Catalytic cracking aid for producing isomerized low-carbon olefins and its preparation method and application

A technology for catalytic cracking aids and low-carbon olefins, which is used in hydrocarbon cracking to produce hydrocarbons, carbon compound catalysts, catalysts, etc., can solve problems such as low propylene content, and achieve the effect of reducing gasoline loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

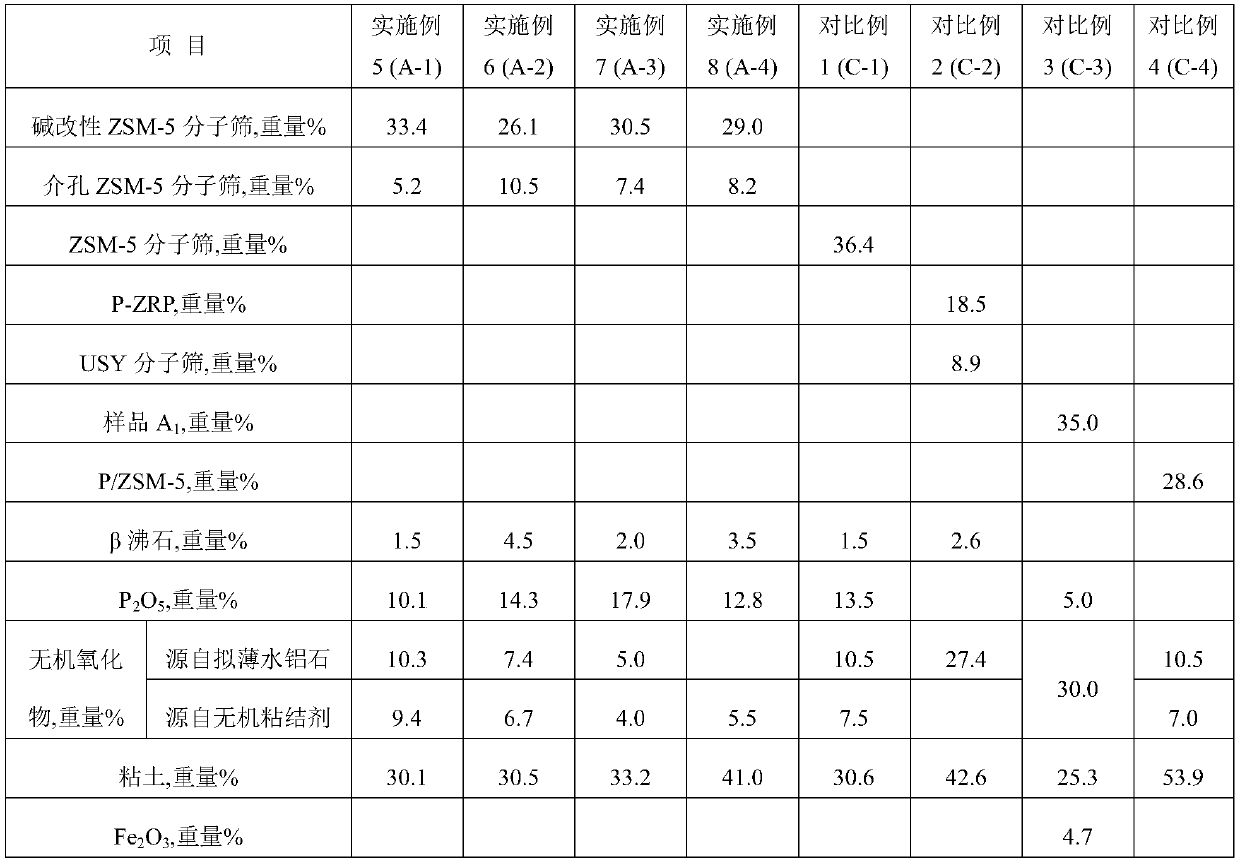

[0053] The first embodiment of the present invention provides a kind of catalytic cracking aid of prolific isomerism low-carbon olefins, wherein, on a dry basis, based on the total weight of the catalytic cracking aid, comprising:

[0054] 15-45% by weight of alkali-modified ZSM-5 molecular sieve;

[0055] 1-20% by weight of mesoporous ZSM-5 molecular sieve;

[0056] 1 to 10% by weight of beta zeolite;

[0057] 3 to 25% by weight of P 2 o 5 ;

[0058] 3 to 25% by weight of inorganic oxides; and

[0059] The remainder of the clay.

[0060] In the present invention, the ZSM-5 molecular sieve has a higher ratio of silicon to aluminum. Before the ZSM-5 molecular sieve is modified, the silicon-aluminum ratio of the ZSM-5 molecular sieve can be 15-400. In the present invention, the content of the alkali-modified ZSM-5 molecular sieve is 15-45% by weight, preferably 20-40% by weight, based on the total weight of the catalytic cracking additive on a dry basis.

[0061] The out...

no. 2 approach

[0084] The second embodiment of the present invention provides a kind of preparation method of the catalytic cracking aid of prolific isomeric low-carbon olefins, comprising: the step of uniformly mixing the materials, then the step of drying and molding, and the step of curing by roasting.

[0085] Specifically, the step of uniformly mixing materials includes:

[0086] Mix clay, optional pseudo-boehmite, and water, add phosphorus-containing compounds, and beat to obtain a carrier slurry. Preferably, the beating time is 0.5 to 3 hours; wherein, based on the total weight of the catalytic cracking additive , the content of the phosphorus-containing compound is P 2 o 5 Calculated as 3 to 25% by weight;

[0087] After mixing the alkali-modified ZSM-5 molecular sieve, the mesoporous ZSM-5 molecular sieve and the beta zeolite, add water and make a slurry to obtain a molecular sieve slurry; wherein, the solid content of the molecular sieve slurry is not less than 30% by weight;

...

no. 3 approach

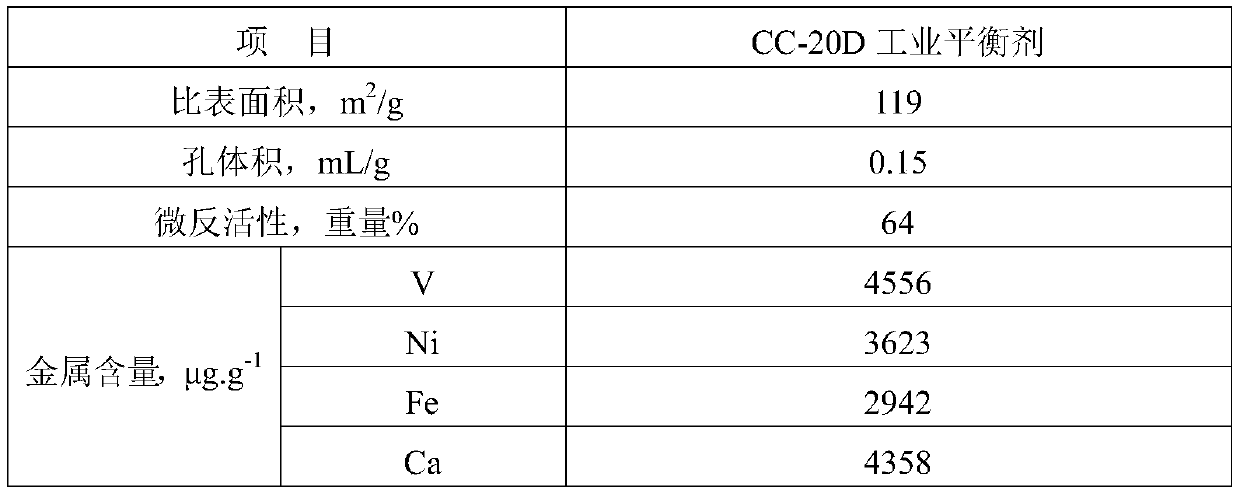

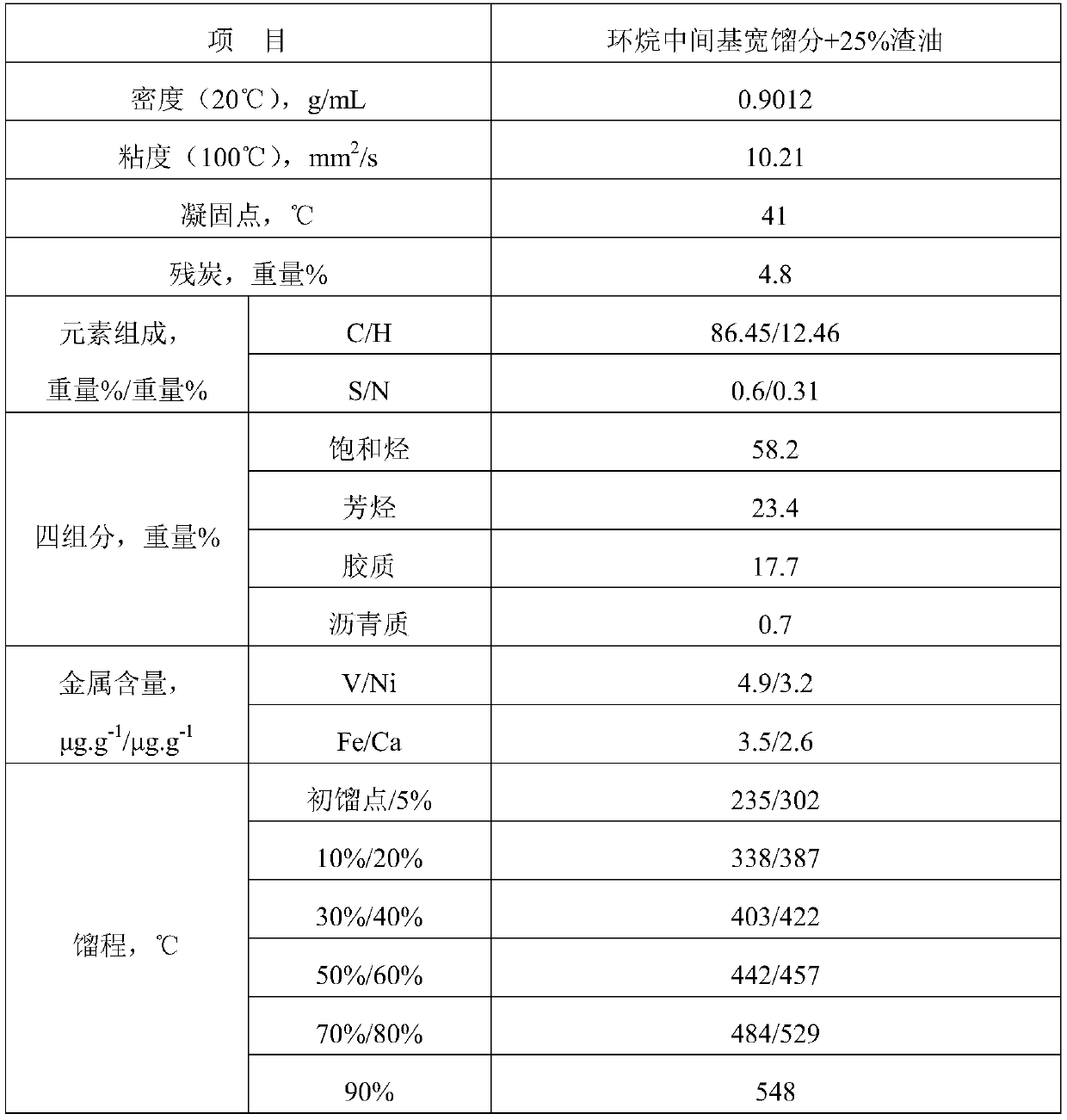

[0090] The third embodiment of the present invention provides a catalytic cracking catalyst system, including the catalytic cracking aid for prolific isomerization of low-carbon olefins in the first embodiment of the present invention or the prolific isomeric low-carbon olefins prepared by the preparation method of the second embodiment Catalytic cracking aids for low carbon olefins.

[0091] When the auxiliary agent provided by the invention is used in the catalytic cracking process, it can be added to the catalytic cracking reactor alone, or it can be mixed with the catalytic cracking catalyst. When used in combination with a catalytic cracking catalyst, based on the total weight of the catalytic cracking catalyst system, the content of the catalytic cracking aid for prolific isomeric low-carbon olefins is 2-20% by weight, preferably 3-15% by weight .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com