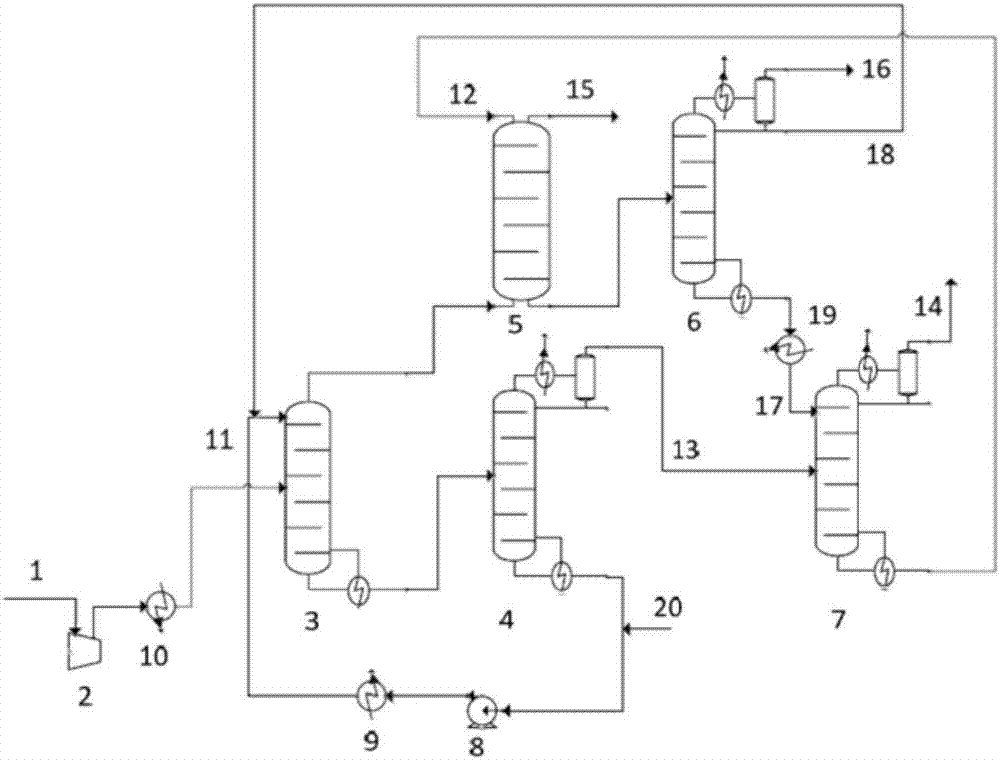

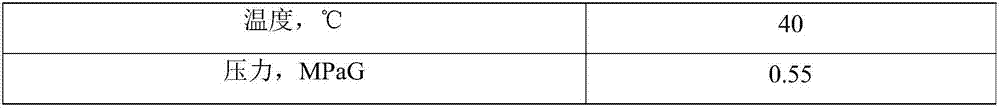

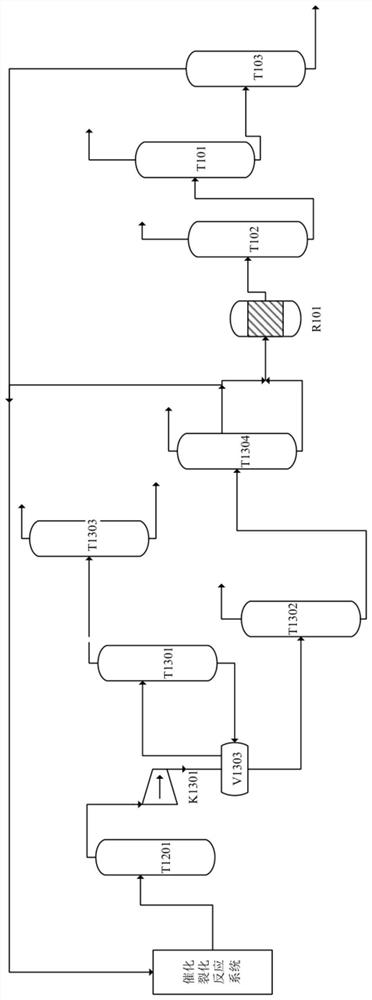

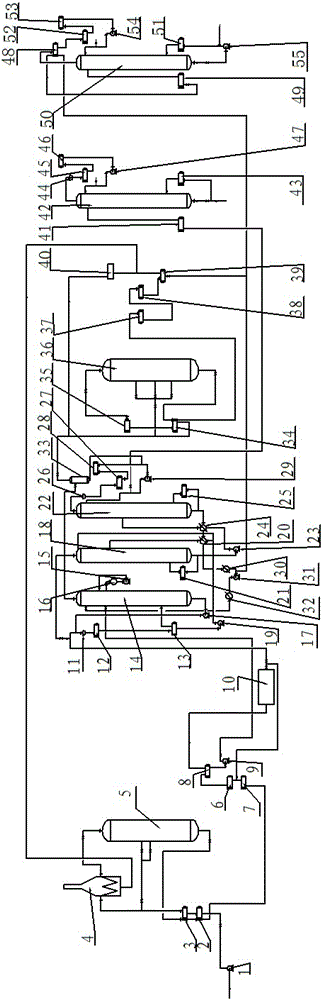

Device for processing preparation of hydrocarbon by utilizing liquefied gas

ActiveCN103755508AConcentrated and pureComponents are pureLiquid hydrocarbon mixtures productionDistillation purification/separationAromatizationProcess engineering

The invention discloses a device for processing preparation of hydrocarbon by utilizing liquefied gas. The device comprises a cracking reaction system, an absorption stabilizing system, an aromatization reaction system, a gas raw material gas stripping and concentrating system, and an aromatic hydrocarbon purifying system. After the process is adopted, operation of a deisobutanizer is stopped, 90 kg of standard coal is consumed to treat each ton of C4 raw materials, and the energy consumption is saved by 48.5%; the content of gas propylene in a gas raw material is high, and the mass fraction is improved from the original 15% to 50%; and the device has low requirements on equipment and heat energy, is easy to realize, and has the advantages of being simple in flow, liable to manipulate, low in energy consumption and stable in operation.

Owner:SHANDONG ORIENT HONGYE CHEM

Method for increasing diene conversion in EPDM type polymerizations

The present invention relates to the use in multi-stage reactors selected from ethylene, C 3 -C 8 Monomers of alpha-olefins and non-conjugated dienes Process for preparing polymer compositions such as EPDM compositions. In particular, the present invention relates to a method for increasing the conversion rate of diene monomer by using multi-stage reactors and metallocene catalyst system when preparing the above polymer composition.

Owner:EXXON CHEM PAT INC

Propylene catalyst prepared from methanol as well as preparation method and application thereof

InactiveCN101648141AGain selectivityHigh propylene contentMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sievePtru catalyst

The invention relates to a propylene catalyst prepared from methanol, which consists of molecular sieve, alumina and Ca, and proportion by weight of the molecular to alumina to Ca is 150-450 to 50-300to 1-45.The invention has the advantages of high propylene selectivity, high propylene content in the product and good catalysis stability.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

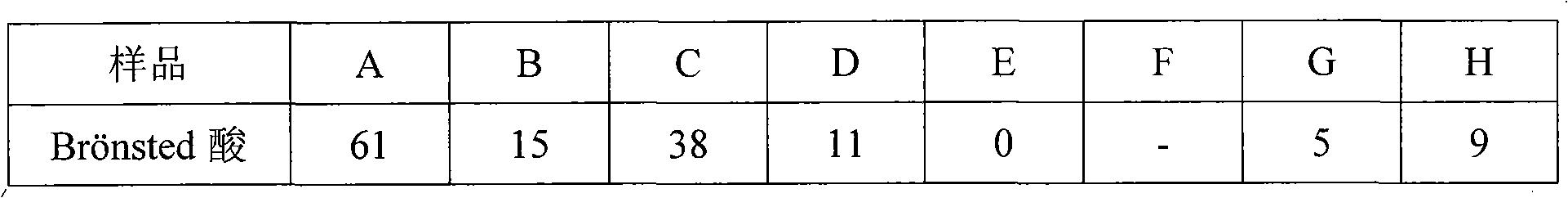

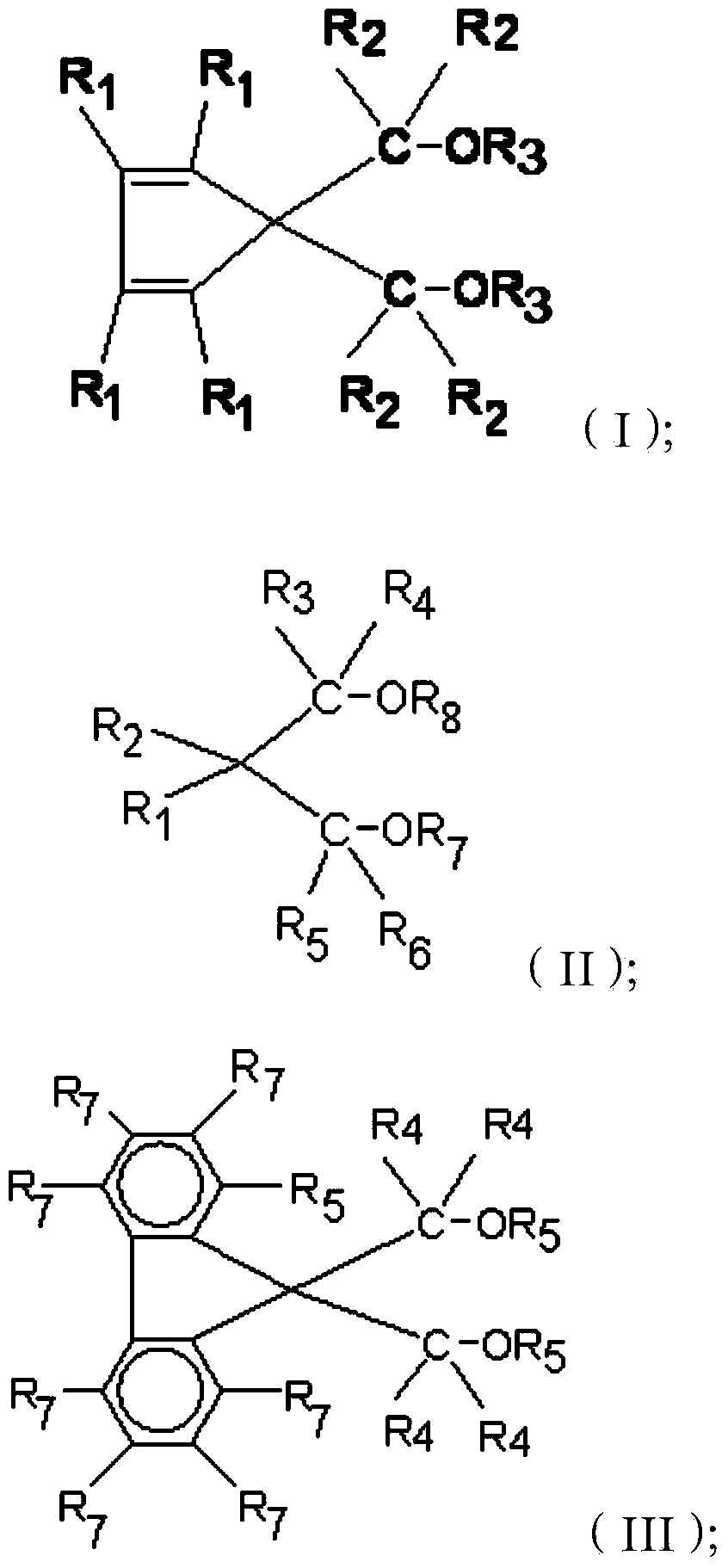

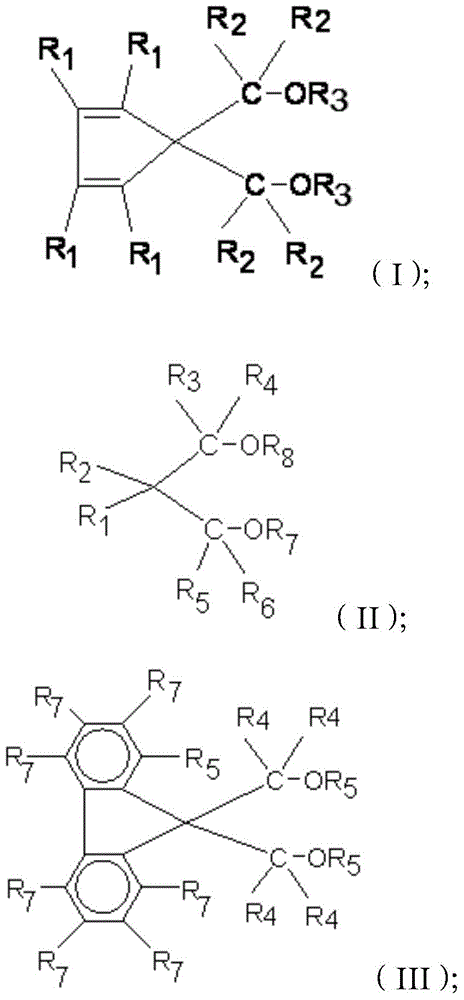

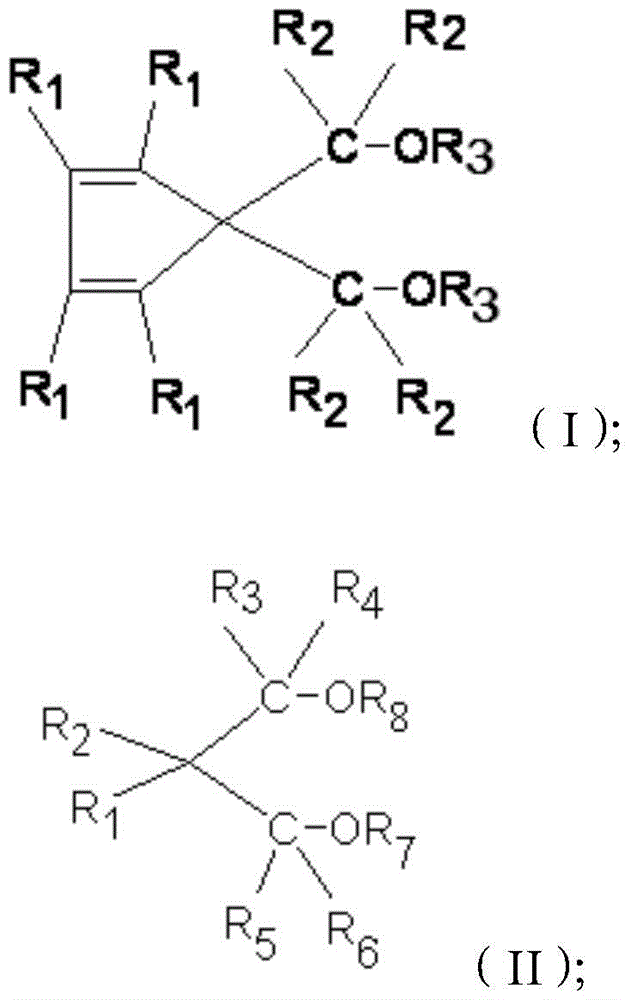

Vanadium catalyst, as well as preparation method and applications thereof

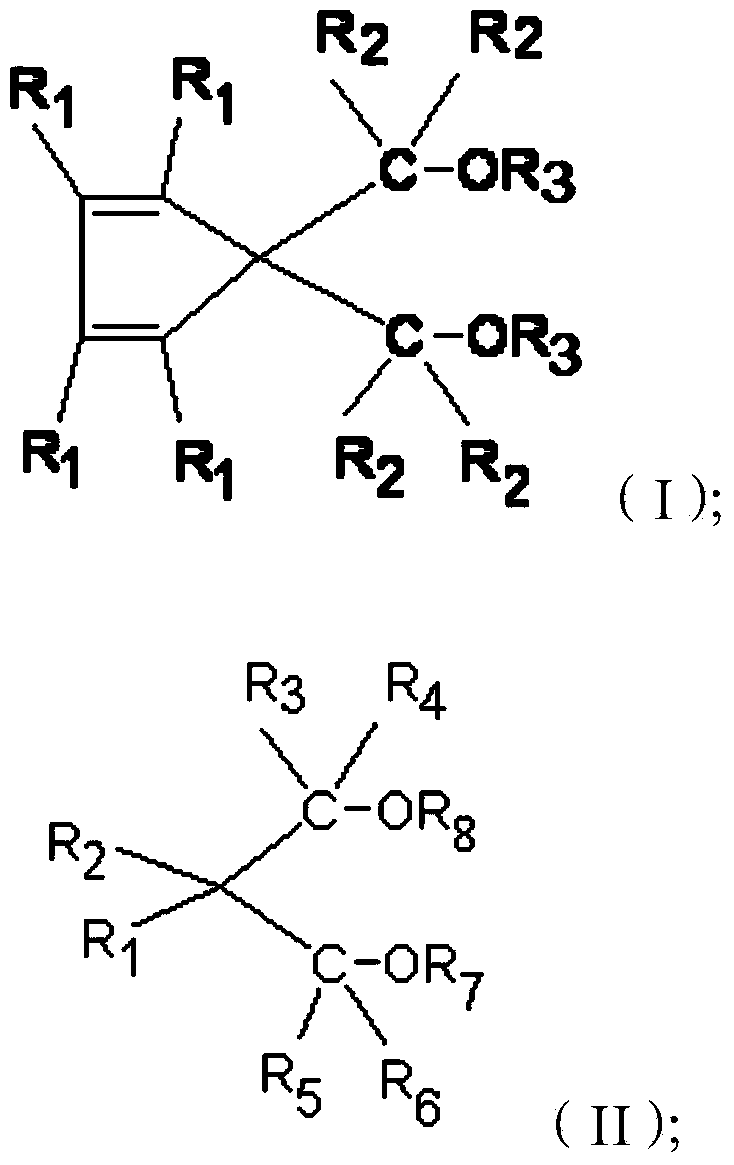

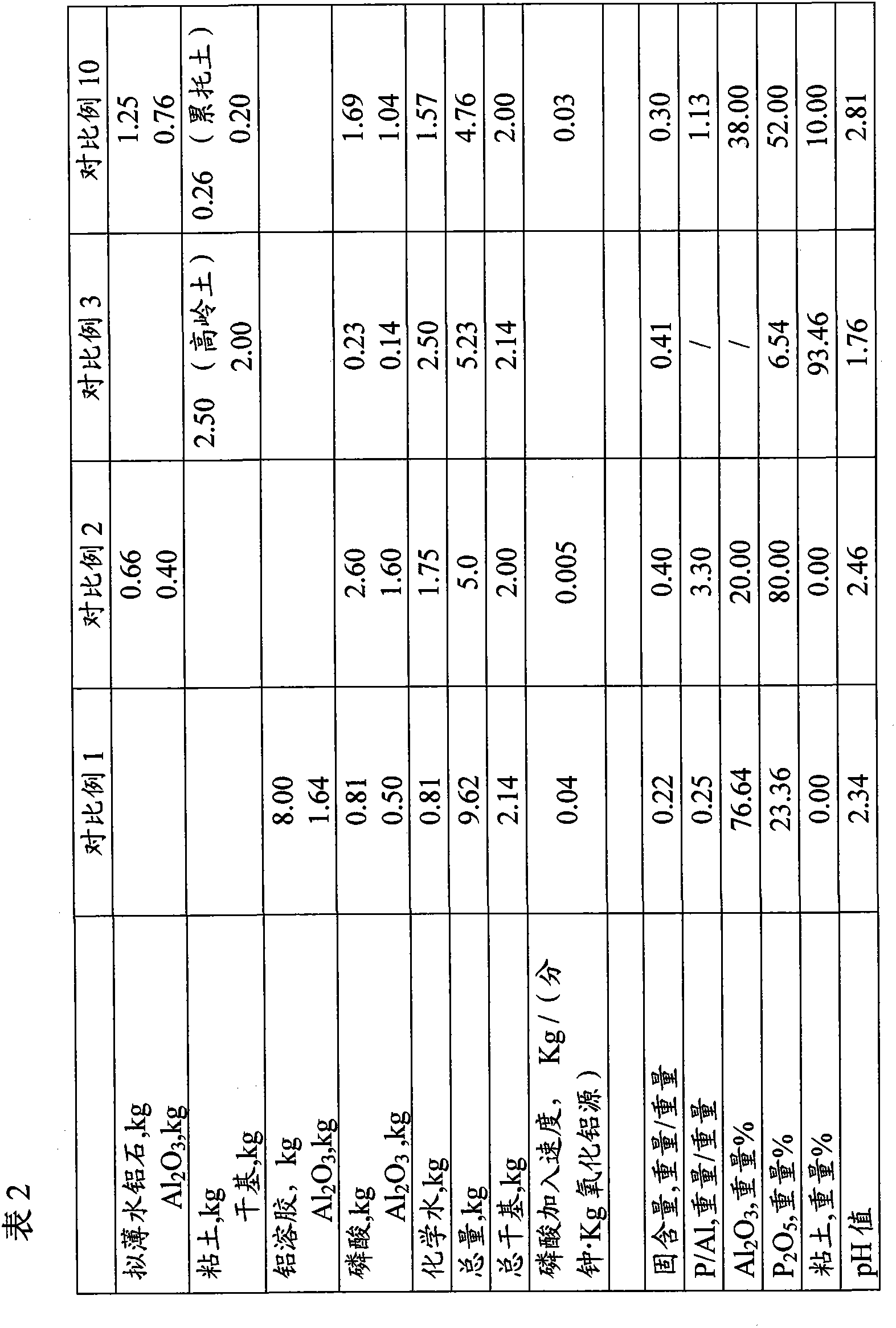

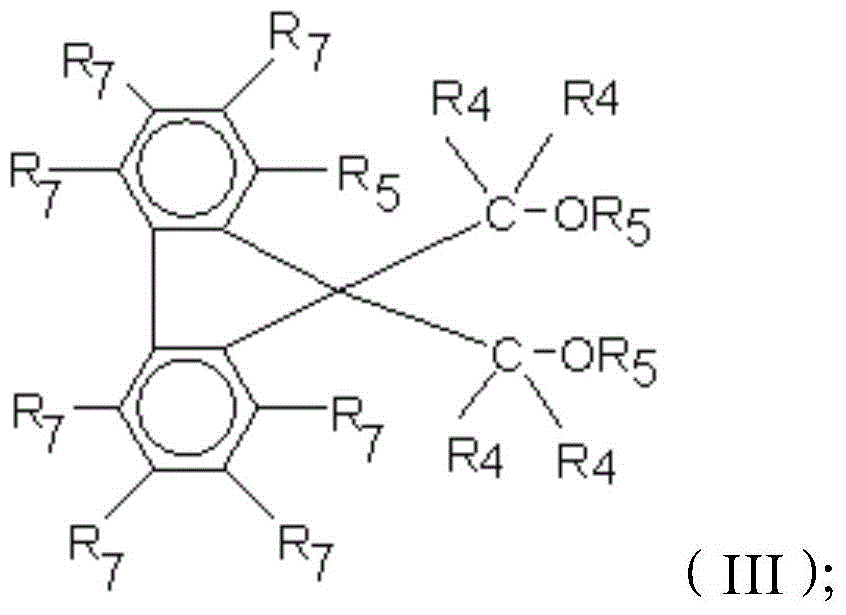

The invention provides a vanadium catalyst which consists of a main catalyst and an auxiliary catalyst, wherein the main catalyst is formed by matching a vanadium compound with an electron donor, or by a vanadium complex with an electron donor; the vanadium compound is V(acac)3, VO(OR)3, VO(acac)3, VO(OR)2Cl, VO(OR)Cl2, VCl4 or VOCl3; the ligand of the vanadium complex is fatty alcohol, amines, phosphates, beta-diones, 8-hydroxyquinoline or oximes; the electron donor is a mononuclear aromatics compound, an acrylic compound, a methacrylate compound, a compound in the formula (I) structure, a compound in the formula (II) structure, and a compound in the formula (III) structure. The stability of the vanadium catalyst on water, air and oxygen is stability. When being used for copolymerization of ethylene and propylene, the vanadium catalyst is high in reaction activity, and the obtained propylene is high in content, and controllable in a structure.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Inorganic binder containing phosphorus and aluminum compounds

ActiveCN102847547BPrevent curingIncrease the feeding speedCatalytic crackingMolecular sieve catalystsAluminium hydroxidePhosphoric acid

The inventive inorganic binder containing phosphorus and aluminum compounds comprises (by weight percentages) alumina 15-40, phosphorus pentoxide 45-80, and clay 1-40. The binder has P / Al weight ratio of 1-6, pH of 1-3, and solid content of 15-60 wt%. The preparation method includes mixing acid-soluble aluminum hydroxide and / or alumina, clay and deionized water; pulping into pulp having solid content of 15-45%; adding concentrated phosphoric acid into the pulp under stirring at P / Al weight ratio of 1-6; and reacting at 50-99 DEG C for 15-90 min. The preparation method can avoid binder solidification due to overheat caused by heat release of non-uniform local instantaneous intensive reaction of materials. The binder can improve wear resistance, activity and selectivity of FCC catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic conversion method for petroleum hydrocarbon

ActiveCN102344832BHigh yieldHigh selectivityTreatment with hydrotreatment processesExtraction purification/separationCatalytic transformationReaction temperature

Owner:CHINA PETROLEUM & CHEM CORP +1

Process and device for processing and preparing hydrocarbon by utilizing liquefied gas

ActiveCN102516007BReduce energy consumptionHigh propylene contentDistillation purification/separationLiquid hydrocarbon mixtures productionAromatizationProcess engineering

Owner:SHANDONG ORIENT HONGYE CHEM

Phosphorus and rare earth synergistically modified ZSM-5 and method for increasing propylene yield through catalytic cracking by using phosphorus and rare earth synergistically modified ZSM-5

InactiveCN110813367AImprove thermal stabilityImprove catalytic cracking conversion efficiencyMolecular sieve catalystsMolecular sieve catalystPtru catalystSilicic acid

The invention relates to phosphorus and rare earth synergistically modified ZSM-5. The phosphorus and rare earth synergistically modified ZSM-5 is composed of the following substances in percentages by mass: 1% to 5% of bentonite, 3% to 5% of titanium dioxide, 3% to 5% of calcium oxide, 2.5% to 3.8% of zinc oxide, 1.1% to 2.7% of copper oxide, 1% to 2.5% of a toughening modifier, 1.1% to 2.1% of acoupling agent, 5.5% to 15% of sepiolite, 4% to 6% of ethyl silicate, 3% to 9% of hollow glass beads, 20% to 35% of aluminum ash, 6% to 11% of quartz sand, 2% to 5% of sodium carbonate, 3.5% to 5.5%of phosphorus pentoxide and 1.1% to 4.8% of light rare earth, with the balance being a silica sol. The method for increasing propylene yield by catalysis comprises two steps, i.e., a step of raw material pretreatment and a step of material mixing. The phosphorus and rare earth synergistically modified ZSM-5 provided by the invention effectively improves the hydrothermal stability of a ZSM-5 molecular sieve, has high activity, long service life and good propylene selectivity, has good compounding effect with a catalytic cracking main catalyst in propylene production, can greatly improve the catalytic cracking conversion efficiency of raw materials, greatly increases the production efficiency of liquefied gas and the content of propylene in the liquefied gas, thereby achieving the purpose ofimproving the efficiency and quality of propylene production operation.

Owner:YANAN UNIV

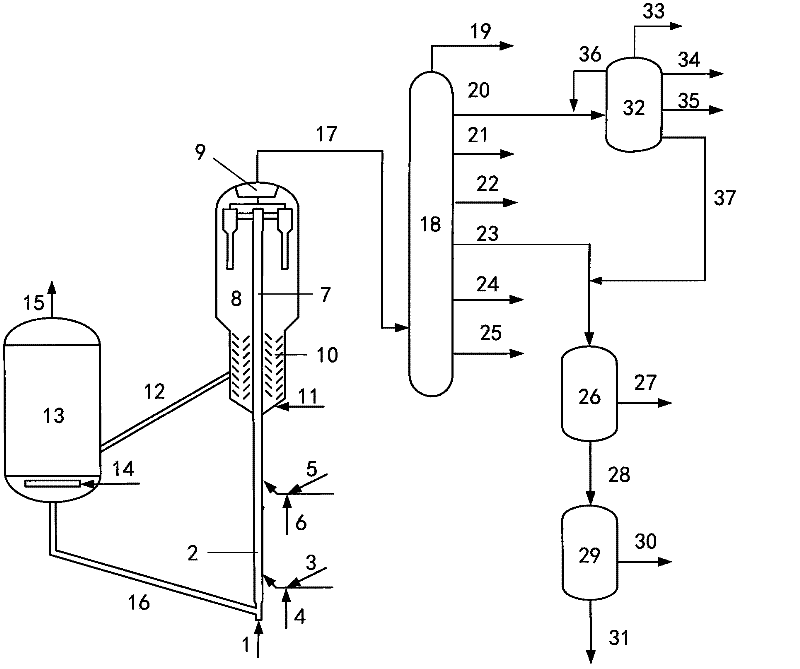

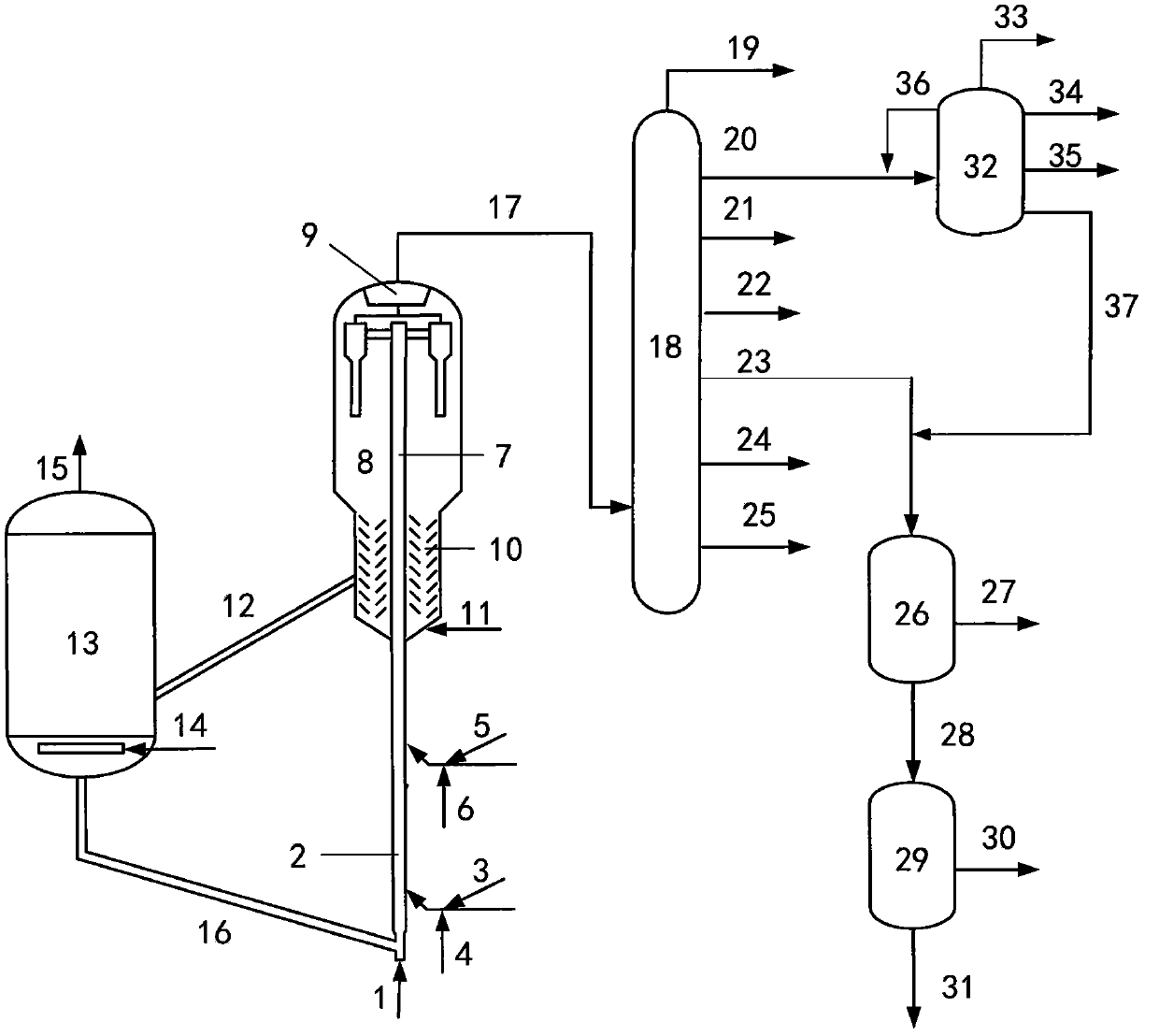

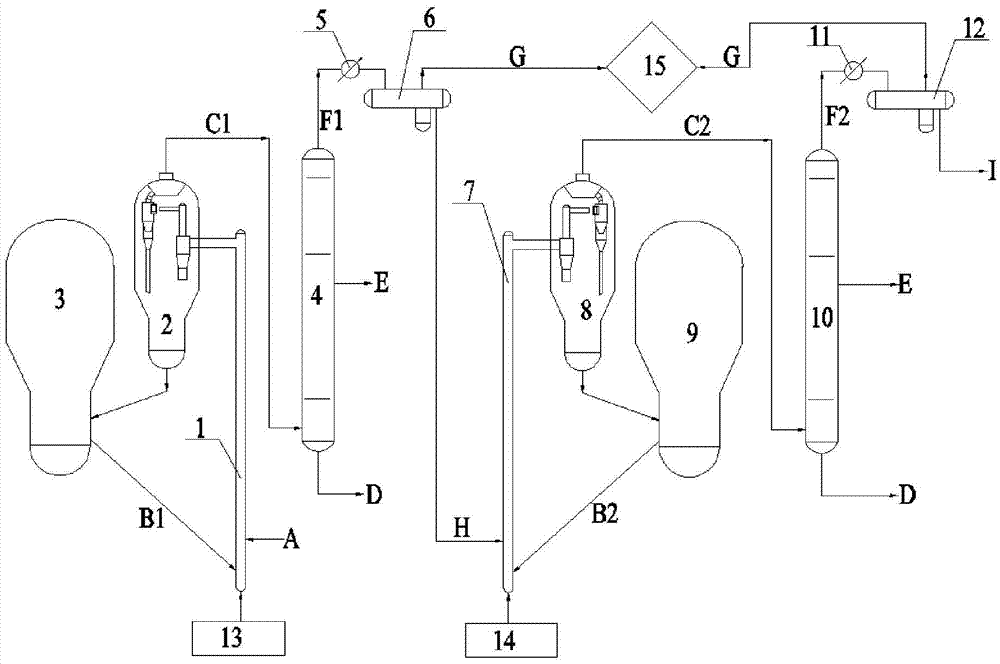

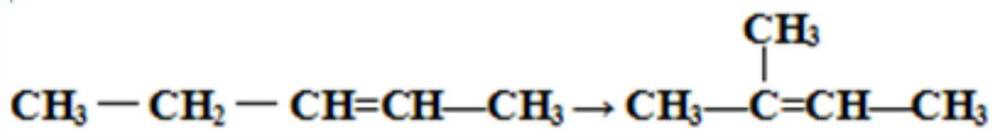

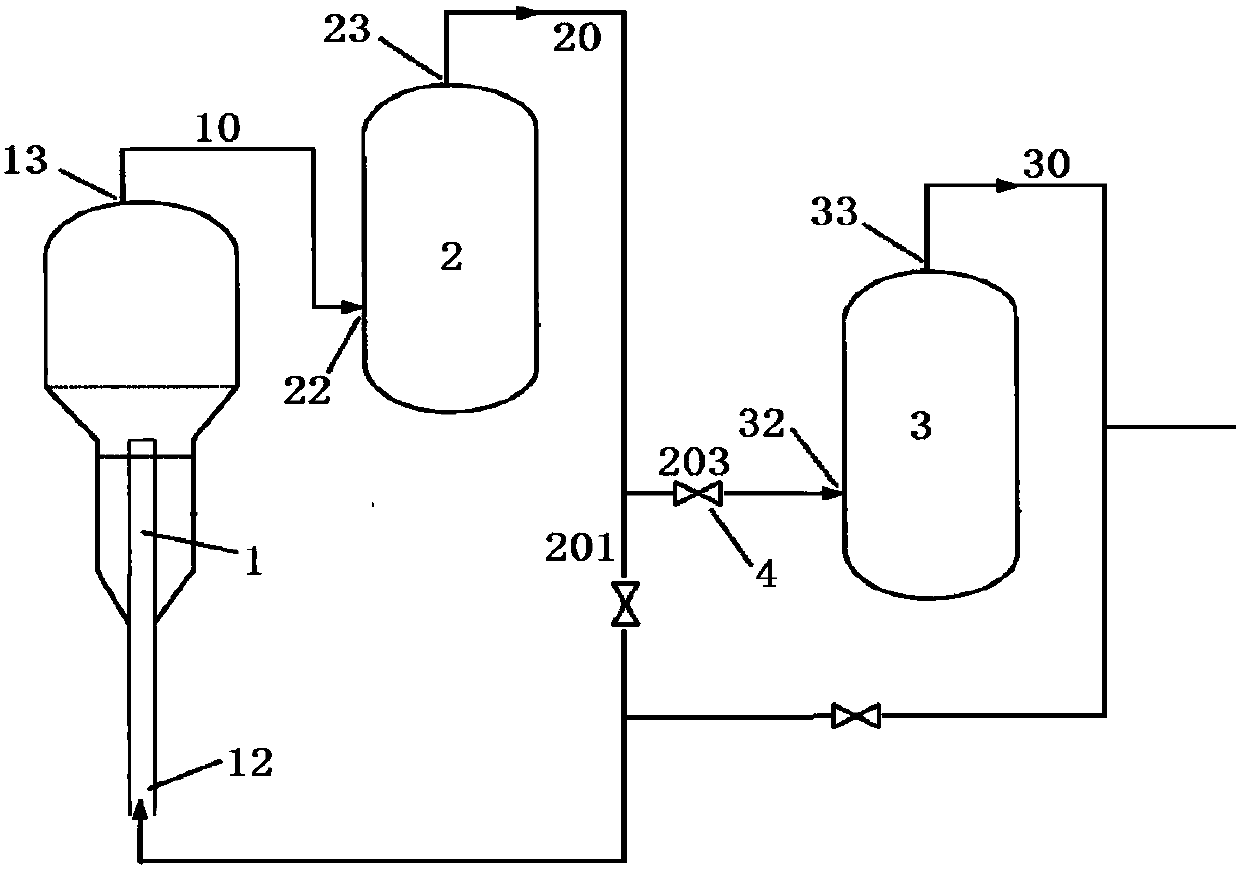

Device and method for producing high-propylene cracking gas and low-olefin gasoline

InactiveCN106893609AQuality improvementHigh propylene contentTreatment with plural serial stages onlyHydrocarbon oils treatment productsVapor–liquid separatorGas phase

The invention discloses a device and method for producing high-propylene cracking gas and low-olefin gasoline and belongs to the field of catalytic cracking. In the device, a first lifting pipe outlet, a first settler inlet and catalyst outlet, a first catalytic cracking regenerator and a first lifting pipe catalyst inlet are communicated with each other in turn; a second lifting pipe outlet, a second settler inlet and catalyst outlet, a second catalytic cracking regenerator and a second lifting pipe catalyst inlet are communicated with each other in turn; and a first settler oil gas outlet, a first fractionating tower raw material inlet and gas phase outlet, a first cooler, a first gas-liquid separator inlet and liquid phase outlet, a second lifting pipe raw material inlet and outlet, a second settler inlet and oil gas outlet, a second fractionating tower raw material inlet and gas phase outlet, a second cooler and a second gas-liquid separator are communicated with each other in turn. The device provided by the invention adopts different catalysts for heavy oil and light oil, is capable of increasing the catalytic selectivity and is capable of obtaining the high-propylene cracking gas and the low-olefin gasoline.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Preparation method of rare earth modified hierarchical porous ZSM-5 molecular sieve for yield increase of propylene

InactiveCN111099619ALow costSmall side effectsMolecular sieve catalystsPentasil aluminosilicate zeoliteMolecular sievePtru catalyst

The invention relates to a preparation method of a rare earth modified hierarchical porous ZSM-5 molecular sieve for yield increase of propylene. The preparation method comprises four steps of material mixing, material modulation, molding processing and modification molding. The preparation method is low in raw material cost, small in toxic and side effects, simple in processing and production process, low in production cost and small in environmental pollution. On one hand, the hydrothermal stability of the ZSM-5 molecular sieve is effectively improved, the activity is high, the service lifeis long, and the propylene selectivity is good; on the other hand, the compounding effect between the ZSM-5 molecular sieve and a catalytic cracking main catalyst in propylene production is good, so that the catalytic cracking conversion efficiency of the raw material can be greatly improved, and the liquefied gas production efficiency and the propylene content in liquefied gas are greatly improved.

Owner:YANAN UNIV

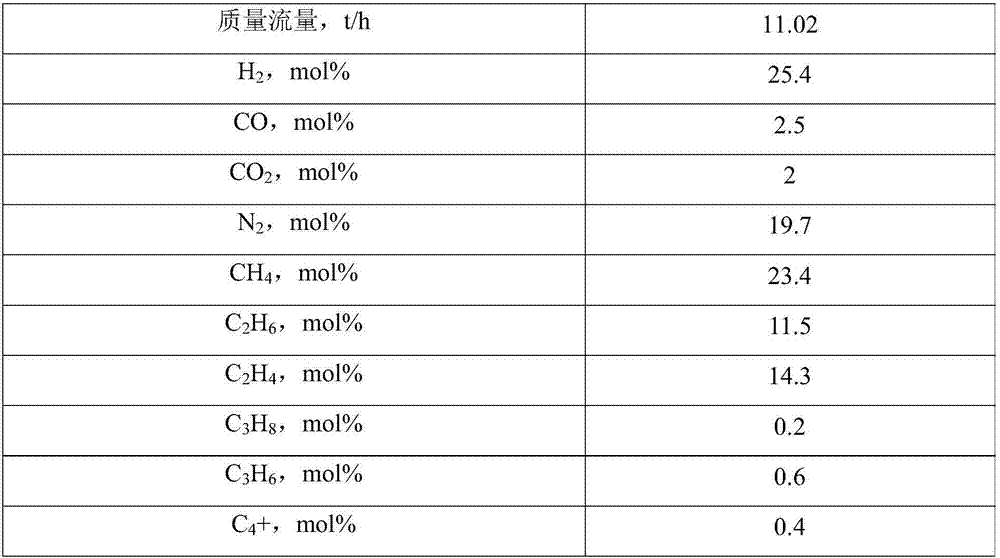

A kind of method for producing propane by conversion of hydrogenated light hydrocarbons

ActiveCN113307717BLow reaction temperatureHigh feed space velocityMolecular sieve catalystDistillation purification/separationAlkanePtru catalyst

The invention discloses a method for producing propane by hydrogen conversion of light hydrocarbons. The light hydrocarbon raw material, hydrogen-rich gas and circulating light hydrocarbons are heated to the reaction temperature, and catalytic cracking reaction occurs under the condition of an acidic catalyst. The reaction products are cooled and fractionated to obtain dry gas, propane, and aromatic gasoline components respectively. Unreacted light components are obtained. The hydrocarbon feedstock, hydrogen-rich gas and recycle light hydrocarbons are returned to the reactor to continue the reaction. On the one hand, the present invention uses light alkanes as raw materials, which can effectively utilize a large amount of excess light alkanes in refineries; Increase feedstock conversion and propane yield.

Owner:洛阳市科创石化科技开发有限公司

A device and method for recovering carbon dioxide from catalytic dry gas

ActiveCN107987884BLow component contentEfficient recyclingDistillation purification/separationHydrocarbonsGasolineOrganic matter

The invention relates to the field of organic matter recovery from gas and discloses a device and a method for recovering C2 from catalytic dry gas. The device comprises a C4 absorption tower, a C4 desorption tower and a second gasoline absorption tower which are connected sequentially as well as a first gasoline absorption tower and a gasoline stabilization tower which are connected. The method comprises the following steps: C4 is contacted with the catalytic dry gas, so that heavy components of C2 or higher in the catalytic dry gas are absorbed; the absorbed C4 and heavy components of C2 orhigher are subjected to first rectification, and crude C2 and C4 are obtained by separation; gasoline is contacted with crude C2, then heavy components in crude C2 are absorbed, and C2 is further separated out; remaining gasoline-containing components are contacted with unabsorbed light components, C4 entrapped in the light components is absorbed, a mixture of absorbed C4 and gasoline is subjectedto second rectification, and C4 and gasoline are separated and reused to previous steps respectively. With adoption of the method, C2 can be recovered from the catalytic dry gas effectively, and content of propylene, ethane and C4 in a product is lower.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking and gasoline hydrogenation combined method

ActiveCN111826198AHigh yieldHigh propylene contentTreatment with hydrotreatment processesHydrocarbon oils treatment productsNaphthaDistillation

The invention provides a catalytic cracking and gasoline hydrogenation combined method which comprises the following steps: carrying out a catalytic cracking reaction on a catalytic cracking raw material, and sequentially carrying out fractionation, separation, desorption, absorption and stabilization to obtain dry gas, liquefied gas, light naphtha, diesel oil and slurry oil; 60-70 wt% of light naphtha and gasoline are sequentially subjected to a gasoline hydrogenation reaction and gasoline hydrogenation separation, and a delivery material and a recycling material are obtained, wherein the distillation range of the light naphtha controls the content of C3 + C4 to be less than 1wt% and the dry point to be 70 DEG C, the distillation range of the recycled material controls the initial boilingpoint to be more than 40 DEG C and the final boiling point to be 90-101 DEG C; 30%-40% of the light naphtha and the recycled material return to continue the catalytic cracking reaction. According tothe method, 30-40% of light naphtha, a recycled material and a catalytic cracking raw material are subjected to a catalytic cracking reaction together so that the yield of liquefied gas and the content of propylene in the liquefied gas are both increased, and the content of ethylene in dry gas is also obviously increased.

Owner:SHANDONG JINGBO PETROCHEM

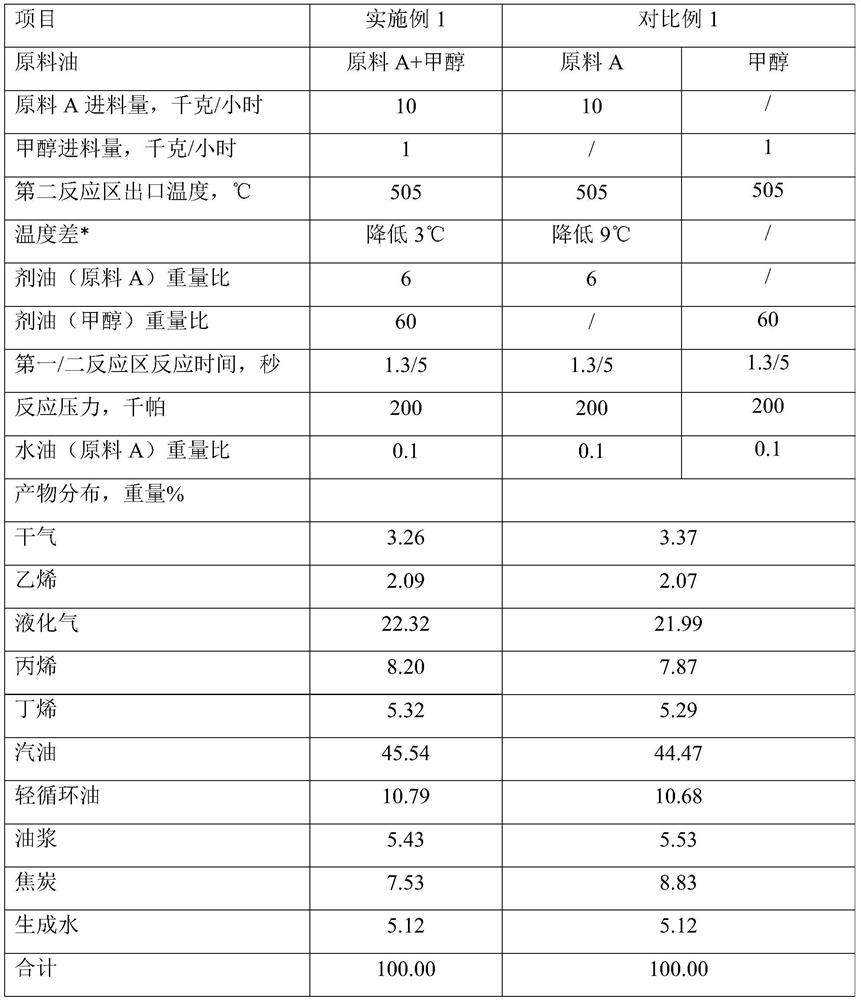

A Catalytic Cracking Method for Improving Heat Distribution

ActiveCN110951502BLower contact temperatureReduce thermal cracking reactionsTreatment with plural serial cracking stages onlyLiquid hydrocarbon mixture productionPtru catalystProcess engineering

The present invention relates to a catalytic cracking method for improving heat distribution, the method comprising: (1), feeding catalytic cracking feedstock oil into the first reaction zone of a catalytic cracking reactor to contact with a catalytic cracking catalyst and performing the first catalytic cracking reaction (2), continuing the second catalytic cracking reaction in the second reaction zone of the catalytic cracking reactor with the first reaction product and the half spent catalyst of the gained, to obtain the second reaction product and the spent catalyst; into the second reaction zone of the catalytic cracking reactor to contact with the first reaction product and the half spent catalyst and carry out the second catalytic cracking reaction together. The method of the invention can improve the heat distribution of the catalytic cracking reactor and improve the distribution of reaction products.

Owner:CHINA PETROLEUM & CHEM CORP +1

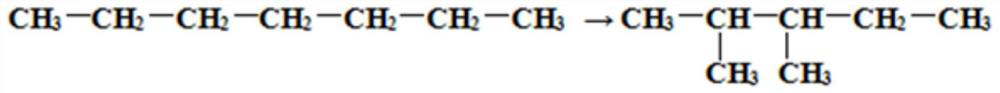

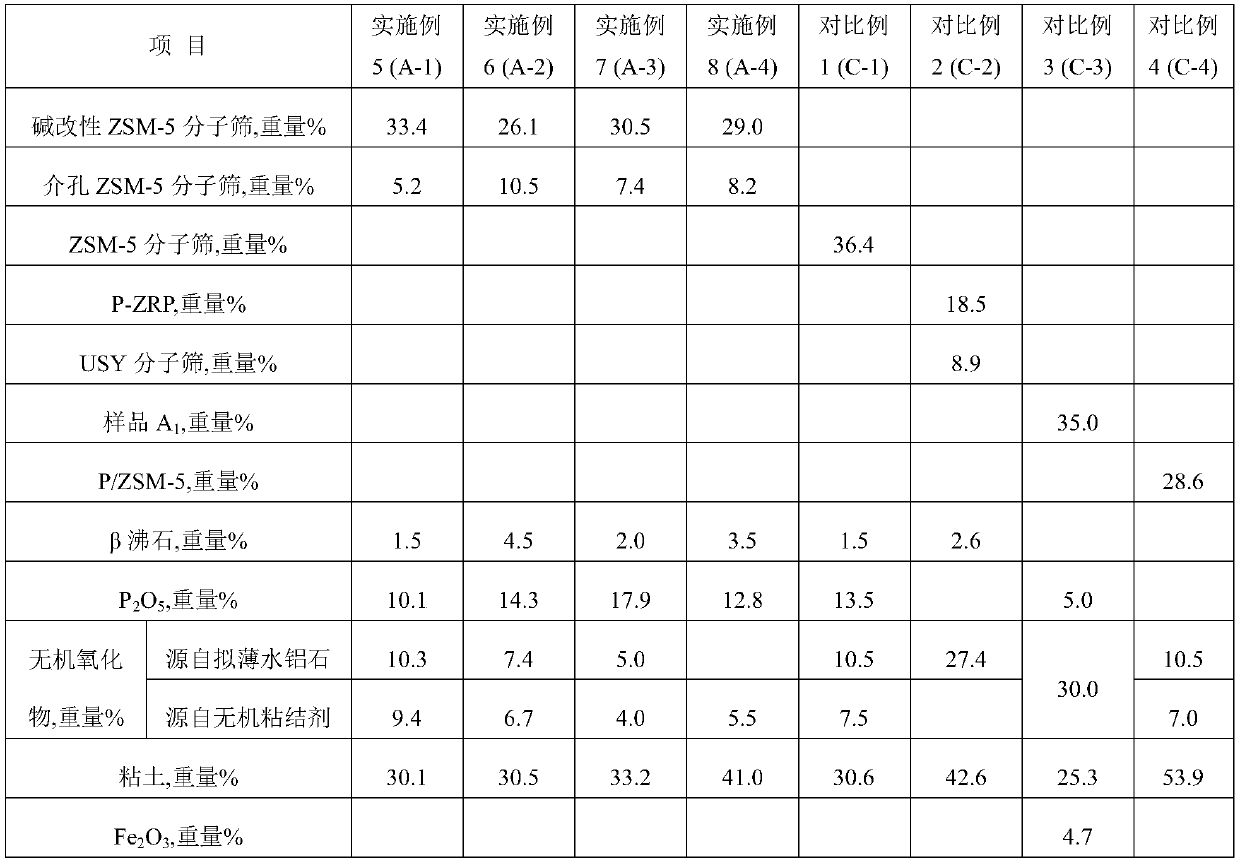

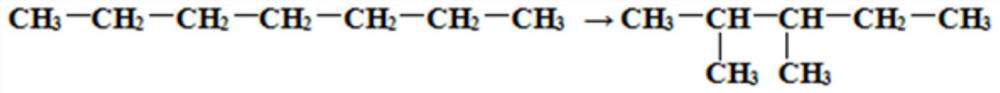

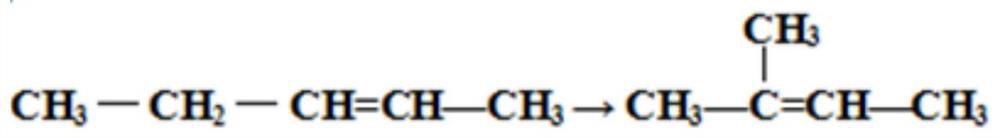

Catalytic cracking aid for producing isomerized low-carbon olefins and its preparation method and application

ActiveCN107282099BFacilitates shape-selective cracking reactionsReduce lossesMolecular sieve catalystsMolecular sieve catalystIsomerizationLiquid gas

The invention relates to a catalytic cracking aid for producing isomeric low-carbon olefins and its preparation method and application. On a dry basis, the catalytic cracking aid for producing isomeric low-carbon olefins, based on the total weight of the catalytic cracking aid, includes: 15 to 45% by weight of alkali-modified ZSM-5 molecular sieve; 1 to 20% by weight % of mesoporous ZSM‑5 molecular sieve; 1 to 10% by weight of beta zeolite; 3 to 25% by weight of P 2 O 5 ; 3 to 25% by weight of inorganic oxides; and the balance clay. The catalytic cracking aid of the present invention that produces high amounts of isomeric low-carbon olefins can promote the shape-selective isomerization cracking reaction of gasoline components above C8 in catalytically cracked gasoline, and can simultaneously increase the yields of propylene, isobutylene and isoamylene, and improve liquefaction. The propylene content in the gas increment (Δpropylene / Δliquefied gas) is increased and high-octane gasoline is co-produced.

Owner:李瑛

Device and method for recovering C2 from catalytic dry gas

ActiveCN107987884ALow component contentEfficient recyclingDistillation purification/separationHydrocarbonsDesorptionGasoline

The invention relates to the field of organic matter recovery from gas and discloses a device and a method for recovering C2 from catalytic dry gas. The device comprises a C4 absorption tower, a C4 desorption tower and a second gasoline absorption tower which are connected sequentially as well as a first gasoline absorption tower and a gasoline stabilization tower which are connected. The method comprises the following steps: C4 is contacted with the catalytic dry gas, so that heavy components of C2 or higher in the catalytic dry gas are absorbed; the absorbed C4 and heavy components of C2 orhigher are subjected to first rectification, and crude C2 and C4 are obtained by separation; gasoline is contacted with crude C2, then heavy components in crude C2 are absorbed, and C2 is further separated out; remaining gasoline-containing components are contacted with unabsorbed light components, C4 entrapped in the light components is absorbed, a mixture of absorbed C4 and gasoline is subjectedto second rectification, and C4 and gasoline are separated and reused to previous steps respectively. With adoption of the method, C2 can be recovered from the catalytic dry gas effectively, and content of propylene, ethane and C4 in a product is lower.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking addition agent with high productivity of propylene and preparation method thereof

InactiveCN101474573BGood choiceHigh yieldCatalytic crackingMolecular sieve catalystsMolecular sieveOrganic acid

The present invention discloses a catalytic cracking assistant for high propylene yield and a preparation method thereof, which pertains to the hydrocarbon oil catalytic cracking assistant catalyst and is characterized by being composed of the following components (wt / %): 10-60 polybasic organic acid modified ZSM-5 molecular sieve, 10-40 Al2O3, 1-20 P (counted by P element), 1-15 rare earth element (counted by RE2O3) and 5-40 clay. Compound use of the assistant and catalytic cracking catalysts in the invention is fit for heavy hydrocarbon oil and hydrocarbon oil of catalytic cracking raw materials from various sources. The catalytic cracking assistant has good propylene selectivity, high catalytic cracking conversion rate, high liquefied gas yield, high propylene content in the liquefied gas and no dry gas or coke increase and greatly improves hydro-thermal activity stability of the main catalyst, thus is an ideal catalytic cracking assistant for high propylene yield.

Owner:青岛鼎诺化工技术有限公司

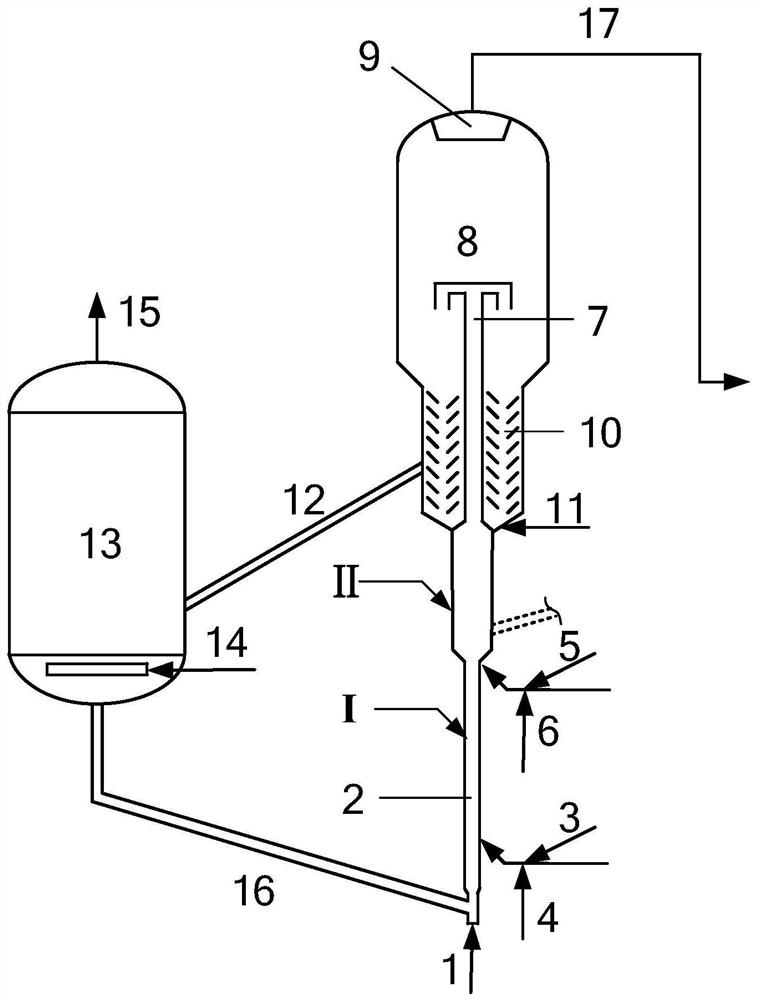

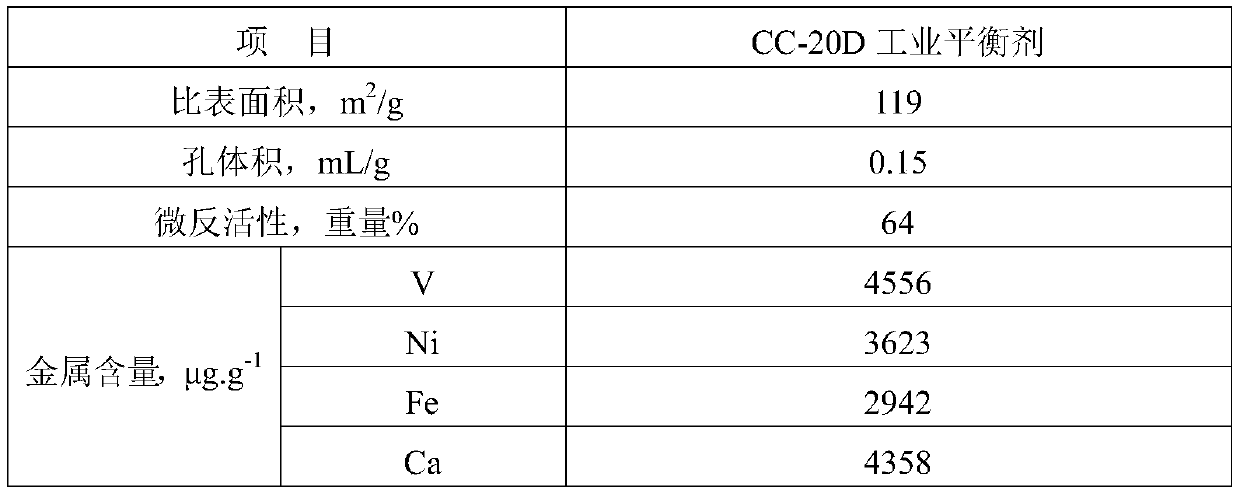

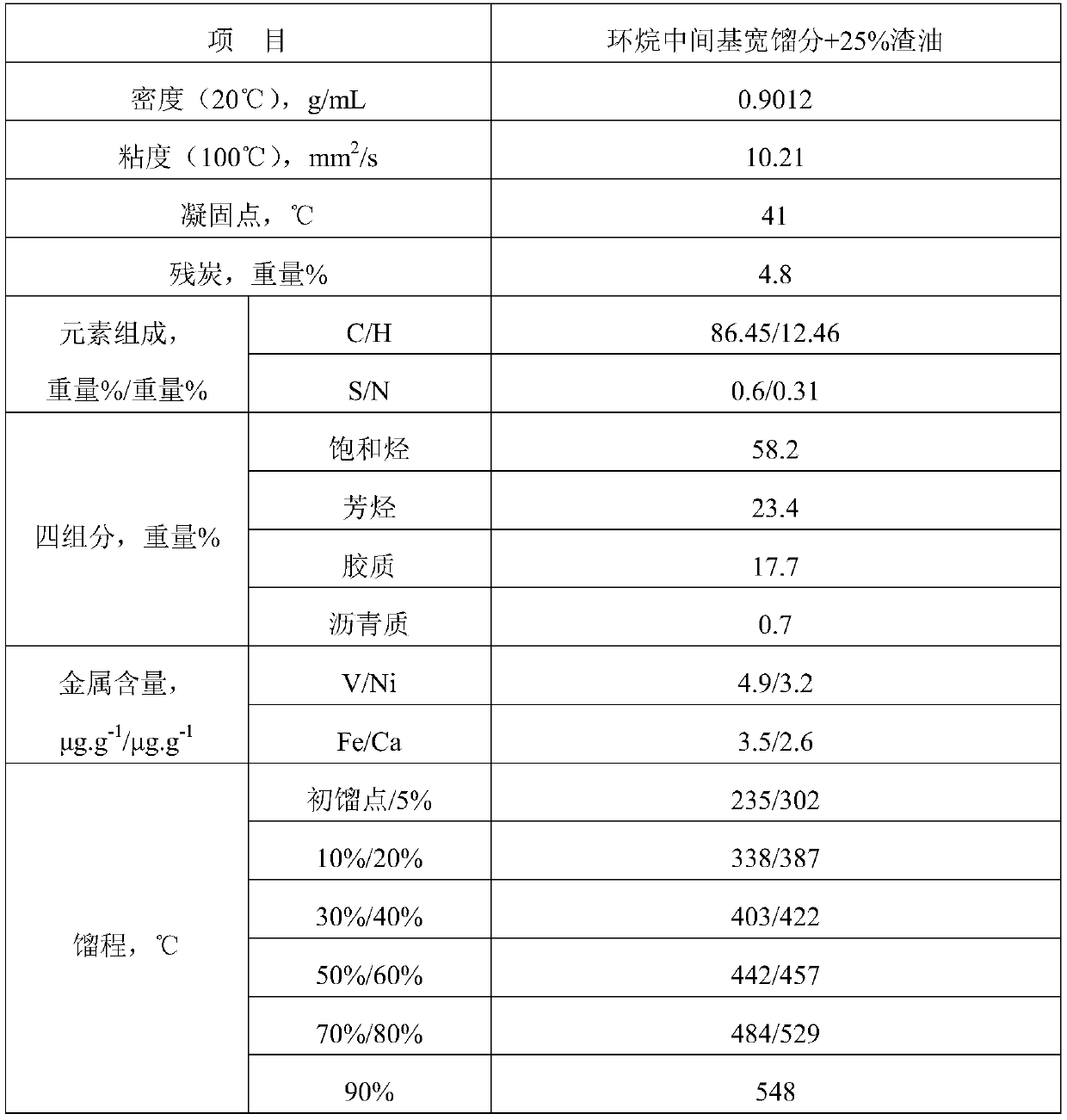

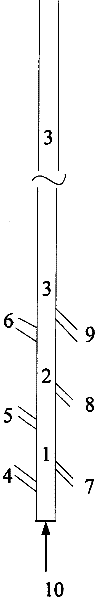

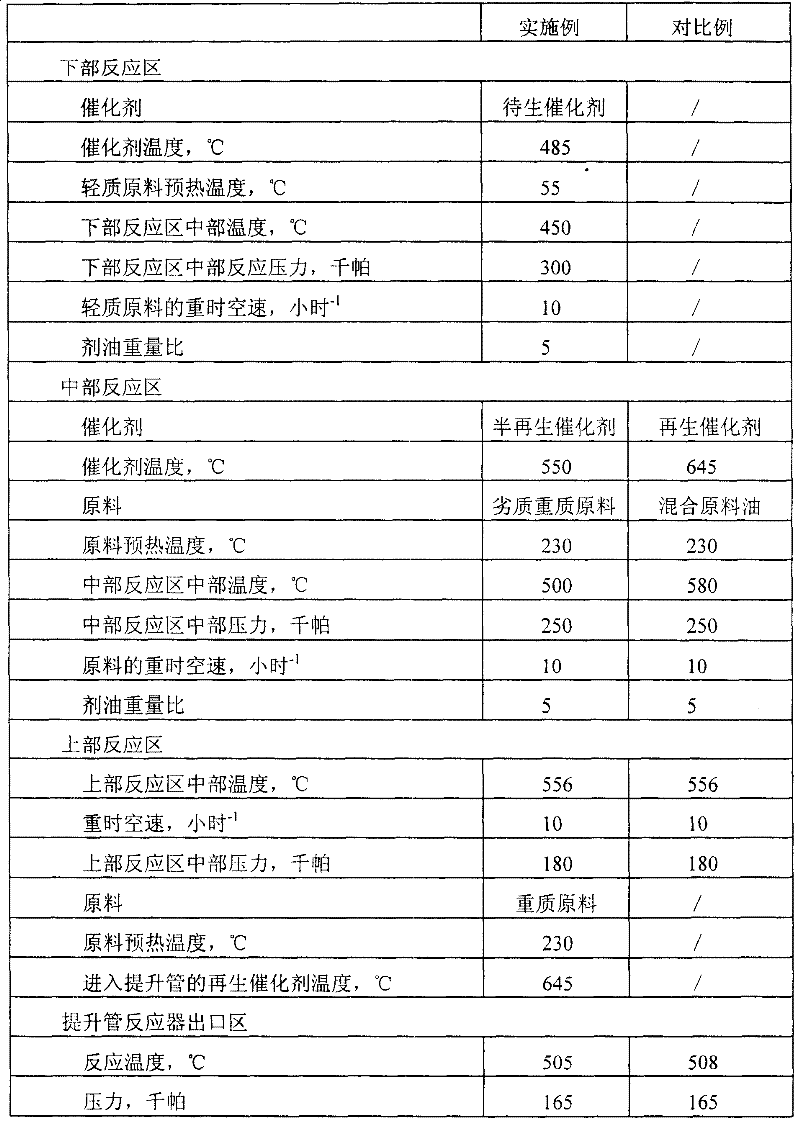

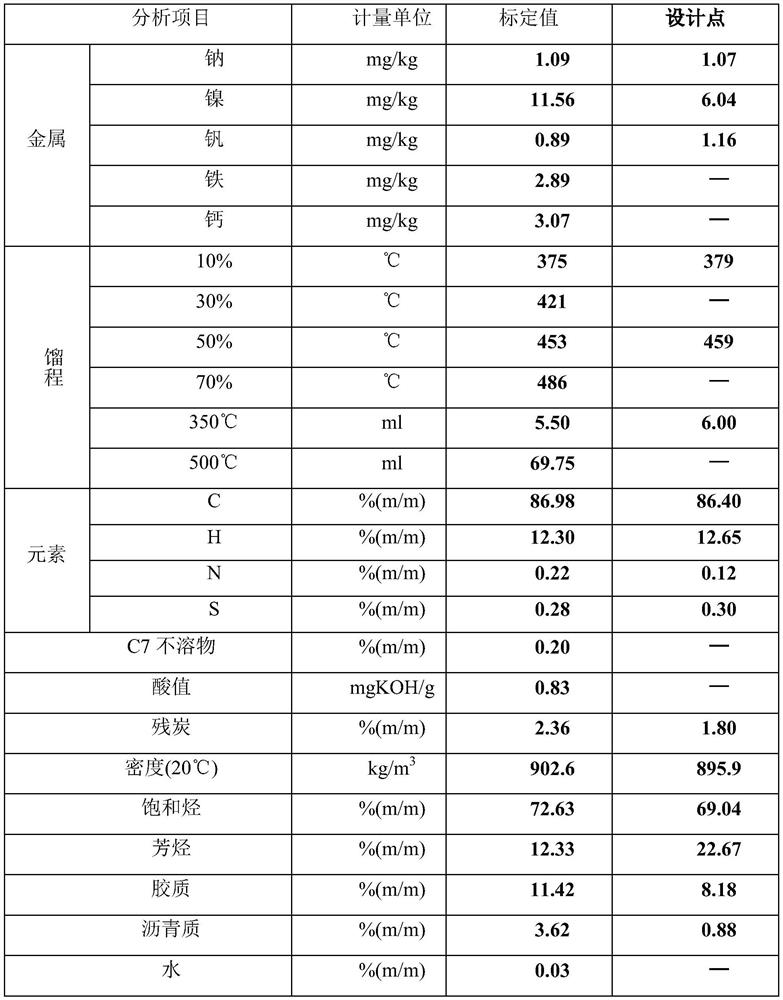

Cracking method for hydrocarbon oil

The invention discloses a hydrocarbon oil cracking method which comprises that: in a riser reactor comprising a plurality of reaction areas, the hydrocarbon oil raw material and the cracking catalyst are made a contact reaction in each reaction area under the condition of cracking reaction, the catalyst is separated from the reaction product to obtain the cracking product and spent catalyst, at least partial spent catalyst is regenerated to obtain the semi-regenerated catalyst and the regenerated catalyst, wherein, the reaction areas comprise at least one middle reaction area and at least one upper reaction area, the upper reaction area is positioned above the middle reaction area; the inferior heavy raw material and the semi-regenerated catalyst are imported in the middle reaction area to allow the heavy raw material to contact the semi-regenerated catalyst; the heavy raw material and the regenerated catalyst are imported in the upper reaction area to allow the heavy raw material to contact the regenerated catalyst. At least one item of the carbon residue content, the content of metal nickel and vanadium, the bitumencarb content and the basic nitrogen content of the inferior heavy raw material is higher than that of the heavy raw material. The method can optimize the cracking conditions of the hydrocarbon oil and improve the distribution of products.

Owner:CHINA PETROLEUM & CHEM CORP +1

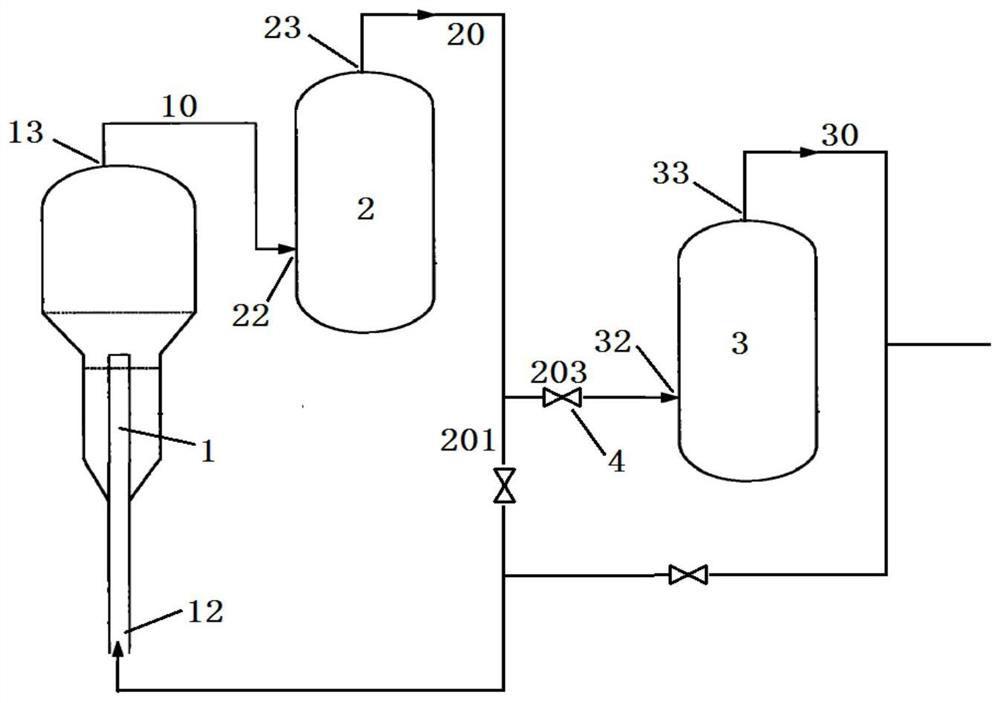

Catalytic cracking method and system

ActiveCN110295059BIncrease productionImprove absorption efficiencyTreatment with plural serial stages onlyThermodynamicsPhysical chemistry

The invention relates to the field of catalytic cracking reactions, and discloses a catalytic cracking method and a catalytic cracking system. The method comprises: under the action of a pre-lifting medium, the catalytic cracking raw material is subjected to a catalytic cracking reaction in a riser reactor, the gas phase is separated from the reaction product, and the gas phase is injected into an absorption tower for treatment, and the gas phase is injected from the top of the absorption tower Lean gas is collected and at least a portion of said lean gas is recycled as a pre-lift medium. The catalytic cracking system includes a reaction device equipped with a riser reactor and an absorption tower, the gas phase outlet at the top of the reaction device communicates with the gas phase inlet of the absorption tower, and the lean gas outlet at the top of the absorption tower communicates with the lift The pre-lift medium inlet at the bottom of the tube reactor communicates. By adopting the catalytic cracking method and the catalytic cracking system of the present invention, the gas phase load of the reabsorption tower can be reduced, the absorption effect can be effectively improved, and the propylene component carried in the dry gas can be reduced.

Owner:CHINA PETROLEUM & CHEM CORP

A kind of method combining catalytic cracking and gasoline hydrogenation

ActiveCN111826198BHigh yieldHigh propylene contentTreatment with hydrotreatment processesHydrocarbon oils treatment productsDistillationSlurry

The invention provides a method for combining catalytic cracking and gasoline hydrogenation, which comprises the following steps: subjecting catalytic cracking raw materials to catalytic cracking reaction, and then performing fractionation, separation, analysis, absorption and stabilization in sequence to obtain dry gas, liquefied gas, Light naphtha, diesel oil and oil slurry; 60-70wt% of light naphtha and gasoline are sequentially separated by gasoline hydrogenation reaction and gasoline hydrogenation to obtain external materials and reuse materials; distillation range of light naphtha Control the C3+C4 content <1wt%, dry point <70℃; the distillation range of the recycled material controls the initial boiling point>40℃, the final boiling point 90~101℃; the light naphtha is 30%~40℃ % and recycled materials are returned to continue the catalytic cracking reaction. In the method, 30% to 40% of the light naphtha is subjected to catalytic cracking reaction together with the recycled material and the catalytic cracking raw material, so that the liquefied gas yield and the propylene content in the liquefied gas are both improved, and the ethylene content in the dry gas is also significantly increased.

Owner:SHANDONG CHAMBROAD PETROCHEMICALS CO LTD

Catalytic cracking method and system

ActiveCN110295059AReduce yieldInhibition of dehydrogenation reactionTreatment with plural serial stages onlyGas phaseTower

The invention relates to the field of catalytic cracking reactions, and discloses a catalytic cracking method and a catalytic cracking system. The method is characterized in that a catalytic crackingraw material is subjected to a catalytic cracking reaction in a riser reactor under the action of a pre-lifting medium; a gas phase is separated from a reaction product; the gas phase is injected intoan absorption tower for treatment; lean gas is collected from the top of the absorption tower, and at least part of the lean gas is used as the pre-lifting medium. The catalytic cracking system comprises a reaction device configured with the riser reactor and the absorption tower; the gas phase outlet on the top of the reaction device is communicated with the gas phase inlet of the absorption tower; the lean gas outlet on the top of the absorption tower is communicated with the pre-lifting medium inlet at the bottom of the riser reactor. Through adopting the catalytic cracking method and thecatalytic cracking system disclosed by the invention, the gas phase load of a reabsorption tower can be reduced; the absorption effect is effectively improved; propylene components carried in dry gasare reduced.

Owner:CHINA PETROLEUM & CHEM CORP

Catalytic cracking aid for producing more propylene and isopentene, its preparation method and application

ActiveCN107185586BHigh yieldFacilitates shape-selective cracking reactionsCatalytic crackingMolecular sieve catalystsCracking reactionLiquid gas

Owner:李瑛

Combined process for treating residual oil

ActiveCN103059998BLess investmentHydrogenation Depth ModerationTreatment with hydrotreatment processesThermal energyLiquid gas

The invention discloses a combined process for treating residual oil. Boiling bed residual oil hydrotreatment, delayed coking, wax oil hydrotreatment and catalytic cracking are organically combined in the method. The method concretely comprises the following steps of: enabling a liquid-phase product obtained after residual oil raw materials are subjected to boiling bed hydrotreatment to directly enter a coking fractional distillation column to be in countercurrent contact with oil gas generated through coking, and then, carrying out fractional distillation to obtain a wax oil fraction, and enabling the wax oil fraction to enter a wax oil hydrotreatment device, wherein the liquid-phase product is not subjected to fractional distillation; enabling the obtained liquid-phase product as a raw material to enter a catalytic cracking unit for treating; enabling circulating oil obtained through the fractional distillation of the coking fractional distillation column to return to a delayed coking unit; generating gasoline and diesel products by the coking fractional distillation column; and carrying out catalytic cracking and fractional distillation to obtain liquefied gas, gasoline and diesel products. Compared with the prior art, the combined process has the advantages that a hydrogenization fractional distillation column can be omitted, the investment cost can be reduced, the coking and catalytic cracking raw material sources are expanded, and the coked and catalyzed light oil yield is increased; and meanwhile, the reaction heat energy is sufficiently utilized, and the production energy consumption is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

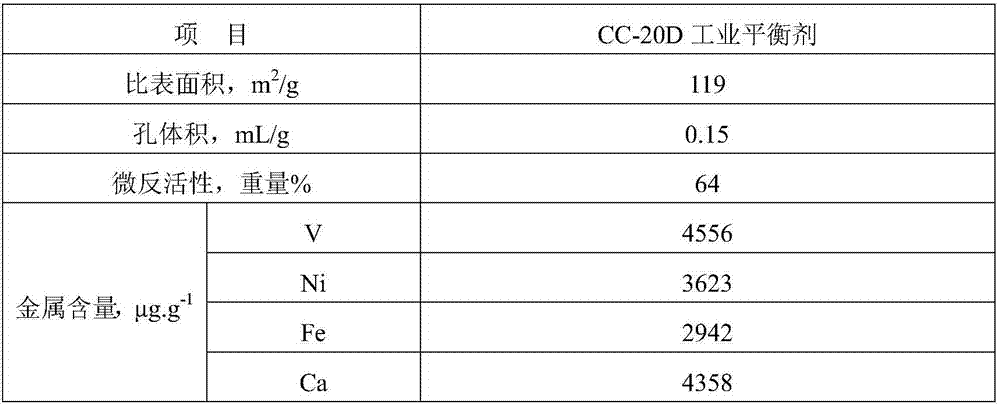

Catalyst for catalytic cracking of hydrocarbon oil and method for catalytic cracking of hydrocarbon oil

ActiveUS10610856B2High yieldHigh propylene contentCatalytic crackingMolecular sieve catalystsPtru catalystAluminium phosphate

A catalyst for catalytic cracking of a hydrocarbon oil can produce a gasoline fraction having a high octane number in high yield while suppressing an increase in yield of a heavy distillate, and produce LPG having a high propylene content in high yield. The catalyst includes a specific amount of a granulated catalyst A that includes a zeolite having a sodalite cage structure, silicon derived from a silica sol, phosphorus and aluminum derived from mono aluminum phosphate, a clay mineral, and a rare-earth metal, and a specific amount of a granulated catalyst B that includes a pentasil-type zeolite, the ratio of the mass of phosphorus and aluminum derived from mono aluminum phosphate included in the granulated catalyst A to the mass of the pentasil-type zeolite included in the granulated catalyst B being 0.015 to 3000.

Owner:COSMO OIL CO LTD

A process for producing hydrocarbons by utilizing liquefied gas

ActiveCN103755508BConcentrated and pureComponents are pureLiquid hydrocarbon mixtures productionDistillation purification/separationAromatizationProcess engineering

The invention discloses a device for processing hydrocarbons by using liquefied gas, including a cracking reaction system, an absorption stabilization system, an aromatization reaction system, a gas separation raw material gas concentration system, and an aromatics purification system; The isobutane tower stopped running, processing 90kg of standard coal per ton of C4 raw material, saving 48.5% of energy consumption, high content of propylene in the raw material gas, increased from 15% of the original mass fraction to 50%, low requirements for equipment and heat energy , easy to implement, simple device process, easy to operate, low energy consumption, and stable operation.

Owner:SHANDONG ORIENT HONGYE CHEM

Vanadium-based catalyst, its preparation method and application

The invention provides a vanadium-based catalyst, including a main catalyst and a co-catalyst, the main catalyst is formed by complexing a vanadium compound and an electron donor, or is formed by complexing a vanadium complex and an electron donor; the vanadium The compound is V(acac)3, VO(OR)3, VO(acac)3, VO(OR)2Cl, VO(OR)Cl2, VCl4 or VOCl3; the ligands of the complexes of vanadium are fatty alcohols, Amines, phosphoric acid esters, β-diketones, octahydroxyquinoline or oximes; the electron donor is a monocyclic aromatic hydrocarbon compound, acrylate compound, methacrylate compound, formula (I) structure The compound of formula (II) structure or the compound of formula (III) structure. The stability of the vanadium-based catalyst to water, air and oxygen is enhanced. When used in the copolymerization of ethylene and propylene, the reaction activity is high, the obtained propylene content is slightly higher, and the structure is controllable.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com