A device and method for recovering carbon dioxide from catalytic dry gas

A technology for recovering carbon and dry gas, applied in chemical instruments and methods, processing of gas mixtures, organic chemistry, etc., can solve the problems of high energy consumption, affecting the purity of product gas ethylene, and large investment, so as to reduce equipment investment and energy. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

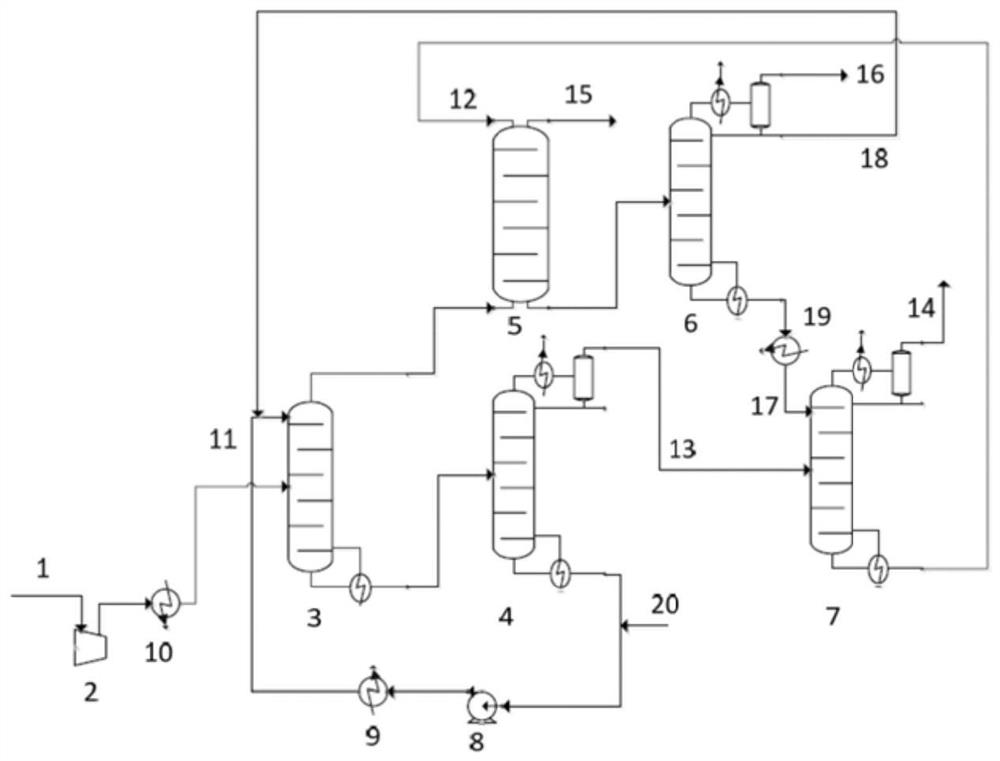

Image

Examples

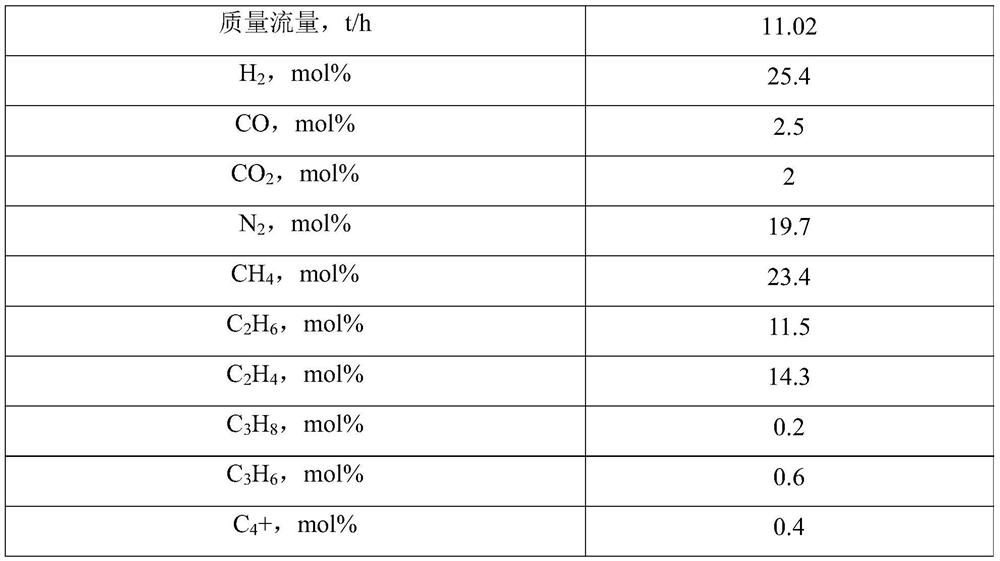

Embodiment 1

[0068] The second section of catalytic dry gas is compressed to 4MPaG and cooled to 15°C, and then mixed with carbon four (the flow rate is 41t / h (by the carbon four recycled in the step (4) and the newly added carbon four (the flow rate is 1.2t / h) h) maintain the constant flow rate)) contact, the conditions for C4 to contact with catalytic dry gas include: the number of theoretical plates is 40, the pressure is 3.6MPaG, the temperature at the top of the tower is 19°C, and the temperature at the bottom of the tower is 115°C; Conditions include: number of theoretical plates is 40, pressure is 2.1MPaG, tower top temperature is 63 ℃, and tower bottom temperature is 124 ℃; The aromatics (flow rate is 0.04t / h) maintains flow rate constant))) and the condition that coarse carbon dioxide contacts comprises: theoretical plate number is 35, and pressure is 2MPaG, and tower top temperature is 37 ℃, and tower bottom temperature is 80 ℃; Step ( 3) The remaining gasoline-containing compone...

Embodiment 2

[0070] The catalytic dry gas is compressed to 3MPaG in the second section and cooled to 10°C, and then mixed with carbon four (flow rate is 47t / h (through the carbon four recycled in step (4) and newly added carbon four (flow rate is 1.2t / h) h) to maintain constant flow rate)) contact, the conditions for C4 to contact with catalytic dry gas include: the number of theoretical plates is 25, the pressure is 3MPaG, the temperature at the top of the tower is 19°C, and the temperature at the bottom of the tower is 101°C; the conditions for the first rectification Including: the number of theoretical plates is 50, the pressure is 2.7MPaG, the temperature at the top of the tower is 59°C, and the temperature at the bottom of the tower is 136°C; Aromatics (flow rate is 1t / h) keep flow rate constant))) and the condition that thick carbon two contacts comprises: theoretical plate number is 25, and pressure is 1.5MPaG, and tower top temperature is 34 ℃, and tower bottom temperature is 70 ℃;...

Embodiment 3

[0072] The catalytic dry gas is compressed to 5MPaG in the second section and cooled to 15°C, and then mixed with carbon four (flow rate is 37t / h (by carbon four recycled in step (4) and newly added carbon four (flow rate is 1.2t / h) h) keep the flow rate constant)) contact, the conditions for C4 to contact with catalytic dry gas include: the number of theoretical plates is 50, the pressure is 4.2MPaG, the temperature at the top of the tower is 19°C, and the temperature at the bottom of the tower is 124°C; Conditions include: number of theoretical plates is 30, pressure is 2.7MPaG, tower top temperature is 59 DEG C, tower bottom temperature is 136 DEG C; The aromatics (flow rate is 1t / h) maintains flow rate constant))) and the condition of coarse carbon dioxide contact comprises: theoretical plate number is 43, and pressure is 2.5MPaG, and tower top temperature is 42 ℃, and tower bottom temperature is 101 ℃; Step ( 3) The remaining gasoline-containing components in the step (1)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com