Catalytic cracking method and system

A catalytic cracking and lean gas technology, which is applied in the field of catalytic cracking methods and catalytic cracking systems, can solve the problems of increased gas phase load, low absorption efficiency, and high propylene content of the reabsorption tower, so as to reduce energy consumption of the device and reduce dry gas and coke Yield, effect of optimized operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

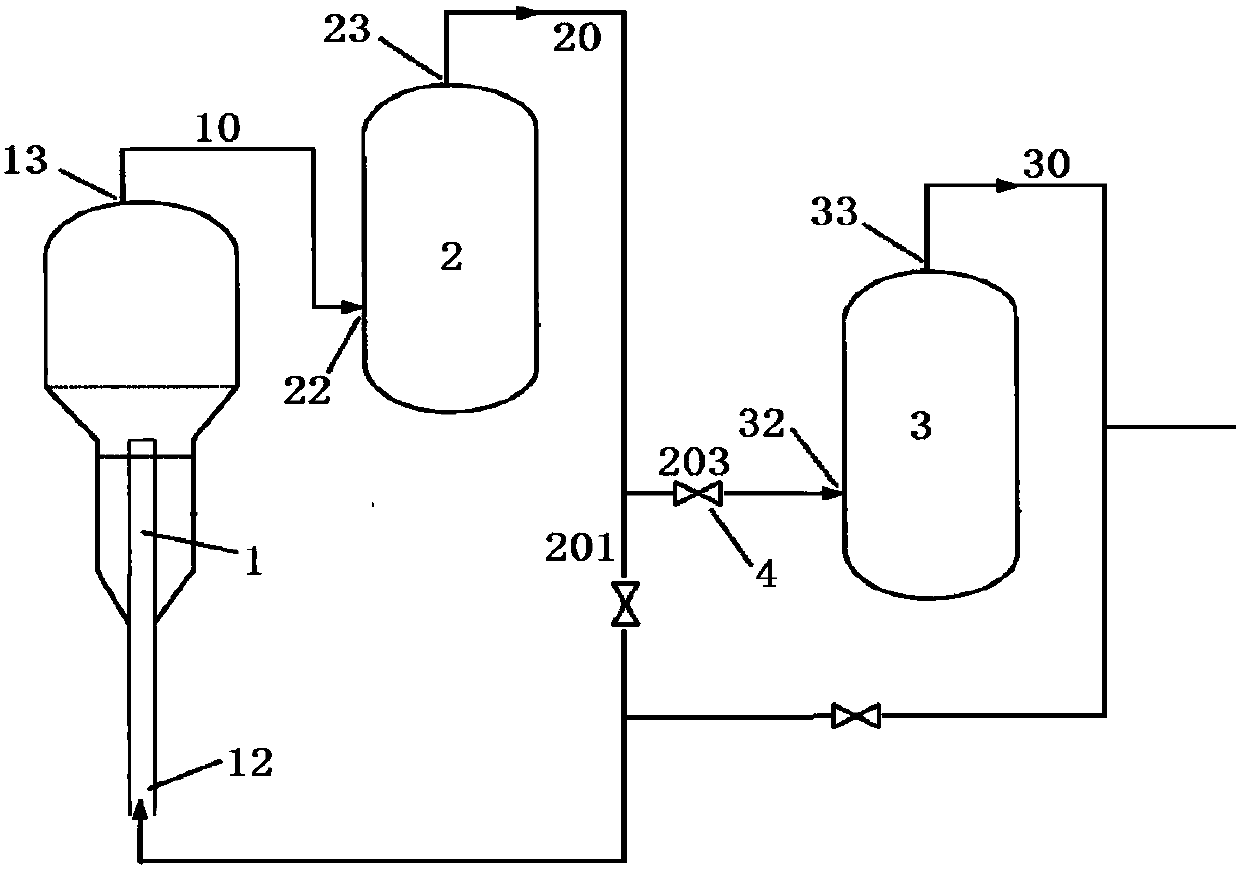

[0058] Feed catalytic cracking raw materials into a riser reactor of equal diameter, react under the conditions of temperature 502°C and pressure 0.2MPa, separate the gas phase product from the reaction product, and lead the gas phase product to the spray absorption tower through pipeline 10 Treatment, the absorbent used is stabilized gasoline. The resulting lean gas composition after absorbent treatment is 96% by volume C 1 、C 2 , about 3.9 vol% C 3 、C 4 and about 0.1% by volume of C 5 the above components. 30% by volume of the lean gas is injected into the riser reactor through the pre-lift medium inlet 12 at the bottom of the riser reactor, and the rest of the lean gas is injected into the reabsorption tower for further processing, wherein the pressure of the lean gas is 1.25 MPa. The obtained product distribution list is shown in Table 2.

Embodiment 2

[0060] Feed catalytic cracking raw materials into a riser reactor of equal diameter, react under the conditions of temperature 430°C and pressure 0.15MPa, separate the gas phase product from the reaction product, and lead the gas phase product to the spray absorption tower through pipeline 10 Treatment, the absorbent used is stabilized gasoline. The resulting lean gas composition after absorbent treatment is 90% by volume C 1 、C 2 , about 9.5 vol% C 3 、C 4 and about 0.5% by volume of C 5 the above components. 50% by volume of the lean gas is injected into the riser reactor through the pre-lift medium inlet 12 at the bottom of the riser reactor, and the rest of the lean gas is injected into the reabsorption tower for further processing, wherein the lean gas pressure is 0.8 MPa. The obtained product distribution list is shown in Table 2.

Embodiment 3

[0062] Feed catalytic cracking raw materials into a riser reactor of equal diameter, react under the conditions of temperature 600°C and pressure 0.3 MPa, separate gas phase products from reaction products, and lead gas phase products to spray absorption tower through pipeline 10 Treatment, the absorbent used is stabilized gasoline. The resulting lean gas composition after absorbent treatment is 99% by volume C 1 、C 2 , about 0.9 vol% C 3 、C 4 and about 0.1% by volume of C 5 the above components. 21% by volume of the lean gas is injected into the riser reactor through the pre-lift medium inlet 12 at the bottom of the riser reactor, and the rest of the lean gas is injected into the reabsorption tower for further processing, wherein the pressure of the lean gas is 1.5 MPa. The obtained product distribution list is shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com